January / February 2005 - CSIR

January / February 2005 - CSIR

January / February 2005 - CSIR

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

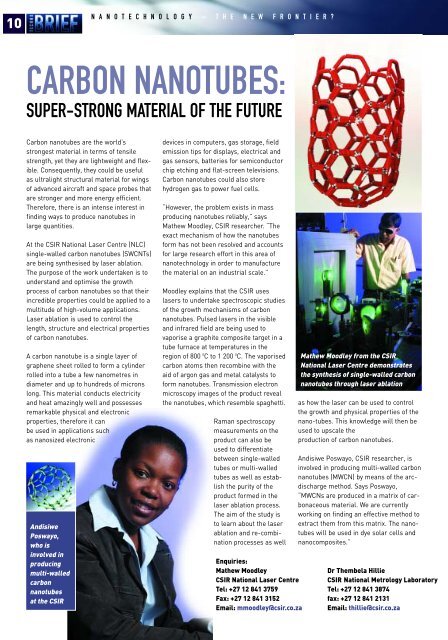

10N A N O T E C H N O L O G Y – T H E N E W F R O N T I E R ?CARBON NANOTUBES:SUPER-STRONG MATERIAL OF THE FUTURECarbon nanotubes are the world’sstrongest material in terms of tensilestrength, yet they are lightweight and flexible.Consequently, they could be usefulas ultralight structural material for wingsof advanced aircraft and space probes thatare stronger and more energy efficient.Therefore, there is an intense interest infinding ways to produce nanotubes inlarge quantities.At the <strong>CSIR</strong> National Laser Centre (NLC)single-walled carbon nanotubes (SWCNTs)are being synthesised by laser ablation.The purpose of the work undertaken is tounderstand and optimise the growthprocess of carbon nanotubes so that theirincredible properties could be applied to amultitude of high-volume applications.Laser ablation is used to control thelength, structure and electrical propertiesof carbon nanotubes.A carbon nanotube is a single layer ofgraphene sheet rolled to form a cylinderrolled into a tube a few nanometres indiameter and up to hundreds of micronslong. This material conducts electricityand heat amazingly well and possessesremarkable physical and electronicproperties, therefore it canbe used in applications suchas nanosized electronicAndisiwePoswayo,who isinvolved inproducingmulti-walledcarbonnanotubesat the <strong>CSIR</strong>devices in computers, gas storage, fieldemission tips for displays, electrical andgas sensors, batteries for semiconductorchip etching and flat-screen televisions.Carbon nanotubes could also storehydrogen gas to power fuel cells.“However, the problem exists in massproducing nanotubes reliably,” saysMathew Moodley, <strong>CSIR</strong> researcher. “Theexact mechanism of how the nanotubesform has not been resolved and accountsfor large research effort in this area ofnanotechnology in order to manufacturethe material on an industrial scale.”Moodley explains that the <strong>CSIR</strong> useslasers to undertake spectroscopic studiesof the growth mechanisms of carbonnanotubes. Pulsed lasers in the visibleand infrared field are being used tovaporise a graphite composite target in atube furnace at temperatures in theregion of 800 0 C to 1 200 0 C. The vaporisedcarbon atoms then recombine with theaid of argon gas and metal catalysts toform nanotubes. Transmission electronmicroscopy images of the product revealthe nanotubes, which resemble spaghetti.Raman spectroscopymeasurements on theproduct can also beused to differentiatebetween single-walledtubes or multi-walledtubes as well as establishthe purity of theproduct formed in thelaser ablation process.The aim of the study isto learn about the laserablation and re-combinationprocesses as wellMathew Moodley from the <strong>CSIR</strong>National Laser Centre demonstratesthe synthesis of single-walled carbonnanotubes through laser ablationas how the laser can be used to controlthe growth and physical properties of thenano-tubes. This knowledge will then beused to upscale theproduction of carbon nanotubes.Andisiwe Poswayo, <strong>CSIR</strong> researcher, isinvolved in producing multi-walled carbonnanotubes (MWCN) by means of the arcdischargemethod. Says Poswayo,“MWCNs are produced in a matrix of carbonaceousmaterial. We are currentlyworking on finding an effective method toextract them from this matrix. The nanotubeswill be used in dye solar cells andnanocomposites.”Enquiries:Mathew MoodleyDr Thembela Hillie<strong>CSIR</strong> National Laser Centre <strong>CSIR</strong> National Metrology LaboratoryTel: +27 12 841 3759 Tel: +27 12 841 3874Fax: +27 12 841 3152 fax: +27 12 841 2131Email: mmoodley@csir.co.za Email: thillie@csir.co.za