January / February 2005 - CSIR

January / February 2005 - CSIR

January / February 2005 - CSIR

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

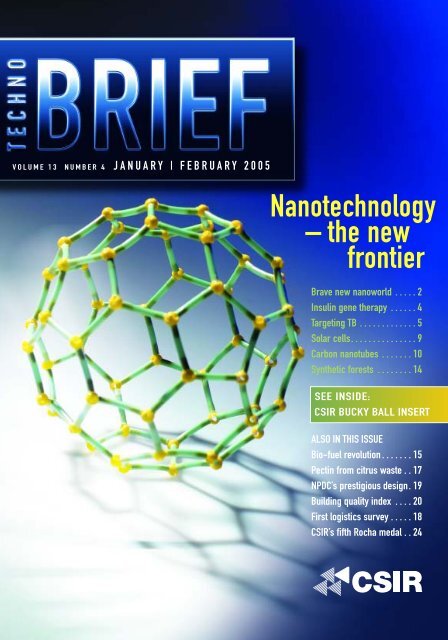

VOLUME 13 NUMBER 4 JANUARY | FEBRUARY <strong>2005</strong>Nanotechnology– the newfrontierBrave new nanoworld . . . . . 2Insulin gene therapy . . . . . . 4Targeting TB . . . . . . . . . . . . . 5Solar cells. . . . . . . . . . . . . . . 9Carbon nanotubes . . . . . . . 10Synthetic forests . . . . . . . . 14SEE INSIDE:<strong>CSIR</strong> BUCKY BALL INSERTALSO IN THIS ISSUEBio-fuel revolution . . . . . . . 15Pectin from citrus waste . . 17NPDC’s prestigious design. 19Building quality index . . . . 20First logistics survey . . . . . 18<strong>CSIR</strong>’s fifth Rocha medal . . 24

2N A N O T E C H N O L O G Y – T H E N E W F R O N T I E R ?THE <strong>CSIR</strong> TAKES ON A BRAVE NEWNANOWORLDThis issue’s coverpicture depicts a C60molecule known asthe bucky ball (seeour insert in thisissue).What is nano?A nanometre (nm) is a unit of measurementequal to a billionth of a metre(10 -9 ), tens of thousands of timessmaller than the width of a human hair.The prefix “nano” comes from the Greekword meaning “dwarf.”Nanoscience is the study of thefundamental principles of moleculesand structures with at least one dimensionroughly between 1 and 100 nm.It is concerned with materials andsystems of which the structures andcomponents exhibit novel andsignificantly improved physical,chemical and biological properties,phenomena andprocessesdue to theirnanoscalesize.Nanotechnology is the application ofnanoscience in technology devices.The essence of nanotechnology is theability to work at the molecular level,atom by atom, to create large structureswith fundamentally new molecularorganisation. Nanotechnology is oftendescribed as having “revolutionary”potential in terms of its possible impacton industry since it offers solutions tomany current problems by means ofcreating smaller, lighter, faster and betterperforming materials, components andsystems. This opens upnew opportunities forwealth creation andemployment.Nanotechnologyis also expectedto make an essentialcontribution tosolving global andenvironmental challengesby realising morespecific-to-useproducts andprocesses, savingresources andreducing wasteand emissions.Dr Thembela Hillie, Chairman of the <strong>CSIR</strong> NanoforumNanoscience and nanotechnologyare presently hot topics on theinternational research agenda withgovernments in Europe, USA and Japanspending more than $600 million per year.The initial hype of nano-robots that willnavigate our bodies to detect cancer orconstruct any product we desire, atomby atom, has been shifted to the background.Instead, practical applicationsare coming to the fore in improved drugdelivery, self-cleaning windows andadvanced materials used in a range ofapplications from golf clubs to plastic carparts and future electronic chips. It isgenerally accepted that nanotechnologywill have a huge impact on industry andfigures of billions of dollars are oftenquoted.Under the chairmanship of Dr ThembelaHillie, the <strong>CSIR</strong> has established a visionand is developing an approach to nanoscienceand nanotechnology within theorganisation through the establishmentof the <strong>CSIR</strong> Nanoforum, launched in<strong>January</strong> <strong>2005</strong>. It comprises <strong>CSIR</strong> scientists,engineers and technologists withappropriate expertise drawn from withinthe organisation. Hillie explains, “Theworking plan for the <strong>CSIR</strong> nano initiativeentails identifying expertise within theorganisation and the infrastructure thatwould support the planned endeavours.These experts are then mobilised toengage in interdisciplinary research acrossthe organisation, partnering academia andindustry, to further the vision of the <strong>CSIR</strong>.Current consortium-based partnershipsinclude the tuberculosis and solid-statelighting projects. This model also utilisesexisting links with international laboratoriesto enhance capacity-building.In this context, interaction with the SwissFederal Institute of Technology (EPFL) inSwitzerland and Manchester Universityin the UK looks most promising.”

3From leftto right,Dr SibusisoSibisi,Dr ThembelaHillie andProf KlausKern atthe <strong>CSIR</strong>President’sLectureIn his address at the launch of the<strong>CSIR</strong> Nanoforum, Hillie said, “Theknowledge-base we establish mustensure that society can reap the benefitsthrough the establishment of newproducts and processes. Our approach,as informed by national priorities, istwo-pronged; one component willaddress social priorities such as health,water and energy and the other willincorporate industry focusing on novelmaterials, and nanoscience beneficiationof minerals and processes, tomention a few. To this end, theNanoforum is in line with the <strong>CSIR</strong>mandate to foster industrial andscientific development with our partnersto contribute to the improvement of thequality of life of the people in SouthAfrica.”The <strong>CSIR</strong> nanotechnology initiative willbe guided by both the South African andthe <strong>CSIR</strong> internal baseline studies onnanotechnology, which will determinethe selection of appropriate projects forcapacity development in both humancapital and infrastructure. The Forumcomprises four subcommittees, focusingon project collaboration, locally andinternationally, including fund-raising;capacity development in human capitaland infrastructure; stakeholder andpublic debates to ensure a commonresponse; as well as development ofnetworks in the health, safety and environmentalarena. Hillie also acknowledgesthe Department of Science andTechnology for their support in bothinfrastructure development and humanresources capital.Hillie confirmed that Prof Klaus Kern,of the Max-Planck Institute for SolidState Research in Germany, has agreedto serve on the <strong>CSIR</strong> InternationalAdvisory Panel, a platform createdto advise the <strong>CSIR</strong> on its nanoinitiativesand assist with capacitybuilding.This panel will alsoorganise access to establishedinternational laboratories forpost-graduate programmes todevelop human capital. Invitedspeaker at the <strong>CSIR</strong> President’sLecture held in <strong>January</strong> <strong>2005</strong>, Kernaddressed the <strong>CSIR</strong> on the potentialimpact of nanotechnology onindustry and highlighted the latesttechnological advances andresearch efforts in nanometrescalescience and technology.Another guest speaker at the launchof the <strong>CSIR</strong> Nanoforum,Dr Solomzi Makohliso, founder andCEO of Ayanda Biosystems SA,based in Switzerland, has beenmandated through the Swiss StateSecretary of Science and Researchto develop a long-term strategy forthe Swiss government to engage inscientific and technologicalcollaboration with South Africa.Said Makohliso, “I believe thatnanoscience and nanotechnologyshould form one of the pillars ofsuch a strategy, given the commercialpotential of this field. However,the development of a sound nanoactivityin South Africa would requirea multi-disciplinary interactionbetween government, industry andacademia. In my opinion, the <strong>CSIR</strong>is the best-positioned institution tospearhead a nano-initiative in SouthAfrica, due to its well-establishedrelationships with the various keystakeholders.”Manfred Scriba, demonstratingthe synthesis of carbon nanotubesNanotechnologyin South AfricaMobilising a country into action around anew technology such as nanotechnologyis no easy task. Nanotechnology officiallytook off in South Africa in 2002 guided bythe Department of Science andTechnology (DST). Over the last two years,the South African Nanotechnology initiative(SANi) has built a network of scientistsand engineers who are interested oractive in nanotechnology R&D, and hasbeen responsible for general awareness,networking and the formulation of aSouth African nanotechnology strategyfor the DST. Nanotechnology relatedactivities are also being implementedthrough the Advanced ManufacturingTechnology Strategy.Manfred Scriba of the <strong>CSIR</strong>, elected asthe first chairman of the SANi, played asignificant role in motivating government,academia and industry to take action inthis arena. At the same time, he ensuredthat the <strong>CSIR</strong> remained involved with theestablishment of an interest group thatlaid the foundation for the establishmentof the <strong>CSIR</strong> Nanoforum. Scriba, who onthe technical level has built an AtomicForce Microscope demonstrator and,together with Dr Thembela Hillie, synthesisedcarbon nanotubes, has supportedand motivated many young (and old) scientiststo start and continue their work innanotechnology. Says Scriba, “I hope thatthe initial mobilisation efforts will inspireour young scientists to see nanotechnologyas an opportunity to make bigthings possible in future.”

