Expanding the Footprint - Skanska

Expanding the Footprint - Skanska

Expanding the Footprint - Skanska

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Diversity NetworkWith more than 7,000 employees in <strong>the</strong> U.S. and hundreds ofactive projects, maintaining a focus on diversity, compliance andinclusion can be a huge task. To meet this demand, several newteam members have been added to <strong>the</strong> diversity team. While someare new to <strong>Skanska</strong>, o<strong>the</strong>rs are longtime employees in new roles.Audra Tiemann was working as a project engineer in Texas when anopportunity became available to work with USA Civil West’s CaliforniaDistrict’s diversity and inclusion team.“The move to this role was a great decision,” she explains. “My team issupportive, <strong>the</strong> office embraces <strong>the</strong> <strong>Skanska</strong> culture and I love being partof making such instrumental changes.”Mari Comer was working as a project administrative assistant on <strong>the</strong>Gun Lake Casino project in Wayland, Mich., when a new diversity andoutreach coordinator position for <strong>the</strong> Detroit and Kalamazoo officesopened up.“I loved working with <strong>the</strong> subcontractor community on <strong>the</strong> projectlevel,” Mari says, “but to be able to develop ongoing relationships with localDisadvantaged Business Enterprise (DBE) subcontractors and be able toreally affect <strong>the</strong>ir business for years to come is a very rewarding experience.”"Developing ongoingrelationships with localDisadvantaged BusinessEnterprise (DBE) subcontractorsand be able to really affect <strong>the</strong>irbusiness for years to come is a veryrewarding experience.”Rodney Renix joined USA Civil Sou<strong>the</strong>ast earlier this year as regionalDBE compliance officer to help <strong>the</strong> office comply with all relevantfederal, state and local laws, rules and regulations pertaining to small,women and minority-owned businesses.“It’s been great to be a part of a company that practices what <strong>the</strong>ypreach on <strong>the</strong> job, and in <strong>the</strong> community. <strong>Skanska</strong> is really committed tonot just saying it, but doing it,” he says.“The growth of <strong>Skanska</strong>’s diversity network has been a catalyst forincreased efforts in developing a significant presence in <strong>the</strong> communityand among diverse contractors,” says James Threalkill, senior nationaldirector of diversity. “This demonstrates our commitment to embracingdiversity as a key business strategy and priority in our cultural growth.” ◆The <strong>Skanska</strong> USA Diversity NetworkShelby AdamsCommunications Manager, <strong>Skanska</strong> USA, U.S.Nyime BrownDiversity and Outreach Coordinator, USA Civil, VirginiaMaritza BurgosDiversity Manager, USA Building, TexasMari ComerDiversity Coordinator, USA Building, MichiganGeorge CuckieDBE Compliance Manager, USA Civil, ColoradoFred FoxDBE Coordinator, USA Civil, NorthwestAndre GuenoDBE Coordinator, USA Civil, CaliforniaGeorge HanibleRegional DBE Compliance Officer, USA Civil, West CoastRachel HendrixDiversity Manager, <strong>Skanska</strong> USA, GeorgiaWaiel HusseinCompliance Officer, USA Civil, U.S.Mel JonesDiversity Manager, USA Building, Oregon/WashingtonRenee JonesDiversity Manager, USA Building, CarolinasMichelle MasonDBE Coordinator, USA Civil, ArizonaSherry NacciDiversity Coordinator, USA Building, PennsylvaniaRodney RenixRegional DBE Compliance Officer, USA Civil, VirginiaRoi SmithContract Manager, USA Civil, New YorkVan ThompsonDiversity Manager, <strong>Skanska</strong> USA Building, New York/New JerseyJames ThrealkillSenior National Director, Diversity, <strong>Skanska</strong> USA, U.S.Audra TiemannSenior DBE Compliance Manager, USA Civil, CaliforniaHorrace TobinEqual Employment Opportunity Compliance, <strong>Skanska</strong> USA, VirginiaCommunityTimelineHouston, Texas:Helping local studentsEmployees in Houstonand College Station,Texas, collected schoolsupplies for Communitiesin Schools and delivereditems to Pine ShadowsElementary School.Oakland, Calif.: Giving away goodsThe office donated remaining office suppliesfrom <strong>the</strong> Central Utility Plant jobsite, withan estimated worth of $4,012, to two localchildren’s organizations.Boston, Mass.:Cradles to crayonsEmployees participated in<strong>the</strong> fifth annual Ready forSchool campaign, helpingto fill more than 15,000backpacks with crayons,pencils, notebooks and o<strong>the</strong>rsupplies for disadvantagedschool-aged children.Alexandria, Va.:Getting physicalID Americas spearheadeda drive with <strong>the</strong> D.C.