Ingersoll-Rand Air Solutions 2003 Installation Accessories

Ingersoll-Rand Air Solutions 2003 Installation Accessories

Ingersoll-Rand Air Solutions 2003 Installation Accessories

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Ingersoll</strong>-<strong>Rand</strong> <strong>Air</strong> <strong>Solutions</strong><br />

<strong>2003</strong> <strong>Installation</strong> <strong>Accessories</strong><br />

Piping and Distribution<br />

Filtration<br />

Condensate Management<br />

<strong>Accessories</strong><br />

2 0 0 3 <strong>Installation</strong> <strong>Accessories</strong>

CONDENSATE MANAGEMENT<br />

Drain Valves<br />

System Saver Drains (SSD2) . . . . . . . . . . . . . . . . . . . . . .4<br />

EDV-2000 Electronic Drain Valve . . . . . . . . . . . . . . . . . . .5<br />

Oil/Water Separators<br />

EnviroSep Condensate System . . . . . . . . . . . . . . . . . . . .6<br />

PolySep Condensate Separator . . . . . . . . . . . . . . . . . . . .7<br />

FILTERS<br />

Compressed <strong>Air</strong> Filters . . . . . . . . . . . . . . . . . . . . . . . . . .8<br />

PIPING AND DISTRIBUTION<br />

Aluminum Piping<br />

SpeedLine (SL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9<br />

Simpl<strong>Air</strong> Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9<br />

Gripple Hang-Fast Hanging Systems . . . . . . . . . . . . . . . .9<br />

POINT-OF-USE PRODUCTS<br />

Hot Tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11<br />

PacE unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11<br />

PUP Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12<br />

PUP Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13<br />

SIMPLAIR EL<br />

Piping <strong>Accessories</strong><br />

Simpl<strong>Air</strong> Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14<br />

<strong>Accessories</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15<br />

Ball Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15<br />

Pipe Cutter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15<br />

Hose Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15<br />

COOLANT<br />

Ultra Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16<br />

Ultra Plus Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . .17<br />

<strong>Air</strong>Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18<br />

Fluid Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18<br />

3<br />

2 0 0 3 <strong>Installation</strong> <strong>Accessories</strong>

4<br />

Condensate Management<br />

D R A I N V A L V E S<br />

System Saver Drains (SSD2)<br />

The <strong>Ingersoll</strong>-<strong>Rand</strong> System Saver Drains have an electronic level sensing capability which<br />

only discharges when condensate is present, thus preventing unnecessary loss of valuable<br />

compressed air. This intelligent sensing system operates with all levels of condensate from<br />

100% oil to 100% water.<br />

The System Saver Drains can be purchased as a bare drain valve or as a kit. The kit<br />

simplifies installation by supplying not only the bare drain valve, but also a ball valve and an<br />

adapter fitting.<br />

• Designed to complement all compressed air systems including<br />

compressors, filters, water separators, dryers, coolers and receivers<br />

• Easy mounting and installation – no additional mounting brackets required<br />

• Zero air loss, zero energy loss, less maintenance and easy-to-access components<br />

• One-year diaphragm seal guarantee, five-year warranty on the electronics and valve housing<br />

Maximum Electrical Compressor Refrigerator<br />

Operating Pressure Requirements Input Power Capacity Dryer Connections<br />

Model CPN PSIG/BARG V-Ph-He (watts) SCFM/m3/min SCFM/m3/min Inlet Outlet<br />

SSD2-7 89324511 232/16 110-1-60/50 26 W 175/5.0 303/8.6 1xG1/2” 3/8" i/d hose<br />

230-1-60/50 1xG1/4”<br />

SSD2-14 89324529 204/14 110-1-60/50<br />

230-1-60/50<br />

26 W 349/9.9 607/17.2 2xG1/2” 5/16" i/d hose<br />

SSD2-21 89324537 232/16 110-1-60/50 44 W 708/20.0 1230/34.8 1xG3/4” G3/8<br />

230-1-60/50 29 W 2xG1/2”<br />

SSD2-28 89324545 232/16 110-1-60/50 44 W 3399/96.3 5904/167.2 1xG3/4” G3/8<br />

230-1-60/50 29 W 2xG1/2”<br />

SSD2-35 89324552 232/16 110-1-60/50 44 W 33517/949.1 58223/1649 1xG3/4” G3/8<br />

230-1-60/50 29 W 2xG1/2”