4N A N O T E C H N O L O G Y – T H E N E W F R O N T I E R ?Nano-based DNA delivery systems forinsulin gene therapy in the pipelineGene therapy is used to replace defective or lost genes. Carrier molecules (vectors)are used to deliver the replacement genes into target cells. The mostcommonly used carriers are viruses that have been modified to carry thereplacement gene, and are non-disease causing. However, efforts areunder way to develop non-viral carriers. Nanotechnology can contributeto this effort. Medication will transport nanoparticles,which are coated in such a way that they only act at the sourceof the illness.The <strong>CSIR</strong> is working on developing a nano-system thatwould be used in insulin replacement for the treatmentof diabetes. Diabetes is a disease where patients areunable to control glucose levels in the blood due tothe inability of the pancreas to synthesise insulin.Current forms of treatment of diabetes includemultiple insulin injections. Patients normallymonitor their glucose levels by finger-prickingand using mechanical glucose sensors to test thelevel of glucose in the blood.“Through nanotechnology, we aim to develop acontrolled DNA-based insulin delivery systemthat can mimic the functions of pancreaticß cells. This system would therefore operatelike a biological artificial pancreas. It should beable to adequately sense the levels of bloodglucose, and secrete insulin in response to thischallenge,” says Dr Lungile Shoba, <strong>CSIR</strong> scientist.Shoba says that a DNA-based system is mostpreferred since it would enable regulated deliveryof insulin that would be acutely sensitive to the physiologicalchanges in glucose levels. A multi-disciplinaryapproach is used to develop a micro-system that woulddetect physiological glucose levels and then initiate aresponse that would result in the expression of a recombinantinsulin gene, as well as synthesis and secretion of insulin.This work involves collaboration between scientists at the <strong>CSIR</strong>,Wits University, the University of the Free State, and the MedicalResearch Council.Dr Lungile Shoba,working ondeveloping anano-systemthat would beused in insulinreplacementfor the treatmentof diabetesDNA-based drug delivery systems for insulin are not available yet. Only devicesthat contain the insulin protein are available, and those that contain a glucose sensorcoupled to insulin protein are still under development. Shoba explains, “A DNA-baseddelivery system would be ideal because it would be self-regulating and self-replenishing.This would prolong the lifespan of the delivery system, and therefore prevent frequent changes.Once developed, this system can be adapted to many diseases that require genetic-basedtherapy, such as sickle cell anaemia, cancers that result from defects or down-regulation oftumour-suppressor genes and cystic fibrosis.”Enquiries: Dr Lungile Shoba, <strong>CSIR</strong> Food, Biological and Chemical TechnologiesTel: +27 11 605 2632 Fax: +27 11 608 2540 Email: lshoba@csir.co.za

5New nanodrugcarrier to targetTB sufferersDr Hulda Swai, <strong>CSIR</strong> scientist working onthe TB nano drug delivery projectTuberculosis (TB) is gaining ground: in2001, the disease killed more peoplethan any previous year in history.Globally, there is a 3% increase in newTB cases each year, while in Africa, theincrease is 20% per year, largely due toco-infection with HIV/Aids. Every year,eight million people worldwide developactive TB and three million die from it,while more than 400 000 new cases ofmulti-drug resistant (MDR) TB are diagnosed.Although an effective therapeuticregimen is available, patient noncompliance(because of the need to takeanti-TB drugs daily or several times aweek for at least six months) results intreatment failure, while the emergenceof drug resistance can lead to MDR-TB.Not a single new class of TB drug hasbeen developed in over 40 years. Thatmeans that today’s TB patients, rich andpoor alike, are still treated with drugsdiscovered 60 years ago. Research anddevelopment of new TB drugs languishunder a perceived lack of need in thedeveloped world.The drawbacks of conventionalchemotherapy necessitate the developmentof a delivery or carrier system torelease drugs slowly over extendedperiods of time.The <strong>CSIR</strong>’s Centre for PolymerTechnology, in collaboration with theUniversity of South Africa, hopes tochange this situation through the use ofnanotechnology as a suitable means ofdelivering TB drugs. Dr Hulda Swai,<strong>CSIR</strong> scientist working on the TB nanodrugdelivery project, says, “Withnanotechnology we are closer than everbefore to reaching the long-awaitedgoal of precise delivery of a drug to aspecific compartment in the target cellthrough intracellular delivery.”Swai explains that the <strong>CSIR</strong> hasmanaged to nano-encapsulate ananti-TB drug (isoniazid (INH) - one ofthe most potent anti-TB drugs onthe market) in a biodegradablepolymer with particle size rangingfrom 186 to 290 nm, through thedouble emulsion solvent evaporationmethod. This is the required sizefor oral or pulmonary nano-drugdelivery. Says Swai, “We have alsomanaged to alter the method slightlyand have been able to makemicroparticles ranging from 700 nmto 500 µm. The nanoparticles aresubmicron-sized (less than 1 µm)polymeric colloidal particles with atherapeutic agent encapsulatedwithin their polymeric matrix, oradsorbed or conjugated onto thesurface. The release of the activeagent may be constant over a longperiod; it may be cyclical; or it maybe triggered by the environment oranother external event.”“The main objective of the <strong>CSIR</strong>study,” says Swai, “is to addresspatient non-compliance in TB controlprogrammes. The project seeks todevelop a system whereby anti-TBdrugs can be administered in areduced dose frequency, i.e. onceevery ten days, as opposed to thecurrent regimen of four antibioticstaken daily for six to nine months.By shortening the duration of thetreatment from six months to lessthan two months, patient compliancewill improve substantially. The newdelivery system will also ensureimproved bio-availability, e.g.700 mg of isoniazid can be administeredonce in ten days in five dosesaltogether, which is equivalent to300 mg of isoniazid taken daily forsix to nine months.”The slow release treatment willminimise MDR-TB (through improvedcompliance) and indeed hopefullycontribute meaningfully to totallyeliminating TB. This delivery processhas huge potential to be used inpharmaceuticals once optimised,not only in the case of TB, but alsomalaria and HIV treatment.Swai recently presented her work onthe preliminary results of the newdelivery system at the NanoMedConference in Berlin, Germany, whichwas very well received. Future plansinclude training <strong>CSIR</strong> scientists at theSwiss Federal Institute of Technology,the University of London’s School ofPharmacy and Harvard in differentencapsulation techniques. Swai isconfident that a prototype of thisnew delivery system will be ready forcommercialisation within the next twoto three years.Enquiries:Dr Hulda Shaidi Swai<strong>CSIR</strong> Manufacturing and MaterialsCentre for Polymer TechnologyTel: 27 12 841 2366Fax: 27 12 841 3553Email: hswai@csir.co.za