-areabusiness units to collectexercise equipment fordisabled and disadvantagedchildren enrolled in KidsEnjoy Exercise Now.Washington, D.C.:Carrying <strong>the</strong> torchMore than 25 employees from<strong>the</strong> Rockville and Arlingtonoffices teamed up to sponsorand participate in <strong>the</strong> 2011Juvenile Diabetes ResearchFoundation’s Real Estate Games.JUNE JULYAUGUSTPortland, Ore.: Tools for schoolsTeam members helped pack backpacks for a KnowledgeUniverse Tools for Schools event at Schoolhouse Suppliesand <strong>the</strong>n dropped off <strong>the</strong> backpacks at a high-need school.Orlando, Fla.:School supplies driveThe George C. Young FederalBuilding and Courthouse teamworked with <strong>the</strong> NemoursChildren’s Hospital teamto hold a school suppliesdrive for <strong>the</strong> children of <strong>the</strong>Orlando Union Rescue Mission,contributing $635 in Target,Wal-Mart and Old Navy giftcards, more than 70 backpacksand two trucks of supplies.Philadelphia, Pa.:Responding to <strong>the</strong> callHosting its ninth blooddrive, <strong>the</strong> office collected20 donations, some ofwhich were double redblood cell donations.Raleigh, N.C.:Successful food driveFollowing <strong>the</strong> tornadoes thatstruck North Carolina, <strong>the</strong> WakeCounty Detention Center projectteam donated 990 pounds offood to <strong>the</strong> Food Bank of Central& Eastern North Carolina.Seattle, Wash.: Playing it safeThe office donated 125 pairs of safety glasses and75 pairs of gloves to a Boy Scouts of America CubScout Day Camp so that <strong>the</strong> 250 attendees couldparticipate safely in <strong>the</strong> event’s activities.New York, N.Y.: Helpingtornado victimsUSA Civil Nor<strong>the</strong>ast employeesin New York and New Jerseydonated more than 1,500pounds of necessities toChristian Service Missionto help tornado victims inAlabama and Missouri.6 coast to coastcoast to coast7

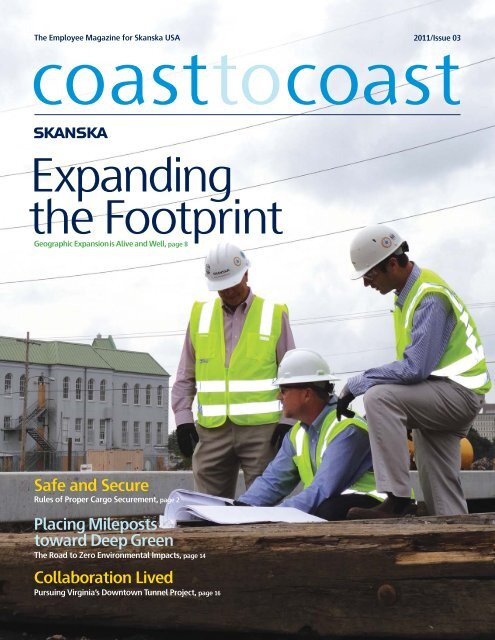

» Mission Critical's work on two facilities in Canada is underway.<strong>Expanding</strong> <strong>the</strong> <strong>Footprint</strong>Profitable growth remains <strong>the</strong> objective of <strong>the</strong> 2011-2015 U.S. Business Plan, and one approach toachieving profitability is geographic expansion. Coast to Coast examines how <strong>Skanska</strong> USA is takingaction to expand by way of organic growth and strategic acquisitions.» The Cincinnati office opened for business in April.North of <strong>the</strong> borderPrimarily made up of employees from <strong>the</strong> Michigan and New YorkMetro offices, <strong>the</strong> project teams hard at work in Sou<strong>the</strong>rn Ontario,Canada, are quietly building giants for <strong>the</strong> Mission Critical Centerof Excellence.For starters, in Guelph, about an hour west of Toronto, <strong>the</strong> teamis working on a 226,000-square-foot facility expansion currentlyaveraging about 250 craft workers.“There have been some adjustments working up here, but manyhave been good,” says Senior Project Manager Bill Laurain. “TheCanadian subcontractors want to be safe out-of-<strong>the</strong>-box, so our culturemeshes perfectly. It’s a collaborative team that respects one ano<strong>the</strong>r.”In Stratford, roughly in between Toronto and Detroit, ano<strong>the</strong>rteam is working on a new 400,000-square-foot facility. This projectwill peak at about 800 craft workers in coming months.“It’s a gigantic job,” says Senior Project Manager FrankScandariato, “and <strong>the</strong>re’s definitely been a blend of <strong>the</strong> fast-pacedAmerican culture with <strong>the</strong> more relaxed approach of <strong>the</strong> Canadians.The results, though, have been fantastic.”The jobs total $390 million and will wrap in early 2012. Bothare joint ventures with Toronto-based Giffels, which has been asignificant help with subcontractors.