Kingzip Seam Roof System - BD Online Product Search

Kingzip Seam Roof System - BD Online Product Search

Kingzip Seam Roof System - BD Online Product Search

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

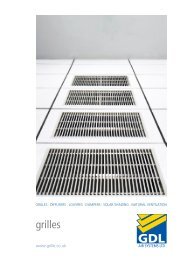

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.info<strong>Product</strong> Data 231Model Specifications 235Fastener Selection 242Construction Details 245• Side, End Laps &Fastener Locations 245• Ridge 246• Verge 247• Eaves 248• Hip 249• Barrel Vault 250• Penetrations 252• Curved <strong>Roof</strong> 253KS500/1000 <strong>Kingzip</strong>Standing <strong>Seam</strong><strong>Roof</strong> <strong>System</strong><strong>Kingzip</strong>Insulated Standing<strong>Seam</strong> <strong>Roof</strong> <strong>System</strong>229

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.info“Certainty of thermal, air andweathertightness combinedwith rapid build speed”230

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS500/1000 Zip <strong>Roof</strong> <strong>System</strong><strong>Kingzip</strong> - Standing <strong>Seam</strong>Application<strong>Kingzip</strong> is a high specification insulated standing seam roof systemsuitable for new build and refurbishment:i) roof slopes 1.5° or greater, after deflectionsii) curved roofs 150 metre radius and over.Dimensions & Weight<strong>Product</strong> ReferenceKS500/1000 ZIPKS500/1000 ZIP-LPCBCert. No. 260aApplication DescriptionStandard standing seam roof panel.Standing seam roof panel with LossPrevention Certification Board (LPCB)approval for roof applications.KS1000 ZIP1000mm cover widthKS500 ZIP500mm cover width65 mm±1 mmB65 mm±1 mmABKS500/1000 <strong>Kingzip</strong><strong>Product</strong> DataAA - Core thickness (mm) 45 90*B - Overall dimension (mm) 112 157KS500 ZIP KS1000 ZIP KS500 ZIP KS1000 ZIPkg/m 2 kg/lin m kg/m 2 kg/m 2 kg/lin m kg/m 2Weight 0.9 aluminium/ 0.4 steel 9.12 4.56 8.26 11.12 5.56 10.260.5 steel/0.4 steel 11.12 5.56 10.01 13.12 6.56 12.01*This panel thickness complies with Part L2 (England & Wales) and Part J (Scotland)<strong>Product</strong> ToleranceCut to Length -5mm +10mmLiner Sheet Length -5mm +10mmCover Width -2mm +3mmThickness -2mm +2mmAvailable LengthsIt is recommended (where possible) that panels are continuousfrom ridge to eaves. Panels are available in lengths from 1.8 to 30metres. It is essential to identify panel lengths at specification andquotation time. Panels less than 1.8m long can be supplied but donot have a cut back as standard and are subject to extra charge.Panel End Cut BackIt is recommended (where possible) that panels are continuousfrom ridge to eaves. Panels are available in lengths from 1.8 to 30metres. It essential to identify panel lengths at specification andquotation time. Panels less than 1.8m long can be supplied but donot have a cut back as standard and are subject to extra charge.End LapIt is recommended that panels are used in continuous lengthsfrom ridge to eaves with no end laps. However, where an end lapmust be used, the flush end of the down slope panel has a factoryfitted end lap stitching plate, this is shown in the constructiondetails.Stucco aluminium faced panel end laps can be site welded.Panel Length231

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS500/1000 Zip <strong>Roof</strong> <strong>System</strong><strong>Kingzip</strong> - Standing <strong>Seam</strong>Materials - SteelSubstrate• HPS200: ZA255 Galvalloy hot-dip alloy coated steel (=95%Zn/=5% Al) to BS EN 10214: 1995.• Hot-dipped zinc coated steel to BS EN 10147: 1992. Coatinglining enamel or Stelvetite.• Standard external sheet thickness 0.5mm, standard internalsheet thickness 0.4mm. Other thicknesses can be supplied tospecial order.Coatings - External Weather Sheet• HPS200 Plastisol: 200 micron thick high performance coatingapplied to the weatherside of the panel. Designed to achievehigh levels of durability and colour stability, is highly resistant todamage in transit and on-site.Coatings - Internal Liner Sheet• Lining Enamel: 15 micron thick coating developed for use forthe internal lining of insulated panels. Standard colour is “brightwhite” with an easily cleaned surface.• HPS200 Plastisol: 200 micron thick coating used in areaswhere there is high internal humidity, or a corrosive environment.• Stelvetite Food & Hygiene Safe: This is a 120 micron thickchemically inert polymer film bonded to steel suitable forcladding the interior of coldstores, food processing orpreparation buildings and other hygiene applications.• Reverse side of sheet coated with a light grey polyester coating.• The sheet is available in stucco embossed finish.Materials - AluminiumSubstrate• Aluminium substrate, Grades 3105 series.• Standard external sheet thickness 0.9mm.Coatings - External Weather Sheet• PVDF: 25 micron thick stoved fluorocarbon coating which hasexcellent colour stability even at temperatures as high as 120˚C.• ARS Abrasion Resistant: 28 micron thick polyester orpolyurethane resin reinforced with polyamide high durabilitycoating with exceptionally good handling characteristics.• Silicone Polyester: An economical coating with medium termlife for worldwide use.• Alternatively the weather sheet can be supplied in mill finish,stucco embossed.Insulation Core• Polyisocyanurate (PIR): with zero ozone depletion (Zero ODP).Available in LPCB certified product range, please contactKingspan Technical Design Bureau.SealsFactory Applied Side Lap TapeAll side joints have factory applied airtightness and anticondensationseals.For internal high humidity/temperature applications an additionalsite applied side lap seal is required subject to project specificassessment.Under Lap Protection (steel only)If end laps are required, additional under lap corrosion protectionfor aggressive environments can be factory applied at extra cost.232

