You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

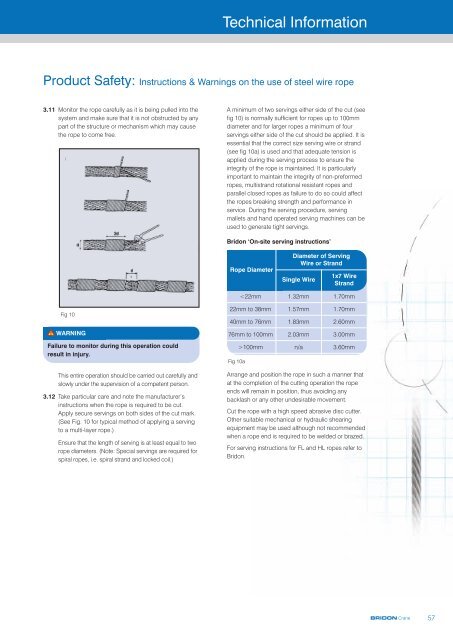

Technical Information<strong>Product</strong> <strong>Safety</strong>: Instructions & Warnings on the use of steel wire rope3.11 Monitor the rope carefully as it is being pulled into thesystem and make sure that it is not obstructed by anypart of the structure or mechanism which may causethe rope to come free.A minimum of two servings either side of the cut (seefig 10) is normally sufficient for ropes up to 100mmdiameter and for larger ropes a minimum of fourservings either side of the cut should be applied. It isessential that the correct size serving wire or strand(see fig 10a) is used and that adequate tension isapplied during the serving process to ensure theintegrity of the rope is maintained. It is particularlyimportant to maintain the integrity of non-preformedropes, multistrand rotational resistant ropes andparallel closed ropes as failure to do so could affectthe ropes breaking strength and performance inservice. During the serving procedure, servingmallets and hand operated serving machines can beused to generate tight servings.<strong>Bridon</strong> ‘On-site serving instructions’Rope DiameterDiameter of ServingWire or StrandSingle Wire1x7 WireStrand100mmFig 10an/a3.60mmThis entire operation should be carried out carefully andslowly under the supervision of a competent person.3.12 Take particular care and note the manufacturer’sinstructions when the rope is required to be cut.Apply secure servings on both sides of the cut mark.(See Fig. 10 for typical method of applying a servingto a multi-layer rope.)Ensure that the length of serving is at least equal to tworope diameters. (Note: Special servings are required forspiral ropes, i.e. spiral strand and locked coil.)Arrange and position the rope in such a manner thatat the completion of the cutting operation the ropeends will remain in position, thus avoiding anybacklash or any other undesirable movement.Cut the rope with a high speed abrasive disc cutter.Other suitable mechanical or hydraulic shearingequipment may be used although not recommendedwhen a rope end is required to be welded or brazed.For serving instructions for FL and HL ropes refer to<strong>Bridon</strong>.BRIDON Crane57