Universal Coating and Material Property Measurement ... - Labsys

Universal Coating and Material Property Measurement ... - Labsys

Universal Coating and Material Property Measurement ... - Labsys

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

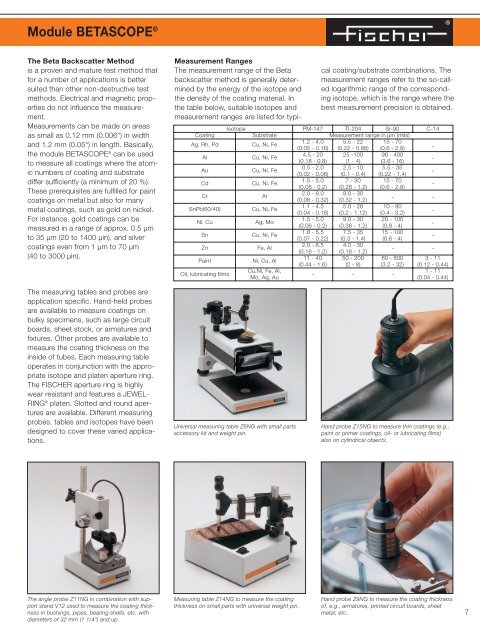

®The Beta Backscatter Methodis a proven <strong>and</strong> mature test method thatfor a number of applications is bettersuited than other non-destructive testmethods. Electrical <strong>and</strong> magnetic propertiesdo not influence the measurement.<strong>Measurement</strong>s can be made on areasas small as 0.12 mm (0.006“) in width<strong>and</strong> 1.2 mm (0.05“) in length. Basically,the module BETASCOPE ® can be usedto measure all coatings where the atomicnumbers of coating <strong>and</strong> substratediffer sufficiently (a minimum of 20 %).These prerequisites are fulfilled for paintcoatings on metal but also for manymetal coatings, such as gold on nickel.For instance, gold coatings can bemeasured in a range of approx. 0.5 µmto 35 µm (20 to 1400 µin), <strong>and</strong> silvercoatings even from 1 µm to 70 µm(40 to 3000 µin).Module BETASCOPE ® <strong>Measurement</strong> RangesThe measurement range of the Beta cal coating/substrate combinations. Thebackscatter method is generally determinedmeasurement ranges refer to the so-call-by the energy of the isotope <strong>and</strong> ed logarithmic range of the correspond-the density of the coating material. In ing isotope, which is the range where thethe table below, suitable isotopes <strong>and</strong> best measurement precision is obtained.measurement ranges are listed for typi-Isotope PM-147 Tl-204 Sr-90 C-14<strong>Coating</strong> Substrate <strong>Measurement</strong> range in µm (mils)Ag, Rh, PdCu, Ni, Fe1.2 - 4.0 5.5 - 22 15 - 70(0.05 - 0.16) (0.22 - 0.88) (0.6 - 2.8) -AlCu, Ni, Fe4.5 - 20 25 -100 90 - 400(0.18 - 0.8) (1 - 4) (3.6 - 16)-AuCu, Ni, Fe0.5 - 2.0 2.5 - 10 5.5 - 35(0.02 - 0.08) (0.1 - 0.4) (0.22 - 1.4)-CdCu, Ni, Fe1.5 - 5.0 7 - 30 15 - 70(0.06 - 0.2) (0.28 - 1.2) (0.6 - 2.8)-CrAl2.0 - 8.0 8.0 - 30(0.08 - 0.32) (0.32 - 1.2)--SnPb(60/40)Cu, Ni, Fe1.1 - 4.5 5.0 - 28 10 - 80(0.04 - 0.18) (0.2 - 1.12) (0.4 - 3.2)-Ni, CuAg, Mo1.5 - 5.0 9.0 - 30 20 - 100(0.06 - 0.2) (0.36 - 1.2) (0.8 - 4)-SnCu, Ni, Fe1.8 - 5.5 7.5 - 35 15 - 100(0.07 - 0.22) (0.3 - 1.4) (0.6 - 4)-ZnFe, Al2.0 - 6.5 4.0 - 30(0.16 - 1.2) (0.16 - 1.2)--PaintNi, Cu, Al11 - 40 50 - 200 80 - 800 3 - 11(0.44 - 1.6) (2 - 8) (3.2 - 32) (0.12 - 0.44)Oil, lubricating filmsCu,Ni, Fe, Al, 1 - 11---Mo, Ag, Au (0.04 - 0.44)7The measuring tables <strong>and</strong> probes areapplication specific. H<strong>and</strong>-held probesare available to measure coatings onbulky specimens, such as large circuitboards, sheet stock, or armatures <strong>and</strong>fixtures. Other probes are available tomeasure the coating thickness on theinside of tubes. Each measuring tableoperates in conjunction with the appropriateisotope <strong>and</strong> platen aperture ring.The FISCHER aperture ring is highlywear resistant <strong>and</strong> features a JEWEL-RING ® platen. Slotted <strong>and</strong> round aperturesare available. Different measuringprobes, tables <strong>and</strong> isotopes have beendesigned to cover these varied applications.<strong>Universal</strong> measuring table Z6NG with small partsaccessory kit <strong>and</strong> weight pin.H<strong>and</strong> probe Z15NG to measure thin coatings (e.g.,paint or primer coatings, oil- or lubricating films)also on cylindrical objects.The angle probe Z11NG in combination with supportst<strong>and</strong> V12 used to measure the coating thicknessin bushings, pipes, bearing shells, etc. withdiameters of 32 mm (1 1/4“) <strong>and</strong> up.Measuring table Z14NG to measure the coatingthickness on small parts with universal weight pin.H<strong>and</strong> probe Z9NG to measure the coating thicknessof, e.g., armatures, printed circuit boards, sheetmetal, etc..