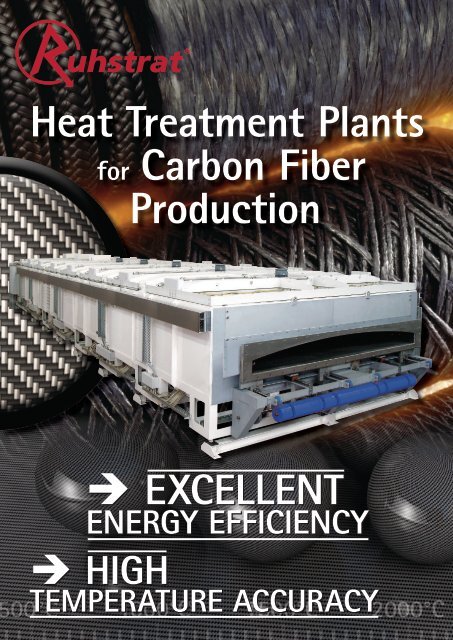

Heat Treatment Plants for Carbon Fiber Production - Ruhstrat GmbH

Heat Treatment Plants for Carbon Fiber Production - Ruhstrat GmbH

Heat Treatment Plants for Carbon Fiber Production - Ruhstrat GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

HEAT TREATMENT PLANTS FOR CARBON FIBER PRODUCTIONSolutions fitted exactlyto the Process Requirements <strong>for</strong><strong>Carbon</strong> <strong>Fiber</strong> <strong>Production</strong>The advantages of the industrial furnace plants of<strong>Ruhstrat</strong> <strong>GmbH</strong> are:• up to 50 % less installedpower than the competition.• high temperature constancyover the width of the fiberthrough hot gas fans and panelheating of the LT-furnace.• high temperature constancyover the width of the fiberthrough a circular heatingaround the muffles of the HTandUHT-furnace.• low energy losses through theapplication of high quality insulationmaterials.• low consumption of protectiongas because of the <strong>Ruhstrat</strong>sealingbox systems.• high durability of the mufflesthrough patented bearings andadditional components <strong>for</strong> thecontrolled expansion.• low shutdown time and maintenancecosts through the choiceof high qualitymaterials and components.<strong>Ruhstrat</strong> <strong>GmbH</strong> · Leinetal / Auf der Mauer 1 · 37120 Bovenden · Germany phone +49 (0) 55 1 820 830 - 0 · fax +49 (0) 55 1 820 830 - 50 e-mail: info@ruhstrat.com · www.ruhstrat.com

HEAT TREATMENT PLANTS FOR CARBON FIBER PRODUCTIONLT-Furnace The Muffle has patented bearings. The expansion of the muffle from themuffles middle to the outside. The expansion in longitudinal directionis supported and controlled by a specialequipment. Construction of the muffle is made by aspecial software. This eliminates thermal tension insidethe muffle. Durability and life time of the muffleincreases. By using special stream plates in the inletarea of the muffle, the condensateof tar is minimized. <strong>Heat</strong>ing consists of high quality ceramicfiber modules with integrated heating.<strong>Heat</strong>ing conductors are made <strong>for</strong>a max. heating conductor temperatureof 1,180 °C. This means a durability ofseveral years. By using these heating modules a veryhomogeneous temperature spreading isattained. The insulation of the backward wall consistsof high quality mineral fiber. Thisreduces the loss of heat. Lost power isapprox. 350 W per m² at 850° furnacetemperature.central exhaustgas treatmentunwindersoxidation oven<strong>Ruhstrat</strong> <strong>GmbH</strong> · Leinetal / Auf der Mauer 1 · 37120 Bovenden · Germany phone +49 (0) 55 1 820 830 - 0 · fax +49 (0) 55 1 820 830 - 50 e-mail: info@ruhstrat.com · www.ruhstrat.com

HEAT TREATMENT PLANTS FOR CARBON FIBER PRODUCTIONHT-Furnace The body of the furnace is equippedwith special cooling plates whichcool directly the heating space, no„sandwich“ construction: metal-wall-thermal conduction cement –coolingplates. This avoids local overheating ofthe body. The insulation consists of only highquality graphite insulation (graphitefelts). As last layer there is a high qualityceramic fiber. The heating is located around themuffle. This makes the furnace to attaina very homogeneous balancedtemperature. Each heating zone is 3-phase. Thismeans that the supply network systemis charged in a symmetric way. As an option we can provide speciallyby <strong>Ruhstrat</strong> manufactured variabletrans<strong>for</strong>mers. Advantages over thyristerregulations are that the powernetwork is not loaded with harmonicwaves. Expensive compensation equipmentis there<strong>for</strong>e not needed. The high current trans<strong>for</strong>mers manufacturedby <strong>Ruhstrat</strong> are integratedinto the supporting stand. There is noneed <strong>for</strong> caves on the ground floor. Water coolings are cased as much aspossible. Hoses will be avoided whereit is possible.inletsealing boxlow temperaturefurnaceoutletsealing box<strong>Ruhstrat</strong> <strong>GmbH</strong> · Leinetal / Auf der Mauer 1 · 37120 Bovenden · Germany phone +49 (0) 55 1 820 830 - 0 · fax +49 (0) 55 1 820 830 - 50 e-mail: info@ruhstrat.com · www.ruhstrat.com

HEAT TREATMENT PLANTS FOR CARBON FIBER PRODUCTIONSealing boxes Sealing boxes are made of stainlesssteel. Inside the sealing boxes there are adjustableand distortion free orificesmade of stainless steel, CFC, graphite,according to applied temperature.There<strong>for</strong>e the transition gap is constantall over the total width. The inlet and outlet compartments canbe opened and shut together or separatelyby hand wheels. This means thatthe gap can be adjusted to the threadpass-through in ideal way during theprocess. The inlet sealing boxes are insulatedand can be run at 400 °C hot nitrogen. The gas heater including the necessarygas armatures is available at an extracharge. The outlet sealing boxes are watercooled and serve in cooperation withthe inlet cold nitrogen as cooling zone.inletsealing boxhigh temperaturefurnacedamping zone withoutlet sealing boxsurftreat<strong>Ruhstrat</strong> <strong>GmbH</strong> · Leinetal / Auf der Mauer 1 · 37120 Bovenden · Germany phone +49 (0) 55 1 820 830 - 0 · fax +49 (0) 55 1 820 830 - 50 e-mail: info@ruhstrat.com · www.ruhstrat.com