6In the textile industry, research anddevelopment efforts are aimed particularlyat integrating new functionalcharacteristics into textiles to generateadditional benefits and create acompetitive advantage. The applicationof nanotechnology will improve thecharacteristics and functions of fibres,finishes, dyes, colouration systems andtextile composites.The <strong>CSIR</strong>’s National Fibre, Textile andClothing Centre, heads up a numberof projects in this area including thefollowing:The South Africa / Hungary Scienceand Technology Programme:Research was undertaken under theSouth African / Hungarian Science andTechnology Cooperation Programmeinvolving the <strong>CSIR</strong> and the Bay ZoltánInstitute for Materials Science andTechnology. The project comprises thedevelopment of nanocomposites withß polypropylene matrices and surfacetreatment of bentonite for preparationof fibrous nanocomposites. There is anextensive collection of nanomaterials,however, the most promising applicationsat this stage reside with nanocomposites,i.e. composites reinforcedwith nanoparticles. The increase insurface-to-volume of nanoparticles hasan enormous effect on the properties ofN A N O T E C H N O L O G Y – T H E N E W F R O N T I E R ?Innovative textiles with nanotechnologyresultant composites. An applicationreceiving much attention is nanocompositeswith montmorillonitenano-clay particles. Montmorillonitebelongs to the family of 2:1 layeredsilicates. The products are moreapplicable in packaging andautomotive parts.Nanofibre-based non-wovenformation:With the improvement in electrospinningtechniques for spinningnanofibres from polymers, the fusionof different technologies can lead totremendous opportunities fordifferentiated products with dramaticimprovements in the end-use properties.The fusion of electrospinning andnon-woven technologies can provideavenues for designing new highperformancefilters for air filtrationwhere high environmental standardsare required to be met. The <strong>CSIR</strong> hasinvested in state-of-the-art non-woventechnologies and has initiated novelresearch ideas to develop nano-filters.Multi-functional natural fibre:This project aims to improve themulti-functionality of cotton, specificallyby imparting flame retardancy tothe cotton using various techniques.Nanofinishes can add additional functionalityto fabrics, by making them antistatic,fire-resistant, antimicrobial,temperature regulated, stain-, oil- andwaterproof and wrinkle resistant. Thevarious treatments protect each individualfibre through sophisticated molecularengineering on the nanometre scale withminimal impact on the feel and drape ofthe fabric.This technology will find application inmany industries, including the miningand medical field. Future research willbe directed in this area.Nanofibres have various applications andunique properties that contribute toproduct functionality by improving themechanical and chemical properties offibres. Properties of nanofibres include ahigh surface area, a small fibre diameter,good filtration properties, thin layers andhigh permeability.Valencia NyatiEnquiries:Valencia Nyati<strong>CSIR</strong> National Fibre,Clothing andTextile CentreTel: +27 41 508 3229Fax: +27 41 583 2325Email: vnyati@csir.co.zaUntreated cottonfabric (left) and sol-gel treated cottonfabric (right) beforethe flammability test.Application of theflame to the base ofthe fabrics.The untreated fabricbegins to burn.Afterglow is evident atthe base of the fabric.The sol-gel treatedfabric is charring withlittle afterglow.The untreated fabriccontinues to burn,flames spreading up thefabric, with afterglowcombustion starting toconsume the fabric atthe base. The sol-geltreated fabric charsalong the contact pointwith the burninguntreated fabric.The untreated fabric isburning, flames spreadingalong the entire length ofthe fabric, and afterglowcombustion is consumingthe fabric from the baseupwards. The sol-gelfabric chars along thecontact point with theburning untreated fabricwith no after-flame andlittle afterglow.

7Lighting the futureResearch into the unique propertiesand applications of quantum dotsand nano-phosphors is rapidlyincreasing internationally.In collaboration with the Universityof Zululand and the University of theFree State, the <strong>CSIR</strong> has undertakena research project on solid-statelighting (SSL) utilising quantum dotsand nano-phosphors to harnesstheir unique properties with aview to replacing conventionalincandescent lighting throughnanotechnology.The project will include fine-tuningthe optical properties of the quantumdots and other nano-phosphorsand their subsequent degradationunder electron and photon bombardment.Its objective will beutilisation of quantum dots andother nano-phosphors, pumpedeither electrically or by photons(UV light and laser), to producelow-energy consumption and highefficiencyillumination.This project will also involve synthesisand fine-tuning of biodegradablequantum dots which will have ahuge impact on medical diagnosis.The absorption of a quantum dot isinfluenced by the chemical environmentthat differs between a healthyand a pathological tissue. Thebiodegradable quantum dots cantherefore be fine-tuned (either bysize or surface chemistry) to be sensitiveto these changes.What are Nano-phosphorsPhosphors are wide bandgap semiconductor materials that areintentionally doped with impurities to emit the desired wavelength oflight.Quantum dots?Quantum dots are nano-scale crystalline semiconductor structureswith a size dependent bandgap that can be altered to change thecolour of light.What is solid-state lighting?Solid-state lighting (SSL) is the first truly new lighting technology toemerge for nearly 100 years. Lighting applications that use either asingle system (light emitting diodes (LEDs), organic light emittingdiodes (OLEDs)), or a hybrid system (LED with phosphors or quantumdots) are collectively referred to as SSL. Major benefits of SSLsystems include:• Long life - reduced maintenance cost• Reduced energy consumption - especially when coloured light isneeded• Better quality light output - minimum ultraviolet (UV) andinfrared (IR) radiation• Intrinsically safe - low voltage• Smaller flexible light fixtures - useful for lighting tight spaces• Durable - no filament to break.The development of hybrid solidstatelight sources will provide lowpower consumption, long lifetime,high efficiency and cool lightsources that could be utilised inboth households and in industry,especially the hot mining environment.SSL promises to replace conventionallight sources with impressiveeconomic and environmentalsavings. The low energy consumption,high-efficiency and long lifetimelighting sources will have ahuge impact on the quality of lifeof the under-privileged who do nothave access to power.Project leader, Dr Thembela Hillie,says that not only does the projecthave the potential to make animpressive long-term social impact,it also provides an opportunity foryoung scientists from previously disadvantagedcommunities to undergotraining and gain practical experiencein this field, thereby buildingcapacity in a new area of scientificresearch. Four PhD and three MScstudents are already involved in thisproject. Furthermore, ten MScstudents have been identified forsupport by the <strong>CSIR</strong> bursary schemein nanotechnology-related areas andsome of these students would laterbe incorporated into the project.SSL will increasingly be used in avariety of applications in the future.In time, SSL devices will provideinexpensive, environmentally friendlyillumination that will change theway we think about using artificiallight.Enquiries:Dr Thembela Hillie<strong>CSIR</strong> National MetrologyLaboratoryTel: +27 12 841 3874Fax: +27 12 841 2131Email: thillie@csir.co.za

8N A N O T E C H N O L O G Y – T H E N E W F R O N T I E R ?Biological unit of the rotary motor of ATP synthasefrom yeast mitochondrion. A number of differentsubunits (coloured differently)make up this complexenergy generatorKinesin, one of the proteinsresponsible for moving cargoalong tubules in the cellExploiting proteins to build molecular motorsThe study of proteins and theirchemistry has been a majorresearch focus over the last 60years. These magnificent moleculesprovide the functional scaffoldingthat make up all organisms, as wellas enabling complex chemicalreactions that can convertthousands of substrate moleculesper second (carbonic anhydrasecan convert 600 000 carbon dioxidemolecules per second).These enzymes are highly organised,forming efficient and somewhatstable protein complexes.Understanding the mechanisms ofinteractions and communicationnetworks amongst proteins andtheir structure requires tools, suchas x-ray crystallography and atomicforce microscopy that can "see"these nano- to micro-sized particles.Determining the stability of thecomplexes provides us with insightinto how these proteins are able tofold correctly and interact in acrowded environment such as thecell, as well as perform reactionsthat are not possible or aremediocre at best in a chemistrylaboratory.Dr Neeresh Rohitlall, <strong>CSIR</strong>researcher, says that his researchgroup will be exploiting these proteincharacteristics to buildnanomotors. “Imagine using light toactivate molecules that can kill cancercells, or even help break upclots in blood vessels in the brain?Such technology would greatlyenhance medical science. Whatabout a molecular dispenser thatdispenses medication directly intothe blood stream in TB, HIV anddiabetic patients? If that’s notfascinating, try space applicationsin controlling unmanned vessels,satellites and telecommunicationsapplications,” he says.Nanotechnologists are increasinglyappreciating the potential of biologicalmolecules and systems such asnanodevices. To function, any devicerequires energy, and for many biologicalsystems this is in the formof adenosine triphosphate (ATP)generated from ATP synthase.The use of ATP to drive a biologicalmotor enables the design of acont-rollable "molecular switch"that is able to move to a desiredlocation, thus activating the necessaryresponse. Such a nano-steppingmotor is a promising tool foruse as a building block for nanodevicesand for drug delivery.The aim of the <strong>CSIR</strong>’s molecularmotor project is to engineer a lightactivatedcontrollable power sourcethat can be coupled to a variety ofnanodevices. Says Rohitlall, “Theproposed nanoscopic energy sourceis probably the smallest and mostefficient known energy source.It is the only such power supply tointroduce on/off controllability asfundamental to its design. Thenanodevice can be developed forspecific applications such as drugdelivery, nano-engineering orminimally invasive nano-surgery,particularly for delicate tissuessuch as the retina.”Dr Neeresh RohitlallEnquiries:Dr Neeresh Rohitlall<strong>CSIR</strong> Food, Biologicaland Chemical TechnologiesTel: +27 11 605 2294Fax: +27 11 608 3020Email: nrohitlall@csir.co.za

