DR4500A Truline HTST, STLR, and Pasteurization Flow ... - Honeywell

DR4500A Truline HTST, STLR, and Pasteurization Flow ... - Honeywell

DR4500A Truline HTST, STLR, and Pasteurization Flow ... - Honeywell

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

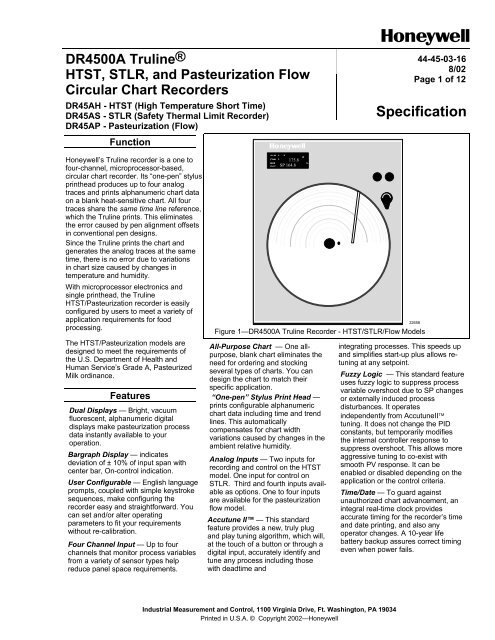

<strong>DR4500A</strong> <strong>Truline</strong>®<strong>HTST</strong>, <strong>STLR</strong>, <strong>and</strong> <strong>Pasteurization</strong> <strong>Flow</strong>Circular Chart RecordersDR45AH - <strong>HTST</strong> (High Temperature Short Time)DR45AS - <strong>STLR</strong> (Safety Thermal Limit Recorder)DR45AP - <strong>Pasteurization</strong> (<strong>Flow</strong>)Function44-45-03-168/02Page 1 of 12Specification<strong>Honeywell</strong>’s <strong>Truline</strong> recorder is a one tofour-channel, microprocessor-based,circular chart recorder. Its “one-pen” stylusprinthead produces up to four analogtraces <strong>and</strong> prints alphanumeric chart dataon a blank heat-sensitive chart. All fourtraces share the same time line reference,which the <strong>Truline</strong> prints. This eliminatesthe error caused by pen alignment offsetsin conventional pen designs.Since the <strong>Truline</strong> prints the chart <strong>and</strong>generates the analog traces at the sametime, there is no error due to variationsin chart size caused by changes intemperature <strong>and</strong> humidity.With microprocessor electronics <strong>and</strong>single printhead, the <strong>Truline</strong><strong>HTST</strong>/<strong>Pasteurization</strong> recorder is easilyconfigured by users to meet a variety ofapplication requirements for foodprocessing.The <strong>HTST</strong>/<strong>Pasteurization</strong> models aredesigned to meet the requirements ofthe U.S. Department of Health <strong>and</strong>Human Service’s Grade A, PasteurizedMilk ordinance.FeaturesDual Displays — Bright, vacuumfluorescent, alphanumeric digitaldisplays make pasteurization processdata instantly available to youroperation.Bargraph Display — indicatesdeviation of ± 10% of input span withcenter bar, On-control indication.User Configurable — English languageprompts, coupled with simple keystrokesequences, make configuring therecorder easy <strong>and</strong> straightforward. Youcan set <strong>and</strong>/or alter operatingparameters to fit your requirementswithout re-calibration.Four Channel Input — Up to fourchannels that monitor process variablesfrom a variety of sensor types helpreduce panel space requirements.ALMCHNRSPOUT22F175.8SP 164.8A%22658Figure 1—<strong>DR4500A</strong> <strong>Truline</strong> Recorder - <strong>HTST</strong>/<strong>STLR</strong>/<strong>Flow</strong> ModelsAll-Purpose Chart — One allpurpose,blank chart eliminates theneed for ordering <strong>and</strong> stockingseveral types of charts. You c<strong>and</strong>esign the chart to match theirspecific application.“One-pen” Stylus Print Head —prints configurable alphanumericchart data including time <strong>and</strong> trendlines. This automaticallycompensates for chart widthvariations caused by changes in theambient relative humidity.Analog Inputs — Two inputs forrecording <strong>and</strong> control on the <strong>HTST</strong>model. One input for control on<strong>STLR</strong>. Third <strong>and</strong> fourth inputs availableas options. One to four inputsare available for the pasteurizationflow model.Accutune II — This st<strong>and</strong>ardfeature provides a new, truly plug<strong>and</strong> play tuning algorithm, which will,at the touch of a button or through adigital input, accurately identify <strong>and</strong>tune any process including thosewith deadtime <strong>and</strong>integrating processes. This speeds up<strong>and</strong> simplifies start-up plus allows retuningat any setpoint.Fuzzy Logic — This st<strong>and</strong>ard featureuses fuzzy logic to suppress processvariable overshoot due to SP changesor externally induced processdisturbances. It operatesindependently from AccutuneIItuning. It does not change the PIDconstants, but temporarily modifiesthe internal controller response tosuppress overshoot. This allows moreaggressive tuning to co-exist withsmooth PV response. It can beenabled or disabled depending on theapplication or the control criteria.Time/Date — To guard againstunauthorized chart advancement, anintegral real-time clock providesaccurate timing for the recorder’s time<strong>and</strong> date printing, <strong>and</strong> also anyoperator changes. A 10-year lifebattery backup assures correct timingeven when power fails.Industrial Measurement <strong>and</strong> Control, 1100 Virginia Drive, Ft. Washington, PA 19034Printed in U.S.A. © Copyright 2002—<strong>Honeywell</strong>

