- Page 3:

CUTTERBAR COMPONENT LOCATOR27.29.28

- Page 7 and 8:

SICKLE ASSEMBLIES FOR CHALLENGERCOM

- Page 9 and 10:

SICKLE ASSEMBLIES FOR CHALLENGERLEF

- Page 11 and 12:

SICKLE ASSEMBLIES FOR CHALLENGERCOM

- Page 13 and 14:

SICKLE ASSEMBLIES FOR GLEANER(Forme

- Page 15 and 16:

SICKLE ASSEMBLIES FOR GLEANER(Forme

- Page 17 and 18:

SICKLE ASSEMBLIES FOR GLEANER(Forme

- Page 19 and 20:

SICKLE ASSEMBLIES FOR GLEANER(Forme

- Page 21 and 22:

SICKLE ASSEMBLIES FOR GLEANER(Forme

- Page 23 and 24:

SICKLE SECTIONS FOR GLEANER(Formerl

- Page 25 and 26:

SICKLE ASSEMBLIES FOR HESSTONSWATHE

- Page 27 and 28:

SICKLE ASSEMBLIES FOR HESSTONWINDRO

- Page 29 and 30:

SICKLE ASSEMBLIES FOR HESSTONLEFT H

- Page 31 and 32:

SICKLE ASSEMBLIES FOR HESSTONMOWER-

- Page 33 and 34:

SICKLE ASSEMBLIES FOR HESSTONLEFT H

- Page 35 and 36:

CUTTERBAR COMPONENTS FOR HESSTONOrd

- Page 37 and 38:

SICKLE ASSEMBLIES FOR MASSEY FERGUS

- Page 39 and 40:

SICKLE ASSEMBLIES FOR MASSEY FERGUS

- Page 41 and 42:

SICKLE ASSEMBLIES FOR MASSEY FERGUS

- Page 43 and 44:

SICKLE ASSEMBLIES FOR MASSEY FERGUS

- Page 45 and 46:

SICKLE ASSEMBLIES FOR MASSEY FERGUS

- Page 47 and 48:

SICKLE ASSEMBLIES FOR MASSEY FERGUS

- Page 49 and 50:

CUTTERBAR COMPONENTS FOR MASSEY FER

- Page 51 and 52:

SICKLE ASSEMBLIES FOR NEW IDEAMOWER

- Page 53 and 54:

SICKLE ASSEMBLIES FOR PMI(Formerly

- Page 55 and 56:

SICKLE ASSEMBLIES FOR WHITEWINDROWE

- Page 57 and 58:

SICKLE ASSEMBLIES FOR WHITECOMBINES

- Page 59 and 60:

ALL-MAKESALL-MAKESSECTION

- Page 61 and 62:

SICKLE ASSEMBLIES FOR CASE IH(Forme

- Page 63 and 64:

SICKLE ASSEMBLIES FOR CASE IH(Forme

- Page 65 and 66:

SICKLE ASSEMBLIES FOR CASE IH(Forme

- Page 67 and 68:

SICKLE ASSEMBLIES FOR CASE IH(Forme

- Page 69 and 70:

SICKLE ASSEMBLIES FOR CASE IH(Forme

- Page 71 and 72:

SICKLE ASSEMBLIES FOR CASE IH(Forme

- Page 73 and 74:

CUTTERBAR COMPONENTS FOR CASE IH(Fo

- Page 75 and 76:

SICKLE ASSEMBLIES FOR FORDMOWERS: 1

- Page 77 and 78:

SICKLE ASSEMBLIES FOR FORDMOWER-CON

- Page 79 and 80:

SICKLE ASSEMBLIES FOR GEHL/OWATONNA

- Page 81 and 82:

SICKLE ASSEMBLIES FOR GEHL/OWATONNA

- Page 83 and 84:

SICKLE ASSEMBLIES FOR HART-CARTERCO

- Page 85 and 86: SICKLE ASSEMBLIES FOR JOHN DEEREMOW

- Page 87 and 88: SICKLE ASSEMBLIES FOR JOHN DEERELEF

- Page 89 and 90: SICKLE ASSEMBLIES FOR JOHN DEEREWIN

- Page 91 and 92: SICKLE ASSEMBLIES FOR JOHN DEERELEF

- Page 93 and 94: SICKLE SECTIONS FOR JOHN DEEREH1304

- Page 95 and 96: SICKLE ASSEMBLIES FOR KOSCHMOWERS:

- Page 97 and 98: SICKLE SECTIONS FOR J.E. LOVEL193Or

- Page 99 and 100: SICKLE ASSEMBLIES FOR MACDONLEFT HA

- Page 101 and 102: SICKLE ASSEMBLIES FOR MACDONWINDROW

- Page 103 and 104: SICKLE ASSEMBLIES FOR MACDONWINDROW

- Page 105 and 106: SICKLE SECTIONS FOR MACDON34390Orde

- Page 107 and 108: SICKLE ASSEMBLIES FOR NEW HOLLANDMO

- Page 109 and 110: SICKLE ASSEMBLIES FOR NEW HOLLANDLE

- Page 111 and 112: SICKLE ASSEMBLIES FOR NEW HOLLANDWI

- Page 113 and 114: SICKLE ASSEMBLIES FOR NEW HOLLANDCO

- Page 115 and 116: OVERLAP SECTIONS & KITS FOR NEW HOL

- Page 117 and 118: SICKLE ASSEMBLIES FOR OWATONNAWINDR

- Page 119 and 120: SICKLE SECTIONS FOR SCH (SCHUMACHER

- Page 121 and 122: SICKLE ASSEMBLIES FOR VERSATILEWIND

- Page 123 and 124: SICKLE SECTIONS FOR VERSATILEOrder

- Page 125 and 126: 7/32" DIAMETER BOLT-ON FASTENERSOrd

- Page 127 and 128: OVERLAP SECTIONSILLUSTRATION OF OVE

- Page 129 and 130: MALLEABLE GUARDSOrderNumber Descrip

- Page 131 and 132: KNIFEHEAD PIN REPLACEMENT KITSFor C

- Page 133 and 134: DRILLED KNIFEBACKOrder Replacement

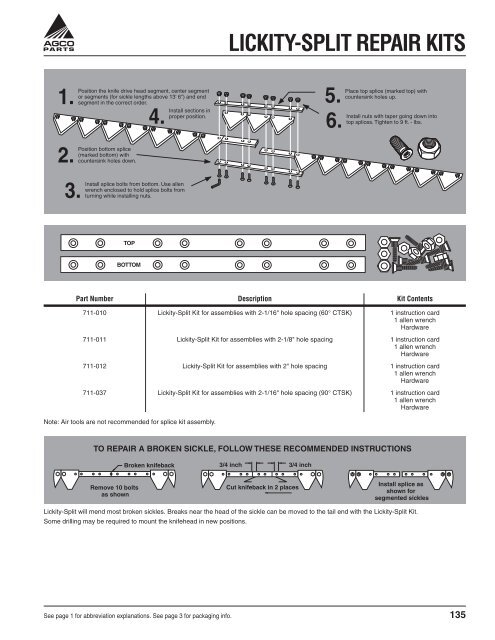

- Page 135: CARDED AND PLASTIC BOX PACKAGESAttr

- Page 139 and 140: DISC MOWER REPLACEMENT KITS11 Degre

- Page 141 and 142: DISC MOWER KNIVES FOR CHALLENGERAGC

- Page 143 and 144: DISC MOWER KNIVES FOR HESSTONAGCO A

- Page 145 and 146: DISC MOWER KNIVES FOR MASSEY FERGUS

- Page 147 and 148: DISC MOWER KNIVES FOR MASSEY FERGUS

- Page 149 and 150: DISC MOWER KNIVES FOR NEW IDEAAGCO

- Page 151 and 152: DISC MOWER KNIVES FOR NEW IDEAAGCO

- Page 153 and 154: DISC MOWER KNIVES FOR BUSH HOGAGCO

- Page 155 and 156: DISC MOWER KNIVES FOR DEUTZ-FAHRAGC

- Page 157 and 158: DISC MOWER KNIVES FOR GEHLAGCO A21-

- Page 159 and 160: DISC MOWER KNIVES FOR GREENLAND/DEU

- Page 161 and 162: DISC MOWER KNIVES FOR JOHN DEEREAGC

- Page 163 and 164: DISC MOWER KNIVES FOR KUHNAGCO A31-

- Page 165 and 166: DISC MOWER KNIVES FOR LELYAGCO A21-

- Page 167 and 168: DISC MOWER KNIVES FOR NEW HOLLANDAG

- Page 169 and 170: DISC MOWER KNIVES FOR VICONAGCO A31

- Page 171 and 172: TYPE 2 KNIVES — OPPOSITE BEVEL, 1

- Page 173 and 174: TYPE 3 KNIVES — OPPOSITE BEVEL, 1

- Page 175 and 176: TYPE 5 KNIVES — TOP BEVEL, 11° T

- Page 177 and 178: TYPE 6 KNIVES — OPPOSITE BEVEL, 1

- Page 179 and 180: TYPE 9 KNIVES — OPPOSITE BEVEL, 1

- Page 181 and 182: MOWER HARDWARE FOR CASE IHOrder Rep

- Page 183 and 184: AGCO PART NUMBER INDEXPart No. ....

- Page 185 and 186: OEM PART NUMBER INDEXPart No. .....

- Page 187 and 188:

OEM PART NUMBER INDEXPart No. .....