D R A I N V A L V E S<br />

EDV-2000 Electronic Drain Valve<br />

The EDV-2000 is a full-feature automatic electronic drain valve that cost-effectively removes condensate from<br />

compressors, receivers, dryers, aftercoolers, filters and drip legs.<br />

Each EDV-2000 includes an electric drain, manual blowdown valve, and a strainer/ball valve, which prevents<br />

debris from clogging the drain valve. The maximum pressure is 250 PSI.<br />

• Manual test button<br />

• Two-year warranty<br />

• Prevents rusting<br />

• Delivers drier air to extend the life of tools and pneumatic equipment<br />

• Eliminates manual draining<br />

Voltage Inlet Pipe Outlet Pipe Orifice<br />

110/120V 230/240V Connection Connection (in)<br />

38000865 38000873 1/2” (12mm) BSP 1/4” (6mm) BSP 7/16 (11mm)<br />

38000808 38000881 1/2” (12mm) BSP 1/2” (12mm) BSP 7/16 (11mm)<br />

5

6<br />

Condensate Management<br />

O I L / W A T E R S E P A R A T O R S<br />

All compressed air systems contain water, dirt, rust and even degraded lubricating oil which all mix together to form<br />

unwanted compressed air condensate. This condensate should be treated and have the oil removed before discharging to a<br />

sanitary sewer, unless lubricant is biogradable. Oil/water separators are installed as part of the compressed air system and<br />

simply reduce the oil concentration in the collected condensate. Reducing oil concentration in water to a permitted level<br />

allows larger volumes of clean water, up to 98% of the total condensate, to be discharged safely into the sanitary sewer.<br />

This leaves the relatively small amount of concentrated oil to be disposed of legitimately and economically.<br />

To meet all of your oil/water separation needs and to address the full range of lubricants on the market, IR offers both a<br />

gravitational, activated carbon separator as well as an absorption separator to separate emulsions.<br />

• EnviroSep System • PolySep System<br />

S E P A R A T O R S<br />

EnviroSep Condensate System<br />

The simple, economical and environmental solution is an <strong>Ingersoll</strong>-<strong>Rand</strong> oil/water separator. It is designed to<br />

separate compressor oil from condensate by gravitational methods, and activated carbon, without the use of<br />

electricity. To simplify the selection, lubricant classifications have been split into three bands depending upon<br />

their ability to separate within a static type oil/water separator. This separation device is not recommended with<br />

the use of emulsible lubricants such as polyglycol.<br />

• Helps protect and maintain the environment<br />

• Efficiently separates oil and water. Allows up to 98% of the condensate to be safely<br />

discharged to a sanitary sewer<br />

• Simple to install, operate and maintain<br />

• One-year warranty<br />

<strong>Air</strong>flow with <strong>Air</strong>flow with<br />

<strong>Air</strong>flow with Band B Band C<br />

Band A Lubricant Lubricant<br />

Lubricant (Mineral (Diesters, Connection Connection<br />

(Turbine Oil) Oil, PAOs) Triesters) Inlet Outlet Dimensions Approx.<br />

Model CPN m3/min(CFM) m3/min(CFM) m3/min(CFM) NPT (in) NPT (in) HxWxD (mm) Weight (kg)<br />

ECS6 42515205 1.2 (43) 1.0 (36) 0.9 (30) 3/4 3/4 842 x 550 x 316 6<br />

ECS12 42515213 3.5 (124) 3.0 (106) 2.4 (86) 3/4 1 810 x 350 x 433 10<br />

ECS18 42515221 5.4 (191) 4.6 (162) 3.7 (132) 3/4 3/4 803 x 350 x 450 12<br />

ECS24 42515239 7.6 (268) 6.4 (225) 5.2 (185) 1 1 1195 x 650 x 500 27<br />

EC530 42515247 15.1 (535) 12.7 (450) 10.5 (370) 1 1 1196 x 650 x 650 x 750 36<br />

EC536 42515254 30.1 (1062) 25.5 (900) 20.8 (734) 1 1 1535 x 860 x 700 x 1090 70<br />

EC542 42515288 59.8 (2113) 51.0 (1800) 41.4 (1461) 1 1 1536 x 860 x 1000 x 1090 97<br />

Replacement Carbon Packs and Vent Filters<br />

Model Carbon Pack CPN Qty Vent Filter Qty<br />

ECS6 38019444 1 38019568 1<br />

ECS12 38019444 1 38019568 1<br />

ECS18 38019444 1 38019568 1<br />

ECS24 38019451 1 38019576 1<br />

ECS30 38019451 2 38019576 1<br />

ECS36 38019469 1 38019576 1<br />

ECS42 38019469 2 38019576 1

S E P A R A T O R S<br />

PolySep Condensate Separator<br />

The PolySep addresses the inability of the traditional gravity separators to handle<br />

emulsions, such as polyglycol lubricant.<br />

The unique design of the PolySep system utilises a proprietary adsorption module to<br />

“break” the chemical bond and entrain the emulsified lubricant within the adsorption<br />

module. The solids are collected in the adsorption module and the cleaned condensate<br />

safely disposed of into the sanitary sewer.<br />

Advantages of the PolySep Condensate Separator:<br />

• Separates polyglycol – and other difficult to separate emulsions<br />

• Multiple capacities – allows for systems that use multiple equipment with different lubricants to be sent to one location for separation<br />

