Koropon® HS topcoats - ABLE Aerospace Adhesives

Koropon® HS topcoats - ABLE Aerospace Adhesives

Koropon® HS topcoats - ABLE Aerospace Adhesives

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Koropon ® <strong>HS</strong> CA 3000 serieshigh solids epoxy <strong>topcoats</strong>application guide

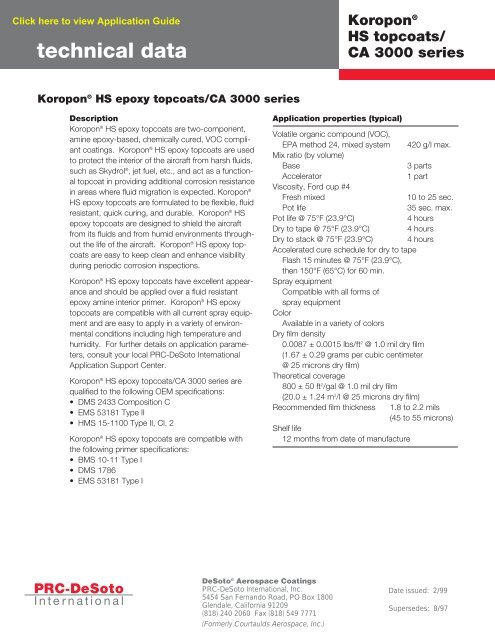

PRC-DeSoto InternationalSpecificationsDMS 2433 Composition C and EMS 53181, Type IIHMS 15-1100, Type II Class 2UseKoropon ® <strong>HS</strong> epoxy <strong>topcoats</strong> are used on aircraftinteriors and on aircraft components where excellentchemical and corrosion resistance are required.Koropon ® <strong>HS</strong> <strong>topcoats</strong> have a VOC of 420 gramsper liter which meets or exceeds the EnvironmentalProtection Agency’s (EPA) air quality requirementsfor aerospace <strong>topcoats</strong>.Surface preparationIt is extremely important to thoroughly prepare and cleanthe surface of an aircraft before priming. This will ensurethat the coating has good appearance, adhesion, fluidresistance, and corrosion resistance.Note: Use DMS 1786 primer with DMS 2433 topcoat,EMS 53181 Type I primer with EMS 53181 Type II topcoat,and HMS 15-1100 Type I primer with HMS 15-1100 Type IItopcoat.After priming, perform the following surface preparationbefore applying the topcoat:1. If the primer surface has defects, such as dry spray ordust inclusions, scuff with Scotch-Brite pads and removethe dust with either an epoxy compatible tack rag or bywiping with a clean rag saturated with Desoclean ® 110cleaner.Note: Apply the tack rag lightly to the surface of thecoating. Excessive pressure will leave a tackifier residueon the surface of the primer and can cause problemswith de-wetting and crawling of the topcoat.2. If the primer has cured for more than 24 hours but lessthan 48 hours, it should be scuffed with Scotch-Britepads and tacked off or wiped with Desoclean ® 110cleaner.3. If the primer has cured for more than 48 hours, it shouldbe scuffed and cleaned as in step 2. Then apply a lightcoat of primer and allow it to cure before applying thetopcoat.MixingBefore mixing any paint, the cans should be allowed toreach room temperature. This can be done by leaving thecans at room temperature for about 24 hours beforemixing. Be sure all mixing and measuring containers areclean and free from contamination. Shake the base or stir itthoroughly until there is no solid material left on the bottomof the can. In this 3:1 system, mix three parts of the basecomponent to one part of the curing solution.Always add the curing solution slowly to the base whileagitating the material. If the materials are added in thewrong order or all at once, local areas of incompatibility canoccur. This will cause the resin or pigment to “kickout” intosmall particles. These particles are difficult to re-disperseand can cause rough surfaces or cratering.Note: Curing solution should be added just beforepainting begins.Do not add extra thinner or flow control to the mixedmaterial. This is a VOC compliant material with a VOCof 420 grams per liter.Pot lifeKoropon ® <strong>HS</strong> high solids epoxy <strong>topcoats</strong> are ready tospray as soon as they are mixed. An induction time is notnecessary. Strain the mixed coating through a fine meshcloth to remove any particles that may have beenintroduced into the coating during mixing or measuring.Stir or agitate the mixed material before and during use.The usable pot life of the mixed topcoat depends ontemperature. Its typical pot life is four hours at 77°F.Higher temperatures will shorten the pot life.Note: Discard any unused material that has exceededits usable pot life limits. A topcoat that has exceeded itspot life may still have low viscosity, but it will developsevere orange peel.Spray equipmentKoropon ® <strong>HS</strong> <strong>topcoats</strong> have been developed to besprayed with conventional spray or HVLP spray guns.Small parts and large interior surfaces are not usuallysprayed with electrostatic equipment.Material inspectionPrior to using, inspect the containers for damage or leaksthat may have occured during shipping. The condition ofthe curing solution is an important factor in obtaining theoptimum properties from Koropon ® <strong>HS</strong> <strong>topcoats</strong>. Theappearance of a white haze in the curing solution is anindication of moisture contamination.2