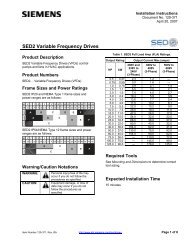

44-45-03-16Page 2Features, continuedControl Output — Versatile PID controllerlets you configure the exactcontrol action (3-mode or on-off)needed to control:• Hot Water Loop (<strong>HTST</strong>) <strong>and</strong> <strong>Flow</strong>Diversion Valve position (<strong>HTST</strong> <strong>and</strong><strong>STLR</strong>)• <strong>Flow</strong> Rate <strong>and</strong> <strong>Flow</strong> Diversion Valveposition (<strong>Pasteurization</strong>)Diversion Valve Position Indication- <strong>HTST</strong> <strong>and</strong> <strong>STLR</strong> (Optional on <strong>Flow</strong>Version) Red <strong>and</strong> Green lights, visiblethrough the door, indicate flowdiversion valve position. Red indicatesflow diversion; while greenindicates forward flow.A digital input activates a frequencypen that records the valve position onthe outer portion of the chart.Dual Setpoint Diversion —- usingthe Digital Input capability, theDR45AH model can be set up toswitch between two specific setpoints<strong>and</strong> to record the set-point change onthe chart.External InterfaceSelections• Digital Input — Activates the penthat records the divert valve positionon the chart.• Auxiliary Output — there is also a4 to 20 mA current output available.It can be used to retransmit aprocess variable. In addition, the4-20 outputs on the control boardcan be used as an auxiliary output ifnot used for control.Options• Third <strong>and</strong> Fourth Input - Used formonitoring additional process variablessuch as Cold Milk Temperatureor other temperatures.When Digital Reference temperaturemeasurement at the divertvalve is selected, Input 1 is theDigital Reference <strong>and</strong> Input 3, ifenabled, becomes the Hot Watertemperature input.• Door Options — Choice of gray,black or blue doors with st<strong>and</strong>ardlatch or optional lock. Heavy dutyStainless Steel doors availableALMCHNRSPOUT1 FX HR %CHRT SPAFUNCSETUPLOWRDISPMANAUTO CHARTRUNHOLDFigure 2—Operator interface includes displays <strong>and</strong> keypad for comprehensiveinteraction with the recorder <strong>and</strong> the process.Options, continued• Configuration Lockout Switch —This security switch limits access toconfiguration parameters, includingthe Hot Milk Diversion Setpoint, sothat they may not be changedwithout detection.• CE Mark — Conformity with73/23/EEC, Low Voltage Directive<strong>and</strong> 89/336/EEC EMC Directive.• Approval Body Options — FMapproval, CSA certification <strong>and</strong> ULListing or a combination is availableoptions.• Customer ID Tag — (30 charactersmax.)User ConfigurableIn the <strong>DR4500A</strong> Series recorder,microprocessor control replacesconventional electro-mechanicalrecording techniques. This means thatits software now primarily determinesthe recorder's capabilities.Since <strong>Honeywell</strong> has preprogrammeda variety of functional capabilities intothe recorder, you only have toconfigure those functions that arespecific for the given application. Youconfigure the recorder by followingEnglish language prompts that appearin the digital displays.The configuration data (type of input,chart speed, chart range, alarmsettings, tuning constants, etc.) arestored in nonvolatile memory for safekeeping in the event of a powerfailure.Operator InterfaceTwo digital displays (Figure 2) presentthe process variable (PV) value <strong>and</strong> bykey selection, the controller set point;controller output; deviation fromreference input; or engineering unitsas desired. The lower display can beset to scroll or hold.20951When the optional inputs formeasuring the temperature at thedivert valve is active, the lower displayindicates the temperature beingmeasured at the divert valve as thedefault value. In configuration mode,digital displays are pre-empted byEnglish language prompts <strong>and</strong> valuesthat you use to enter configurationdata.Indicators light to show alarmconditions, which channel PV is ondisplay, use of remote set point,which output relay is on, selectedtemperature unit, <strong>and</strong> controller’smode of operation.A deviation bargraph lets operators tellat a glance if the process variable isat, above, or below the controller’ssetpoint. The keypad through whichconfiguration data is entered alsoserves as an integralautomatic/manual station that providesbumpless transfer for controllers.Recording <strong>and</strong> PrintingBoth the chart <strong>and</strong> the printhead aredriven by the stepper motors, whichare controlled by the microprocessorallowing precise maintenance freeoperation.Since chart speed is configurable, youcan easily alter the chart speedthrough the keypad. Gear changing oradditional motors are no longerrequired.The microprocessor uses the configuredchart range data as well as theinput data to determine the properprinthead position. The stepper motoraccurately positions the printheaddrive.