• Easy to maintain – adsorption modules are sized to operate 8,000 hrs/1 year under standard operating conditions. Adsorption modules are self<br />

contained and are very easy to changeout and dispose of<br />

• Superior holding capacity – the adsorption module contains a special zeolite adsorbent that holds up to four times more than a standard<br />

activated carbon filter<br />

• One-year warranty<br />

Max Max <strong>Air</strong> Condensate<br />

Capacity Max Lubricant Inlet Inlets Oil Water Dimensions Weight<br />

Model CPN SCFM Kw Capacity (Ltr) (NPT) (3) Total Outlet Outlet LxWxH (mm) (kg)<br />

PS-60 42528455 60 15 4 N/A 1/2” N/A 3/4” 292 x 292 x 699 23<br />

PS-250 42528463 250 37 56 1/4” 1/2” 3/4” 3/4” 1130 x 495 x 960 48<br />

PS-560 42528471 560 75 114 1/4” 1/2” 3/4” 3/4” 1155 x 495 x 960 97<br />

PS-1125 42528489 1125 150 209 1/4” 1/2” 3/4” 3/4” 1155 x 495 x 960 188<br />

37.8<br />

19.5<br />

35.0<br />

9.8<br />

DIFFUSER<br />

(NOTE 3)<br />

24.3<br />

OIL OUTLET<br />

.75FPT<br />

9.8<br />

1.8<br />

4.8<br />

DELIVERY<br />

SYSTEM<br />

29.5<br />

ACCESS LID<br />

3.5<br />

CONDENSATE INLETS (3)<br />

.5 FPT<br />

45.5<br />

A<br />

A<br />

"B"<br />

WATER OUTLET<br />

.75 HOSE<br />

FILTER<br />

MODULE<br />

"B"<br />

CONTROL AIR<br />

INLET FILTER<br />

.25 FPT<br />

"A"<br />

5.8 9.4<br />

DIMENSIONS AND WEIGHTS<br />

ITEM<br />

DELIVERY SYSTEM<br />

15 GALLON MODULE<br />

30 GALLON MODULE<br />

55 GALLON MODULE<br />

SECTION A-A<br />

"A"<br />

-<br />

20<br />

28.5<br />

32.5<br />

"B"<br />

-<br />

15<br />

18.6<br />

23<br />

DRY WGTS#<br />

75<br />

90<br />

200<br />

400<br />

NOTES:<br />

NOTE 1: ALL DIMENSIONS ARE IN INCHES<br />

NOTE 2: TOLERANCES- ALL DIMENSIONS ARE<br />

+/-.50 UNLESS OTHERWISE SHOWN.<br />

NOTE 3: DIFFUSER IS ROTATABLE IN 90 DEGREE<br />

INCREMENTS.<br />

OIL TO MODULE<br />

OUTLET CONN.<br />

.25 FPT<br />

30.5<br />

7

8<br />

Filters<br />

Compressed <strong>Air</strong> Filters<br />

<strong>Ingersoll</strong>-<strong>Rand</strong> coalescing filters save energy and protect your tools, machinery and equipment from<br />

harmful contaminants by effectively removing solid particulates, liquid water, oil and aerosols from<br />

compressed air. The new filter design is easy to install and is loaded with standard features to reduce<br />

maintenance and downtime. All filters feature a 10-year warranty on housing.<br />

Grade GP – General Purpose Protection<br />

Particle removal down to 1 micron including coalesced liquid water and oil, providing a maximum<br />

remaining oil aerosol content of 0.5 ppm (0.5 mg/m3) @ 70°F (21°C).<br />

Grade HE – High Efficiency Oil Removal Filtration<br />

Particle removal down to 0.01 micron including water and oil aerosols, providing a maximum remaining oil<br />

aerosol content of 0.01 ppm (0.01 mg/m3) @ 70°F (21°C). (Precede with Grade GP filter.)<br />

Grade AC – Activated Carbon Filtration<br />

Oil vapour and hydrocarbon odour removal, giving a maximum remaining oil content of

Piping and Distribution<br />

A L U M I N U M P I P I N G<br />

SpeedLine (SL)<br />

SpeedLine (SL) has been designed to provide an efficient, low-cost method of installing air compressor<br />

systems using bendable tubes and a unique round aluminum extrusion. SL is a unique round aluminum<br />

extrusion, anodised to prevent corrosion and manufactured in-line with Simplair’s advanced piping<br />

concept.<br />

Benefits:<br />

• No corrosion/high-quality air<br />

• More efficient air delivery<br />

• Reduced pressure loss<br />

• Higher flow rates<br />

• Easy and fast installation<br />

SpeedLine (SL) is available in 3 sizes: 14 mm, 22 mm, and 28 mm.<br />

Diameter (mm) SCFM @ 103 PSIG SCFM @ 118 PSIG SCFM @ 147 PSIG SCFM @ 176 PSIG SCFM @ 203 PSIG<br />

