Electromagnetic clutches and brakes from INTORQ & magneta

Electromagnetic clutches and brakes from INTORQ & magneta

Electromagnetic clutches and brakes from INTORQ & magneta

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

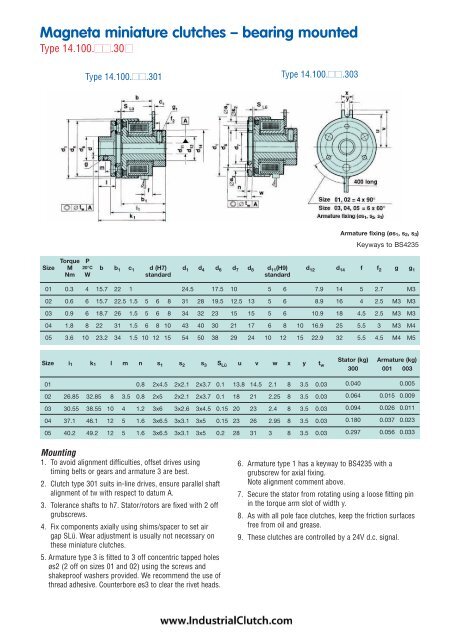

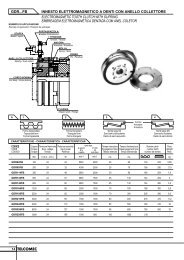

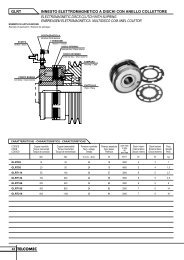

Magneta miniature <strong>clutches</strong> – bearing mountedType 14.100.■■.30■Type 14.100.■■.301Type 14.100.■■.303Armature fixing (øs 1 , s 2 , s 3 )Keyways to BS4235Torque PSize M 20°C b b 1 c 1 d (H7) d 1 d 4 d 6 d 7 d 8 d 11 (H9) d 12 d 14 f f 2 g g 1Nm W st<strong>and</strong>ard st<strong>and</strong>ard01 0.3 4 15.7 22 1 24.5 17.5 10 5 6 7.9 14 5 2.7 M302 0.6 6 15.7 22.5 1.5 5 6 8 31 28 19.5 12.5 13 5 6 8.9 16 4 2.5 M3 M303 0.9 6 18.7 26 1.5 5 6 8 34 32 23 15 15 5 6 10.9 18 4.5 2.5 M3 M304 1.8 8 22 31 1.5 6 8 10 43 40 30 21 17 6 8 10 16.9 25 5.5 3 M3 M405 3.6 10 23.2 34 1.5 10 12 15 54 50 38 29 24 10 12 15 22.9 32 5.5 4.5 M4 M5Size i 1 k 1 l m n s 1 s 2 s 3 S Lü u v w x y t w01 0.8 2x4.5 2x2.1 2x3.7 0.1 13.8 14.5 2.1 8 3.5 0.0302 26.85 32.85 8 3.5 0.8 2x5 2x2.1 2x3.7 0.1 18 21 2.25 8 3.5 0.0303 30.55 38.55 10 4 1.2 3x6 3x2.6 3x4.5 0.15 20 23 2.4 8 3.5 0.0304 37.1 46.1 12 5 1.6 3x6.5 3x3.1 3x5 0.15 23 26 2.95 8 3.5 0.0305 40.2 49.2 12 5 1.6 3x6.5 3x3.1 3x5 0.2 28 31 3 8 3.5 0.03Stator (kg) Armature (kg)300 001 0030.040 0.0050.064 0.015 0.0090.094 0.026 0.0110.180 0.037 0.0230.297 0.056 0.033Mounting1. To avoid alignment difficulties, offset drives usingtiming belts or gears <strong>and</strong> armature 3 are best.2. Clutch type 301 suits in-line drives, ensure parallel shaftalignment of tw with respect to datum A.3. Tolerance shafts to h7. Stator/rotors are fixed with 2 offgrubscrews.4. Fix components axially using shims/spacer to set airgap SLü. Wear adjustment is usually not necessary onthese miniature <strong>clutches</strong>.5. Armature type 3 is fitted to 3 off concentric tapped holesøs2 (2 off on sizes 01 <strong>and</strong> 02) using the screws <strong>and</strong>shakeproof washers provided. We recommend the use ofthread adhesive. Counterbore øs3 to clear the rivet heads.6. Armature type 1 has a keyway to BS4235 with agrubscrew for axial fixing.Note alignment comment above.7. Secure the stator <strong>from</strong> rotating using a loose fitting pinin the torque arm slot of width y.8. As with all pole face <strong>clutches</strong>, keep the friction surfacesfree <strong>from</strong> oil <strong>and</strong> grease.9. These <strong>clutches</strong> are controlled by a 24V d.c. signal.A1-4Tel: 01234 753201 Techdrives Email: sales@techdrives.co.uk