9SOLAR CELLSA SOLUTION TO THE ENERGY CRISIS?As our fuel sources become depleted,we will increasingly turn toalternative sources of energy, particularlysolar energy, since it isclean, abundant and renewable.However, the cost, performanceand convenience of the currentsystems will have to be improved ifsolar energy is to be successfullyintegrated into our homes and businesses.One such novel system is the use ofdye-sensitised solar cells (DSC), inconjunction with several new concepts,such as nanotechnology andmolecular devices. An efficient andlow-cost cell can be produced byusing simple materials. The processgenerates very small quantities ofresidue, resulting in environmentallyfriendly devices with low energydemandingproduction techniques.Furthermore, recentdevelopments inthe area ofsensitisersfor thesedeviceshave led to the production of dyesthat absorb across the visible spectrumleading to higher efficienciesthat hold great potential.The <strong>CSIR</strong> is working toward DSCniche applications, which includealternative energy devices to beused in cell phone chargers, laptopsand radio batteries. Lukas le Roux,<strong>CSIR</strong> researcher, mentions that thesolar cells produced at the <strong>CSIR</strong>have successfully driven a miniaturewindmill and a kitchen clock. Theresults look promising and furtherdevelopments are in the pipeline.Le Roux explains that the dyesensitisedsolar cell is composedof two surfaces of transparentconductor (mostly a conductingoxide on glass), onto which a fewmicrons of thick film of bandgapsemiconductor is deposited in theform of a self-connected network of3 nm-sized particles, with a networkof similarly or large sized self-connectedpores between the particles.Energy conversion in a DSC is basedon the injection of an electron froma photo-excited state of the sensitiserdye into the conduction band ofthe nanocrystalline semiconductor(TiO2 is by far the most employedoxide semiconductor). These cellsalso employ a liquid electrolyte(usually an iodide/triiodide redoxactivecouple dissolved in an organicsolvent) to reduce the dye cation,i.e to regenerate the ground stateof the dye.Enquiries: Lukas le Roux<strong>CSIR</strong> Manufacturing andMaterials TechnologyTel:+27 12 841 4946Fax: +27 12 841 4395Email: lleroux@csir.co.zaLukas le Roux(right) andDr AndreGermishuizen(left) picturedwith the successfullyproducedsolar cells

10N A N O T E C H N O L O G Y – T H E N E W F R O N T I E R ?CARBON NANOTUBES:SUPER-STRONG MATERIAL OF THE FUTURECarbon nanotubes are the world’sstrongest material in terms of tensilestrength, yet they are lightweight and flexible.Consequently, they could be usefulas ultralight structural material for wingsof advanced aircraft and space probes thatare stronger and more energy efficient.Therefore, there is an intense interest infinding ways to produce nanotubes inlarge quantities.At the <strong>CSIR</strong> National Laser Centre (NLC)single-walled carbon nanotubes (SWCNTs)are being synthesised by laser ablation.The purpose of the work undertaken is tounderstand and optimise the growthprocess of carbon nanotubes so that theirincredible properties could be applied to amultitude of high-volume applications.Laser ablation is used to control thelength, structure and electrical propertiesof carbon nanotubes.A carbon nanotube is a single layer ofgraphene sheet rolled to form a cylinderrolled into a tube a few nanometres indiameter and up to hundreds of micronslong. This material conducts electricityand heat amazingly well and possessesremarkable physical and electronicproperties, therefore it canbe used in applications suchas nanosized electronicAndisiwePoswayo,who isinvolved inproducingmulti-walledcarbonnanotubesat the <strong>CSIR</strong>devices in computers, gas storage, fieldemission tips for displays, electrical andgas sensors, batteries for semiconductorchip etching and flat-screen televisions.Carbon nanotubes could also storehydrogen gas to power fuel cells.“However, the problem exists in massproducing nanotubes reliably,” saysMathew Moodley, <strong>CSIR</strong> researcher. “Theexact mechanism of how the nanotubesform has not been resolved and accountsfor large research effort in this area ofnanotechnology in order to manufacturethe material on an industrial scale.”Moodley explains that the <strong>CSIR</strong> useslasers to undertake spectroscopic studiesof the growth mechanisms of carbonnanotubes. Pulsed lasers in the visibleand infrared field are being used tovaporise a graphite composite target in atube furnace at temperatures in theregion of 800 0 C to 1 200 0 C. The vaporisedcarbon atoms then recombine with theaid of argon gas and metal catalysts toform nanotubes. Transmission electronmicroscopy images of the product revealthe nanotubes, which resemble spaghetti.Raman spectroscopymeasurements on theproduct can also beused to differentiatebetween single-walledtubes or multi-walledtubes as well as establishthe purity of theproduct formed in thelaser ablation process.The aim of the study isto learn about the laserablation and re-combinationprocesses as wellMathew Moodley from the <strong>CSIR</strong>National Laser Centre demonstratesthe synthesis of single-walled carbonnanotubes through laser ablationas how the laser can be used to controlthe growth and physical properties of thenano-tubes. This knowledge will then beused to upscale theproduction of carbon nanotubes.Andisiwe Poswayo, <strong>CSIR</strong> researcher, isinvolved in producing multi-walled carbonnanotubes (MWCN) by means of the arcdischargemethod. Says Poswayo,“MWCNs are produced in a matrix of carbonaceousmaterial. We are currentlyworking on finding an effective method toextract them from this matrix. The nanotubeswill be used in dye solar cells andnanocomposites.”Enquiries:Mathew MoodleyDr Thembela Hillie<strong>CSIR</strong> National Laser Centre <strong>CSIR</strong> National Metrology LaboratoryTel: +27 12 841 3759 Tel: +27 12 841 3874Fax: +27 12 841 3152 fax: +27 12 841 2131Email: mmoodley@csir.co.za Email: thillie@csir.co.za

11Measurement technologiesto support nanoscienceSam Thema, <strong>CSIR</strong> dimensional metrologistThe challenge for metrologists in the future isto devise measurement techniques that willkeep abreast of developments in nanotechnology.These will ensure reliable comparablereference measurements with results traceableto an agreed metrology scale helping toensure products that are interchangeable.Measurements of line standards, step heightstandards and grid standards are the threestandards required to calibrate dimensionalmeasuring equipment in the nano-field. Linestandards (diffraction gratings) using laserdiffraction, have already been completed atthe the <strong>CSIR</strong>’s National Metrology Laboratory(NML). A comparison with METAS inSwitzerland on a 2 400 lines/mm (400 nm)grating has resulted in agreement to ±0.2 nm.However, refining is still required to furtherreduce the uncertainties of measurement.Measurement and testing in nanotechnologyis investment-intensive, requiring highlyskilled people and specialised equipment.Martin van Staden of the <strong>CSIR</strong> NML saysthat the NML has actively developed highprecisionmeasurement techniques(nanometrology) and commissioned acomprehensive suite of analytical tools, suchas a high-resolution scanning electron microscope,scanning electron spectroscopy forchemical analysis microprobe, a scanningauger electron microprobe, x-ray diffractionand glow discharge optical emission spectroscopy.The acquisition of an atomic forcemicroscope (AFM), which produces atomicresolution images and measurement of nanoparticles and surfaces, is also on the cardsin the near future. A time-of-flight secondaryion mass spectrometer is also envisaged forqualitative and quantitative analysis ofnanometre size particles and ultra-thincoatings.<strong>CSIR</strong> metrologist, Sam Thema, commentsthat the acquisition of an AFM will ideallycomplement the suite of instrumentation atthe organisation. “We incorporate He-Nelasers in all three axes (x, y, z) of the AFM,”he says, “such that the metrology istraceable back to the national standardfor length.”“AFMs probe a surface with a very fine tip,”explains Thema. “The coordinates recordedin this way make it possible to gain a threedimensionalimage of a surface. The highestresolution obtained makes it possible to ‘see’individual atoms. The AFM works by scanninga sharp tip over a material’s surfacemuch the same way as a phonograph needlescans a record. It can work in contact mode,i.e. the tip scanning the surface; non-contactmode or tip-tapping across the surface. It isa versatile instrument able to work in air,liquid and vacuum conditions.”Proper measurement and testing areessential to ensure that sectors such asbiomolecular technology, aerospace, telecommunications,chemical engineering,electronics, the automotive industry, etc,develop to their full potential to participatesuccessfully in local and international markets.XPS analysischamberwith samplefor thin filmsurfaceanalysisEnquiries:Martin van StadenSam Thema<strong>CSIR</strong> National MetrologyLaboratoryTel: +27 12 841 3366Tel: +27 12 841 4798Email: mvanstaden@csir.co.zaEmail: sthema@csir.co.za