14 36 41 47 55 62<br />

22 75 86 111 142 167<br />

28 126 148 175 231 281<br />

A L U M I N U M P I P I N G<br />

Simplair Piping<br />

Simplair is a high-performance modular aluminum piping system that is easy to install and simple to<br />

extend or modify. The non-corrosive extruded aluminum provides structural strength and delivers<br />

contaminate-free air in a leak-free piping system. The smooth bore of Simplair tubing prevents highpressure<br />

losses and allows for higher flow rates and performance than that of conventional piping<br />

systems. The positive O-ring seal ensures that no leaks occur at any stage of the system’s life. No air leakage ensures minimum running costs.<br />

A L U M I N U M P I P I N G<br />

Gripple Hang-Fast Hanging Systems<br />

The Gripple Hang-Fast available from <strong>Ingersoll</strong>-<strong>Rand</strong> is the fastest and most adaptable M&E hanging system in the world. The Hang-Fast system is a quick<br />

and safe replacement for threaded rod or chain due to its fast installation, ease of use, versatility, lightweight performance and aesthetic appearance.<br />

The Hang-Fast products come in five load-rated sizes that are value engineered to provide the most cost-effective solutions for hanging M&E services.<br />

Each size accommodates a specific range designated with a Safe Working Load (SWL), which is common to the “loop,” “stud” and “toggle” end fixing<br />

ranges. The SWL gives a minimum 5:1 safety factor in a vertical plane and is maintained irrespective of length chosen for any designated model.<br />

Each Hang-Fast kit contains a length of steel wire rope, with a choice of three integral standard end fixings, a Gripple for height adjustment and<br />

a setting key to unlock the Gripple if required.<br />

Loop-Fast<br />

The “loop” anchor fixing secures the Gripple Hang-Fast to an existing structure. This method simply requires the loop end<br />

to be wrapped around the support (purlin or truss), then the tail end is fed through the loop and pulled tight.<br />

14 mm 22 mm 28 mm<br />

9

10<br />

Piping and Distribution<br />

Stud-Fast<br />

The “stud” anchor fixing secures the Gripple Stud-Fast into a concrete structure. This<br />

method simply requires the “stud” end to be screwed directly into a drop-in anchor, which<br />

is supplied free with the kit.<br />

Toggle-Fast<br />

The “toggle” anchor fixing, which uses a restraining plate and end stop, secures the Gripple<br />

Toggle-Fast into a pre-drilled or punched hole. This method is ideal for attachment into<br />

metal sheeting and pressed metal fabrications with a cavity on the restraining side.<br />

Size End Fixing Length Pk Qty CPN<br />

No. 1 Loop-Fast 1 mtr 10 88304936<br />

10kg SWL 3 mtr 10 88304944<br />

5 mtr 10 88304951<br />

10 mtr 10 88304969<br />

Stud-Fast 1 mtr 10 88304977<br />

3 mtr 10 88304985<br />

5 mtr 10 88304993<br />

10 mtr 10 88305008<br />

Toggle-Fast 1 mtr 10 88305016<br />

3 mtr 10 88305024<br />

5 mtr 10 88305032<br />

10 mtr 10 88305040<br />

No. 2 Loop-Fast 1 mtr 10 88305057<br />

45kg SWL 3 mtr 10 88305065<br />

5 mtr 10 88305073<br />

10 mtr 10 88305081<br />

Stud-Fast 1 mtr 10 88305099<br />

3 mtr 10 88305107<br />

5 mtr 10 88305115<br />

10 mtr 10 88305123<br />

Toggle-Fast 1 mtr 10 88305131<br />

3 mtr 10 88305149<br />

5 mtr 10 88305156<br />

10 mtr 10 88305164<br />

No. 3 Loop-Fast 1 mtr 10 88305172<br />

91kg SWL 3 mtr 10 88305180<br />

5 mtr 10 88305198<br />

10 mtr 5 88305206<br />

Stud-Fast 1 mtr 10 88305214<br />

3 mtr 10 88305222<br />

5 mtr 10 88305230<br />

10 mtr 5 88305248<br />

Toggle-Fast 1 mtr 10 88305255<br />

3 mtr 10 88305263<br />

5 mtr 10 88305271<br />

10 mtr 5 88305289<br />

No. 4 Loop-Fast 1 mtr 10 88305297<br />

225kg SWL 3 mtr 5 88305305<br />

5 mtr 5 88305313<br />

10 mtr 2 88305321<br />

No. 5 Loop-Fast 1 mtr 5 88305339<br />

325kg SWL 3 mtr 5 88305347<br />

5 mtr 2 88305354<br />

10 mtr 2 88305362

Point-of-Use Products<br />

Complete Kits<br />

Pipe sizes CPN<br />

25-32-50-63-80 54446711<br />

25-32 54446729<br />

50-63 54446737<br />

80 54446745<br />

Maintenance Kit for the above items 54402383<br />

PacE - for Economic System Control<br />

Installing a PacE unit in your compressed air system will be the easiest decision you will ever make.<br />