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS500/1000 Zip <strong>Roof</strong> <strong>System</strong><strong>Kingzip</strong> - Standing <strong>Seam</strong>PerformanceThermal InsulationPanel Thickness (mm)U value W/m 2 K45 0.4590 0.25*U - Thermal transmittance W/m 2 K* U Value calculated in accordance with the method required by the BuildingRegulations Part L2 (England & Wales) and Building Standards Part J (Scotland)BiologicalKingspan panels are normally immune to attack from mould, fungi,mildew and vermin. No urea formaldehyde is used in theconstruction, and the panels are not considered deleterious.FireSteel and aluminium outer and steel inner facings have Class 1surface spread of flame to BS 476: Part 7: 1987, and are Class 0,as defined by Building Regulations. The panel surfaces are ratedFAA/SAA to BS 476: Part 3: 1975. KS500/1000 Zip panels areavailable with LPCB certification, with steel and aluminium outerfacings and steel internal liners.Acoustics<strong>Kingzip</strong> panels comply with Building Regulations Part E for nondomesticbuildings. For residential, domestic, education andhealthcare building applications, BB93 and HTM 2045solutions, consult Kingspan Technical Design Bureau.All steel faced <strong>Kingzip</strong> KS500/1000 Zip panels have a single figureweighted sound reduction Rw = 27dB.Sound Reduction Index (SRI)Frequency Hz 63 125 250 500 1k 2k 4k 8kSRI dB 14 14 19 24 27 34 43 52All aluminium external faced/steel internal faced <strong>Kingzip</strong>KS500/1000 Zip panels have a single figure weighted soundreduction Rw = 25dB.For a building or room where a very quiet internal environment is vital, forexample a library or a bedroom an additional suspended ceiling and possiblyacoustic insulation or other measure may be necessary to reduce the effect ofrain drumming nuisance in ‘heavy downpour’ conditions.Building Regulations & StandardsKingspan insulated roof and wall systems conform to the followingBuilding Regulations and Standards (Non-domestic buildings):i) Approved Document A: Structure (England & Wales)ii) Approved Document B: Fire (England & Wales)iii) Approved Document E: Resistance to the Passage of Sound(England & Wales)iv) Approved Document Part L2: Conservation of Fuel & Power(England & Wales)v) Building Standard Part D: Structural Fire Precautions (Scotland)vi Building Standard Part H: Resistance to the Transmission ofSound (Scotland)vii) Building Standard Part J: Conservation of Fuel & Power (Scotland)viii) Building Standard Part L: Conservation of Fuel & Energy (Ireland))Quality & DurabilityKingspan Insulated Panels are manufactured from the highestquality materials, using state of the art production equipment torigorous quality control standards, complying with ISO 9001: 2000standard, ensuring long term reliability and service life.Guarantees & WarrantiesKingspan will provide external coating and product warranties andguarantees on an individual project basis.PackingStandard Packing<strong>Kingzip</strong> KS500/1000 Zip panels are stacked weather sheet up(to allow ease and safety of removal from pack and installation).The top, bottom, sides and ends are protected with foam andtimber packing and the entire pack is wrapped in plastic. Thiscould be subject to change and checks should be made withCustomer Services.<strong>Kingzip</strong> KS500/1000 Zip are stacked interleaved weather sheet toweather sheet/liner to liner (to minimise pack height-removal frompack and installation eased due to narrow cover width).Two KS500/1000 Zip panels are transported side by side within apack to minimise packaging and stabilise pack.The number of panels in each pack depends on panel thicknessand length. The tables below are shown as a guide. Quantities arereduced for exceptionally long panels. Typical pack height is1100mm. Maximum pack weight is 1500kg.KS500 ZIP KS1000 ZIPPanel Core Thickness 45 90 45 90No. Panel/Pack (max.) 20 16 9 6Sea FreightFully timber crated packs are available on projects requiringdelivery by sea freight shipping, at additional cost. Alternatively,steel containers can be used. Special loading charges apply.DeliveryAll deliveries (unless indicated otherwise) are by road transport toproject site. Off loading is the responsibility of the client.Site Installation ProcedureSite assembly instructions are available from theKingspan Technical Design Bureau.KS500/1000 <strong>Kingzip</strong><strong>Product</strong> Data233