12N A N O T E C H N O L O G Y – T H E N E W F R O N T I E R ?Gold micro-electrodearray on anSi/Sio wafer afterimmunodetectionof DNA fragments.Only the bottomset of electrodesare coated with DNADr AndreGermishuizen,<strong>CSIR</strong> researcher,is optimistic asto the potentialof biosensorresearch at theorganisationUsingnature’sbuilding blocksto benefitmankindNature provides us with very usefulbuilding blocks for the construction ofbiotechnological and nanotechnologicaldevices. In particular, the selfassemblyproperties of these buildingblocks enable us to build devices fromthe bottom up with very precise controlover the function and geometry ofthe device. One example of such adevice is a biosensor.A biosensor is an analytical devicethat combines a biological element,such as a cell, DNA or a protein and aphysical element, converting a biologicalresponse into an electrical signalto detect the presence of analytes.Because the analytes bind specificallyto the biological element, very lowconcentrations can be determined.Optical and electrical techniques canbe used to amplify the signal, to getan idea of the concentration of theanalyte.These devices can be used in a widerange of applications such as:• medicine: (e.g. detecting bacteriaand viruses such as TB and HIV, etc)• environmental monitoring: (e.g.detecting pollutants such asmercury)• defence: (e.g.detecting bio-terroragents such as anthrax)• drug development: (e.g. researchinto binding of DNA and proteins).A number of analytical techniques,including atomic force microscopy(AFM), which will soon be available atthe <strong>CSIR</strong>, can be used to study theassembly of molecules in the biosensordevice. The AFM will enable adirect observation of the density ofbiological molecules on the substratesurface and their orientation, and willfacilitate the study of their activitytowards the analyte molecules.Biosensors represent a rapidlyexpanding field, with an estimated60% annual growth rate; the majorimpetus coming from the health-careindustry. For example, 6% of theWestern world is diabetic and wouldbenefit from the availability of arapid, accurate and simple biosensorfor glucose.“Currently very little research is donein this field in South Africa,” says DrAndre Germishuizen, researcher atthe <strong>CSIR</strong>, “despite the fact that wecan benefit greatly from suchdevices, especially in terms of healthand environment. The knowledge andexperience I gained at the Universityof Cambridge in the UK have enabledme to contribute to such multidisciplinaryresearch at the <strong>CSIR</strong>. Otherpossible applications of this technologyavailable at the <strong>CSIR</strong> involvetissue engineering scaffolds, capableof controlled release of growthhormones, and drug release systems.”Enquiries: Dr Andre Germishuizen<strong>CSIR</strong> Manufacturing and MaterialsTechnologyTel: + 27 12 841 3756Fax: +27 12 841 3553Email: agermishuizen@csir.co.za

13CHARACTERISINGDIETARY FIBREWITH NANOTECHNOLOGYDietary fibre consists of a variety of cellwall polysaccharides, which play animportant role in nutrition; they havebeen cited for their role in improvingcolonic disorders and Type II diabetes.They are also one of the most commonlyused biopolymers in food products.The application of nanotechnology canlead to advances in the understanding ofthe functionality of these polysaccharides.Its application in the food industryhas led to a totally new understanding ofthe functional properties of food biopolymers.Food scientists can now characterisethe molecular size, shape andnature of intermolecular interactionsresponsible for the use of these polymerssuch as gelling, thickening andstabilising agents in the food industry.The <strong>CSIR</strong> has undertaken a project tocharacterise and determine the molecularstructure of various fruit and cerealdietary fibre at the molecular level usingnanotechnology. One of the aspects to beinvestigated is the water-binding capacityof dietary fibres, which is considered animportant marker used by health-careindustries and research organisations toscreen proposed fibre-based products.It also plays a significant role in thedetermination of the intrinsic commercialvalue of the dietary fibres. AndréMunian, <strong>CSIR</strong> researcher, explains thatthe maximum amount of water that fibremay hold is a function of the structure,composition, source (fruit, cerealand cellulosic) and the preparativeprocesses, which can affect the ability ofthe fibre to entrap water within its fibrematrix.“A complete understanding of the relationshipbetween structure and functionis required,” says Munian, “and nanotechnologycould be used to provide this.This research will help improve the application ofvarious cereal and fruit dietary fibre in a widerange of products throughout the food industry.”Munian cites investigations by Round et al (1997)on tomato cell wall polysaccharides, which concludethat nanotechnology can be used todetect certain types and characteristics ofpolysaccharides, which are not possibleby conventional chemical or enzymaticmethods. It is therefore a useful toolin providing qualitative informationon molecular size of thepolysaccharide structure.In addition, nanotechnologycan be used to measure themechanical properties andintermolecular interactionsof polysaccharides, toidentify the bindingsites of polysaccharidesand the strength ofthese binding sites tovarious surfaces underdifferent environmentalconditions.It may also be used toexplain the effect ofvarious processing effectson the solubility andthixotropy of various types ofpolysaccharides and can beused to determine the hydrationand dehydration characteristics ofpolysaccharides. It is this applicationthat will be used to determinethe water-binding capacity of cell wallpolysaccharides of dietary fibres.Enquiries: André Munian<strong>CSIR</strong> Food, Biological and ChemicalTechnologiesTel: +27 21 689 9341Fax: +27 21 686 6116Email: amunian@csir.co.zaEmail: jbarnett@csir.co.zaAndré Munian

14N A N O T E C H N O L O G Y – T H E N E W F R O N T I E R ?TOWARDS DEVELOPING THESYNTHETICFORESTSOF THE FUTUREPlant cells possess built-in capabilitiesthat can help us address future importanttechnological and economic shortcomingsfaced by our society. Theseinclude energy storage and processingas well as materials synthesis, whichare captured in a plant through theprocess of photosynthesis and mitochondrialrespiration respectively.In order to remain competitive globally,the South African forest products industryneeds to meet increasing challengessuch as reduced access to fibre due todecreasing forest resources; stricterenvironmental regulation; energy costs;international trade barriers andincreasing international competition forlow-cost producers.Developing local nanotechnologicalexpertise in South Africa would add furthervalue to the manufacture of woodand wood-composites, pulp, paper andcellulose derivatives of high relevance tothe textile industry such as acetate,rayon and viscose. The new nanotech-nology capabilities developed could notonly meet the challenges mentioned, butalso reduce energy consumption.James Wesley-Smith, <strong>CSIR</strong> researcher,says, “It is conceivable that the processof cell wall formation can be used as atemplate to engineer mimicking devicesallowing the manufacture of cellulosefibres and composites outside the cell,using cellulose synthase proteins asbuilding blocks. The <strong>CSIR</strong>’s ultimate goalwould be to engineer an ‘artificial cell’capable of engaging simultaneously inphotosynthesis and cellulose synthesis,in other words, develop a synthetic forest.”Wesley-Smith cites that the potentialbenefits from nanotechnology includeincreased rate of fibre production; reduceddependence on harvesting; eliminationof the lignin removal process for pulps;molecular scale control of compositematerial production; engineering of newmaterial properties to add value to products;lower energy consumption and environmentallyfriendly production processes.While many biological processes withinplant cells are well documented andunderstood, there are many areas ofphotosynthesis and cellulose synthasebiochemistry that need to be understoodfurther before they can be modelled andreplicated outside the cell. For example,the structure, function and regulation ofcellulose synthase, and the process ofassembling cellulose molecules into cellwall composite material would have tobe researched. Understanding how noncellulosicmaterials are incorporated intocellulose fibrils, and the role these play inconferring strength, resistance to decayand insulation are also other aspects tobe addressed. And then there is the bigquestion: can the practical efficiency ofphotosynthesis be improved by newdevices?Enquiries:James Wesley-Smith<strong>CSIR</strong> Water, Environment and ForestryTechnologyTel: +27 31 242 2316Fax: +27 31 261 1216Email: jwesleysmith@csir.co.za

