CPC 20 POLYESTER POWDER COATING - Helios

CPC 20 POLYESTER POWDER COATING - Helios

CPC 20 POLYESTER POWDER COATING - Helios

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

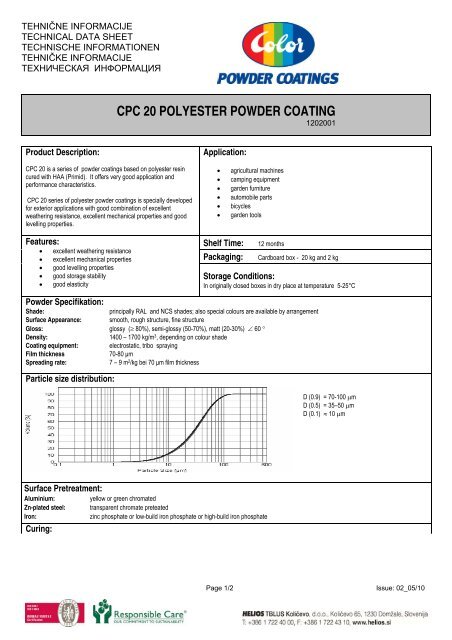

TEHNIČNE INFORMACIJETECHNICAL DATA SHEETTECHNISCHE INFORMATIONENTEHNIČKE INFORMACIJEТЕХНИЧЕСКАЯ ИНФОРМАЦИЯ<strong>CPC</strong> <strong>20</strong> <strong>POLYESTER</strong> <strong>POWDER</strong> <strong>COATING</strong>1<strong>20</strong><strong>20</strong>01Product Description:Application:<strong>CPC</strong> <strong>20</strong> is a series of powder coatings based on polyester resincured with HAA (Primid). It offers very good application andperformance characteristics.<strong>CPC</strong> <strong>20</strong> series of polyester powder coatings is specially developedfor exterior applications with good combination of excellentweathering resistance, excellent mechanical properties and goodlevelling properties.agricultural machinescamping equipmentgarden furnitureautomobile partsbicyclesgarden toolsFeatures:excellent weathering resistanceexcellent mechanical propertiesgood levelling propertiesgood storage stabilitygood elasticityShelf Time:Packaging:12 monthsCardboard box - <strong>20</strong> kg and 2 kgStorage Conditions:In originally closed boxes in dry place at temperature 5-25°CPowder Specifikation:Shade:Surface Appearance:Gloss:Density:Coating equipment:Film thicknessSpreading rate:principally RAL and NCS shades; also special colours are available by arrangementsmooth, rough structure, fine structureglossy ( 80%), semi-glossy (50-70%), matt (<strong>20</strong>-30%) 60 1400 – 1700 kg/m 3 , depending on colour shadeelectrostatic, tribo spraying70-80 μm7 – 9 m 2 /kg bei 70 μm film thicknessParticle size distribution:D (0.9) = 70-100 mD (0.5) = 35–50 mD (0.1) 10 mSurface Pretreatment:Aluminium:yellow or green chromatedZn-plated steel: transparent chromate preteatedIron:zinc phosphate or low-build iron phosphate or high-build iron phosphateCuring:Page 1/2Issue: 02_05/10

TEHNIČNE INFORMACIJETECHNICAL DATA SHEETTECHNISCHE INFORMATIONENTEHNIČKE INFORMACIJEТЕХНИЧЕСКАЯ ИНФОРМАЦИЯ<strong>CPC</strong> <strong>20</strong> <strong>POLYESTER</strong> <strong>POWDER</strong> <strong>COATING</strong>1<strong>20</strong><strong>20</strong>012<strong>20</strong><strong>CPC</strong> <strong>20</strong>-1, <strong>20</strong>-5, <strong>20</strong>-72<strong>20</strong><strong>CPC</strong> <strong>20</strong>-2, <strong>20</strong>-6, <strong>20</strong>-8<strong>CPC</strong> <strong>20</strong> -3Object temeperature<strong>20</strong>01801601405 10 15 <strong>20</strong>MinutesObject temeperature<strong>20</strong>01801601405 10 15 <strong>20</strong>MinutesObject temeperature2<strong>20</strong><strong>20</strong>01801601405 10 15 <strong>20</strong>MinutesTest Results :Physical Properties (0,8 mm steel panel)) Glossy Semi glossy MattCure parameters (object conditions) 10 min / 180°C 10 min / 180°C <strong>20</strong> min / 180°CFilm thickness in m (ISO 2808) 60-70 60-70 60-80Gloss, units 60° (ASTM 523, DIN 2813) ≥ 80 50-70 <strong>20</strong>-30Adhesion (ISO 2409) Gt 0 Gt 0 Gt 0Bend Test (ISO 1519) ≥ 3 mm ≥ 4 mm ≥ 4 mmElasticity - Cupping Test (DIN ISO 15<strong>20</strong>) ≥ 7 mm ≥ 6 mm ≥ 6 mmHardness (Bucholz) (ISO 2815) ≥ 91 ≥ 91 ≥ 91Chemical Properties (0,7 mm chromated Aluminium)Salt spray 500 h (DIN 50021 SS)– Delamination at cut: max. 1 mm max. 1 mm max. 1 mmHum. cabinet 500 h (DIN 50017 SK)– Delamination at cut: max. 1 mm max. 1 mm max. 1 mmWeather resistance – QUV test – gloss retention (15 cycles, ASTM D4587, G 53) 40% 40% 40%This technical data and suggestions for use in this technical data sheet are currently correct to the best of knowledge based on laboratory work and practicalexperience but are subject to change without notice. Because application and conditions vary, and are beyond our control, we are not responsible for resultsobtained in using this product, even when used as suggested. The user should conduct tests to determine the suitability of the product for the intended use. Anyliability we may have (including liability for breach of warranty, strict liability in tort, negligence or otherwise) is limited exclusively to replacement of the product orrefund of its price. Under no circumstance are we liable for incidental and consequential damages.The quality system conforms to ISO 9001.Page 2/2Issue: 02_05/10