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS500/1000 Zip <strong>Roof</strong> <strong>System</strong><strong>Kingzip</strong> - Standing <strong>Seam</strong>KS500 ZIP Load Span TableUnfactored Load/Span Table (use calculated design windload values unfactored)SPAN Core Load Uniformly Distributed Loads (kN/m 2 )CONDITION Thickness Type Span L in metresmm 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0SINGLE SPAN 45 Downwards 5.29 4.23 3.48 2.92 2.49 2.15 1.87 1.52 1.22Outer sheet Suction 5.31 4.27 3.55 3.01 2.60 2.27 2.01 1.80 1.620.5mm steel 90 Downwards 5.80 5.06 4.48 4.03 3.65 3.34 3.03 2.68 2.26Inner sheet0.4 mm steelSuction 5.98 5.25 4.67 4.21 3.84 3.52 3.23 2.96 2.72Outer sheet 45 Downwards 5.80 5.06 3.96 2.99 2.30 1.80 1.42 1.12 0.890.9 mm alum. Suction 5.63 4.53 3.75 3.18 2.74 2.28 1.82 1.47 1.20Inner sheet 90 Downwards 5.80 5.06 4.48 4.03 3.65 3.20 2.66 2.22 1.870.4mm steel Suction 5.98 5.25 4.67 4.21 3.84 3.52 3.26 3.03 2.60LDOUBLE SPAN 45 Downwards 2.58 2.25 1.99 1.78 1.60 1.36 1.17 1.02 0.89Outer sheet Suction 2.25 2.00 1.80 1.59 1.36 1.18 1.05 0.94 0.860.5mm steel 90 Downwards 3.11 2.70 2.39 2.13 1.93 1.76 1.62 1.50 1.39Inner sheet0.4mm steelSuction 3.28 2.87 2.56 2.32 2.12 1.95 1.81 1.69 1.59Outer sheet 45 Downwards 3.17 2.76 2.45 2.20 1.99 1.82 1.68 1.55 1.450.9mm alum. Suction 2.76 2.44 2.20 2.02 1.86 1.74 1.63 1.54 1.46Inner sheet 90 Downwards 3.17 2.75 2.43 2.17 1.97 1.79 1.65 1.52 1.420.4mm steel Suction 2.63 2.29 2.04 1.84 1.69 1.57 1.46 1.38 1.30L LKS1000 ZIP Load Span TableUnfactored Load/Span Table (use calculated design windload values unfactored)SPAN Core Load Uniformly Distributed Loads (kN/m 2 )CONDITION Thickness Type Span L in metresmm 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0SINGLE SPAN 45 Downwards 2.97 2.40 1.99 1.68 1.44 1.25 1.09 0.92 0.72Outer sheet Suction 3.02 2.48 2.10 1.82 1.59 1.42 1.27 1.15 1.050.5mm steel 90 Downwards 4.28 3.68 3.22 2.86 2.56 2.31 2.10 1.91 1.68Inner sheet0.4mm steelSuction 4.39 3.82 3.40 3.07 2.80 2.58 2.38 2.20 2.05Outer sheet 45 Downwards 3.71 3.06 2.56 1.93 1.47 1.13 0.87 0.67 0.510.9mm alum. Suction 3.13 2.57 2.16 1.86 1.63 1.44 1.22 0.99 0.81Inner sheet 90 Downwards 4.75 4.14 3.67 3.29 2.97 2.45 2.03 1.69 1.410.4mm steel Suction 4.94 4.33 3.86 3.48 3.17 2.91 2.70 2.47 2.13LDOUBLE SPAN 45 Downwards 2.58 2.25 1.99 1.78 1.60 1.36 1.17 1.02 0.89Outer sheet Suction 2.25 2.00 1.80 1.59 1.36 1.18 1.05 0.94 0.860.5mm steel 90 Downwards 2.53 2.19 1.93 1.72 1.55 1.40 1.21 1.06 0.93Inner sheet0.4mm steelSuction 2.69 2.36 2.11 1.91 1.74 1.61 1.50 1.37 1.25Outer sheet0.9mm alum. 45 Downwards 2.58 2.25 1.99 1.78 1.60 1.36 1.17 1.02 0.89Inner sheetSuction 2.25 2.00 1.80 1.59 1.36 1.18 1.05 0.94 0.860.4mm steel90 Downwards 2.57 2.23 1.97 1.76 1.59 1.44 1.33 1.22 1.14Suction 2.10 1.82 1.62 1.47 1.35 1.25 1.18 1.11 1.05L LNotes:1. Values calculated in accordance with the ‘European Recommendations forthe Design of Sandwich Panels” written by ECCS document )TC 7 andWorking Group TWG 7.4) and modified to suit UK climate taking imposedloads, temperature and creep into account, by Professor J. Michael Davies,Manchester University.2. For each value individual and combined load cases with appropriate loadfactors and temperatures have been considered. These are detailed under“Structural Performance” in the Building Design Section.3. The table is for medium and light coloured panels, as recommended byKingspan for roof applications.4. The following deflection limits have been used:Downward loading L/200Suction loading L/1505. For intermediate values linear interpolation may be used.6. Minimum 2 No. fasteners per halter per purlin used for KS500 ZIP panel.Minimum 4 No. fasteners per halter per purlin used for KS1000 ZIP panel.7. Load span tables for panel specifications not shown are available fromthe Kingspan Technical Design Bureau.8. KS500 ZIP halter working load is 3.1kN9. KS1000 ZIP halter working load is 5.1kN234

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoKS500/1000 <strong>Kingzip</strong>Model Specifications235