Benefits:<br />

• Energy savings – 7% for every 14 psi reduction in<br />

system pressure<br />

• Single point control for your whole system<br />

• Protection for all downstream equipment<br />

• Prolonged equipment life<br />

• Reduced maintenance costs<br />

• Simple installation and operation<br />

P O I N T - O F - U S E<br />

HOT TAP<br />

No more lost production or expensive sub contract labour. Simpl<strong>Air</strong>, through a<br />

constant desire to improve the flexibility of their revolutionary piping system, have<br />

designed a HOT TAP device, which enables you to drill into your compressed air<br />

piping system under full working pressure, under complete safety, and fit whatever<br />

size connection is required.<br />

The HOT TAP is a five minute operation that can be carried out by anyone at any<br />

time. Not only has the HOT TAP been designed to drill into the system under full<br />

working pressure, it has also been designed to prevent contamination from the<br />

drilling process entering into the piping system.<br />

As the HOT TAP starts to break through the surface of the extrusion, air pressure<br />

forces all loose particles back through an exhaust chamber in the drills body where<br />

they become trapped in a pleated filter. This process ensures that no contamination<br />

enters the piping, maintaining the systems integrity. Drills, cutters and a simple<br />

maintenance kit are available to support the unit.<br />

Why? Well it’s simple.<br />

PacE will provide you the ability to control your entire air system's pressure<br />

from one convenient unit.<br />

Storing air at a high pressure is good working practice. This enables you to have a<br />

greater volume in your air receiver to cover peak system demands, but letting this<br />

high pressure feed into your distribution system can be detrimental.<br />

First, high pressure will affect the performance and life expectancy of your<br />

production equipment. Most pneumatic components and tools are designed to<br />

operate at between 80 – 90 psi. Any pressure higher than this will cause excessive<br />

wear and inevitable component failure.<br />

The second reason is leakage. All air systems can potentially have leaks.<br />

However, losing air at 80 psi is better than losing it at 125 psi. Reducing the<br />

pressure that air leaks from your system reduces the volume of air that is lost. This<br />

results in less loading of your air compressor and considerable running cost<br />

savings. It is possible in some installations to actually turn off compressors,<br />

achieving not only power cost savings but also reducing maintenance costs and<br />

extending the life of your compressor.<br />

11

12<br />

Point-of-Use Products<br />

P O I N T - O F - U S E<br />

PUP Filter<br />

The Point-of-Use Provider (PUP) is a 3-in-1 solution for the bottom of a<br />

compressed air drop. In one compact unit, the PUP is a filter, an automatic<br />

drain, and a manifold for multiple distribution.<br />

A 1-micron coalescing filter efficiently removes particles of moisture, oil and<br />

any other contaminant. The automatic drain (with manual override) at the<br />

bottom of the PUP reliably removes condensate from the air line to help protect<br />

instruments from rust and scale.<br />

The PUP has a 1-inch female inlet port on the top of the unit, and on the sides<br />

of the PUP are (two) 1/2-inch and (two) 3/8-inch outlet ports to allow easy<br />

installation into any system.<br />

Technical Specifications<br />

Particle removal down to 1 micron including coalesced liquid water and oil,<br />

providing a maximum remaining oil aerosol content of 0.6 mg/m3 (0.5 ppm) at<br />

21°C (70°F).<br />

Operating Limitations<br />

Maximum Flow of Unit: 1.70 m3/min (60 SCFM)<br />

Maximum Operating Pressure: 16 BARG (232 PSIG)<br />

Maximum Recommended Operating Temperature: 150°F (66°C)<br />

Minimum Recommended Operating Temperature: 34°F (1°C)<br />

Recommended Filter Element Change: 12 months or 6,000 hours<br />

Description CPN<br />

BSP PUP 42526715<br />

Filter Element 38027223<br />

Wall Mounting Bracket 38027249<br />

Automatic Drain Assembly (Filter 2000 Drain) 88344171<br />

O-Ring Kit 38032165

P O I N T - O F - U S E<br />

Point-Of-Use Provider Manifold<br />

The outlet manifold provides a simple, cost-effective solution to the untidy<br />

array of tees and elbows normally used to create outlets.<br />

The manifold is made of lightweight, durable anodised aluminum and<br />

features the following outlets: (2) 1-inch BSP (top & bottom), (2) 1/2-inch BSP,<br />