“Giffels has been a tremendous partner,” Bill says. “They know <strong>the</strong>subcontractor community and <strong>the</strong>y know how system works here.”Planting deeper roots in <strong>the</strong> heartlandWhile working in Ohio isn’t new to <strong>Skanska</strong>, its first officialoffice opened in Cincinnati in April – just in time to coincidewith opening day for <strong>the</strong> Cincinnati Reds.<strong>Skanska</strong> began working in Ohio almost 10 years ago ona master agreement account for a large telecommunicationscompany. Six years ago <strong>the</strong> company won a $140 million hospitalproject just outside of Cincinnati. The project was a success andled to two more large healthcare projects in <strong>the</strong> area. The teamis also currently completing an office headquarters project inCincinnati.“We see Cincinnati as a market with a lot of potential,” saysAccount Manager Craig Eckert. “Having a strong, ongoingrelationship with clients, designers and subcontractors gives usa good foundation for growth and success in <strong>the</strong> market.”“When we looked at expanding into Cincinnati, we knew itwould be important to have an address but knew we neededto start small and grow as work increased,” adds Co-ChiefOperating Officer Joey Hatch. “We were able to find a smalloffice space in <strong>the</strong> heart of downtown Cincinnati that’s <strong>the</strong> rightsize for our support staff and in close proximity to many designand engineering firms. Success in this market will play a key partin enabling us to reach our 2015 business plan goals for <strong>the</strong>Midwest region.”8 coast to coastcoast to coast9

» The Aviation Center of Excellence established a home base in Chicago.Chicago office takes flight<strong>Skanska</strong> also has a new Chicago address. The Aviation Center ofExcellence has established a home base here and is finding successnot only at Chicago’s O’Hare International Airport, but across <strong>the</strong>country too.In <strong>the</strong> past four months, <strong>the</strong> team has won three key aviationprojects: a baggage inspections system project at O’Hare, a terminalimprovement project at Greenville-Spartanburg Airport in Greer,S.C., and a new regional jet terminal project at George BushInternational Airport in Houston.» Lance Charriere and Eric Bunner at <strong>the</strong> Dallas office.The office will also look at opportunities in <strong>the</strong> healthcare, highereducation and public markets collaborating with groups like <strong>the</strong>Healthcare Center of Excellence and o<strong>the</strong>r offices in <strong>the</strong> Midwest.“By 2015 our goal is to have 70 percent of USA Building’s workcome from <strong>the</strong> COEs. And a large part of our ability to achievethat is through internal collaboration,” says General Manager JimClemens. “In <strong>the</strong> short time <strong>the</strong> Aviation COE and Chicago officehave been in existence we’ve worked with 12 offices around <strong>the</strong>country, which has been a huge contributor to our success thus far.”Setting up shop in <strong>the</strong> Big DAs one of <strong>the</strong> country’s fastest growing markets, Texas is a perfectplace to expand <strong>the</strong> company’s footprint. And with a 10-yearhistory of working in <strong>the</strong> state’s second largest city, it was an easydecision to plant <strong>Skanska</strong>’s flag in Dallas.“When we were ready to expand in <strong>the</strong> state this yearto support <strong>the</strong> 2015 business plan, Dallas was <strong>the</strong> naturalchoice,” explains General Manager Brian Freeman. “It’s a globalcity with a lot of opportunity and a strong, diverse economy.”<strong>Skanska</strong> first made a name for itself in Texas eight years agowith <strong>the</strong> completion of Reliant Stadium. Since <strong>the</strong>n, <strong>the</strong> Texasteam has been gaining <strong>the</strong> trust of key clients such as TexasA&M University, HCA and Harris County Hospital District.But it takes more than local experience to create success; italso takes <strong>the</strong> right people. Two local construction veterans wereidentified as key hires for <strong>the</strong> new Dallas team. Lance Charriere,vice president of business development, has worked in <strong>the</strong>market for international construction firms for many years andbrings with him strong contacts with owners and design firms.Shannon