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.info236

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoConstruction ApplicationStandard External and Internal EnvironmentsAluminium External / Steel Liner - LPS Grade BKS500/1000 ZIP/Zero ODP/LPCB Standing <strong>Seam</strong> <strong>Roof</strong> <strong>System</strong>Ref No: 1/5.13/LPS-BApplicationThe following specification is for the KS500/1000 ZIP/Zero ODP/LPCB certified <strong>Kingzip</strong> Insulated Standing <strong>Seam</strong> <strong>Roof</strong> Panel usedfor buildings with roof slopes of 1.5° and above and internalhumidity class environments 1-4 inclusive.KS500/1000 ZIP is Loss Prevention Certification Board (LPCB)certified to LPS 1181 Grade B.Materials & CoatingsExternal Weather SheetSubstrate to be 0.9mm thick aluminium to BS EN 485, BS EN515,BS EN1396, minimum alloy / temper 3105 H46. External to be millfinish lacquered and stucco embossed.Reverse to have RAL 7035 wash coat.Insulation CoreTo consist of 90mm thick, closed cell, with zero ozone depletion(Zero ODP) and LPCB certified polyisocyanurate (PIR) insulation.The auto adhesive properties of the core bond the external andinternal sheets together, and control the panel thickness achievedduring manufacture.Internal Liner SheetSubstrate to be 0.4mm thick hot-dip zinc coated Steel toBS EN10147: 1992.Internal coating to be Lining Enamel, 15 microns thick.Colour - White.Reverse to have a light grey polyester coating.PerformanceThermal InsulationThe panel must have a Thermal transmittance (U value) of0.25 W/m 2 K calculated using the method required by the BuildingRegulations Part L2 (England & Wales) and Building StandardsPart J (Scotland).FireThe external and internal faces of the panel to be Class 0 inaccordance with the Building Regulations when tested to BS 476:Part 6: 1989 and Part 7: 1987.The panel must be rated SAA when tested to BS 476: Part 3:1975.The system has passed all the requirements of LPS 1181: Issue 3ceiling lining test.AirtightnessOverall airtightness for complete envelope less than 10m 3 /hr/m 2at 50Pa.Seals & FillersSide JointAll side joints have a 45 x 6mm & 18 x 4mm factory applied anticondensationtapes.End LapAll external end laps to be 200mm long, and weather sealed alongthe full width with a single unbroken run of KZ2 50mm wide x3mm thickness co-laminate PVC / low temperature butyl rubbersealant, positioned 10mm back from over-lap.An additional unbroken 5mm diameter bead of Scapa Tapes noncuringmastic Grade 0100 to be gun applied across full width ofdown slope panel adjacent to flush end.End laps to be tail stitched with austenitic Grade 304 stainlesssteel low profile headed fixing screws, complete with 19mmdiameter bonded stainless steel washers.Tail stitching to be positioned 35mm up slope from end lap andfive number per panel.Fasteners to penetrate the factory applied end lap stitching platepositioned in the down slope panel at the flush end.Power seaming of end-laps only to be in downwards direction.Profiled FillersWhere flashings are fixed across the profile of the insulated panel,EPDM closed cell fillers bed in Scapa Tapes non-curing masticGrade 0100 should be used to seal and close the profile. Theflashing and filler to be supported using a KZ10A support zed.JunctionsJunctions between the roof panel system and walls / penetrationsinsulated with PIR board insulation any gaps filled with AlfasbondFR fire rated gun applied canister urethane insulation.Internal face of panel to be air sealed along the full length by anunbroken Scapa Tape 6mm diameter butyl rubber sealant tape.FastenersHalter ClipThe panel is fastened to each purlin using the KS1-90 stainlesssteel halter clip with EPDM thermal break pad at each standingseam side joint.PrimaryAll primary fasteners must be manufactured from austenitic Grade304 stainless steel and be a minimum 5.5mm diameter. Minimumof 2 fasteners per halter per panel seam to be used.To comply with the requirements of BS 6399: Part 2:1997, it maybe necessary to provide additional fixings at the side profile of thepanel in areas of high local suction.To verges, hips and other areas where a halter clip cannot alwaysbe fitted to the seam, primary fasteners to be used behind sealedflashings and to be high-threaded type manufactured fromaustenitic Grade 304 stainless steel and fitted with a 19mmdiameter bonded stainless steel washer.Where purlins are of a thickness less than 1.5mm,Kingspan Technical Design Bureau should be contacted.SecondaryFlashings to be stitched at 400mm centres (maximum) withstainless steel low profile headed stitching screws complete with14mm diameter bonded stainless steel washers.KS500/1000 <strong>Kingzip</strong>Model Specifications237

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoConstruction ApplicationStandard External and Internal EnvironmentsAluminium External / Steel Liner - LPS Grade BKS500/1000 ZIP/Zero ODP/LPCB Standing <strong>Seam</strong> <strong>Roof</strong> <strong>System</strong>Ref No: 1/5.13/LPS-B220C - Fasteners• Manufacturer:SFS Intec Ltd, tel. 0113 208 5500Ejot Ecofast Ltd, tel. 0113 247 0880• Halter fasteners:Self drilling, self tapping screws.Type(s), size(s) and drilling capacity: As re-commended byfastener manufacturer to suit type and thickness of supports,and thickness of cladding panels.Screw material: Grade 304 austenitic stainless steel.Washer material: Grade 304 austenitic stainless steel.Heads: Not coloured• End lap stitchers: Self drilling, self tapping screws with bondedwashers.Screw material: As primary fasteners.• Secondary fasteners: Stitching screws with bonded washers.Screw/washer material: As primary fasteners.Washer size: 19mm diameter.Heads: Coloured plastic heads.• Flashing fasteners: Stitching screws with bonded washers.Screw/washer material: As primary fasteners.Washer size: 14mm diameter.Heads: Low profiled heads to match colour of the flashing.223 - Prevention of Electrolytic Action• Isolating tape: PVC• Location: To contact surfaces of supports and sheets ofdissimilar metals.275 - Continuity Thermal Insulation• Junctions between the roof panel system andwalls/penetrations insulated with PIR board insulation any gapsfilled with Alfasbond FR fire rated gun applied canister urethaneinsulation.• Placement: Secure and continuous with cladding/coveringinsulation.310A - Purpose Made Cold Formed Metal Accessories -External• Drawing reference(s): _________• Material/finish: As external face of cladding.Thickness: 0.9mmColour: To match external face of cladding.Workmanship as section Z11.• Fixing: Stitch to external face of panels at 400mm centresusing secondary fasteners as specified for the claddingsystem. Only one flashing end to be stitched to butt strap anda 3mm gap should be left between flashing ends.• Sealing: Single line of 20mm x 3mm Scapa Tapes, Ref: 0311butyl rubber, site applied between flashing and panel.311A - Purpose Made Cold Formed Metal Accessories -Internal• Drawing reference(s): _________• Material/finish: As internal face of cladding.Thickness: 0.4 mmColour: White.Workmanship as section Z11.• Fixing: Stitch to internal face of panels at 450mm centresusing secondary fasteners as specified for the claddingsystem.• Sealing: Single line of 6mm diameter Scapa Tapes, Ref: 0311butyl rubber, site applied between flashing and panel.• End laps to be air sealed with Vapourflex or gun-grade sealant.300A - Profiled Fillers• Drawing reference(s): _________• Manufacturer and reference: Hartington Conway 0825, typeto suit cladding profile.Material: EPDM foam.Colour: Black.• Fixing: Seal the top, bottom and sides of each profiled fillerwith a single line of 12mm x 1mm Scapa Tapes Ref: 0311sealant tape or non-setting gun-grade, Scapa Tapes Ref: 0100.• Locate where shown on drawings and wherever necessary toclose off corrugation cavities from the inside and outside of thebuilding. Ensure a tight fit and leave no gaps.240