(2) 3/8-inch BSP, and (2) 1/4-inch BSP.<br />

Plugs are provided for each outlet and have O-rings so that pipe sealant is<br />

not required. The point-of-use manifold is suitable for use with SpeedLine SL,<br />

steel, copper and other piping systems.<br />

Model CPN<br />

Point-of-Use Provider Manifold 38004347<br />

13

14<br />

Simpl<strong>Air</strong> EL<br />

Simpl<strong>Air</strong> EL<br />

Easy to use push-in system for Piping Systems<br />

The Simpl<strong>Air</strong> EL way of push-in fittings and pipe provide the ideal<br />

connection from the compressed air receiver, throughout the entire<br />

distribution system, right to the point-of-use. Using the Simpl<strong>Air</strong> EL<br />

system a compressed air piping system can be installed quickly and<br />

easily, considerably reducing the need for specialist staff and reducing<br />

production downtime.<br />

No need to prepare threaded pipe or apply solvent, all the connections<br />

can be made with a simple push-in action. The system is then<br />

immediately ready for use. Complex systems can be assembled much<br />

more rapidly than with traditional methods. Since they also are easy to<br />

disconnect, systems are easy to alter or extend.<br />

A L U M I N I U M P I P I N G<br />

Simpl<strong>Air</strong> EL<br />

Simpl<strong>Air</strong> (EL) has been designed to provide an efficient, low-cost<br />

method of installing compressed air piping systems.<br />

EL is a unique round aluminium extrusion, manufactured in-line with<br />

Simpl<strong>Air</strong>’s advanced piping concept.<br />

Simpl<strong>Air</strong> is available in 2 sizes: 22mm (1”) and 28mm (1 1 /4”)<br />

TUBING<br />

PART NO. TUBE OD TUBE LENGTH PK QTY<br />

38332540 22 (1") 3 metres (10ft) 10<br />

38332656 28 (1 1 ⁄4”) 3 metres (10ft) 10<br />

EQUAL ELBOW<br />

STRAIGHT CONNECTOR<br />

EQUAL TEE<br />

STEM ELBOW<br />

REDUCER<br />

WATER TRAP TEE<br />

PART NO. TUBE OD<br />

38332565 22 (1”)<br />

38332672 28 (1 1 ⁄4”)<br />

PART NO. TUBE OD<br />

38332557 22 (1”)<br />

38332664 28 (1 1 ⁄4”)<br />

PART NO. TUBE OD<br />

38332573 22 (1”)<br />

38332680 28 (1 1 ⁄4”)<br />

PART NO. TUBE OD<br />

38332623 22 (1”)<br />

PART NO. STEM OD TUBE OD<br />

38332581 28 (1 1 ⁄4”) 22 (1”)<br />

PART NO. TUBE OD<br />

38332631 22 (1”)

Brass Fittings<br />

WATER TRAP TEE CONVERTOR<br />

<strong>Accessories</strong><br />

PART NO. SIZE<br />

38332714 28 (1 1 ⁄4”)<br />

The Simpl<strong>Air</strong> EL Water Trap Tee Convertor is a simple and convenient way of<br />

converting a standard 28mm Tee, Part No. 38332680, to a Water Trap Tee.<br />

When fitted, it will reduce condensed water within the Piping System Circuit<br />