44-45-03-16Page 3Recording <strong>and</strong> Printing,continuedBy using a “one-pen” printhead that iscapable of printing alphanumericcharacters, you can now set various“printed” chart data through configuration.This means that such chartdata as range marking in engineeringunits, digital values for processvariables, <strong>and</strong> trace identification areeasily personalized for the application.This data, plus printed time lines <strong>and</strong>engineering units of scale eliminatethe need to maintain an inventory of avariety of preprinted charts.The <strong>Truline</strong> recorder uses a dot filltechnique from a microprocessoralgorithm to produce a continuousanalog trace of a process variable.Digital ControllerThe <strong>DR4500A</strong> Series recordercontroller includes an integralmicroprocessor-based, one or twoloop, PID controller. The recordercontroller produces a 4–20mA outputfor controlling the Hot Water loop or<strong>Flow</strong> <strong>and</strong> on-off relay output for thedivert valve.As with the record functions, Englishlanguage prompts quickly guide youthrough the entry of all the controller’sconfigurable parameters.A second optional control output isavailable to control system backpressure on the DR45AP version.In addition to this, a high pressure limitoutput can be set.DiagnosticsAll <strong>DR4500A</strong> Series recorders includeself-diagnostic systems that checkcritical operations <strong>and</strong> provide errormessages to alert you about detectedfaults.Power-up self-diagnostics is amicroprocessor controlled diagnosticprogram that runs tests on selectedcircuitry when the recorder is poweredup. A “key” test allows you to initiate,on dem<strong>and</strong>, a self-diagnostic routinethat checks the keypad <strong>and</strong> frontpanel displays.Process InterfacePower, input, <strong>and</strong> output wiringconnect to terminations inside thecase. Knockouts in the sides <strong>and</strong>bottom of the case accept conduitconnections for convenient wire entry.ConstructionThe <strong>DR4500A</strong> Series recorder ishoused in a molded case, which canbe panel or surface mounted.Circuitry is partitioned on printedcircuit boards for ease of service.A UL <strong>and</strong> FM approved NEMA4X dooris also available.Input ProcessingThe recorder requires a 3-A approvedsanitary high-speed RTD sensor(Such as RDF Model 21345-6-E-T11/2-2) to measure hot milktemperature. Various types of sanitaryfittings <strong>and</strong> sizes available with thishighly responsive, reduced tip sensorwill meet your specific applicationrequirements.For DR45AH/AS recorders using theoptional Digital ReferenceMeasurement, a 3-A approved sanitaryhigh-speed, dual element RTDsensor (Such as RDF Model#21345(SP)-6-E-T11/2-2) orequivalent is required to measure theHot Milk Temperature <strong>and</strong> the DigitalReference Temperature.Each input is sampled at a rate of 3times per second for 1 or 2 inputs, or 3times in 2 seconds for 3 or 4 inputs.Each sample is amplified <strong>and</strong> thenconverted to a digital signal which isisolated <strong>and</strong> passed to themicroprocessor. A digital filter withconfigurable time constants lets youapply input signal smoothing asdesired. All non-linear inputs arelinearized by the microprocessor.In the unlikely event of failure, you caneasily <strong>and</strong> quickly replace theresistance bulb temperature sensor.Compliance to MilkOrdinance RegulationsDR45AH/AS/AP fully complies with thestrict regulations of the “Grade APasteurized Milk Ordinance”.Compliance features include:• Internal configuration switchThis security switch limits access toconfiguration parameters.In the switch “off” position, you canconfigure all the recorder/controllerparameters to the desired value.The “on” position locks the majorityof the configurable parameters,including hot milk diversionsetpoint, so that they may not bechanged.The only functions remaining in the“on” (locked) position are:Chart - start the chart or place it inhold.Man/Auto - You can place the hotwater temperature controller (whichcontrols the Milk temperatureindirectly) in Manual or Automaticmode as defined below:MAN - The output signal to thehot water valve is manuallycontrolled.AUTO - The setpoint for the hotwater controller is adjustable.Lowr/Disp - Lets you scroll throughthe process variable inputs,outputs, setpoints <strong>and</strong> deviationfrom setpoint.Configuration - allows changes toControl 1 <strong>and</strong> Control 2 tuningparameters plus adjustments totime/date/day/year.• Diversion Valve PositionIndicationRed <strong>and</strong> Green lights, visiblethrough the door, indicate flowdiversion valve position.Red indicates flow diversion,Green indicates forward flow.• Electronics Access ControlChart Plate sealing provisions,using a wire lead seal, preventaccess to the electronics <strong>and</strong> theinternal configuration switch.

