Series 970 PowerTrip⢠Connectors and Accessories

Series 970 PowerTrip⢠Connectors and Accessories

Series 970 PowerTrip⢠Connectors and Accessories

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

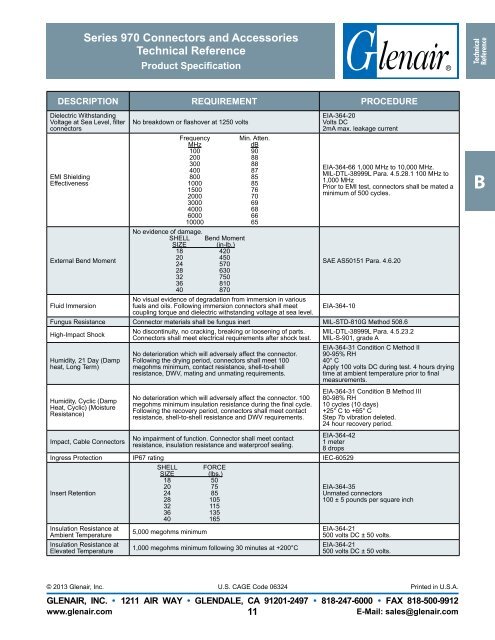

<strong>Series</strong> <strong>970</strong> <strong>Connectors</strong> <strong>and</strong> <strong>Accessories</strong>Technical ReferenceProduct SpecificationTechnicalReferenceDESCRIPTION REQUIREMENT PROCEDUREDielectric Withst<strong>and</strong>ingVoltage at Sea Level, filterconnectorsNo breakdown or flashover at 1250 voltsEIA-364-20Volts DC2mA max. leakage currentFrequency Min. Atten.MHzdB100 90200 88300 88400 87EIA-364-66 1,000 MHz to 10,000 MHz.EMI Shielding800 85MIL-DTL-38999L Para. 4.5.28.1 100 MHz toEffectiveness1000 851,000 MHz1500 76Prior to EMI test, connectors shall be mated a2000 70minimum of 500 cycles.3000 694000 686000 6610000 65No evidence of damage.SHELL Bend MomentSIZE (in-lb.)18 420External Bend Moment2024450570SAE AS50151 Para. 4.6.2028 63032 75036 81040 870Fluid ImmersionNo visual evidence of degradation from immersion in variousfuels <strong>and</strong> oils. Following immersion connectors shall meet EIA-364-10coupling torque <strong>and</strong> dielectric withst<strong>and</strong>ing voltage at sea level.Fungus Resistance Connector materials shall be fungus inert MIL-STD-810G Method 508.6High-Impact ShockHumidity, 21 Day (Dampheat, Long Term)Humidity, Cyclic (DampHeat, Cyclic) (MoistureResistance)Impact, Cable <strong>Connectors</strong>No discontinuity, no cracking, breaking or loosening of parts.<strong>Connectors</strong> shall meet electrical requirements after shock test.No deterioration which will adversely affect the connector.Following the drying period, connectors shall meet 100megohms minimum, contact resistance, shell-to-shellresistance, DWV, mating <strong>and</strong> unmating requirements.No deterioration which will adversely affect the connector. 100megohms minimum insulation resistance during the final cycle.Following the recovery period, connectors shall meet contactresistance, shell-to-shell resistance <strong>and</strong> DWV requirements.No impairment of function. Connector shall meet contactresistance, insulation resistance <strong>and</strong> waterproof sealing.MIL-DTL-38999L Para. 4.5.23.2MIL-S-901, grade AEIA-364-31 Condition C Method II90-95% RH40° CApply 100 volts DC during test. 4 hours dryingtime at ambient temperature prior to finalmeasurements.EIA-364-31 Condition B Method III80-98% RH10 cycles (10 days)+25° C to +65° CStep 7b vibration deleted.24 hour recovery period.EIA-364-421 meter8 dropsIngress Protection IP67 rating IEC-60529SHELL FORCESIZE(lbs.)18 5020 75EIA-364-35Insert Retention24 85Unmated connectors28 105100 ± 5 pounds per square inch32 11536 13540 165Insulation Resistance atAmbient TemperatureInsulation Resistance atElevated Temperature5,000 megohms minimum1,000 megohms minimum following 30 minutes at +200°CEIA-364-21500 volts DC ± 50 volts.EIA-364-21500 volts DC ± 50 volts.B© 2013 Glenair, Inc. U.S. CAGE Code 06324 Printed in U.S.A.GLENAIR, INC. • 1211 AIR WAY • GLENDALE, CA 91201-2497 • 818-247-6000 • FAX 818-500-9912www.glenair.com11E-Mail: sales@glenair.com