from entering the vertical take-off spurs.<br />

MANIFOLD - FEMALE THREADED<br />

PART NO. THREAD BSP THREAD NPT<br />

54742721 1"<br />

38004347 1"<br />

Manifolds are supplied with the following<br />

plugged outlets:<br />

2 x 1/4"<br />

2 x 3/8"<br />

2 x 1/2"<br />

1 x 1"<br />

MALE BRASS STEM ADAPTOR<br />

PLUG<br />

PIPE CUTTER<br />

PART NO. STEM OD THREAD THREAD<br />

BSP NDT<br />

38332599 22 (1") 3/4"<br />

38332607 22 (1") 1"<br />

38332698 28 (11 ⁄4") 1"<br />

38332961 22 (1") 3/4"<br />

38332615 22 (1") 1"<br />

38332706 28 (11 ⁄4") 1"<br />

PART NO. TUBE OD COLOUR<br />

38332649 22 (1") BLACK<br />

38332722 28 (1 1 ⁄4") BLACK<br />

PART NO. TUBE SIZES<br />

88162466 22 - 28 (1" - 1 1 ⁄4")<br />

<strong>Accessories</strong> (continued)<br />

PIPE CLIPS AND SPACERS<br />

CLIP<br />

PART NO.<br />

TUBE OD COLOUR<br />

38332730 22 (1") BLACK<br />

38332755 28 (1 1 ⁄4") BLACK<br />

SPACER<br />

PART NO.<br />

38332748 22 - 28 (1" - 11 ⁄4") BLACK<br />

BALL VALVES - WITH COMPRESSION ENDS<br />

PART NO. TUBE SIZE<br />

88306139 22 (1")<br />

88306402 28 (1 1 ⁄4")<br />

SPARE NUTS FOR BALL VALVES<br />

PART NO. TUBE SIZE<br />

88306410 22 (1")<br />

88306436 28 (1 1 ⁄4")<br />

SPARE FERRULES FOR BALL VALVES<br />

PART NO. TUBE SIZE<br />

88306428 22 (1")<br />

88306444 28 (1 1 ⁄4")<br />

HOSE REEL - 10mm Diameter<br />

PART NO. MAX WORKING LENGTH<br />

88306105 7 mtr<br />

15

16<br />

Rotary Screw <strong>Air</strong> Compressors<br />

ULTRA COOLANT ONLY<br />

!<br />

ULTRA COOLANT ONLY<br />

!<br />

S S R S E R I E S<br />

Ultra Coolant<br />

Ultra Coolant is an engineered synthetic coolant designed to achieve peak compressor<br />

performance for contact cooled rotary screw air compressors. Ultra Coolant’s unique<br />

formulation allows for long life, excellent cooling performance and improved<br />

compressor efficiency.<br />

• Two years/8,000 hours useful life, saving you money on cost and disposal<br />

• Low carryover – up to 75% lower than mineral oils and PAOs, which<br />

means less fluid for makeup and less contamination<br />

• Superior compressor performance, leading to lower cost from excellent<br />

cooling and better efficiency<br />

• Lower maintenance costs, because other lubricants require changing up to eight<br />

times more often as Ultra Coolant<br />

Ultra Coolant CPN<br />

1 Litre 1-Ltr 92837095<br />

5 Litre 5-Ltr 92692284<br />

25 Litre 25-Ltr 92692292<br />

208 Litre 208-Ltr 39433743<br />

ULTRA COOLANT ONLY<br />

Coolant/Lubricant Base Stock Viscosity Index Hours ISO Viscosity Grade SAE Grade<br />

Ultra Coolant PAG-Ester 172 8,000 (2 yr) 46 10W20<br />

!<br />

ULTRA COOLANT ONLY<br />

!

S S R U P - S E R I E S<br />

Start-Up Kits<br />

Ultra Plus Coolant-based Start-Up Kits provide improved protection for UP-Series rotary screw air<br />

compressors. Each kit contains all the parts needed to correctly start up and maintain your<br />

compressor for a full year, plus the added protection of an extended two-year warranty.*<br />

Kit Includes:<br />

• Coolant filter (1) • Ultra Plus Coolant (5 litres)<br />

Compressor Model CPN<br />

UP5-15kw/22kw 22114193<br />

*<strong>Ingersoll</strong>-<strong>Rand</strong> also offers extended warranties up to five years. In order to qualify, compressors must have started and run<br />

continuously on Ultra Plus Coolant while using only genuine <strong>Ingersoll</strong>-<strong>Rand</strong> replacement parts. Ask your local <strong>Ingersoll</strong>-<strong>Rand</strong><br />

representative about this program.<br />

S S R U P - S E R I E S<br />

Maintenance Kits<br />

The competitively priced Maintenance Kit includes all parts required for every<br />

3,000-hour or annual maintenance of your UP-Series rotary compressor.<br />

Kit Includes:<br />

• Coolant filter (1) • <strong>Air</strong> filter element (1)<br />

• Separator cartridge (1) • Package pre-filter (1)<br />

• Ultra Plus Coolant (for top-off) (5 litres)<br />

Compressor Model CPN<br />

UP5-15kw/22kw 22114201<br />

After 9,000 hours or two years of service, the Maintenance Kit plus 20 litres of Ultra Plus Coolant for complete coolant change-out are recommended. Ultra Plus Coolant is available in 5-litre or<br />

20-litre bottles.<br />

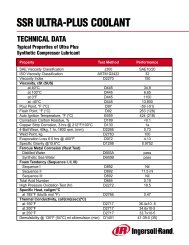

S S R U P - S E R I E S<br />

Ultra Plus Coolant<br />

<strong>Ingersoll</strong>-<strong>Rand</strong>’s exclusive Ultra Plus Coolant, an advanced synthetic lubricant based on molecular chemistry<br />

used in today’s aerospace technologies, was developed to improve the efficiency and value of <strong>Ingersoll</strong>-<strong>Rand</strong>’s<br />

UP-Series rotary screw air compressors.<br />

• Reduces friction and delivers lower rates of wear than possible with conventional lubricants<br />

