Excess Flow, Check, Filler & Vapor Equalizing Valves

Excess Flow, Check, Filler & Vapor Equalizing Valves

Excess Flow, Check, Filler & Vapor Equalizing Valves

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

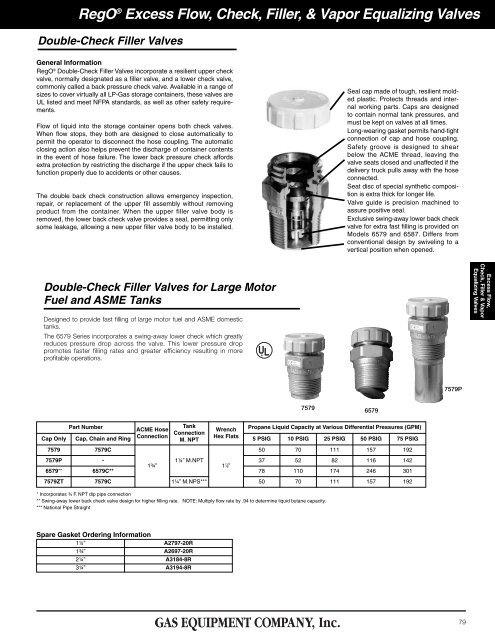

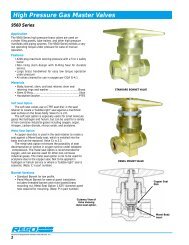

RegO ® <strong>Excess</strong> <strong>Flow</strong>, <strong>Check</strong>, <strong>Filler</strong>, & <strong>Vapor</strong> <strong>Equalizing</strong> <strong>Valves</strong>Double-<strong>Check</strong> <strong>Filler</strong> <strong>Valves</strong>General InformationRegO ® Double-<strong>Check</strong> <strong>Filler</strong> <strong>Valves</strong> incorporate a resilient upper checkvalve, normally designated as a filler valve, and a lower check valve,commonly called a back pressure check valve. Available in a range ofsizes to cover virtually all LP-Gas storage containers, these valves areUL listed and meet NFPA standards, as well as other safety requirements.<strong>Flow</strong> of liquid into the storage container opens both check valves.When flow stops, they both are designed to close automatically topermit the operator to disconnect the hose coupling. The automaticclosing action also helps prevent the discharge of container contentsin the event of hose failure. The lower back pressure check affordsextra protection by restricting the discharge if the upper check fails tofunction properly due to accidents or other causes.The double back check construction allows emergency inspection,repair, or replacement of the upper fill assembly without removingproduct from the container. When the upper filler valve body isremoved, the lower back check valve provides a seal, permitting onlysome leakage, allowing a new upper filler valve body to be installed.Seal cap made of tough, resilient moldedplastic. Protects threads and internalworking parts. Caps are designedto contain normal tank pressures, andmust be kept on valves at all times.Long-wearing gasket permits hand-tightconnection of cap and hose coupling.Safety groove is designed to shearbelow the ACME thread, leaving thevalve seats closed and unaffected if thedelivery truck pulls away with the hoseconnected.Seat disc of special synthetic compositionis extra thick for longer life.Valve guide is precision machined toassure positive seal.Exclusive swing-away lower back checkvalve for extra fast filling is provided onModels 6579 and 6587. Differs fromconventional design by swiveling to avertical position when opened.Double-<strong>Check</strong> <strong>Filler</strong> <strong>Valves</strong> for Large MotorFuel and ASME TanksDesigned to provide fast filling of large motor fuel and ASME domestictanks.The 6579 Series incorporates a swing-away lower check which greatlyreduces pressure drop across the valve. This lower pressure droppromotes faster filling rates and greater efficiency resulting in moreprofitable operations.<strong>Excess</strong> <strong>Flow</strong>,<strong>Check</strong>, <strong>Filler</strong> & <strong>Vapor</strong><strong>Equalizing</strong> <strong>Valves</strong>7579P75796579Part NumberTankACME HoseWrenchPropane Liquid Capacity at Various Differential Pressures (GPM)ConnectionCap Only Cap, Chain and RingConnectionHex FlatsM. NPT5 PSIG 10 PSIG 25 PSIG 50 PSIG 75 PSIG7579 7579C50 70 111 157 1927579P - 1¼” M.NPT37 52 82 116 1421¾”1 7 ⁄8”6579** 6579C** 78 110 174 246 3017579ZT 7579C 1¼” M.NPS*** 50 70 111 157 192* Incorporates ¾ F. NPT dip pipe connection** Swing-away lower back check valve design for higher filling rate. NOTE: Multiply flow rate by .94 to determine liquid butane capacity.*** National Pipe StraightSpare Gasket Ordering Information1¼” A2797-20R1¾” A2697-20R2¼” A3184-8R3¼” A3194-8R79