WALL THIMBLES

WALL THIMBLES

WALL THIMBLES

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

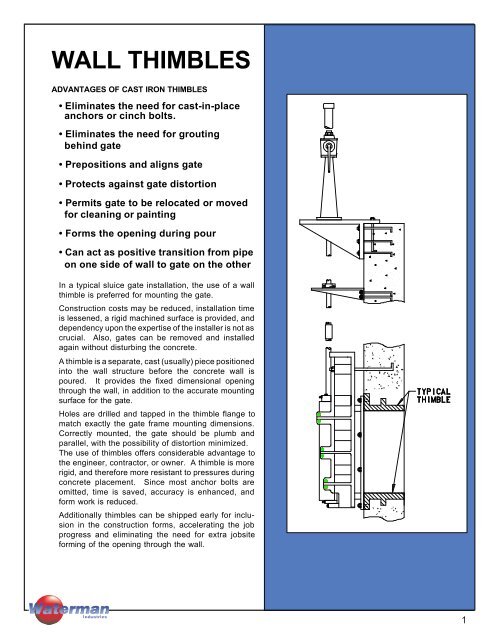

<strong>WALL</strong> <strong>THIMBLES</strong>ADVANTAGES OF CAST IRON <strong>THIMBLES</strong>• Eliminates the need for cast-in-placeanchors or cinch bolts.• Eliminates the need for groutingbehind gate• Prepositions and aligns gate• Protects against gate distortion• Permits gate to be relocated or movedfor cleaning or painting• Forms the opening during pour• Can act as positive transition from pipeon one side of wall to gate on the otherIn a typical sluice gate installation, the use of a wallthimble is preferred for mounting the gate.Construction costs may be reduced, installation timeis lessened, a rigid machined surface is provided, anddependency upon the expertise of the installer is not ascrucial. Also, gates can be removed and installedagain without disturbing the concrete.A thimble is a separate, cast (usually) piece positionedinto the wall structure before the concrete wall ispoured. It provides the fixed dimensional openingthrough the wall, in addition to the accurate mountingsurface for the gate.Holes are drilled and tapped in the thimble flange tomatch exactly the gate frame mounting dimensions.Correctly mounted, the gate should be plumb andparallel, with the possibility of distortion minimized.The use of thimbles offers considerable advantage tothe engineer, contractor, or owner. A thimble is morerigid, and therefore more resistant to pressures duringconcrete placement. Since most anchor bolts areomitted, time is saved, accuracy is enhanced, andform work is reduced.Additionally thimbles can be shipped early for inclusionin the construction forms, accelerating the jobprogress and eliminating the need for extra jobsiteforming of the opening through the wall.1

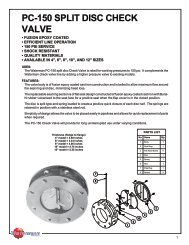

THIMBLE TYPESThimble types are named for the casting cross sectionshape. Each type has its own application, and remainsthe same even though the size and depth of thimblemay vary. The illustrations at right indicate the mostpopular types and their particular application.F"F" THIMBLEThe "F" type wall thimble is the most widely used formounting sluice or flap gates which are subject to anyseating pressure and moderate unseating pressure.As is shown, the "F" thimble has a flange for mountingthe gate on one side only. The small inner staff of the"F" thimble provides both a cleat for holding the thimblemore securely in the wall and a water stop to prevent"end run" seepage. The end opposite the flange merelyforms the opening to the other side of the wall orbulkhead.E"E" THIMBLEThe "E" type wall thimble is similar to the "F" thimbleexcept that it has a flange on both ends. It is requiredfor sluice gates subjected to high unseating heads,severe conditions, and when extension, another typeflange, trash racks, or flap gates may be added to theback of the thimble. As with the "F" type thimble, thesmall inner staff of the "E" provides both a holding cleatand a water stop."MJ" THIMBLEThe Mechanical Joint type wall thimble has a standardflange on one end and a mechanical joint type flange onthe other. It is the most widely used for directconnection to pipeline or penstock without requiring aflange on the pipe end. The "mechanical joint" employsa following ring around the pipe which is cinchedto a minor bolt flange on the thimble end. In cinchingthe ring a rubber gasket is squeezed between thetapered end of the thimble and he pipe, thus holding thepipe into the thimble end through friction, as well asproviding a seal. (It should be noted that mechanicaljoints are not recommended for concrete pipe.)"BELL" THIMBLEThe "Bell" type wall thimble is similar to the MechanicalJoint thimble in that opposite the flanged end theopening is "belled" out to accept a pipe. It does nothave a minor bolt flange for cinching a following ring.After the pipe is inserted into the "belled" end, caulkingis required to provide a seal.OTHER <strong>THIMBLES</strong>For special applications, such as thin or narrow walls,"C" (or "U") and "L" type thimbles are available.MJBELL2

