Ingersoll-Rand Air Solutions 2003 Installation Accessories

Ingersoll-Rand Air Solutions 2003 Installation Accessories

Ingersoll-Rand Air Solutions 2003 Installation Accessories

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

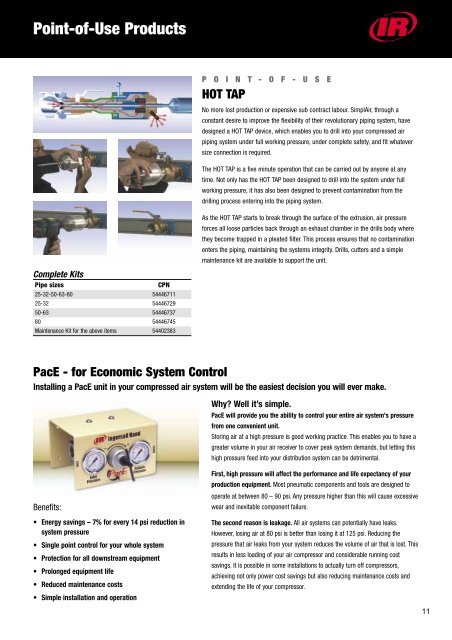

Point-of-Use Products<br />

Complete Kits<br />

Pipe sizes CPN<br />

25-32-50-63-80 54446711<br />

25-32 54446729<br />

50-63 54446737<br />

80 54446745<br />

Maintenance Kit for the above items 54402383<br />

PacE - for Economic System Control<br />

Installing a PacE unit in your compressed air system will be the easiest decision you will ever make.<br />

Benefits:<br />

• Energy savings – 7% for every 14 psi reduction in<br />

system pressure<br />

• Single point control for your whole system<br />

• Protection for all downstream equipment<br />

• Prolonged equipment life<br />

• Reduced maintenance costs<br />

• Simple installation and operation<br />

P O I N T - O F - U S E<br />

HOT TAP<br />

No more lost production or expensive sub contract labour. Simpl<strong>Air</strong>, through a<br />

constant desire to improve the flexibility of their revolutionary piping system, have<br />

designed a HOT TAP device, which enables you to drill into your compressed air<br />

piping system under full working pressure, under complete safety, and fit whatever<br />

size connection is required.<br />

The HOT TAP is a five minute operation that can be carried out by anyone at any<br />

time. Not only has the HOT TAP been designed to drill into the system under full<br />

working pressure, it has also been designed to prevent contamination from the<br />

drilling process entering into the piping system.<br />

As the HOT TAP starts to break through the surface of the extrusion, air pressure<br />

forces all loose particles back through an exhaust chamber in the drills body where<br />

they become trapped in a pleated filter. This process ensures that no contamination<br />

enters the piping, maintaining the systems integrity. Drills, cutters and a simple<br />

maintenance kit are available to support the unit.<br />

Why? Well it’s simple.<br />

PacE will provide you the ability to control your entire air system's pressure<br />

from one convenient unit.<br />

Storing air at a high pressure is good working practice. This enables you to have a<br />

greater volume in your air receiver to cover peak system demands, but letting this<br />

high pressure feed into your distribution system can be detrimental.<br />

First, high pressure will affect the performance and life expectancy of your<br />

production equipment. Most pneumatic components and tools are designed to<br />

operate at between 80 – 90 psi. Any pressure higher than this will cause excessive<br />

wear and inevitable component failure.<br />

The second reason is leakage. All air systems can potentially have leaks.<br />

However, losing air at 80 psi is better than losing it at 125 psi. Reducing the<br />

pressure that air leaks from your system reduces the volume of air that is lost. This<br />

results in less loading of your air compressor and considerable running cost<br />

savings. It is possible in some installations to actually turn off compressors,<br />

achieving not only power cost savings but also reducing maintenance costs and<br />

extending the life of your compressor.<br />

11