You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

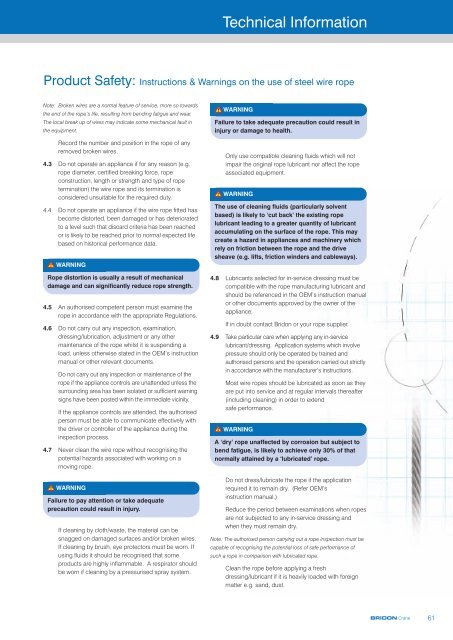

Technical Information<strong>Product</strong> <strong>Safety</strong>: Instructions & Warnings on the use of steel wire ropeNote: Broken wires are a normal feature of service, more so towardsthe end of the rope’s life, resulting from bending fatigue and wear.The local break up of wires may indicate some mechanical fault inthe equipment.Record the number and position in the rope of anyremoved broken wires.4.3 Do not operate an appliance if for any reason (e.g.rope diameter, certified breaking force, ropeconstruction, length or strength and type of ropetermination) the wire rope and its termination isconsidered unsuitable for the required duty.4.4 Do not operate an appliance if the wire rope fitted hasbecome distorted, been damaged or has deterioratedto a level such that discard criteria has been reachedor is likely to be reached prior to normal expected lifebased on historical performance data.WARNINGRope distortion is usually a result of mechanicaldamage and can significantly reduce rope stren gth.4.5 An authorised competent person must examine therope in accordance with the appropriate Regulations.4.6 Do not carry out any inspection, examination,dressing/lubrication, adjustment or any othermaintenance of the rope whilst it is suspending aload, unless otherwise stated in the OEM’s instructionmanual or other relevant documents.Do not carry out any inspection or maintenance of therope if the appliance controls are unattended unless thesurrounding area has been isolated or sufficient warningsigns have been posted within the immediate vicinity.If the appliance controls are attended, the authorisedperson must be able to communicate effectively withthe driver or controller of the appliance during theinspection process.4.7 Never clean the wire rope without recognising thepotential hazards associated with working on amoving rope.WARNINGFailure to pay attention or take adequateprecaution could result in injury.If cleaning by cloth/waste, the material can besnagged on damaged surfaces and/or broken wires.If cleaning by brush, eye protectors must be worn. Ifusing fluids it should be recognised that someproducts are highly inflammable. A respirator shouldbe worn if cleaning by a pressurised spray system.WARNINGFailure to take adequate precaution could result ininjury or damage to health.Only use compatible cleaning fluids which will notimpair the original rope lubricant nor affect the ropeassociated equipment.WARNINGThe use of cleaning fluids (particularly solventbased) is likely to ‘cut back’ the existing ropelubricant leading to a greater quantity of lubricantaccumulating on the surface of the rope. This maycreate a hazard in appliances and machinery whichrely on friction between the rope and the drivesheave (e.g. lifts, friction winders and cableways).4.8 Lubricants selected for in-service dressing must becompatible with the rope manufacturing lubricant andshould be referenced in the OEM’s instruction manualor other documents approved by the owner of theappliance.If in doubt contact <strong>Bridon</strong> or your rope supplier.4.9 Take particular care when applying any in-servicelubricant/dressing. Application systems which involvepressure should only be operated by trained andauthorised persons and the operation carried out strictlyin accordance with the manufacturer’s instructions.Most wire ropes should be lubricated as soon as theyare put into service and at regular intervals thereafter(including cleaning) in order to extendsafe performance.WARNINGA ‘dry’ rope unaffected by corrosion but subject tobend fatigue, is likely to achieve only 30% of thatnormally attained by a ‘lubricated’ rope.Do not dress/lubricate the rope if the applicationrequired it to remain dry. (Refer OEM’sinstruction manual.)Reduce the period between examinations when ropesare not subjected to any in-service dressing andwhen they must remain dry.Note: The authorised person carrying out a rope inspection must becapable of recognising the potential loss of safe performance ofsuch a rope in comparison with lubricated rope.Clean the rope before applying a freshdressing/lubricant if it is heavily loaded with foreignmatter e.g. sand, dust.BRIDON Crane61