Arnold, <strong>Skanska</strong>’s newest account manager, will join<strong>the</strong> Dallas team November 1. Shannon has a wealth of Dallasconstruction leadership experience. Project Executive EricBunner also moved from San Antonio to Dallas to help support<strong>the</strong> new office’s efforts.» The project team ventured deep into <strong>the</strong> desert for <strong>the</strong> SR111 bypass project.The California desertUSA Civil’s Rocky Mountain and California Districts are no strangersto working in far-flung areas. Few sites are as remote as two sites in <strong>the</strong>Sou<strong>the</strong>rn California desert, though.The two districts are collaborating on a major project for a confidentialclient near Mountain Pass, Calif., a mere 15 miles from <strong>the</strong> Nevada border.It’s a contrast to a recently-completed highway job by <strong>the</strong> CaliforniaDistrict in Brawley, Calif., which is about 25 miles from <strong>the</strong> Mexicanborder. While Mountain Pass sits at nearly 4,800 feet of elevation, Brawleysits 112 feet below sea level.In Brawley, challenges abounded on <strong>the</strong> recently completed $70 millionphase of <strong>the</strong> SR111 bypass, which helps ease traffic heading to and from <strong>the</strong>international border."We understand <strong>the</strong> importance of creatingdiverse partnerships by hiringlocal and minority- and women-ownedsubcontractors who know <strong>the</strong>community…"“Our hottest day on-site was in 2009 when it hit 124 degrees,” saysProject Manager Jerry Iniguez.Proper preparation helped ensure zero heat-related incidents. Muchmore was needed to avoid issues while building two bridges spanning ahazardous river.The New River flows out of Mexico and through Brawley. Often called<strong>the</strong> most polluted river in America, it’s been spoiled by agricultural andchemical runoff from both <strong>the</strong> United States and Mexico, as well as by» <strong>Skanska</strong> will make its mark in New Orleans on <strong>the</strong> University Medical Center project.sewage from <strong>the</strong> Mexican city of Mexicali. The result is a stew that includesvolatile organic compounds, heavy metals and pathogens includingtuberculosis, polio, cholera, typhoid and hepatitis.“A lot of planning went into how to build <strong>the</strong> bridges without cominginto contact with <strong>the</strong> river,” Jerry says. “We had to take steps to makesure workers wouldn’t touch <strong>the</strong> water and we held daily safety meetingsspecific to <strong>the</strong> river. Before work started, a lot of workers had to bevaccinated for a number of diseases as ano<strong>the</strong>r protective step.”Making moves in <strong>the</strong> Crescent CityNew Orleans is still recovering from Hurricane Katrina six years after<strong>the</strong> storm tore through <strong>the</strong> Gulf Coast, and <strong>Skanska</strong> has venturedinto this new market to aid in <strong>the</strong> city’s recovery and support <strong>the</strong>community’s healthcare needs.A team made up of <strong>the</strong> Healthcare Center of Excellence, <strong>the</strong> Florida,Atlanta and Durham offices and joint-venture partner MAPP Construction,a Louisiana-based contractor, have joined forces to construct <strong>the</strong> UniversityMedical Center – a state-of-<strong>the</strong>-art, 1 million-square-foot hospital campus.The team has begun Phase 1 of <strong>the</strong> project, which is valued at $522 millionand includes a 424-bed hospital, an adjoining diagnostic and treatmentcenter, utility/infrastructure installation, lighting, roadways and parking. Theteam will soon be enlisted for Phase 2 as well, which is valued at $150 million.The team isn’t carrying out <strong>the</strong> job alone ei<strong>the</strong>r. <strong>Skanska</strong> MAPP heldseveral networking events, attracting nearly 100 local subcontractors andminority- and women-owned businesses interested in <strong>the</strong> project.“<strong>Skanska</strong> MAPP understands <strong>the</strong> importance of creating diversepartnerships by hiring local and minority- and women-ownedsubcontractors who know <strong>the</strong> community and want to make it betterthrough <strong>the</strong> construction of new facilities such as <strong>the</strong> UniversityMedical Center,” says Senior Vice President Fred Hames. “It’s importantthat we reinvest in <strong>the</strong> community through our hiring practices.” ◆10 coast to coast coast to coast11