15Wonder crop could pave the wayfor bio-fuel revolution“The price of petrol and dieselis going up!” This has become afamiliar announcement on theevening news. High oil prices dueto increased demand, tougherenvironmental requirements,uncertainties linked to terrorismand instability in the Middle Eastare some of the pressures thatare influencing the quest for alternative,cleaner forms of energy.Some would say that the bio-fuelrevolution has begun.Farming for energy is one avenuethat is being actively explored. Whileoffering a potential solution to theagricultural sector’s quest for ruralemployment and poverty alleviation,it could also fulfil the need forincreased use of renewable energyresources.In response to these trends, recentbusiness initiatives have proposedthe introduction of so-called “wonder-crop”exotic species for largescaleplanting and bio-diesel productionin South Africa. The motivesbehind these initiatives have beenthe laudable themes of ecologicalsustainability, poverty alleviation, jobcreation and business development.However, questions around thepotential hydrological, ecologicaland socio-economic effects of theassociated land-use changes remainunanswered due to a lack of information.The Land Use Hydrology group ofthe <strong>CSIR</strong> in Pietermaritzburg formspart of a team tasked by the WaterResearch Commission to conduct astudy into some of the impactsassociated with the large-scaleplanting of Jatropha curcas. The<strong>CSIR</strong>’s task is to conduct hydrologicalprocess studies of Jatrophawater use at selected sites inKwaZulu-Natal, using appropriatetechniques (site water balance andevapotranspiration measurements).This is to be followed by a modellingexercise wherein site-specific simulationsof water use will be verifiedagainst the measured data andextrapolated to a larger scale.Mark Gush, research scientist workingon this project, explains thatJatropha curcas was identified as anideal species to use for this studybecause it has been widely acceptedto be suitable for the production ofbio-diesel and secondary products.The prime ingredient in the manufactureof bio-diesel is vegetable oil(e.g. sunflower, soya or peanut oil),however, these oils are edible andgenerally fetch high prices, whichpreclude them from being used inbio-diesel production. Researchindicated that Jatropha curcasmerited serious consideration as aviable alternative.This small tree (of Central Americanorigin) is from the Euphorbiaceaefamily, and produces seeds containinghigh percentages (30-35%) of oil,which can be extracted easily forfurther processing (trans-esterificationinto bio-diesel) and refinement.The processed oil can then be usedin compression-ignition (diesel)engines after minor modifications.It can also be blended with conventionaldiesel to avoid the needfor engine modification. Theby-products of the bio-dieselprocessing plant are the nitrogenrichpress cake and glycerol, whichhave good commercial value asfertiliser and as a base for soap andcosmetics respectively. The leaves,roots and bark could also havepotential for numerous other industrialand pharmaceutical uses.Jatropha curcas grows readily inareas of low rainfall (less than250 mm per year) and in poor soils,allowing the potential use of lowfertility, marginal, degraded andotherwise unproductive lands. Thetrees are easy to establish (fromseeds or cuttings), grow relativelyquickly (producing seed after theirsecond year) and are hardy todrought, although they are relativelysensitive to frost.“The interest in this species hasheightened to a stage where therelevant national governmentdepartments (Agriculture, WaterAffairs and Forestry, EnvironmentalAffairs etc.) need to make a decisionas to whether or not to allow thelarge-scale propagation and commercialisationof this crop,” saysGush. “This project aims to contributeto the StrategicEnvironmental Assessment (SEA)proposed by the Department ofAgriculture to investigate the feasibility,viability and advisability of thewide-scale introduction of Jatrophacurcas to the KwaZulu-Natalprovince and South Africa as awhole.”Enquiries: Mark Gush<strong>CSIR</strong> Water, Environment andForestry TechnologyTel: +27 33 260 5783Fax: +27 33 260 5266Email: mgush@csir.co.za

16ENZYMES PUT TO WORK IN THE PRODUCTION OFPECTIN FROM CITRUS WASTELIFElab ECoBio awards funding to improve competitiveness ofSouth African citrus producers through waste beneficiation.Biochemists at the <strong>CSIR</strong> are joining forces with the University of Durban-Westville, the Chemin incubator and Kat River Citrus Co-op Ltd to set upa pectin production plant that uses enzymes in the production of pectinsfrom citrus waste.LIFElab ECoBio is one of three Biotechnology Regional InnovationCentres (BRICS) set up in 2002 by the Department ofScience and Technology under the auspices of itsNational Biotechnology Strategy. LIFElab’smandate is to stimulate and promote thecreation of a vibrant biotechnologyeconomy in the East Coast region,stretching from Nelspruit in theNorth, to Durban in the centreand onwards to PortElizabeth in the South.The South African citrusindustry is one of thebiggest exporters inthe world and produceslarge volumesof waste in the formof citrus peel. Pectinis a polysaccharidefound abundantly inthe primary wallsand the intercellularlayers of plant cellsand is obtained froma variety of sourcesincluding many fruitpulps, for example inorange and apple pulp.In citrus fruit, pectin is aconstituent of the whitespongy inner part of thepeel. Traditionally, pectin isproduced by chemical hydrolysis,with significant yield lossesand the production of substantialwaste streams.Fanie Marais, Manager of Fine and SpecialityChemicals at the <strong>CSIR</strong>, says the extraction ofcrude high-methoxyl (HM) pectin from citrus peel is asimple downstream process that does not need specialisedchemicals or equipment. However, the first focus of this three-yearproject is to adapt the current HM pectin extraction process to enableSMMEs to operate the extraction facilities. The second focus, whichrepresents a significant opportunity for long-term sustainability, is toconvert HM pectin to value-added low-methoxyl(LM) pectin, using an enzyme-based process.“Recent years have seen strong growth in the LMpectin market. LM pectins are used as thickeningor gelling agents in a broad range of formulatedfoods such as yoghurt, milk desserts and jellies.Increasingly, pectin production facilities are beingmoved closer to citrus-producing areas to eliminatethe transport of dried citrus waste over longdistances and the resulting loss in yield andquality,” he says.These developments and a commitment to utilisebiotechnologies in South Africa’s bid to increaseits competitiveness, led to a decision by LIFElabECoBio to invest in research using the enzyme,called pectin esterase, to modify HM pectin intoLM pectin.Marais says the prototype development on theextraction of HM Pectin is well-advanced as aresult of earlier research. During the first phasesof the project, the focus will be on establishingsmall HM extraction plants that would be simpleto operate and be located in rural communitiesclose to orange juice producers. The aim is toproduce a range of stable, commercial quality HMpectins. At the same time, researchers at the <strong>CSIR</strong>will focus on the development of an enzyme-basedprocess for the conversion of the HM pectin intohigher value LM pectin.The University of Durban-Westville will developdrying technology to ensure pectin production inthe off-season; Chemin will provide the businessincubation for a proposed spin-off company; whileKat River Co-op will provide the materials andfacilities for the first extraction facility. <strong>CSIR</strong> Food,Biological and Chemical Technologies will utiliseits skills in process chemistry, biotechnology,chemical engineering and food science to developthe technology required for the extraction, hydrolysis,purification and formulation.Enquiries: Michael Barkhuysen<strong>CSIR</strong> Food, Biological andChemical TechnologiesTel: +27 11 605 2330E-Mail: mbarkhuysen@csir.co.za

Celebrating100 yearsof safe minehoistingIn the face of growing health andsafety challenges, stringent governmentregulations and rapid transformation,the local mining industry hasone success record that it can lookback on with pride. Last year marked100 years of hoist rope testing inSouth Africa, which was celebrated ata centenary event held at theCottesloe testing facility of <strong>CSIR</strong>Mining Technology in November 2004.Vishnu Pillay, Director of <strong>CSIR</strong> MiningTechnology, explains that as depthsincrease, along with the demand forbigger and heavier payloads, ropetesting is an increasingly importantpart of mine safety. The <strong>CSIR</strong> currentlyruns one of only two hoist-ropetesting facilities approved by theDepartment of Minerals and Energy(DME) in South Africa, at its Cottesloelaboratory in Johannesburg.“The records of the DME show morethan 1 000 registered mines in SouthAfrica, of which an estimated 135 areunderground operations,” says Pillay.“The <strong>CSIR</strong>’s own rope databasereflects more than 1 150 hoist ropesin use, illustrating the responsibilitythat rests with our laboratory toprovide mine engineers with accuratetest data and results.”The statutory testing of mine hoistropes was introduced following thefailure of a winding rope in No. 2Shaft, Robinson Deep, on 25 April1904. This accident caused the deathof over 40 men and led to the immediateintroduction of a government regulationthat stipulated the periodicremoval of a section of head ropeadjacent to the skip, to be tested atthe Government MechanicalLaboratory of the Department ofMines.The Department of Mines relinquishedcontrol over the GovernmentMechanical Laboratory in 1964, whenit was taken over by the <strong>CSIR</strong> andincorporated into its NationalMechanical Engineering ResearchInstitute. This laboratory now formspart of <strong>CSIR</strong> Mining Technology andcontinues to conduct statutory testson mine hoist ropes and providerelated mechanical testing services.The largest tensile test machine inuse at Cottesloe is a 15 MN MFLmachine that was commissioned in1989. In addition to the testing ofmine hoist ropes, the MFL machine isable to accommodate large diameterwire ropes (~160 mm) as used in theoil drilling, bridge and shippingindustries. The capacity of the 15 MNmachine also caters for tensile testson conveyor belts up to 1.2 m wideand large-link chains, such as thoseused on coal mine draglines.The hoist rope tests evaluate a rope’sabsolute breaking force, mechanicalproperties, modes of wire and strandfailure, extent of corrosive and abrasivedamage, and the state of lubrication.If the results of the test showthat the rope does not conform to thecode of practice (SABS 0293, 1996),then the recommendation is that therope be discarded. The majority ofropes, however, only reach thiscondition following several yearsof service. The results of the test,a graphical history thereof and subsequentvisual examination of thetest specimen, are recorded on atest certificate supplied to the mine.In addition to the testing of minehoist ropes, the <strong>CSIR</strong> offers a rangeof other mechanical tests includingtensile, proof and compression testsof a broad range of mining andindustrial products.Enquiries:Andrew Peake<strong>CSIR</strong> Mining TechnologyTel: +27 11 853 4550Email: miningtek@csir.co.zaHoist rope fact fileSouth African mines hoist about280 000 people up and down mineshafts each day.The same mines hoist about10 million tons of ore every month.An eight-compartment 2 000 m deepshaft contains more than 16 km ofhoist rope.In the deepest shaft each hoist ropeis more than 3 000 m long.DME regulations stipulate that ropesinstalled on licensed winders mustbe tested every six months.Canada has adopted certain SouthAfrican standards relating to ropediscard criteria.<strong>CSIR</strong>’s hoisting and mechanicaltesting laboratory tests between2 000 and 3 000 ropes every year,including hoist ropes, scraper ropes,dragline ropes and ropes for marineapplications.The biggest specimen the centre hasever tested is a 153 mm diametersteel wire rope, which was locallymanufactured, and was to be usedas one element of a sling for anengineering application.The biggest steel wire rope usedfor mine hoisting in South Africa is63 mm in diameter, and weighs17 kg per metre. At a depth of morethan 2 000 m, the weight of this ropealone – without any skip or cageattached – is some 34 tons.Although mines sometimes experiencewinding accidents, they arerarely due to rope failure. Ropetesting allows mines to predict andprevent such failure. Testing alsokeeps costs down, as it helps minesto avoid premature replacement ofexpensive steel wire rope.The <strong>CSIR</strong> maintains the largestdatabase of rope tests in Africa,to ensure the traceability of allspecimens tested.17