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoConstruction ApplicationStandard External and Internal EnvironmentsAluminium External / Steel Liner - LPS Grade BKS500/1000 ZIP/Zero ODP/LPCB Standing <strong>Seam</strong> <strong>Roof</strong> <strong>System</strong>Ref No: 1/5.13/LPS-<strong>BD</strong>etail 1 - Side LapDetail 2 - End Lap200mm end lapHalter35mmHalterTail stitcherGun-grade sealantHalter fasteners50mm x 3mmco-laminate endlap sealantFactory fitted plateGun-grade sealantKS500/1000 <strong>Kingzip</strong>Model SpecificationsDetail 3 - Fastener LocationsNote: For curved end lap details contact Kingspan Technical Design Bureau.Detail 4 - Ridge DetailRidge supportHalter at side jointShroud over profiled fillerRidge panels turned up on site prior to fittingRidge flashing75mm66mmAir seal - 8mm Ø butyl rubber sealantSite applied Alfasbond fire rated(FR) canister insulationEPDM ridge fillerAir seal - 8mm Ø butyl rubber sealantLiner flashing with 150mmend-laps and sealed with241

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoFastener Selector GuideEJOT Ecofast Fasteners<strong>Product</strong>: Aluminium - KS500/1000 ZIP Standing <strong>Seam</strong> <strong>Roof</strong> <strong>System</strong>CoreAustenitic Stainless Steel FastenersPurlinThickness(All Building Classifications)Frequency Per ClipType &Thickness (mm) Hexagonal Head KS500 ZIP KS1000 ZIPCold Rolled 45 JT3-3 6.3x50 2 31.5-3mm90 JT3-3 6.3x50 2 3Hot Rolled 45 JT3-12 5.5x67 2 24-12mm90 JT3-12 5.5x67 2 2Timber 45 JT3-2 6.5x80 2 2*90 JT3-2 6.5x80 2 2**Only 2 fasteners can be used into timber and the working pullout value of the fastener from timber may dictate the span of the panel rather than the load-span table.The cladding contractor should check this with the fastener supplier.End lap stitching fastenersJT3-FR6 5.5x35 S19 5 per end lap 10 per end lapStitcher fasteners for steel flashings, shrouds etcJT3-FR-2H 4.8x19 S14Stitcher fasteners for aluminium flashings, shrouds etcJT3-FR-2H 6.3x25 S16SFS Intec Fasteners<strong>Product</strong>: Aluminium - KS500/1000 ZIP Standing <strong>Seam</strong> <strong>Roof</strong> <strong>System</strong>PurlinType &ThicknessCoreAustenitic Stainless Steel FastenersThickness(All Building Classifications)Frequency Per Clip(mm) Hexagonal Head KS500 ZIP KS1000 ZIPCold Rolled 45 SX3/20-5,5x50 Less than 1.8mm = 3 Less than 1.8mm = 41.5-3mm90 SX3/20-5,5x50 Over 1.8mm = 2 Over 1.8mm = 3Hot Rolled 45 SX14/38-5,5x61 2 24-14mm90 SX14/38-5,5x61 2 2Timber 45 TDA-S-6,5x76 2 2*90 TDA-S-6,5x76 2 2*Pre-drill 4mm pilot hole in panel/timber*Only 2 fasteners can be used into timber and the working pullout value of the fastener from timber may dictate the span of the panel rather than the load-span table.The cladding contractor should check this with the fastener supplier.End lap stitching fastenersSX3/15-L12-S19-5.5x38 5 per end lap 10 per end lapStitcher fasteners for steel and aluminium flashings, shrouds etcSXL2-L12-A14-5,5x22 (x colour)Irius head (powder coated where applicable)242