On <strong>the</strong>Road AgainCalifornia’s Big Bear Lake has a populationof about 5,000. Since it offers year-roundrecreation though, weekends can see morethan 100,000 sou<strong>the</strong>rn Californians making<strong>the</strong> trip “up <strong>the</strong> hill” for fun in <strong>the</strong> outdoors.When record-breaking rainfall last December washed out hugesections of state route 330 – a primary road to Big Bear from SanBernardino and <strong>the</strong> Inland Empire – drivers faced a tough choice.“Drivers could take a long detour that could add hours to <strong>the</strong>ir tripor stay home,” says Senior Project Executive Dennis Cox. “As you canimagine, businesses that depend on tourists were especially interestedin restoring highway 330 to service quickly.”When record-breaking rainfalllast December washed outhuge sections of stateroute 330 – a primary roadto Big Bear from San Bernardinoand <strong>the</strong> Inland Empire – driversfaced a tough choice… addhours to <strong>the</strong>ir trip,or stay home.When Three Heads are Better than OneLocated on Fort Sam Houston in San Antonio, Texas, <strong>the</strong> Tri-Service Research Laboratory wasconstructed by <strong>Skanska</strong> to provide a space for three branches of <strong>the</strong> U.S. Armed Forces to worktoge<strong>the</strong>r as one joint force.USA Civil West’s California District was awarded two contractstotaling $16 million to rebuild SR330. Initially, Caltrans estimated that<strong>the</strong> project would take a year to complete. However, favorable wea<strong>the</strong>r,strong coordination by <strong>the</strong> project team with Caltrans and <strong>the</strong> UnitedStates Forest Service had work well ahead of schedule by Memorial Day.“It was <strong>the</strong> perfect mix of good conditions and a great team,”Dennis says.It was a proud moment on June 17 when <strong>the</strong> highway reopened forfull use. Praise came in <strong>the</strong> form of positive press and a happy client.“Without <strong>the</strong> dedicated perseverance of <strong>the</strong> contractors, localelected officials and agencies, as well as Caltrans' staff, <strong>the</strong> successof <strong>the</strong> project would never have been possible,” Caltrans District 8Director Dr. Raymond Wolfe told <strong>the</strong> Mountain News. ◆The design-build facility will house Navy, Air Force and Armyresearch programs designed to evaluate <strong>the</strong> health and safetyeffects of exposure to energy devices. The 181,000-square-footbuilding houses various laser and biological research labs andecho-free chambers, which allows each military branch tosimultaneously conduct research on <strong>the</strong> biological effects ofdirected-energy devices.The scope of <strong>the</strong> project included <strong>the</strong> design and constructionof <strong>the</strong> $70 million facility within a 24-month time frame. <strong>Skanska</strong>partnered with Jacobs Engineering to provide design services andutilized a pre-engineered metal building system for <strong>the</strong> structureto both accelerate <strong>the</strong> schedule and minimize cost. On-timecompletion of <strong>the</strong> project was critical, as <strong>the</strong> dates for relocationof personnel and equipment were already identified.The project required <strong>Skanska</strong>’s team to become familiar with<strong>the</strong> standards, policies and procedures of <strong>the</strong> federal government.This resulted in extensive coordination with <strong>the</strong> numerousagencies representing <strong>the</strong> U.S. Army Corps of Engineers, FortSam Houston, each branch of <strong>the</strong> military, <strong>the</strong> end user groupsand o<strong>the</strong>r civilian contractors. The project team ensuredadherence to government standards such as <strong>the</strong> Buy AmericanAct, which stipulates that all construction materials must be fromdomestic sources or approved trading partners, and <strong>the</strong> DCID6/9, which provides guidelines on construction of secure spaces.The project, which is seeking LEED® Silver certification, wascompleted on time and <strong>Skanska</strong> plans to use lessons learnedat <strong>the</strong> Tri-Services Research Laboratory on future federalgovernment projects. ◆12 coast to coast coast to coast13