18Logistics costs for South African represent 14.7% ofour GDP or R180 billion, compared to 8.5% in the USA.FirstannualState ofLogisticsSurvey forSouthAfricaThe first survey to measure intrinsiclogistics costs for the South Africaneconomy was released by the <strong>CSIR</strong> in<strong>January</strong> <strong>2005</strong>. Sponsored by the <strong>CSIR</strong>Centre for Logistics and DecisionSupport (CLDS) and Spoornet, thesurvey is the first of a planned annualinitiative to evolve a comprehensivepicture of the state of logistics in SouthAfrica. The University of Stellenboschcontributed to the research on whichthe survey is based.According to Hans Ittmann, CLDSManager, the survey incorporates amacro-economic viewpoint (top-down),an industry-level perspective (bottomup),and a small business developmentperspective, dealing with logistics as adevelopmental constraint for SMMEsand isolated rural environments.“The inability to measure logistics costson a regular basis hampers a continuousmacro understanding of the state oflogistics in South Africa, and also rendersit impossible to gauge the impactof various public and private sector initiativesto reduce South Africa’s logisticscost,” says Ittmann. “As SouthAfrica grapples with new investmentrequirements in rail, highway, ports andother logistics infrastructure, policymakersare experiencing an everincreasingshortage of useful measurementtools to guide decision-makingand measure performance. The State ofLogistics Survey intends to fill this voidspecifically,” Ittmann explains.Some of South Africa’s core structuralproblems are highlighted by the survey:• Logistics costs represent aconsiderable percentage of theGDP (14.7% or R180 bn, comparedto 8.5% in the USA).• The “normal” macro economicmodel is to transport long-distancecorridor freight by rail, with feederand distribution services providedby road. In South Africa, however,structural myopia has caused anunhealthy situation, with threequartersof long-haul tonnage byroad.• Our dense long-haul road corridorsare intrinsically more expensivethan a possible intermodal solution.A number of actions are identified ascritical in addressing the current problems,including assigning nationalaccountability and responsibility for supplychain, investment and maintenancepolicy and strategies; continuous andvisible measurement of South Africa’smacro-economic state of transport andlogistics; investing in multimodality; andsupport and logistics access to SMMEsand smaller industries.According to Ittmann, these actions willfacilitate a structural change based onan efficient intermodal solution, solvingSouth Africa’s long-term freight corridordilemma. In addition, this will make sufficientgovernment funds available tobalance the issue of national logisticscompetitiveness with addressing currentand future metropolitan congestion, aswell as SMME and rural development.“The <strong>CSIR</strong> and our research partners arekeen to see this survey becoming anannual institution in South Africa. We arealso actively encouraging the participationof other role-players, especially inareas such as information-sharing andresearch support,” says Ittmann. “It willassist the country to develop strategicallyrelevant policies and make strategicinfrastructure investment and maintenancedecisions, which in turn will facilitatesustainable industry and small businessdevelopment. Time series data willalso enable us to measure the successof these interventions over time.”Enquiries:Hans Ittmann<strong>CSIR</strong> Centre for Logistics and DecisionSupportTel: +27 12 841 3051Fax: +27 12 841 4720Email: hittmann@csir.co.za

19NPDC designsprominentawardThe <strong>CSIR</strong>’s National Product Development Centre(NPDC) designers, Gold Mametja and Bernard Smith,are the creative brains behind the design of theprestigious Philip Tobias Lecture Award.The NPDC was contracted by the Department ofScience and Technology (DST) to design and developthe award, following the department’s decision toestablish the annual Prof Philip Tobias Lecture, whereprominent professionals and government representativesfrom all over the world will be invited to bekeynote speakers. The establishment of this lecturesubsequently led to the development of an awarddesigned in Prof Tobias’s honour, for the researchcontributions he made in the fields of gene-tics,anatomical studies and palaeontology. Prof SydneyBrenner, the esteemed 2002 Nobel Prize Winner inMedicine, delivered the inaugural lecture at GallagherEstate as part of the recently held INSITE exhibition.Brenner himself is a South African-born scientist withimpeccable achievements in genetics and molecularbiology.The original design concept of this particular award isbased within the shape of a complete circle, creating asense of purity and continuity. It contains three mainelements that represent the life and work of one ofSouth Africa's most famous and world-renownedscientists. The flint stands for Philip Tobias, the person.The central core depicts the focus of his work andthe outer ring is the time line of evolution.Gold Mametja, through the NPDC, previously completedthe design and development of two of the threenew National Orders for the State President as well asthe technical work for the production of the thirdorder. The DST commissioned Mametja, together withBernard Smith, to design two gifts for the presidentialvisit to Haiti in December 2003. Early in 2004, Mametjawas also contracted by the Independent ElectoralCommission to design the IEC Awards that were presentedto the commissioners and staff who served inthis capacity during the first 10 years of South Africa'sdemocracy.Enquiries: Gold Mametja<strong>CSIR</strong> National Product Development CentreTel: +27 12 841 3773Fax: +27 12 841 3378Email: gmametja@csir.co.za

20BUILDINGQUALITYINDEXFOR HOUSESIn a project commissioned by the National Home Builders RegistrationCouncil (NHBRC), <strong>CSIR</strong> Building and Construction Technology has developedthe building quality index for houses (BQIH), a comprehensive appraisalsystem to measure quality standards of houses in South Africa. A paper byJ Mahachi (NHBRC), AM Goliger (<strong>CSIR</strong>) and F Wagenaar (NHBRC) highlightsthe role of the NHBRC in the development of the BQIH, and the relevance ofrisk management and performance-based codification. It also summarisesthe typical structural problems that occur in South African housing, presentsselected statistics of damage and their socio-economical implications andconsiders ways of improving the situation nationally.A large pool of technical and legislative information on good house constructionpractices is available in South Africa. Despite this, a lack of adherence toquality standards is evident throughout the entire spectrum of housing (i.e.low to high income). Furthermore, there are no formal mechanisms, methodologyand socially accepted platforms for proactive and consistent monitoringof quality of housing stock.Prior to developing the BQIH, a research study was undertaken on the internationallyaccepted quality assessment scheme, Conquas 21, developed andimplemented by the Construction Industry Development Board of Singapore.A multidisciplinary team of experts subsequently developed the BQIH forpost-construction assessment. The basic principles of the BQIH system followthose adopted in Conquas. However, due to the pronounced contextual andtechnological differences in the residential sectors of Singapore and SouthAfrica, there are also a number of significant differences between the twosystems.The development process was followed by a pilot study in which the applicabilityof the BQIH system to the South African house construction industry hasbeen evaluated and verified.Enquiries:Dr Adam Goliger<strong>CSIR</strong> Building and Construction TechnologyTel: +27 12 841 2472Fax: +27 12 841 3504Email: agoliger@csir.co.za