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoFastener Selector GuideMAGE Fasteners<strong>Product</strong>: Aluminium - KS500/1000 ZIP Standing <strong>Seam</strong> <strong>Roof</strong> <strong>System</strong>PurlinType &ThicknessCoreAustenitic Stainless Steel FastenersThickness(All Building Classifications)Frequency Per Clip(mm) Hexagonal Head KS500 ZIP KS1000 ZIPCold Rolled 45 7516/63/047/E 2 31.5-1.9mm90 7516/63/047/E 2 3Cold Rolled 45 7517/63/047/E 2 32-2.5mm90 7517/63/047/E 2 3Hot Rolled 45 7530/55/062/E 2 24-12.5mm90 7530/55/062/E 2 2KS500/1000 <strong>Kingzip</strong>Fastener SelectionTimber 45 7571/55/070/E 2 2*90 7571/55/070/E 2 2**Only 2 fasteners can be used into timber and the working pullout value of the fastener from timber may dictate the span of the panel rather than the load-span table.The contractor should check this with the fastener supplier.End lap stitching fastenersStitcher fasteners for steel flashings, shrouds etc7140/48/020/E/S14Stitcher fasteners for aluminium flashings, shrouds etc7140/63/022/E/S167110/55/038/E/S19 5 per end lap 10 per end lap• The load span tables for the <strong>Kingzip</strong> insulated standing seam roof panel system are generally dictated by the structural performance of the halters which have a working load of1) 3.1kN for the KS500 <strong>Kingzip</strong> panel and2) 5.1kN for the KS1000 <strong>Kingzip</strong> panel.• The fastener quantities above are minimum and are to be used as broad guidelines only. With the <strong>Kingzip</strong> panel, (as with any other panel), design suction loads on the roof cladding should becalculated and issued by the Project Engineer. The uplift load can then be calculated for the purlin spacing and applied to the individual halter. This calculation will give the required quantity offasteners per halter. The design suction loads to local areas of roof such as verges, ridge and eaves can be considerably more than general areas and must also be checked against thefastener arrangement.• Individual fastener performance values can be obtained from the fastener supplier. Note that when talking directly to a fastener supplier a customer should be aware that the supplier may/willbe talking about a fastener’s ultimate structural characteristic performance and not the working load which will be half of the ultimate as recommended in BS 5427: Part 1: 1996 Annex B.• Thinner purlins may mean lower fastener pull-out values from the purlins under wind uplift. This may then require the use of additional fasteners. The fastener pull-out values could actuallydictate closer purlin spacings than usual. With purlins of thickness less than 1.5mm, please contact the Kingspan Technical Design Bureau at the earliest opportunity.• Note that there will be instances where an alternative fastener or pre-drilling will be required, for example, where a gutter wing rests over a purlin. Please contact the fastener supplier for advice.Contact for further advice: Kingspan Technical Design Bureau on Tel: 01352 716101, Fax: 01352 716111243

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.info244

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoSide & End Lap DetailsSide Lap DetailKS 500 Zip End Lap - Fastener Locations500mm cover widthHalter fasteners:KS500 ZIP 2 fastenersKS1000 ZIP 3 fasteners(minimum)Locations forend lap screwsthrough endlap intostitching plateKS500/1000 <strong>Kingzip</strong>Construction DetailsKS500 Halter200mm end lapKS500 Halter35mmTail stitcherGun-grade sealant50mm x 3mmco-laminate endlap sealantGun-grade sealantFactory fitted plate245

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoEnd Lap DetailsKS1000 Zip End Lap - Fastener Locations1000mm cover width500mmKS 1000 Zip End Lap DetailKS1000 HalterNote: KS1000 halter onlyused at intermediatepurlin positions. UseKS500 halter at eaves,ridge hips etc.35mm200mm end lapKS1000 HalterTail stitcherGun-grade sealant50mm x 3mmco-laminate endlap sealantGun-grade sealantFactory fitted plateRidge Detail* Ridge supportHalter at side joint# Shroud over profiled filler.Shroud stitched to each panelwith sealed stitching screwsRidge panels turned up on site prior to fittingRidge flashing stitched toshroud @ max 400mm c/csand bed on 20mm x 3mmbutyl rubber sealant75mm66mmAir seal - 8mm Ø butyl rubber sealantor 8mm bead of gun-grade sealantSite applied Alfasbond firerated (FR) canister insulationEPDM ridge filler: KZ3-500 for 500 wide panelKZ3-1000 for 1000 wide panel bed in 5mm(generous) bead of Scapa Tapes, Ref: 0100non-curing mastic ensuring no visiblegaps between panel profile and fillerAir seal - 8mm Ø butyl rubber sealantor 8mm bead of gun-grade sealantLiner flashing with 150mmend-laps and sealed withBuilding Regulations Part L2 Thermal Datafmin = 0.97 Y = 0.004 W/mKThe above values are only applicable to the components on this detail. Changesto the components will have an effect on the given values.* KZ20-1000S: 1000 wide steel ridge supportKZ20-1000A: 1000 wide aluminium ridge supportKZ20-1000S: 500 wide steel ridge supportKZ20-1000A: 500 wide aluminium ridge support#KZ4-1000S: 1000 wide steel shroudKZ4-1000A: 1000 wide aluminium shroudKZ4-500S: 500 wide steel shroudKZ4-500A: 500 wide aluminium shroud246

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoVerge DetailsVerge Detail - StartPIR board insulation withAlfasbond fire rated (FR) canisterapplied insulation to fill any gaps ifrequired to maintain continuity ofinsulationVerge flashing with 150mmsealed butt strapsNote: for aluminium flashingsallow for expansion/movement# Flashing max unstiffened legwidth 250mmDirection of lay75mmFix flashings at max 400mm centres20 x 3mm butyl rubber sealantAir seal - 8mm Ø butyl rubber sealant or 8mm bead of gun-grade sealantKS1000 ZIP insulated roof panelAir seal - 6mm Ø butyl rubber sealant4mm Ø butyl rubber sealantKS1000 MR/LPCB horizontally laidPurlinCleader angle by steel sub-contractor withair seal Vapourflex sealant applied at jointsKS500/1000 <strong>Kingzip</strong>Construction DetailsBuilding Regulations Part L2 Thermal Datafmin = 0.96 Y = 0.01 W/mKThe above values are only applicable to the components on this detail.Changes to the components will have an effect on the given values.Verge Detail - EndDirection of layFix flashings at max 400mm centres20 x 3mm butyl rubber sealantAir seal - 8mm Ø butyl rubber sealant or 8mm bead of gun-grade sealantKS1000 ZIP insulated roof panel20 x 3mm butyl rubber sealantPIR board insulation with Alfasbond firerated (FR) canister applied insulation tofill any gaps if required to maintaincontinuity of insulationVerge flashing with 150mmsealed butt strapsNote: for aluminium flashingsallow for expansion/movement.# Flashing max unstiffenedleg width 250mmAir seal - 6mm Ø bead of gun-grade sealantPurlin4mm Ø butyl rubber sealantCleader angle by steel sub-contractor withair seal Vapourflex sealant applied at jointsBuilding Regulations Part L2 Thermal Datafmin = 0.97 Y = 0.01 W/mKThe above values are only applicable to the components on this detail.Changes to the components will have an effect on the given values.KS1000 MR/LPCB horizontally laid247

