Ingersoll-Rand Air Solutions 2003 Installation Accessories

Ingersoll-Rand Air Solutions 2003 Installation Accessories

Ingersoll-Rand Air Solutions 2003 Installation Accessories

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6<br />

Condensate Management<br />

O I L / W A T E R S E P A R A T O R S<br />

All compressed air systems contain water, dirt, rust and even degraded lubricating oil which all mix together to form<br />

unwanted compressed air condensate. This condensate should be treated and have the oil removed before discharging to a<br />

sanitary sewer, unless lubricant is biogradable. Oil/water separators are installed as part of the compressed air system and<br />

simply reduce the oil concentration in the collected condensate. Reducing oil concentration in water to a permitted level<br />

allows larger volumes of clean water, up to 98% of the total condensate, to be discharged safely into the sanitary sewer.<br />

This leaves the relatively small amount of concentrated oil to be disposed of legitimately and economically.<br />

To meet all of your oil/water separation needs and to address the full range of lubricants on the market, IR offers both a<br />

gravitational, activated carbon separator as well as an absorption separator to separate emulsions.<br />

• EnviroSep System • PolySep System<br />

S E P A R A T O R S<br />

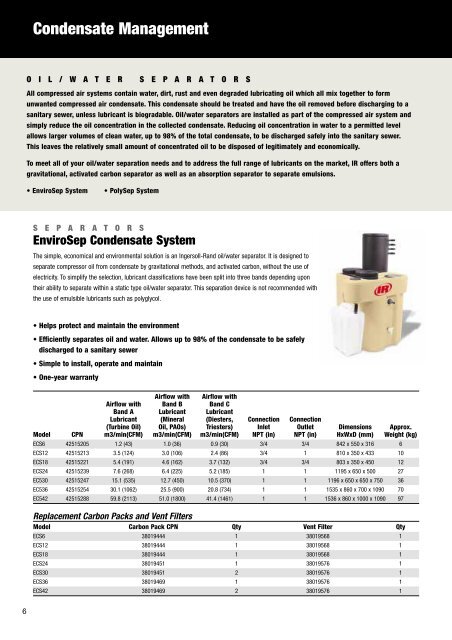

EnviroSep Condensate System<br />

The simple, economical and environmental solution is an <strong>Ingersoll</strong>-<strong>Rand</strong> oil/water separator. It is designed to<br />

separate compressor oil from condensate by gravitational methods, and activated carbon, without the use of<br />

electricity. To simplify the selection, lubricant classifications have been split into three bands depending upon<br />

their ability to separate within a static type oil/water separator. This separation device is not recommended with<br />

the use of emulsible lubricants such as polyglycol.<br />

• Helps protect and maintain the environment<br />

• Efficiently separates oil and water. Allows up to 98% of the condensate to be safely<br />

discharged to a sanitary sewer<br />

• Simple to install, operate and maintain<br />

• One-year warranty<br />

<strong>Air</strong>flow with <strong>Air</strong>flow with<br />

<strong>Air</strong>flow with Band B Band C<br />

Band A Lubricant Lubricant<br />

Lubricant (Mineral (Diesters, Connection Connection<br />

(Turbine Oil) Oil, PAOs) Triesters) Inlet Outlet Dimensions Approx.<br />

Model CPN m3/min(CFM) m3/min(CFM) m3/min(CFM) NPT (in) NPT (in) HxWxD (mm) Weight (kg)<br />

ECS6 42515205 1.2 (43) 1.0 (36) 0.9 (30) 3/4 3/4 842 x 550 x 316 6<br />

ECS12 42515213 3.5 (124) 3.0 (106) 2.4 (86) 3/4 1 810 x 350 x 433 10<br />

ECS18 42515221 5.4 (191) 4.6 (162) 3.7 (132) 3/4 3/4 803 x 350 x 450 12<br />

ECS24 42515239 7.6 (268) 6.4 (225) 5.2 (185) 1 1 1195 x 650 x 500 27<br />

EC530 42515247 15.1 (535) 12.7 (450) 10.5 (370) 1 1 1196 x 650 x 650 x 750 36<br />

EC536 42515254 30.1 (1062) 25.5 (900) 20.8 (734) 1 1 1535 x 860 x 700 x 1090 70<br />

EC542 42515288 59.8 (2113) 51.0 (1800) 41.4 (1461) 1 1 1536 x 860 x 1000 x 1090 97<br />

Replacement Carbon Packs and Vent Filters<br />

Model Carbon Pack CPN Qty Vent Filter Qty<br />

ECS6 38019444 1 38019568 1<br />

ECS12 38019444 1 38019568 1<br />

ECS18 38019444 1 38019568 1<br />

ECS24 38019451 1 38019576 1<br />

ECS30 38019451 2 38019576 1<br />

ECS36 38019469 1 38019576 1<br />

ECS42 38019469 2 38019576 1