Brochure ALMAC CU 1007 - Tornos

Brochure ALMAC CU 1007 - Tornos

Brochure ALMAC CU 1007 - Tornos

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Going for heart testsWhat the test isA cardiac catheterization (cath) is a diagnosticheart test. It is used to find out how well your heartis working and if any of the arteries feeding yourheart muscle (coronary arteries) are blocked.Getting ready• Don’t eat or drink anything for at least 6 to 8hours before the test (or as your doctor tells you).• If you take medicine (especially diabetesmedicine), check with your doctor to seewhat you should do about takingit before the test.• Tell your doctor if you:✔ take aspirin or a blood thinner(you may need to stop takingthese days before the procedure)✔ have any allergies to foods,medicines, x-ray dye or shellfish✔ are pregnant or think you might be• Find out when you should be at thehospital. Arrange for someone totake you and bring you home.Your cardiac catheterizationHow the test works• You will most likely be given medicine throughan IV in your arm to relax you.• The skin where the catheter will be inserted willbe scrubbed with a special soap.• In the cath lab, you will lie on a bed under an x-raycamera that is hooked to 1 or more monitors.• Electrodes (sticky pads) will be put on your chest tohook you up to an electrocardiogram (ECG) machine.This will monitor your heartbeat during the cath.• A local anesthetic will be injected into the skinaround the insertion site in your upper leg (groin)or arm to numb it.This may be alittle uncomfortable.• A needle-like tube(introducer) isinserted in your bloodvessel. Then, a long,thin tube (catheter)is inserted through itinto the blood vessel.Continued on other side ➤®Pritchett & Hull Associates, Inc. Atlanta, GA 800-241-4925Bringing Patients & Health TogetherProduct # 370Copyright © 2000-2010Pritchett & Hull Associates, Inc.DO NOT DUPLICATE.

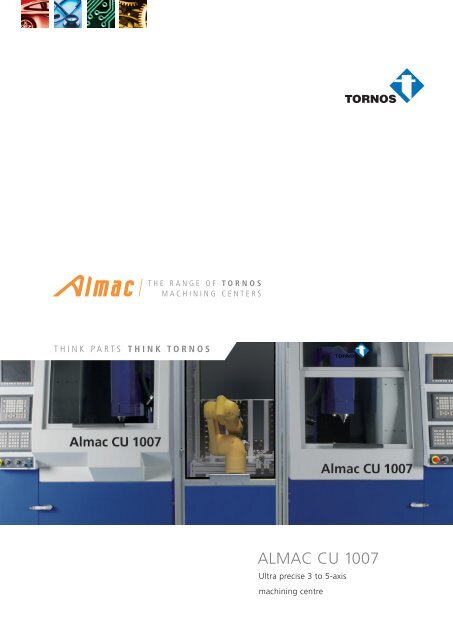

HIGH PRECISION WITH 3 TO 5 AXESA total of four versions are available dependingon the complexity of the parts to be machined :■3-axis■4½-axis■5-axis (4 simultaneous)■5-axis (all simultaneous)Longitudinal travelTransversal travelVertical travelX = 220 mmY = 120 mmZ = 230 mmRigid and highly stable, thanks to the self-supportingcast iron in the mechanically weldedhousing, the <strong>ALMAC</strong> <strong>CU</strong> <strong>1007</strong> machining centreensures an excellent finish for machined parts.A total of four basic configurations which can beused with additional equipment, thus increasingits capacities, and also with a loading/unloadingrobot, as well as a mirrored version, making it asupple and flexible instrument.The <strong>CU</strong> <strong>1007</strong> has X and Y slides on prestressedrails and a ballscrew. The vertical axis is formedby a solid cast iron prism upon which a rectangularsleeve moves, guided by four rails and movedby a ballscrew.All drives are operated by brushless AC motorswith digital servo.Four linear guide rails fixed on a prismFeedrates : 16 m/minGlass scales (1/10 µm)<strong>ALMAC</strong> <strong>CU</strong> <strong>1007</strong>3

PROGRESSIVE AND MODULARA completely customised solution, with integratableoptions and unbeatable modularityThe first and only machining tool that adapts andevolves to suit different production needs :■Standard machine■Machining centre + loading/unloading system■Machining centre + loading/unloading system+ a mirrored machining centre2629 mm1305 mm1912 mm2629 mm2708 mm1912 mm2629 mm4016 mm1912 mm4 <strong>ALMAC</strong> <strong>CU</strong> <strong>1007</strong>

AUTOMATION OF OPERATIONSThe integration of a 6-axis high performance robotoffers the <strong>CU</strong> <strong>1007</strong> unbeatable autonomy ofmovement : loading, unloading, palletising, deburring,buffing, flipping and reloading the machiningunit with a precision of ± 0.03 mm.Robot Stäubli TX60LGripping, intermediary stocking and repositioningwith the required precisionHandling of 300 x 400 mm pallets.Grinding available as an optionFANUC, <strong>ALMAC</strong>'s preferred choice, the mostevolved CNC programming system allowing theperformance of your machine tools to be optimised,whilst simplifying the work of programmers.■Optional :3, 4½ and 5-axis Fanuc Oi-MD(4 simultaneous)5-axis (all simultaneous) Fanuc 31<strong>ALMAC</strong> <strong>CU</strong> <strong>1007</strong>5