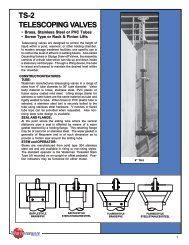

<strong>THIMBLES</strong>HAPESThimble shape is determined by the combination formedby the opening or body of the thimble, which is cast intothe wall, and the flange(s) to which the gate, or gates,is attached. Shown at right are the basic shapes.However, combinations of those shapes such as squareflange-round opening-round flange "E" thimbles canoccur but are not pictured.ROUND FLANGE-ROUND OPENINGThis thimble consists of a round opening with a roundflange attached to it. It is used primarily for round flapgates, although it may be used with round flange sluicegates. If used for round flange sluice gates extraclearance is needed at both sides and bottom.ROUND FLANGE, ROUND OPENINGSQUARE FLANGE-ROUND OPENINGThis thimble is used where a round opening is desiredbut a normally square flanged gate is required. Althoughthe body of the thimble is round the front faceis cast with a square flange. All four corners are castwith webs or quadrants of iron to fill the corner quadrantsbetween square frame perimeter and the roundbody. Reinforcing ribs are cast on the back of thethimble flange to impart stiffness and strength. Theseribs are imbedded in the wall. Installation of a gate issimplified with the square flange. All studs are aroundthe outside square, where they are readily accessible.When minimum installation clearance is desired Watermanflatback gates should be used.SQUARE FLANGE, ROUND OPENINGSQUARE FLANGE-SQUARE OPENING, RECTAN-GULAR FLANGE-RECTANGULAR OPENINGThese thimbles are used with square or rectangulargates. They are normally the "F" type and are suppliedin a variety of thicknesses from 8" deep or moredepending on wall thickness.SQUARE FLANGE, SQUARE OPENING3

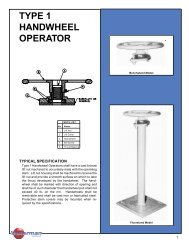

<strong>THIMBLES</strong>PECIFICATIONSWall thimbles shall be heavy, one piece castings. Thefront flange shall be machined to a plane and shall bedrilled and holes tapped to mate the drilling pattern ofthe gate frame. Holes shall be plugged as to preventconcrete from intruding into threaded area. The verticalcenterline shall be clearly shown by permanent marksat the top and bottom of the machined face. The word"top" shall be marked permanently near the top centerlineof the thimble opening. The surfaces to be castinto the concrete shall be free of paint, oil, and grease.Corrosion-resistant studs and nuts shall be providedfor attaching the gate. Mastic is recommended to forma seal between the front face of the thimble and theback of the gate frame.ANCHOR BOLTS& DRILL-INANCHORSFLANGEBACK SLUICE GATE ON "J" ANCHORSFLANGEBACK SLUICE GATE ON EXPANSION ANCHORSAnchor bolts are commonly used to mount sluicegates and other control gates to a headwall in theabsence of thimbles. Waterman can supply anchorbolts of all materials, including galvanized steel andsilicon bronze. Stainless steel is the most commonlypreferred material, and is available either plain or epoxycoated. The accepted practice for mounting gates onanchor bolts is to utilize double nuts, one for positioningthe gate, and the other for securing the gate.Note: In those locations where extended flangeback gatesare used on headwalls without sufficient side or bottomclearance for nut adjustments, anchor bolts can be broughtthrough the gate frame to the front face. Special anchorsand frame drilling must be ordered.EXTENDED FLANGEBACK SLUICE GATE WITH "J"ANCHORS PROJECTING THRU BACK FLANGEExpansion (tap-in) or chemical bonding anchors orstuds are also commonly used to attach gates toheadwalls. While the least preferred of the threemethods, it is sometimes necessary to use this typeof anchor, as in a retrofit situation to an existingstructure. Waterman can supply most major brands ofexpansion anchors.EXTENDED FLANGEBACK SLUICE GATE WITH "J"ANCHORS THRU BOTH FLANGES4