HVLPBINKS Mach ITip size #91-#94Pot pressure11-15 psiAtomization pressure at gun 10 psi maximumGRACO 1265Tip size 0.047” to 0.057”Pot pressure11-15 psiAtomization pressure at gun 10 psi maximumTopcoat applicationFor optimum application apply two medium wet coats ofKoropon ® <strong>HS</strong> topcoat to a dry film thickness of 1.8 to 2.2mils (45 to 55 microns). The time between coats should be30 to 45 minutes at 75°F. Higher temperatures will requireless time between coats; cooler temperatures will requiremore time. It is important to allow the first coat to tack upbefore applying the second coat. Tacking up means thereshould be little or no transfer of wet paint to the fingerwhen lightly touched.Note: Avoid mixing old paint with freshly mixed paint. Thiscan reduce the pot life of the freshly mixed paint and causesevere orange peel.Clean upFlush equipment with Desoclean ® 45 cleaner or Desoclean ®110 cleaner. The coatings are a chemically reactingsystem. They are no longer soluble in solvents after theyhave cured. For this reason, clean equipment as soon aspossible after the coating has been applied and alwaysbefore material has cured. Note that even a fresh coatingdeposits a film on the equipment that does not dissolveeasily. Agitation with a brush or cloth can help removethese deposits.Health and safetyThis product is safe to use and apply when recommendedprecautions are followed. Before using this product, readand understand the PRC-DeSoto International “SafeHandling Guide” for aerospace coatings and the MaterialSafety Data Sheet (MSDS) which provide informationon health, physical and environmental hazards, handlingprecautions and first aid recommendations. An MSDS isavailable on request. Avoid overexposure. All mixing andspraying must be conducted with adequate ventilationand proper personal protective equipment asrecommended. Obtain medical care in case of extremeoverexposure.For emergency medical informationcall 1-800-228-5635.Application conditionsOptimum conditions for application of these epoxy<strong>topcoats</strong> are 70°F to 85°F and 25% to 85% relativehumidity.At higher temperatures Koropon ® <strong>HS</strong> <strong>topcoats</strong> will takeless time to tack up between coats. Two coats are stillrecommended. This will help eliminate any chance ofmicroblistering. At extreme humidities it is possible to“kick out” the curing solution.At lower temperatures it is very important to ensure the firstcoat has tacked up before applying the second coat. Verylow humidities will also retard the cure. Adding moisture tothe air is advised. There is no accelerator that can beadded to the mix to speed up the dry time.RepairTo repair Koropon ® <strong>HS</strong> epoxy <strong>topcoats</strong>, sand or chemicallystrip the entire coating down to either the primer or thebare metal. Solvent wipe with Desoclean ® 45 cleaner orDesoclean ® 110 cleaner. If bare metal is exposed, apply achemical conversion coating. Then apply a coat of primerand allow it to dry to touch before applying the epoxytopcoat.

DeSoto and Desoclean are trademarks of PRC-DeSoto International, Inc., registered with the U.S. Patent Office.Scotch-Brite is a trademark of 3M Corp.All recommendations, statements, and technical data contained herein are based on tests we believe to be reliable and correct, butaccuracy and completeness of said tests are not guaranteed and are not to be construed as a warranty, either expressed or implied.User shall rely on his own information and tests to determine suitability of the product for the intended use and assumes all risks andliability resulting from his use of the product. Seller’s and manufacturer’s sole responsibility shall be to replace that portion of the productof this manufacturer which proves to be defective. Neither seller nor manufacturer shall be liable to the buyer or any third person for anyinjury, loss, or damage directly or indirectly resulting from use of, or inability to use, the product. Recommendations or statements otherthan those contained in a written agreement signed by an officer of the manufacturer shall not be binding upon the manufacturer or seller.Printed in U.S.A., Issued February 1999. Supersedes September 1996.DeSoto ® <strong>Aerospace</strong> CoatingsPRC-DeSoto International, Inc.5454 San Fernando Road, PO Box 1800Glendale, California 91209(818) 240 2060Fax (818) 549 7627www.prc-desoto.com(Formerly Courtaulds <strong>Aerospace</strong>, Inc.)

![3368 Rustilo 4169 (English (GB)) BP EU SDS - Italy [IT-SIBU-Castrol]](https://img.yumpu.com/46809112/1/184x260/3368-rustilo-4169-english-gb-bp-eu-sds-italy-it-sibu-castrol.jpg?quality=85)