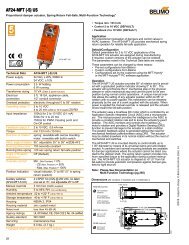

44-45-03-16Page 4Model DR45AHRecorder/ControllerOn the DR45AH recorder, the divertvalve temperature is printed on thechart when Input 1 is programmed asa Digital Reference TemperatureIndicator.When a diversion occurs, the DR45AHrecorder/controller will automaticallyprint on the chart the temperaturemeasured at the divert valve by theDigital Reference Thermometer <strong>and</strong>then, when forward flow is startedagain after the diversion, it will printthe temperature again.In addition, there are red <strong>and</strong> greenindicator lights on the front of therecorder that provide a visualindication of forward flow or flowdiversion.Milk <strong>Pasteurization</strong> ProcessFigure 3 is a flow diagram of the <strong>HTST</strong>milk pasteurization process. Milk flowsfrom the raw milk supply tank throughthe plate-type heat exchanger, whereit is heated to pasteurizationtemperature prior to entering theholding tube.The tube size ensures that the milkremains at the pasteurizationtemperature for the required time.Hot milk temperature is measured as itleaves the holding tube. If thistemperature is above the pasteurizationtemperature, the DR45AH<strong>HTST</strong> allows milk flow to proceed topackaging or storage. If the milk isbelow pasteurization temperature, theDR45AH <strong>HTST</strong> diverts it to the rawmilk tank for reprocessing.For this application, DR45AH <strong>HTST</strong>uses two analog inputs, one digitalinput, one 3-mode controller <strong>and</strong> oneon-off controller to control:• hot water flow to the plate heatexchanger• <strong>Flow</strong> diversion valve position.<strong>Pasteurization</strong> temperature controlconsists of recording the informationshown on the circular chart (Figure 4)<strong>and</strong> implementing the followingstrategies:Model DR45AHRecorder/Controller, continuedMilk <strong>Pasteurization</strong> Process , cont.1. The first analog input is hot watertemperature (if Digital ReferenceTemperature option is selected,then Input 3 is the Hot WaterTemperature) , which indirectlycontrols milk temperature in theplate heat exchanger. Thistemperature may be recorded.2. The hot milk temperature is thesecond analog input. Thistemperature is recorded.The high-precision RTD sensorprovides this temperaturemeasurement. DR45AH <strong>HTST</strong>uses 100-ohm ( α = 0.00385 )platinum bulb actuation to providehot milk temperaturemeasurement accuracy of ±0.3°F3. A switch on the flow diversionvalve provides the digital input toactivate the frequency pen thatrecords the valve position on theouter portion of the chart. The usersupplies <strong>and</strong> installs the two relaysthat connect therecorder/controller to thepasteurizer system wiring.You can also record the flow diversiontemperature setpoint without anadditional analog input.Model DR45ASSafety Thermal Limit RecorderThe DR45AS (<strong>STLR</strong>) model providesall the same features of the DR45AH<strong>HTST</strong> recorder without the integral hotwater control loop.The DR45AS model is set up to recordthe hot milk temperature as well as theflow diversion valve position <strong>and</strong> toindicate this position using red <strong>and</strong>green lights on the front of therecorder.Optionally, it can also be set up withthe integral Digital Reference feature.Model DR45APRecorder/ControllerThe DR45AP <strong>Pasteurization</strong> <strong>Flow</strong>recorder/controller can be set up tocontrol the flow rate in a pasteurizationprocess.In addition to the normal divert valvecontrol provided by high <strong>and</strong> low flowlimit setpoints, optional inputs can beset up to display <strong>and</strong> record the Raw<strong>and</strong> Pasteurized pressures in thesystem.The recorder/controller will display, inthe lower display, the system high <strong>and</strong>low pressures from independentpressure transmitters <strong>and</strong> control thesystem back pressure using thesecond control output from therecorder/controller.In addition, a high-pressure limitoutput can be set.Optional red <strong>and</strong> green lights areavailable on the front of the recorderthat provide a visual indication offorward flow or flow diversion.Milk <strong>Pasteurization</strong> ProcessThe DR45AP controls the flow rate ina pasteurization process (Figure 3).The flow is controlled from the flowinput from a pressure transmitter orMagnetic flowmeter in the constantflow line.The recorder uses PID control <strong>and</strong> a4-20mA output to control a variablespeed pump, which adjusts the flow inthe system.The differential pressure function usespressure inputs from Input 2 <strong>and</strong> Input3 to measure <strong>and</strong> display the high <strong>and</strong>low system pressures (Input 2 – Input3) <strong>and</strong> uses this value <strong>and</strong> the optionalsecond 4-20 mA control output tocontrol the system back pressure.Diverts are based on High <strong>Flow</strong> orLow <strong>Flow</strong> setpoints configured in therecorder/controller. Diversion to theRaw milk tank occurs when the flowrate is below the Low <strong>Flow</strong> setpoint orabove the High flow setpoint.There is a Time Delay that can beconfigured to occur before forwardflow will begin. The configurable rangefor this time delay is from 0 to 60seconds.continued