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoEaves DetailsExternal Gutter20 x 3mm butyl rubber sealant under gutter support600mm long gutter support armfixed over panel crown and alsoto middle of panel cover widthwith KS1000 ZIP100mmSite applied Alfasbond fire rated (FR) canister insulationTop sheetturned downon site withroof pitchbelow 4˚Joint fillerbed in ScapaTapes 0100grade noncuringmasticAir seal - 8mm Ø butyl rubber sealantor 8mm bead of gun-grade sealantAir seal - 6mm Ø bead ofgun-grade sealantLiner side joint locallysealed with ScapaTapes 0100 gradenon-curing mastic35mmEaves beamKS1000 MR/LPCB horizontally laidBuilding Regulations Part L2 Thermal Datafmin = 0.95 Y = 0.13 W/mKThe above values are only applicable to the components on this detail.Changes to the components will have an effect on the given values.Parapet Detail - Boundary Wall GutterPIR insulation boardParapet flashing with 150mm sealed butt strapsSite applied Alfasbond fire rated (FR) canister insulationAWP filler bed in Scapa Tapes 0100 grade non-curing masticAir seal - 6mm Ønominal gungradesealantKS1000 MR/LPCB vertically laidAir seal - 6mm Ø nominal gun-grade sealantKZ12-90 EPDM joint filler tosuit KS500/1000 Zip 90mmpanel at eaves/gutterKS1000 MR/LPCBhorizontally laid100mmLiner side joint locally sealedwith Scapa Tapes 0100grade non-curing mastic60mm2mm external non-thermallybroken factory made gutterwith PIR insulation to 0.25or 0.35 W/m 2 K U-valueHalter at side jointAir seal - 8mm Ø butylrubber sealant or 8mm beadof gun-grade sealantBuilding Regulations Part L2 Thermal Data0.25 W/m 2 K gutter fmin = 0.74 Y = 1.33 W/mK0.35 W/m 2 K gutter fmin = 0.71 Y = 1.18 W/mK0.35 sole width 300mm and depth 150mm, values for other widths availableon request. The above values are only applicable to the components on thisdetail. Changes to the components will have an effect on the given values.248

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoHip DetailsHip DetailHip shroud over raking filler. Shroud supplied in 3 metre lengths andnotched neatly on site to panel upstands. Shroud stitched to everyother mini-rib of panel with sealed stainless steel stitching screwsSkewed EPDM raking fillersto suit pitch and angle of hip.Filler bed in 5mm (generous)bead of Scapa Tapes, Ref:0100 non-curing mastic,ensuring no visible gapsbetween panel profile and fillerHip supportHip panels foam routed out andturned up on site prior to fittingWhere necessary (e.g. at bottom panelrake) a stainless steel high threadedfastener with 19mm Ø washer to be usedHip flashing stitched to shroud atmax 400mm c/cs and bed on20mm x 3mm butyl rubber sealant75mm66mmKS500/1000 <strong>Kingzip</strong>Construction DetailsHalter at side jointAir seal - 8mm Øbutyl rubber sealantAlfasbond fire rated (FR)gun canister foamBuilding Regulations Part L2 Thermal Datafmin = 0.97 Y = 0.004 W/mKThe above values are only applicable to the components on this detail. Changesto the components will have an effect on the given values.Liner flashing with 150mm end lapsand sealed with Vapourflex or gungradesealantAir seal - 8mm Øbutyl rubber sealantContinuous cleader angles tohips supplied by steelworksub-contractor.Note: top leg minimum100mm bearing faceValley Gutter DetailHalter at side jointKZ19A (aluminium)or KZ19S (steel)85 x 45 angle tominimise view ofpanel foamKZ12-90 EPDMjoint filler to suitKS500/1000 Zip90mm panel ateaves/gutterAir seal - 8mm Ø butylrubber sealantFix angle to valleyof panel, typicallytwice per 500mmTop sheetturned down onsite for roofpitches below 4˚Liner side jointlocally sealed withScapa Tapes,Ref: 0100 gradenon-curing masticAir seal - 8mm Ø butylrubber sealant2mm external nonthermallybrokenfactory made gutterwith PIR insulationto 0.25 or 0.35W/m 2 K U-valueBuilding Regulations Part L2 Thermal Data0.25 W/m 2 K gutter fmin = 0.74 Y = 1.07 W/mK0.35 W/m 2 K gutter fmin = 0.71 Y = 1.38 W/mK0.35 sole width 300mm and depth 150mm, values for other widths availableon request. The above values are only applicable to the components on thisdetail. Changes to the components will have an effect on the given values.249