Placing Milepoststoward Deep GreenAny journey takes a good map. Many of <strong>Skanska</strong>’s green leadersknow that as much as “Journey to Deep Green” is discussed, <strong>the</strong>company won’t get anywhere without a plan. Fortunately, leadersfrom across <strong>the</strong> business are helping shape <strong>the</strong> strategy that willguide <strong>the</strong> final destination on its path towards zero environmentalimpacts in delivering high performance, future-proof projects.In place is a plan to recyclemore than 98 percentof all construction wasteby 2015, with annual benchmarksleading up to that goal.What does Deep Green look like?Deep Green is defined by attributes thatrelate to <strong>the</strong> four priority areas for reductionof <strong>the</strong> environmental impact of our projects– water, materials, energy and carbon.The attributes are:and zero potable water forconstruction in civil/infrastructure“We have to be able to drive market change,” says Senior VicePresident Beth Heider, who will soon assume <strong>the</strong> role of chair of<strong>the</strong> United States Green Building Council. “We’re leading through<strong>the</strong> green solutions we recommend to clients, illustrating bottomlinebenefit. And we have to show we believe in <strong>the</strong> benefits bywhat we choose to develop and how we build in <strong>the</strong> field.”In doing so, <strong>Skanska</strong> will have to refocus <strong>the</strong> ways projects areapproached and <strong>the</strong> ways <strong>the</strong> company’s green goals are perceived.Without measurements, a reputation as <strong>the</strong> leading greenconstruction company will only mean so much.“We shouldn’t aim to be <strong>the</strong> best in our industry. We shouldaim to be <strong>the</strong> best company in terms of sustainability, period,” saysEnvironmental Manager Courtney Lorenz. “What we want to do isbe better at managing waste within our company, while deliveringprojects using fewer materials, water and energy.”To get <strong>the</strong>re, each business unit will assign Green StrategicIndicators that will measure actual performance. These indicatorswill align with overall 2011-2015 U.S. Business Plan goals and willbe monitored at a high level.Already in place is a plan to recycle more than 98 percent of allconstruction waste by 2015, with annual benchmarks leading up tothat goal. By <strong>the</strong> end of 2012, <strong>the</strong> target is more than 92 percent.“If we’re going to get to Deep Green, it’s going to take settingbaselines, examining areas where we do well and being honestabout places where we need to step up,” Courtney says. “The rightbenchmarks will help us get better, instead of touting <strong>the</strong> samesuccesses over and over again.”A major part of <strong>the</strong> effort is “investing” in new green methods.<strong>Skanska</strong> was a key member of a team, for example, that built <strong>the</strong>Bertschi School Science Classroom Addition in Seattle, whichis tracking to be a Living Building SM . Pioneering work like that,done at cost, has opened <strong>the</strong> door for <strong>Skanska</strong> to take a leadershipposition on <strong>the</strong> proposed Oregon Sustainability Center, whichcould be <strong>the</strong> world’s first urban mid-rise Living Building.But achieving a true leadership position will take more thana visionary project here and <strong>the</strong>re. Helping move <strong>the</strong> market todemand that a majority of projects surpass basic LEED levels willdo more. <strong>Skanska</strong>, however, can once again lead by example. Forinstance, USA Commercial Development (CD) has set LEED Goldas a minimum requirement for its projects.“We see Gold as <strong>the</strong> start of <strong>the</strong> journey,” says DevelopmentManager Ca<strong>the</strong>rine Dannenbring. “On each project, we’re tryingto incorporate one new green element that hasn’t been tried in CDprojects. Ideally, each project builds on lessons learned from <strong>the</strong> last.That allows us to set a structured way to continually move forward.”CD must work within <strong>the</strong> bounds of whatever future tenantswill desire. By pushing <strong>the</strong> envelope and linking <strong>the</strong> results to» The Bertschi School Science Classroom Addition in Seattle is on track to be a Living Building.tenant business goals, though, it’s possible to move <strong>the</strong> needle a bitcloser to net-zero structures.