Electromagnetic clutches and brakes from INTORQ & magneta

Electromagnetic clutches and brakes from INTORQ & magneta

Electromagnetic clutches and brakes from INTORQ & magneta

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

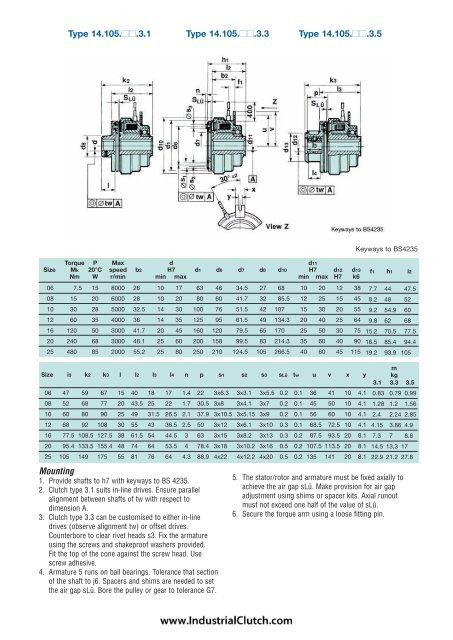

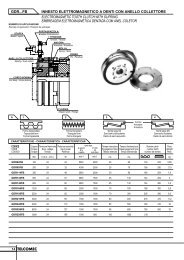

Type 14.105.■■.3.1 Type 14.105.■■.3.3 Type 14.105.■■.3.5Keyways to BS4235Torque P Max d d11Size Mk 20°C speed b2 H7 d1 d6 d7 d8 d10 H7 d12 d13Nm W r/min min max min max H7 k606 7.5 15 8000 26 10 17 63 46 34.5 27 68 10 20 12 3808 15 20 6000 28 10 20 80 60 41.7 32 85.5 12 25 15 4510 30 28 5000 32.5 14 30 100 76 51.5 42 107 15 30 20 5512 60 35 4000 36 14 35 125 95 61.5 49 134.3 20 40 25 6416 120 50 3000 41.7 20 45 160 120 79.5 65 170 25 50 30 7520 240 68 3000 48.1 25 60 200 158 99.5 83 214.3 35 60 40 9025 480 85 2000 55.2 25 80 250 210 124.5 105 266.5 40 60 45 115f1 h1 i27.7 44 47.58.2 48 529.2 54.9 609.8 62 6815.2 70.5 77.516.5 85.4 94.419.2 93.9 105Size i3 k2 k3 l l2 l3 l4 n p s1 s2 s3 sLü tw u v x y06 47 59 67 15 40 18 17 1.4 22 3x6.3 3x3.1 3x5.5 0.2 0.1 36 41 10 4.108 52 68 77 20 43.5 25 22 1.7 30.5 3x8 3x4.1 3x7 0.2 0.1 45 50 10 4.110 60 80 90 25 49 31.5 26.5 2.1 37.9 3x10.5 3x5.15 3x9 0.2 0.1 56 60 10 4.112 68 92 108 30 55 43 36.5 2.5 50 3x12 3x6.1 3x10 0.3 0.1 68.5 72.5 10 4.116 77.5 108.5 127.5 38 61.5 54 44.5 3 63 3x15 3x8.2 3x13 0.3 0.2 87.5 93.5 20 8.120 95.4 133.5 155.4 48 74 64 53.5 4 78.4 3x18 3x10.2 3x16 0.5 0.2 107.5 113.5 20 8.125 105 149 175 55 81 76 64 4.3 88.9 4x22 4x12.2 4x20 0.5 0.2 135 141 20 8.1Mounting1. Provide shafts to h7 with keyways to BS 4235.2. Clutch type 3.1 suits in-line drives. Ensure parallelalignment between shafts of tw with respect todimension A.3. Clutch type 3.3 can be customised to either in-linedrives (observe alignment tw) or offset drives.Counterbore to clear rivet heads s3. Fix the armatureusing the screws <strong>and</strong> shakeproof washers provided.Fit the top of the cone against the screw head. Usescrew adhesive.4. Armature 5 runs on ball bearings. Tolerance that sectionof the shaft to j6. Spacers <strong>and</strong> shims are needed to setthe air gap sLü. Bore the pulley or gear to tolerance G7.mkg3.1 3.3 3.50.83 0.79 0.991.28 1.2 1.562.4 2.24 2.854.15 3.86 4.97.3 7 8.814.5 13.3 1722.9 21.2 27.85. The stator/rotor <strong>and</strong> armature must be fixed axially toachieve the air gap sLü. Make provision for air gapadjustment using shims or spacer kits. Axial runoutmust not exceed one half of the value of sLü.6. Secure the torque arm using a loose fitting pin.A1-8Tel: 01234 753201 Techdrives Email: sales@techdrives.co.uk