44-45-03-16Page 5Model DR45APRecorder/Controller, continuedMilk <strong>Pasteurization</strong> Process,continuedFor <strong>Pasteurization</strong> <strong>Flow</strong>, DR45APuses one analog input for flow, onedigital input, one three modecontroller, <strong>and</strong> one On/Off controller tocontrol:• process flow rate• flow diversion valve positionIf controlling system back-pressure,two additional analog inputs <strong>and</strong> one3-mode, 4-20 mA controller with twoadditional relay outputs is required.<strong>Pasteurization</strong> flow control consists ofrecording the information shown onthe circular chart (Figure 5) for Input 1flow <strong>and</strong> implementing the followingstrategies:3. The first analog input is Process<strong>Flow</strong>.2. Optional Inputs 2, Input 3, <strong>and</strong>Control 2 output can be set torecord the system high <strong>and</strong> lowpressure for differential pressuremeasurement <strong>and</strong> to control thesystem back pressure.<strong>Truline</strong> Pasteruization (<strong>Flow</strong>)Recorder/Controller3. A switch on the flow diversionvalve provides the digital input toactivate the frequency pen thatrecords the valve position on theouter portion of the chart. Theuser supplies <strong>and</strong> installs the tworelays that connect therecorder/controller to thepasteurizer system wiring.<strong>Truline</strong> <strong>HTST</strong>Recorder/Controller<strong>Flow</strong> Recorder OptionSystem Back PressureControl OutputVacuumBreakerOptional High<strong>Flow</strong>Alarm4–20mAOutput1Signal fromMagnetic<strong>Flow</strong>meterPasteurizedOutDivert LineHPLP<strong>Flow</strong> Recorder OptionBooster PressureDifferential SwitchRTDMilkTemp.<strong>Flow</strong>DiversionDeviceHoldingTubeSteamTemp.RTDRegenerator<strong>Flow</strong> TransmitterHeaterSectionHot Wateror Steam<strong>Flow</strong> Control ValveRecycle LineBY-PassValveMagnetic <strong>Flow</strong>meter1Signal to<strong>Flow</strong> RateRecorderRaw InBoosterPumpAC DriveCentrifugal Timing PumpConstant Level TankLEGENDPasteurized MilkRaw MilkHot Water/SteamSignalPressureFigure 3—Diagram of the Milk <strong>Pasteurization</strong> Process

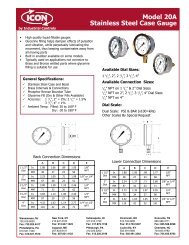

21701803120044-45-03-16Page 6RNG209/26/9413:30140 to 210 DEG F3169.8200313:00 09/26/94RNG1140 to 210 DEG F190118017019012312:30 09/26/94RNG2160169.8140 to 210 DEG F150160169.82150200190180170160150U.S.A.WEL L30755371Hot Milk(Input 2)(Pen 2)Optional HotWater Temp(Input 1 )*(Pen 1)DR45AH only* If optional DigitalReference Temperatureis selected, the Hot WaterTemperature is Input 3.EYHO N2150150160116017017021180190165.122001801165.1190140 to 210 DEG F169.811:302003RNG209/26/9412:00140 to 210 DEG FRNG109/26/94Frequency PenDivert EventMark (DigitalInput) (Pen 3)3140 to 210 DEG F11:00RNG109/26/94Optional Digital ReferenceTemp at Diversion Valve(Input 1) (Pen 1)22660Figure 4—Simulated Printed Chart – <strong>HTST</strong> Model DR45AH, <strong>STLR</strong> Model DR45AS

