The efficiency concept for compressed-air filtration

The efficiency concept for compressed-air filtration

The efficiency concept for compressed-air filtration

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

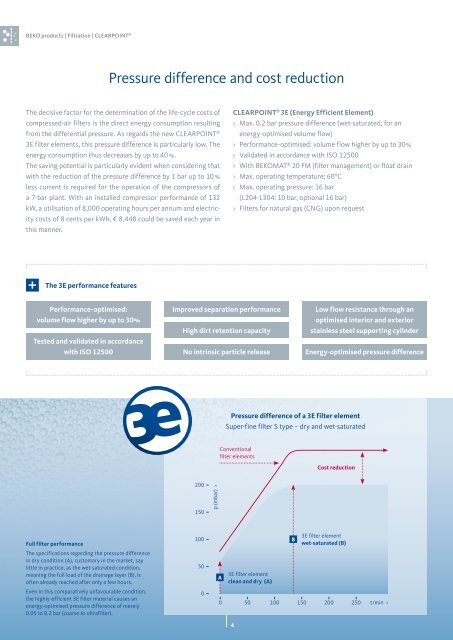

BEKO products | Filtration | CLEARPOINT ® 4Pressure difference and cost reduction<strong>The</strong> decisive factor <strong>for</strong> the determination of the life-cycle costs of<strong>compressed</strong>-<strong>air</strong> filters is the direct energy consumption resultingfrom the differential pressure. As regards the new CLEARPOINT ®3E filter elements, this pressure difference is particularly low. <strong>The</strong>energy consumption thus decreases by up to 40 %.<strong>The</strong> saving potential is particularly evident when considering thatwith the reduction of the pressure difference by 1 bar up to 10 %less current is required <strong>for</strong> the operation of the compressors ofa 7-bar plant. With an installed compressor per<strong>for</strong>mance of 132kW, a utilisation of 8,000 operating hours per annum and electricitycosts of 8 cents per kWh, € 8,448 could be saved each year inthis manner.CLEARPOINT ® 3E (Energy Efficient Element)› Max. 0.2 bar pressure difference (wet-saturated, <strong>for</strong> anenergy-optimised volume flow)› Per<strong>for</strong>mance-optimised: volume flow higher by up to 30%› Validated in accordance with ISO 12500› With BEKOMAT ® 20 FM (filter management) or float drain› Max. operating temperature: 60°C› Max. operating pressure: 16 bar(L204-L304: 10 bar, optional 16 bar)› Filters <strong>for</strong> natural gas (CNG) upon request<strong>The</strong> 3E per<strong>for</strong>mance featuresPer<strong>for</strong>mance-optimised:volume flow higher by up to 30%Tested and validated in accordancewith ISO 12500Improved separation per<strong>for</strong>manceHigh dirt retention capacityNo intrinsic particle releaseLow flow resistance through anoptimised interior and exteriorstainless steel supporting cylinderEnergy-optimised pressure differencePressure difference of a 3E filter elementSuper-fine filter S type – dry and wet-saturatedConventionalfilter elementsCost reduction200150p (mbar) >Full filter per<strong>for</strong>mance<strong>The</strong> specifications regarding the pressure differencein dry condition (A), customary in the market, saylittle in practice, as the wet- saturated condition,meaning the full load of the drainage layer (B), isoften already reached after only a few hours.Even in this comparatively unfavourable condition,the highly-efficient 3E filter material causes anenergy-optimised pressure difference of merely0.05 to 0.2 bar (coarse to ultrafilter).100500A3E filter elementclean and dry (A)B3E filter elementwet-saturated (B)0 50 100 150 200 250 t/min >

![metpoint ® dpm: dewpointmeter dp 109 [pdf 199 kb] - BEKO ...](https://img.yumpu.com/35213737/1/184x260/metpoint-ar-dpm-dewpointmeter-dp-109-pdf-199-kb-beko-.jpg?quality=85)