Tables / Explanations AWG-Sizes - Prysmian Group

Tables / Explanations AWG-Sizes - Prysmian Group

Tables / Explanations AWG-Sizes - Prysmian Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

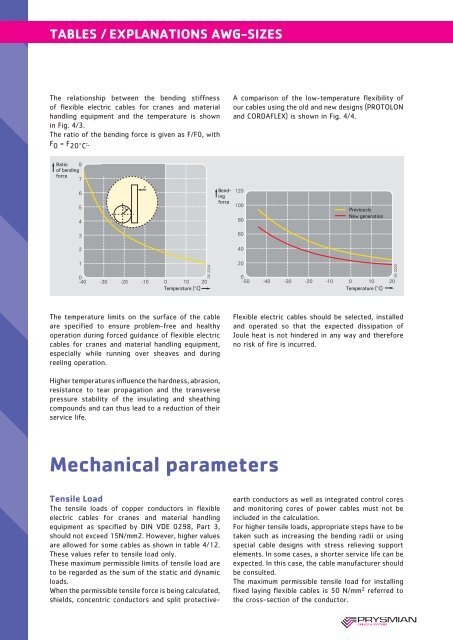

TABLES / EXPLANATIONS <strong>AWG</strong>-SIZESThe relationship between the bending stiffnessof flexible electric cables for cranes and materialhandling equipment and the temperature is shownin Fig. 4/3.The ratio of the bending force is given as F/F0, withF 0 = F 20°C :.A comparison of the low-temperature flexibility ofour cables using the old and new designs (PROTOLONand CORDAFLEX) is shown in Fig. 4/4. The temperature limits on the surface of the cableare specified to ensure problem-free and healthyop er ation during forced guidance of flexible electriccables for cranes and material handling equipment,especially while running over sheaves and duringreeling operation.Flexible electric cables should be selected, installedand operated so that the expected dissipation ofJoule heat is not hindered in any way and thereforeno risk of fire is incurred.Higher temperatures influence the hardness, abrasion,resistance to tear propagation and the transversepressure stability of the insulating and sheathingcompounds and can thus lead to a reduction of theirservice life.Mechanical parametersTensile LoadThe tensile loads of copper conductors in flexibleelectric cables for cranes and material handlingequipment as specified by DIN VDE 0298, Part 3,should not exceed 15N/mm2. However, higher valuesare allowed for some cables as shown in table 4/12.These values refer to tensile load only.These maximum permissible limits of tensile load areto be regarded as the sum of the static and dynamicloads.When the permissible tensile force is being calculated,shields, concentric conductors and split protectiveearthconductors as well as integrated control coresand monitoring cores of power cables must not beincluded in the calculation.For higher tensile loads, appropriate steps have to betaken such as increasing the bending radii or usingspecial cable designs with stress relieving supportelements. In some cases, a shorter service life can beexpected. In this case, the cable manufacturer shouldbe consulted.The maximum permissible tensile load for installingfixed laying flexible cables is 50 N/mm 2 referred tothe cross-section of the conductor.