5.044-45-03-16Page 7Range 2 System Pressures15:00 09/27/943RNG20.0 to 50.0 PSIG140.045.0Process <strong>Flow</strong> Rate(Input 1) (Pen 1)235.0Range 1 <strong>Flow</strong> Rate30.0414:00 09/27/9425.0RNG120.00 to 100 GPM15.010.0908070605010402030U.S.A.LE L30755371N EY WHO5.05.010.0Low Pressure Input- Raw Milk Pressure(optional) (Input 3) (Pen 4)15.020.05.010.015.020.025.010.015.020.04425.030.0235.0140.045.030.0 to 50.0 PSIGRNG413:00 09/27/942Delta Pressure25.030.0130.0High Pressure Input- Pasteurized Milk Pressure(optional) (Input 2) (Pen 2)35.035.040.045.00.0 to 50.0 PSIG12:003RNG209/27/94Frequency Pen Record- Records position of<strong>Flow</strong> Diversion Valve(Digital Input) (Pen 3)22676Figure 5—Simulated Printed Chart – <strong>Flow</strong> Model DR45AP

44-45-03-16Page 8SpecificationsInput ActuationsNumber of InputsModel DR45AHTwo channel model: Two inputs St<strong>and</strong>ard (Hot Milk <strong>and</strong> Hot Water)Three channel model: Three inputs Optional (Cold Milk or Digital Reference)Four channel model: Four inputs Optional (Cold Milk or other temperature)Model DR45APOne channel model: One inputTwo channel model: Two inputsThree channel model: Three inputsFour channel model: Four inputsModel DR45ASOne channel model: One inputTwo InputSt<strong>and</strong>ardOptional (System High PressureMeasurement)Optional (System Low PressureMeasurement)OptionalSt<strong>and</strong>ard (Hot Milk)Optional Digital ReferenceInputs 2–4 OptionalModel DR45AH /AS(Default Input)Model DR45AH <strong>and</strong> <strong>STLR</strong> use a Platinum 100 ohm RTD input. (HighSpeed RTD sensors required)Types of InputActuation 1RTDs 2Platinum100 ohms*(100RH)RangeReference Accuracy˚F ˚C ± ˚F ± ˚C–130 to 392 –90 to 200 0.3 0.16 0.05Temp. Stability± Degrees Error Per 1Degree ∆TModel DR45APThe <strong>Pasteurization</strong> (<strong>Flow</strong>) model DR45AP uses a 4 to 20 mA input.(Default Input)LinearMilliamperes dc 4 to 20 —— 0.10 % —— 0.004 % /˚F1 Not all input Actuations are available on all models of the <strong>Truline</strong> recorder. Consult Model Selection Guide for information.*IEC Alpha (α) = 0.00385 Ω/Ω/˚C2 Includes reference junction calibration of ± 0.01degrees using st<strong>and</strong>ard “ice bath” method of calibration. Factory calibration at reference± 1.2˚F. Note that factory calibration may vary by as much as ± 10 microvolts or ± 0.3 ohms for RTDs which means recalibration may berequired to achieve stated accuracy.ATTENTIONWhen used as a st<strong>and</strong>ard <strong>Truline</strong> recorder, refer to Specification Sheet 44-45-03-14 foravailable input actuations <strong>and</strong> reference accuracy.