<strong>CSIR</strong>boosts youthdevelopmentprogramme21<strong>CSIR</strong> Building and ConstructionTechnology has assisted Mrs ZaneleMbeki, patron of the Youth SkillsDevelopment Programme (YSDP), inconverting an old storage hangar intoa “blue collar” convention centre atSAS Saldanha. The hangar was convertedin two and a half weeks as ademonstration project, at a cost ofR2.9 million, using clean productionprinciples rather than traditionalconstruction principles.The Centre was opened in December2004 by President Mbeki during theYoung SA Women in DialogueConference. In addition to attracting“blue collar” conferences to Saldanha (apresidential poverty node), the Centrewill form part of the EnablementComplex under construction to supportthe YSDP, a joint initiative by theDepartments of Defence and PublicWorks with the <strong>CSIR</strong> as lead agency.The project has attracted in excess ofR20 million in funding in the past. TheIndependent Development Trust (IDT) hascommitted a further R15 million to theYSDP and contract negotiations are at anadvanced stage to allocate this funding.The total estimated cost for implementingthe Enablement Complex isR350 million, with an operational cost ofapproximately R30 million per annum.The intention is to open a further fourEnablement Complexes over the next fiveyears.Left to right: Mrs Zanele Mbeki, Ms Elanca Shelley (<strong>CSIR</strong> Project Leader),President Thabo Mbeki, Ms Cindy Mamabolo (National Co-ordinator forSAWID), Ms Thoko Mpolowano (Commissioner), Captain Robert Shelley (SANavy - SAS Saldanha)Seminar addresses plight of street childrenEven though the rights of children are entrenched in the Constitution, the callto "put children first" remains just as urgent today as in the past. Every year inSouth Africa, thousands of children die from malnutrition and disease. Almost25% of schools do not have water within walking distance and 57 % do not havepower.As part of its contribution to the 16 days of days of activism to unite againstwoman and child abuse, the <strong>CSIR</strong> Crime Prevention Centre recentlyhosted a seminar on "Street Children: Activism, Advocacy, Access to theSystem." A publication will be distributed capturing the outcomes of theseminar, which covered the various approaches to relieving the plight of streetchildren (supported by a literature search done by the <strong>CSIR</strong>) and offered insightinto the roles that different sectors can play in addressing the problem.Opportunities for young scientistsThe <strong>CSIR</strong> is committed to ongoing partnerships with local municipalities. Thevision of these partnerships is to contribute to meeting some of the capacity andtechnical requirements of local government while creating opportunities for youngscientists to learn in a mentored environment.Three science postgraduate students have recently completed a year’s internshipprogramme at <strong>CSIR</strong> Water, Environment and Forestry Technology in partnershipwith the Environmental Management Department (EMD) of the eThekwiniMunicipality in Durban. They have undertaken environmental assessment andState of the Environment reporting projects aligned with the EMD’s own initiatives.From left to right: JeffreyMadingani, Kogilam Iyerand Andrew MothaKogi Iyer, Jeffrey Madingani and Andrew Motha received mentoring and skillsdevelopment while undertaking projects for the municipality. The benefits of thisprogramme were also extended beyond these three graduates to developmentplanners and monthly seminars held for eThekwini council staff with the aim ofsharing knowledge on a variety of environmental topics.Enquiries: Michelle Binedell, <strong>CSIR</strong> Water, Environment and Forestry TechnologyTel: +27 31 242 2366 Email: mbinedell@csir.co.za

22National Accessibility Portalproject gains momentumA significant milestone was reachedwhen the National AccessibilityPortal (NAP) (a collaborative projectbetween the <strong>CSIR</strong>, a representativegroup of Disabled Persons’Organisations, and the Office on theStatus of Disabled Persons in thePresidency) was demonstrated inNovember 2004. Dr Essop Pahad,Minister in the Presidency reconfirmedthe support of the Presidencyfor the NAP demonstrator.NAP is a five-year research andinnovation project aimed at addressingthe marginalisation of peoplewith disabilities from the mainstreameconomy and society. Theproject aims to improve the qualityof life of people with disabilitiesirrespective of age, gender, language,or literacy. Existing devicesand software that allow people withdisabilities to interact with informationand communications technology(ICT) systems are prohibitivelyexpensive and have not beendesigned with the South Africancontext in mind.The NAP team with Dr Essop Pahad: From left, front row: Mackeed Masemola, SebenzileMatsebula and Martin Pistorius. Second row: Johan Viljoen, Buhle Mkhize, Hina Patel,Ronell Alberts, Maluta Mulibana, Anthea Botes, Ngwanakopi Ramushu, Kagiso Chikane.Third row: Dr Louis Coetzee, Laurens Cloete, Dr Essop Pahad, Doreen Letchman, Prof EAlant, Ennio Macagnano, Riette Easton, Rosalie de Villiers, Eric Rossouw, Ilse Viviers andElaine Olivier.Technical challenges that are beingtackled include research and developmentin text-to-sign-language,support for South African languagesand development of quality opensource technologies. A robust textto-speechscreen reader is beingdeveloped in order to make servicesaccessible in an affordable way.Sustainability will be addressedthrough implementation of organisationaland business models thateffectively support and promote economicempowerment of people withdisabilities.Discussions are currently underwaywith the Limpopo ProvincialGovernment regarding the pilotrollout of the system. Subsequentphases will include national rollout.Enquiries:Hina PatelTel: +27 12 841 3777Fax: +27 12 841 4720Email: hpatel@csir.co.za<strong>CSIR</strong> organises firstFLOSS developer roadshowThe first Free/Libre Open Source Software (FLOSS) Developer RoadshowAfrica took place at the University of the Western Cape in Cape Town inDecember 2004. The roadshow is a series of one-week sessions funded by theOpen Source Initiative (OSI)/Open Society Initiative for Southern Africa (OSISA)and convened by the <strong>CSIR</strong>. The event involved software developers in selectedAfrican countries and focused on the theme of localisation and education(e.g. localising an e-learning environment, FLOSS for education and othertopics). For more information on future Developer Roadshows, seehttp://eduforge.org/wiki/wiki/devroadafr/Photograph: courtesy of Neil Blakey-Milner

23Farewell to Executive Vice-PresidentsThe <strong>CSIR</strong> bids farewell to two Executive Vice-Presidents, Tina Eboka and Dr AnthosYannakou. Both had a sustained commitment to the <strong>CSIR</strong> and leave behind a legacyof excellence in their various leadership areas.Dr AnthosYannakou,outgoing <strong>CSIR</strong>Executive Vice-PresidentOperationsDr Anthos Yannakou left the <strong>CSIR</strong> on1 December 2004 after 11 years at the organisation.During this time, he served as Director of the former<strong>CSIR</strong> Food Technology and subsequently as Director of<strong>CSIR</strong> Water, Environment and Forestry Technology.In 1998, Yannakou was appointed as Executive Vice-President: Business Development and TechnologyManagement, and became a member of the ExecutiveBoard. In 2002 his portfolio changed to Operations,which included Business Development, TechnologyManagement, Technology for Development and all the<strong>CSIR</strong> operational issues at business unit and servicedepartment levels.Yannakou serves on a host of advisory boards andreview panels and was the director of several local andinternational boards including the African Centre forGene Technology, the Global Research Alliance, theMerensky Trust, and the Sugar Milling ResearchInstitute. During his career, he managed a wide rangeof functions, including marketing and business development,technical (R&D, quality, project management,factory management), strategic and business planning,operations, and general management. His experiencespans working in academia, the private and publicsectors, to local and multinational organisations. He iswidely published on change management, strategy,and the management of technology.Tina Eboka worked at the <strong>CSIR</strong>for seven years, during which timeshe made an invaluable contribution,starting at <strong>CSIR</strong> Textile Technology inPort Elizabeth in 1997, then at <strong>CSIR</strong>Water, Environment and ForestryTechnology in 2000, and in 2002, as ExecutiveTina Eboka,outgoingExecutiveVice-PresidentHumanResources andOrganisationalDevelopmentVice-President: Organisational Development andCommunications and a member of the ExecutiveBoard. Here she led the organisation in the areasof human resources and employee well-being, andinternal and external communication. She alsospearheaded the <strong>CSIR</strong> NEPAD forum, Technologyfor Women in Business and the <strong>CSIR</strong> SustainableDevelopment Liaison Committee.In addition to her portfolio, she fulfilled her dutiesas board member of a number of organisations,including the UNISA School of BusinessLeadership, the Western Cape Community Chestand the Philadelphia College of Textiles andScience. She has been a recipient of numerousawards in recognition of her leadership skills andhas working experience in the textile industry, privatesector and academic institutions.