• Lower maintenance costs – superior performance allows drain intervals to be extended to<br />

9,000 hours<br />

• There’s no better way to protect your investment! With the use of Ultra Plus Coolant, you<br />

receive the added protection of an extended 24-month warranty (standard warranty 12<br />

months or 18 months from date of shipment)<br />

Coolant/Lubricant Base Stock Viscosity Index Hours ISO Viscosity Grade SAE Grade<br />

Ultra Plus Coolant Inhibited Polyol Ester 150 9,000 (2 yr) 32 10/20<br />

Ultra Plus Coolant CPN<br />

5 litres 22114185<br />

20 litres 88306055<br />

17

18<br />

<strong>Air</strong>Care<br />

Our Pledge: An Absolute Commitment to<br />

Customer Satisfaction<br />

As the owner of an <strong>Ingersoll</strong>-<strong>Rand</strong> air compressor, you’ve made a critical investment for<br />

your company. The additional investment of the exclusive <strong>Ingersoll</strong>-<strong>Rand</strong> <strong>Air</strong>Care Program<br />

ensures that you receive a responsive and flexible contract program providing planned<br />

maintenance for increased system reliability.<br />

<strong>Air</strong>Care keeps your system operating at peak efficiency by a thorough knowledge of<br />

technology, state-of-the-art monitoring equipment and ongoing training of <strong>Ingersoll</strong>-<strong>Rand</strong>’s<br />

service professionals. Our service professionals represent the industry’s largest investment<br />

in ongoing training and equipment – an investment that benefits our customers in every<br />

step of the <strong>Air</strong>Care program.<br />

• Reduced maintenance costs<br />

• Reduced energy usage through optimisation<br />

• Fewer unexpected maintenance requirements and reduced downtime for<br />

scheduled maintenance<br />

• Extended five-year warranty coverage offered with the purchase of<br />

preventative maintenance or inspection agreement<br />

Light industrial products covered by the <strong>Air</strong>Care program include: Premier Series<br />

reciprocating compressors; SSR, SE and UP-Series rotary screw air compressors;<br />

ThermoStar and Thermal Mass refrigerated dryers; and ThermoZorb desiccant dryers.<br />

Contact your local <strong>Ingersoll</strong>-<strong>Rand</strong> authorised service provider for availability and details.<br />

Fluid Analysis<br />

Fluid analysis is an important part of a predictive maintenance program, as it<br />

can increase a compressor's efficiency and reveal a number of equipment<br />

problems before they result in system failure.<br />

Benefits include:<br />

• Significantly extend the life of an air compressor and its parts<br />

• Reduce machine and plant downtime<br />

• Improve compressor reliability, productivity and effectiveness<br />

• Provide extended drain intervals<br />

• Decrease machine maintenance, repair and/or replacement costs<br />

• <strong>Ingersoll</strong>-<strong>Rand</strong>'s fluid analysis program can test any type of<br />

fluid from any type of compressor (even other brands).

For more information on<br />

<strong>Ingersoll</strong>-<strong>Rand</strong> <strong>Air</strong> <strong>Solutions</strong>,<br />

contact us at<br />

www.air.ingersoll-rand.com.<br />

Click on Sales and Service<br />

Locations and enter your<br />

post code for the<br />

authorised <strong>Ingersoll</strong>-<strong>Rand</strong><br />

distributor near you.<br />

<strong>Ingersoll</strong>-<strong>Rand</strong> <strong>Air</strong> <strong>Solutions</strong> – <strong>Air</strong> Compressors,<br />

<strong>Air</strong> Treatment, <strong>Air</strong> Distribution, and Accessory<br />

Equipment, including Piping, Hoses, Fittings,<br />

Pneumatic Tools, <strong>Air</strong>Care Services and More.<br />

Proven Source.<br />

Proven <strong>Solutions</strong>.<br />

19

<strong>Ingersoll</strong>-<strong>Rand</strong> European Sales Limited<br />

Swan Lane, Hindley Green<br />

Wigan<br />

WN2 4EZ<br />

United Kingdom<br />

© <strong>2003</strong> <strong>Ingersoll</strong>-<strong>Rand</strong> CPN 88309968 Printed in UK<br />

Disclaimer: Nothing contained within this brochure<br />

is intended to extend any warranty or<br />

representation, expressed or implied, regarding the<br />

products described herein. Any such warranties or<br />

other terms or conditions of the sale of products<br />

shall be in accordance with <strong>Ingersoll</strong>-<strong>Rand</strong> Standard<br />

Terms and Conditions of Sale for such products<br />

which are available upon request.<br />

Product improvement is a continuing goal at<br />

<strong>Ingersoll</strong>-<strong>Rand</strong>. Designs and specifications are<br />

subject to change without notice or obligation.