44-45-03-16Page 9Specifications, continuedDesignDigital Indication AccuracyMinimum Input SpanInput ImpedanceSource Impedance1 digitRange is fully configurable with span limitation of the operating range selected.4-20 mA dc: 250 ohms0-10 Vdc: 200K ohmsAll others: 10 MegohmsRTD: 100 ohms per lead maximumSampling Rate Each input sampled 3 times a second (1 or 2 inputs); 3 times in 2 seconds (3 or 4inputs).Input Filter Software: Single pole low pass section with selectable time constants (off to 120seconds).Controller OutputAuxiliary LinearOutput (Optional)Alarm Output• On-OffOne SPST electromechanical relay. Control action can be set for direct orreverse;N.O. or N.C. contact selectable.Relay Contact Ratings:Resistive Load: 5A @ 120 Vac, 2.5A @ 240 VacInductive Load: 50 VA @ 120 Vac or 240 Vac• Current Proportional21 mA dc maximum into a negative or positive grounded or non-grounded loadof 0 to 1000 ohms. Output range can be set between 4 <strong>and</strong> 20 mA, <strong>and</strong> asdirect or reverse action.Resolution: 10 bitsAccuracy: 0.5 % full scaleDR45AH - comes st<strong>and</strong>ard with one 4-20mA output for temperature control <strong>and</strong>ON/Off control for Divert Valve.DR45AP - comes st<strong>and</strong>ard with one 4-20mA output for <strong>Flow</strong> control <strong>and</strong> withOn/Off control for Divert Valve. There is a configurable Time Delay on the DivertValve On/Off forward flow. Also, optional 2nd 4-20mA control output for backsystem pressure control, relay output for high pressure alarming, <strong>and</strong> relay outputfor low pressure limit (Booster pump control).DR45AS - has divert valve control action, but no other control output.21 mA dc maximum into a negative or positive grounded load or non-groundedload of 0 to 1000 ohms.Output range can be set between 0 to 21 mA, <strong>and</strong> as direct or reverse action. Itcan be configured to represent any one of 10 parameters. The range of theauxiliary output, as a function of the selected variable, can be scaled. This outputcan be used as a second current output for current duplex outputs.Resolution: 12 bits over 0 to 21 mAAccuracy: 0.2 % of full scaleTemperature Stability: 0.03 % F.S./°CAlarm contact for Digital Reference Input provides ability to alarm on the differencebetween Hot Milk <strong>and</strong> Digital Reference temperature on Model DR45AH/AS.Resistive Load: 1 A @120 Vac, 1/2 A @ 240 Vac

44-45-03-16Page 10Specifications, continuedDesign, continuedDigital DisplaysVacuum fluorescent, alphanumeric.A six-digit display dedicated to the process variable.Alternate information displayed during configuration mode.An eight-digit display shows key selected operating parameters. Also providesguidance during configuration.Digital Reference Temperature or High/Low Pressure are the default valuesshown in the lower display. Hot milk temperature (Input 2) Default Display onDR45AH/AS models.Indicators Channel PV display (CHN 1, 2, 3, or 4)Alarm status (ALM 1, 2)Controller Output (OUT 1 or 2)Remote Set Point (RSP)Temperature unit (F or C) or Engineering unitsController’s mode (A or MAN)DR45AH or DR45AS - Digital Reference Temperature displayed in Lower Displayduring normal operationDR45AP - High-Low system pressure displayed in lower display during normaloperationDeviation BargraphController Modes of OperationTransmitter Supply VoltageCase/DoorChartWiring ConnectionsColorApproval Bodies21 segment, color coded deviation bargraph:Green (large) = On ControlGreen (small) = Deviation to ± 10% of PVManual OperationAutomatic with local set pointAutomatic with remote set point22 Vdc to 26 Vdc at input terminals (50 mA dc at 24 Vdc)Molded, foamed-Noryl* with gasketed door to meet NEMA 3 enclosurerequirements. Panel gasket available separately.An optional UL <strong>and</strong> FM approved NEMA4X door is also available.12-inch (304.8 mm) diameter chart. Plain thermal-sensitive paper.Chart Speed: 8 hr., 24 hr., 7 days, or selected hours per revolution.Hours per Revolution: 6 to 744 Hr.* (12 hr. for Abrasion Resistant Pen)Terminals inside the caseCase: BlackDoor (st<strong>and</strong>ard): Caribbean blue, black or GrayU.L. approval depending on model. Consult Model Selection Guide for information.FM approved for Class I, Div 2, Groups A, B, C, D areas depending on model..Dimensions See Figure 6.WeightMounting16.6 lb. (7.5 kg)Panel or surface mounted. Some adapter kits available for existing panel cutouts.OptionsMiscellaneous • Auxiliary Output• Door Lock• U.L. Listing• Customer ID Tag (30 characters maximum)• Lights on <strong>Pasteurization</strong> <strong>Flow</strong> Model DR45AP• Digital Reference Measurement58 Below 8hrs chart speed (24 hrs chart speed with abrasion resistant pen) printing may be degraded.** Registered Trademark – General Electric Co.