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoBarrel Vault DetailsBarrel Vault <strong>Roof</strong>light Detail - Panel to <strong>Roof</strong>lightUpstand flashing stitchedto shroud at max 400mmcentres and bed on 20mmx 3mm butyl rubber sealantBarrel or multivault rooflightKerb supporting rooflight jambKZ4 shroud over KZ3profiled filler. Shroud stitchedto each pan of panel withsealed stitching screws.EPDM ridge filler:KZ3-500 for 500 wide panelKZ3-1000 for 1000 wide panelbed in 5mm (generous) bead ofScapa Tapes, Ref: 0100 non-curingmastic ensuring no visible gapsbetween panel profile and filler<strong>Roof</strong>light profile filler<strong>Roof</strong>light integral profile fillerAir seal - 8mm Øbutyl rubber sealantDouble-skin in-plane rooflight *Profiled filler bed in mastic closing offunderside of rooflight profile* One metre cover width in-plane rooflight is a different profile to the <strong>Kingzip</strong> panel. The KS500 Zip panel therefore would need central side-joint crown removed on site atend-lap with in-plane rooflightBarrel Vault <strong>Roof</strong>light Detail - Side LapsAlfas C sealcompressed 80%Single skin GRP multivault or barrel vault weather sheet2No. stainless steelfixings per corrugation20mm x 3mm butylrubber sealant66mm75mmMinimum 6 No. stainless steelprimary fixings at all purlinpositions. 2 No. throughweather sheet supportbedded on 2 runs of 9mm x3mm butyl mastic sealant2 runs of 9mm x 3mmbutyl rubber sealantDouble-skin GRP rooflightwith factory applied vapourcheck seals250

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoBarrel Vault DetailBarrel Vault <strong>Roof</strong>light Detail - <strong>Roof</strong>light to PanelAngle flashing support to soaker<strong>Roof</strong>light profile fillerKZ4 shroud<strong>Roof</strong>light integral profile fillerSite applied soakerKerb supporting rooflight jambProfiled filler bed in mastic closingoff underside of rooflight profileAir seal - 8mm Øbutyl rubber sealantPanel upstands notched awayto allow drainage around headof rooflight upstandKS500/1000 <strong>Kingzip</strong>Construction Details251

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoPenetration DetailAluminium OptionTypical air extractor unitSealed washered fastenerThermal break20mm x 3mm butyl rubber sealantAluminium upstand150mmminOn site weldAir seal - 8mm Ø butyl rubber sealantGalvanised support kerbSite inserted aluminiumheat barrier plateAir seal - 8mm Ø butyl rubber sealantPIR insulation boardInsulated Flue PenetrationInsulated flue and sealed cowlby others at eaves/gutterSite applied soakerGun applied neutralcure silicone sealantStanding seam notchedon site if necessaryAir seal - 8mm Øbutyl rubber sealantCoated steel closureAir seal - 8mm Øbutyl rubber sealantTrimmingsteelwork maybe required tobe checkedwith Aperture252

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.infoCurved <strong>Roof</strong> Panel DetailsKS500 Curved <strong>Roof</strong> - End Lap DetailGenerous (approx 5mm Ø bead) gunapplication on site of Scapa Tapes, Ref: 0100non-curing sealant to rounded part of upstandensuring the bead meets the KZ2 seal200mm end lap35mm10mm 10mmGenerous (approx 5mm Ø bead) gun application on siteof Scapa Tapes, Ref: 0100 non-curing sealant to roundedpart of upstand ensuring the bead meets the KZ2 sealHalter at side jointKingspan KZ2 50 x 3mm co-laminatePVC/low temperature butyl end-lap seal,site applied, ensuring seal is pushed intoall profiles (with grey PVC face-up).Seal taken up upstands and stoppedat round part of keyhole profileLow profile headed fastener with 19mm Ø stainless steel washer.Fastener to be stainless steel for aluminium panels/coastal or extendedwarranty requirements. Thread type to suit end lap plate. One fixing pertrough i.e 5 fixings per panel end lapKS1000 Curved <strong>Roof</strong> - End Lap DetailGenerous (approx 5mm Ø bead) gunapplication on site of Scapa Tapes, Ref: 0100non-curing sealant to rounded part of upstandensuring the bead meets the KZ2 seal200mm end lap35mm10mm 10mm10 x 150 x 10 x 1.6mm thick galvanised steelextension channel to give greater bearing forcurved roof end lap tolerances accumulationNominal bearing top panel 50mmFactory fitted end lap plateGenerous (approx 5mm Ø bead) gun application on siteof Scapa Tapes, Ref: 0100 non-curing sealant to roundedpart of upstand ensuring the bead meets the KZ2 sealHalter at side jointKS500/1000 <strong>Kingzip</strong>Construction DetailsKingspan KZ2 50 x 3mm co-laminatePVC/low temperature butyl end lap seal,site applied, ensuring seal is pushed intoall profiles (with grey PVC face-up).Seal taken up upstands and stoppedat round part of keyhole profileLow profile headed fastener with 19mm Ø stainless steel washer. Fastenerto be stainless steel for aluminium panels/coastal or extended warrantyrequirements. Thread type to suit end lap plate. One fixing per troughi.e 10 fixings per end lap10 x 150 x 10 x 1.6mm thick galvanised steelextension channel to give greater bearing forcurved roof tolerances accumulationNominal bearing top panel 50mmFactory fitted end lap plateCurved <strong>Roof</strong> Panel Layout SequencePanel length (L)Ridge panel with end lapat each panel endDownslopeUpslopePanel 2(Crown)Lap angle minimum1.5˚ after deflectionsPanel 1(Eaves)Panel 3(Eaves)Building width of between 70m to 100m approx.Minimum 150m radius (R)253

For more information on Kingspan Insulated Panels visit www.barbourproductsearch.info254