“We need to focus on low life cycle costs ra<strong>the</strong>r than initialinvestment,” Ca<strong>the</strong>rine says. “It’s vital that we show howmeasuring energy consumption and reducing carbon footprintshave tangible bottom line and social benefits.”“We’ve always been at <strong>the</strong> front of <strong>the</strong> pack with green ideasand execution,” Beth says. “This is a moment where we cancombine <strong>the</strong> green-thinking culture of <strong>Skanska</strong> with tangible,business-focused measurement to drive us to a new way toconduct our business.” ◆14 coast to coast coast to coast15

The project does not run on rails“PPPs have a long-term development process in whichexternal and internal factors can change and develop. Theteam is constantly engaged in an evaluative process to notjust process information, but to determine its strategicimpact,” says Frederick Burman, ID Americas projectdevelopment director, commercial.For example, midway through development, <strong>the</strong>client wanted to specify a toll range for users - atremendous challenge from a financing perspective.“In simple terms, <strong>the</strong> toll is an output of <strong>the</strong> costsof <strong>the</strong> project over <strong>the</strong> length of <strong>the</strong> contract,” explainsAndy Sou<strong>the</strong>rland, ID Americas project development,finance. “A pre-determined rate requires inputting to<strong>the</strong> financial model, <strong>the</strong>n working backwards throughan iterative process of matching up <strong>the</strong> project’scommercial terms and optimal financing so thateverything hangs toge<strong>the</strong>r in equilibrium.”Fortunately <strong>the</strong> project team reached an acceptablepath to delivering <strong>the</strong> client’s affordable toll rate.» The <strong>Skanska</strong>-Kiewit-Weeks Marine team works closely with Virginia Department of Transportation (VDOT) Civil Rights: Wade Watson, VDOT’s Shay Ponquinette, Peter Jonna, Mark Apaliski and Rodney Renix.Collaboration LivedThe <strong>Skanska</strong> team pursuing Virginia’s Downtown Tunnel Project is gaining valuable experiencefor future competitive advantage on U.S. public-private partnerships (PPPs).Thirty states havelegislation enabling PPPs, and Virginia has one of <strong>the</strong> longest-standing programs. However,even with an established procurement process, project development for PPPs is nei<strong>the</strong>r linear,nor predictable.“You can’t just ask customers what <strong>the</strong>y want and <strong>the</strong>n try to give that to<strong>the</strong>m. By <strong>the</strong> time you get it built, <strong>the</strong>y’ll want something new,” says Apple’sChairman and Founder Steve Jobs, according to <strong>the</strong> Financial Times.That challenge exists when developing hand-held devices, as it does withdeveloping projects larger than <strong>the</strong> eye can see - like <strong>the</strong> Downtown Tunnel/Midtown Tunnel/MLK Extension Project. The approximately $1.8 billionproject to design, build, finance, operate and maintain a new Midtown Tunnel,existing Downtown and Midtown Tunnels and a new roadway extension is a<strong>Skanska</strong>-led project that involves ID Americas and USA Civil Sou<strong>the</strong>ast.So how is this PPP project being effectively co-developed?“The U.S. is such a dynamic, emerging PPP market, where timelines,objectives, scopes, budgets - and certainly people - are stretched andchallenged in <strong>the</strong> course of developing a project,” explains ID AmericasProject Director Chris Guthkelch.