44-45-03-16Page 11Specifications, continuedEnvironmental <strong>and</strong> Operating ConditionsParameter Reference Rated Extreme Transport <strong>and</strong> storageAmbientTemperature67 to 77 °F19 to 25 °C58 to 131 °F15 to 55 °C32 to 131 °F0 to 55 °C–40 to 151 °F–40 to 66 °CRelativeHumidity (%RH) 0 to 55* 10 to 90* 5 to 90* 5 to 95*VibrationFrequency (Hz)Acceleration (g)000 to 700.10 to 2000.20 to 2000.5Mechanical ShockAcceleration (g)Duration (ms))Mounting Position fromVerticalTilted ForwardTilted BackwardTilted to Side (± )Power RequirementsVoltage (VRMS)Frequency (Hz)Power ConsumptionGeneral Reference DataStray RejectionStatic Charge EffectsRFI SusceptibilityLine Noise EffectsStylus LifeTechnical Assistance005˚5˚5˚119 to 121238 to 24249.8 to 50.259.8 to 60.224 watts maximum1305˚30˚10˚102 to 132204 to 26449 to 5159 to 615305˚90˚20˚102 to 132204 to 26448 to 5258 to 622030AnyAnyAnyN/AN/AN/AN/ACommon Mode Rejection Ratio: 120dB or 1 LSB (whichever is greater) at 60 Hz with maximumsource impedance of 100 ohms.Normal Mode Rejection Ratio: 60dB with a 100% span peak-to-peak maximum at 60 Hz.Exposed panel surfaces capable of withst<strong>and</strong>ing a discharge from a 250pf capacitor charged to10 KV through 100 ohms.Capable of withst<strong>and</strong>ing an EMI-field generated from a 5-watt transmitter being held at 1 meter,<strong>and</strong> operating at 151.685 <strong>and</strong> 450 MHz.Field terminals for connecting power line to recorder can withst<strong>and</strong> the IEEE Surge Withst<strong>and</strong>ingCapability Test to a level of 2.5KV.Typically capable of printing one chart per day for five years under clean room conditions.Toll-free 800 number puts technical assistance only a phone call away.FDA Compliance The <strong>Honeywell</strong> <strong>Pasteurization</strong> High Temperature Short Time (<strong>HTST</strong>) DR45AH, SafetyThermal Limit Recorder (<strong>STLR</strong>) DR45AS, <strong>and</strong> <strong>Pasteurization</strong> <strong>Flow</strong> DR45APRecorder/Controller comply with the requirements of the dairy industry set forth by the U.S.Department of Health <strong>and</strong> Human Services, Food <strong>and</strong> Drug Administration, Grade APasteurized Milk Ordinance. (1993)* The maximum rating only applies up to 104 °F (40 °C). For higher temperatures, the RH specification is derated to maintain constantmoisture content.Specifications subject to change without notice.WARRANTY/REMEDY<strong>Honeywell</strong> warrants goods of its manufacture as being free of defective materials <strong>and</strong> faulty workmanship. Contact your localsales office for warranty information. If warranted goods are returned to <strong>Honeywell</strong> during the period of coverage, <strong>Honeywell</strong>will repair or replace without charge those items it finds defective. The foregoing is Buyer's sole remedy <strong>and</strong> is in lieu of allother warranties, expressed or implied, including those of merchantability <strong>and</strong> fitness for a particular purpose.Specifications may change without notice. The information we supply is believed to be accurate <strong>and</strong> reliable as of thisprinting. However, we assume no responsibility for its use.While we provide application assistance personally, through our literature <strong>and</strong> the <strong>Honeywell</strong> web site, it is up to the customerto determine the suitability of the product in the application.

44-45-03-16Page 12Dimensions:millimetersinches17.50.69St<strong>and</strong>ard DR450032112.6Bottom viewReference20.30.832112.641916.51636.41967.737014.6Surface mounting1817.114.5Short wing latch :.57Double bit latch :5.19Left side view1064.21425.635514Front viewBack view32212.717.50.69NEMA4X DR450032112.6Reference20.30.8•• • • • ••32212.7Bottom view32112.643817.25•• Surface mounting••••••Panel cutout (all models)• • • • •1064.21425.611.0.4338715.25Front viewNEMA4XBack viewFigure 6— <strong>DR4500A</strong> series recorder dimensions - for reference onlyOrdering InformationFor complete ordering information, request Model Selection Guide 44-45-16-07 for <strong>DR4500A</strong> Series CircularChart Recorder.<strong>Honeywell</strong> offers a full line of sensors <strong>and</strong> transmitters that produce a compatible range of dc voltage orcurrent signals which can be used as inputs to the <strong>DR4500A</strong> Series Recorder.These devices measure:Temperature: (Thermocouple or RTD)Pressure<strong>Flow</strong> {4 to 20 mA dc or 1 to 5 Vdc process transmitter}Liquid LevelRelative HumidityIndustrial Measurement <strong>and</strong> Control<strong>Honeywell</strong>1100 Virginia DriveFt. Washington, PA 1903444-45-03-16 0802 Printed in USA www.honeywell.com/imc/