“This project has presented us with tremendous design/buildopportunities - like <strong>the</strong> ability to design from scratch a solution thatminimizes right-of-way and environmental impacts, while achieving<strong>the</strong> client’s goal of a regionally connective roadway network,” adds WadeWatson, vice president of operations for USA Civil Sou<strong>the</strong>ast and leadrepresentative for Elizabeth River Crossing’s construction joint venture<strong>Skanska</strong>-Kiewit-Weeks Marine. “It’s been challenging given limitedfunding for <strong>the</strong> project, but <strong>the</strong> entire team has demonstrated <strong>the</strong> abilityand willpower to make this project a reality.”Coast to Coast asked <strong>Skanska</strong> team members for some top lessons learned.» Top: VDOT’s Tammy Mancinelli collaborates with Mary Humphreys on workforce development. Middle: LincolnSmith and Stephen VanEssendelft with Chris Guthkelch. Above: Horrace Tobin with VDOT’s Shay Ponquinette.Did you know?Collaboration is criticalA PPP development team structure may includeano<strong>the</strong>r equity partner, plus working groups for finance,commercial/legal and technical development. Specialistsfrom partner companies, <strong>the</strong> construction joint ventureand <strong>the</strong> client focus on design-build, traffic and revenue,cost modeling, government affairs and communications,and operations and maintenance, among o<strong>the</strong>rs.“The complexity of this project necessitates anextensive volume of activities and work productsacross multiple disciplines,” says Peter Jonna, projectdevelopment engineer for USA Civil’s Large ProjectsGroup. “The activities impact each o<strong>the</strong>r, so we’vealigned <strong>the</strong> team using all-hands conference calls, inpersonmeetings and even co-locating when needed.”Client relationships are paramountIn Virginia, both <strong>the</strong> central office of <strong>the</strong> VirginiaDepartment of Transportation and its district office areinvolved in development.“It’s important to respect <strong>the</strong>ir chain of commandand ingrained knowledge, and to find ways to add valueand accelerate development,” says Mary Humphreys, IDAmericas communications manager.Currently, <strong>the</strong> majority of issues contained in <strong>the</strong>comprehensive agreement draft have been resolved, and <strong>the</strong>team continues work to bring <strong>the</strong> project to a commercialand financial close, scheduled for year end. In parallel, atransition team has begun work related to establishing andoperating <strong>the</strong> special purpose company. ◆Tolling facilities today implement all electronic tolling, with no cash option, stopping, slowing or toll booths. Drivers pay via an electronicdevice like E-ZPass®, or by an invoice mailed to <strong>the</strong>m. Safety and efficiency are greatly improved. More information can be found atwww.ERC-info.com and www.MidtownTunnel.org.16 coast to coast coast to coast17

coast tocoastThe Employee Magazine for <strong>Skanska</strong> in <strong>the</strong> U.S.The <strong>Skanska</strong> Top 10<strong>Skanska</strong> USA hostedthis year’s annual globalManagement Meetingin San Antonio, Texas.For <strong>the</strong> second year in a row,<strong>Skanska</strong> ID won <strong>Skanska</strong>’sBusiness Unit of <strong>the</strong> Year in<strong>the</strong> Development category. IDAmericas’ team members workacross borders on ID projects.Alongside Railworks, USA CivilNor<strong>the</strong>ast was awarded a $386million contract to furnish andinstall finishes and systems at <strong>the</strong>No. 7 Line Extension projectin New York.733 10th Street in Washington, D.C.,<strong>Skanska</strong>’s first commercialdevelopment in <strong>the</strong> country,is 90 percent leased prior toconstruction completion this fall.Coast to Coast is nowavailable to read anddownload in digitalformat online at:usa.skanska.com/coasttocoast.USA CommercialDevelopment acquiredThe Houston ClubBuilding site, locatedat 811 Rusk Street, indowntown Houston, Texas.MetLife Stadium received<strong>Skanska</strong>’s Building Projectof <strong>the</strong> Year for beingcompleted on-budgetand five months aheadof schedule.USA Civil Nor<strong>the</strong>astProject Executive JohnCrecco received <strong>Skanska</strong>’sGolden Hard Hat awardfor production managerfor demonstrating acommitment to safety,financial focus andleadership ability.<strong>Skanska</strong> is gearing up tolaunch its new talentmanagement system– <strong>Skanska</strong> Talent –with training sessionsthat began last month.In a joint venture withTraylor Bros., Inc., USACivil Nor<strong>the</strong>ast signed a$210 million contractto build <strong>the</strong> SecondAvenue Subway line’s86th Street stationin New York.