INTEGRATED TOOLS3R gripper chuckBLUM tools pre-setting system using theZ-Nano probeRepeatability ± 1 µmTotal travel 10 mm, force 3 to 35 NISO 25 'Random' type 30 position tool changer(optional 64 position HSK 25-A)4-axis dividing head with vertical/horizontal tilt2-axis dividing headAn uncompromising tool, in its basic form itintegrates the essential tools for machining complexparts with the tolerances needed by userswho require continuous production + the correspondingoptions for the more specific needs ofeach customer.6 <strong>ALMAC</strong> <strong>CU</strong> <strong>1007</strong>

TECHNICAL SPECIFICATIONSTECHNICAL SPECIFICATIONSTravel X / Y / Z 280 / 120 / 230 mmFeed rates feed X / Y / Z 0 to 8000 mm / minrapid feed16 m / minresolution0.0001 mmDrive system motors AC typeservosdigitalØ ballscrew20 x 4 mmDividing headCNC, 4th and 5th axesaxis C rotation50 min¯¹axis B rotation50 min¯¹axis B tilting -10° - + 100°Motor spindle lubricated air/oil 100 to 30'000 min-1 (45'000)mechanical power2.0 / 3.0 kW (100 % / 125 % ED)tool holder type ISO 25 / HSK 40-A / HSK 25-ATool changer random type 30 / 64 positions (HSK 25-A)Numerical controlFANUC Oi-MD / 31iCoolant tank capacity 100 l / 205 lflow30 l / minfiltration 35 µm / 28 µmThermostating power 3000 W for ∆ t 1° CConnections installed power 10kVAvoltage3 x 400 V / 50 Hzpneumatic pressure6 barDimensions L x D x H 1300 x 1980 x 2650 mmWeight2000 kgSPECIAL FEATURES• Ergonomic, rigidity and great flexibility of useOPTIONS• Additional HF 80'000 min¯¹ spindle• Cooling unit air / oil spray MECANEX• Robotisation• 2nd high flow coolant pump to clean the machining zone 60 l / min 4 barDYNAMIC CONTROL ACCORDING TO ISO 230-2Subject to technical modifications<strong>ALMAC</strong> <strong>CU</strong> <strong>1007</strong>7

TORNOS S.A.Rue Industrielle 111CH - 2740 MoutierTel: +41 (0) 32 494 44 44Fax: +41 (0) 32 494 49 03contact@tornos.comwww.tornos.com<strong>ALMAC</strong> SA39, Bd des EplaturesCH - 2300 La Chaux-de-FondsTel: +41 (0) 32 925 35 50Fax: +41 (0) 32 925 35 60info@almac.chwww.almac.chTORNOS TECHNOLOGIESDEUTSCHLAND GmbHD - 75179 PforzheimTel: +49 (0) 72 31 910 70Fax: +49 (0) 72 31 910 750contact@tornos.deTORNOS TECHNOLOGIESUK LTDCoalville (LE)Tel: +44 (0) 15 30 513 100Fax: +44 (0) 15 30 814 212sales@tornos.co.ukTORNOS TECHNOLOGIESSHANGHAI LIMITEDCN - Shanghai 200232Tel: +86 21 6235 1235Fax +86 21 6235 1938china.contact@tornos.comTORNOS TECHNOLOGIESFRANCEF - 74807 La Roche sur ForonTel. +33 (0) 4 50 038 333Fax +33 (0) 4 50 038 907contact@tornos.frTORNOS TECHNOLOGIESPOLAND Sp. z o.o.PL - 03-973 WarsawTel: +48 226 72 91 81Fax: +48 226 16 55 81poland.contact@tornos.comTORNOS TECHNOLOGIESASIA LIMITEDHong KongTel: +852 2691 2633Fax: +852 2691 2133asiapacific.contact@tornos.comTORNOS TECHNOLOGIESIBERICAE - 08403 GranollersTel: +34 93 846 59 43Fax: +34 93 849 66 00commercial.tti@tornos.comTORNOS TECHNOLOGIESUS CORPORATIONUS - Lombard, IL 60148Tel: +1 630 812-2040Fax: +1 630 812-2039info-us@tornos.comTORNOS THAILANDREPRESENTATIVE OFFICEBangkok 10110Tel: +66 26 62 3908Fax +66 26 62 3910thailand.contact@tornos.comTORNOS TECHNOLOGIESITALIA SRLI - 20090 Opera / MITel: +39 (0) 2 5768-1501Fax +39 (0) 2 5768-15230italia.contact@tornos.comTORNOS BEIJING OFFICECN - Beijing 100028Tel. +86 10 5979 8583Fax +86 10 5822 0483beijing.contact@tornos.comTORNOS TECHNOLOGIES ASIA LTDMALAYSIA REPRESENTATIVE OFFICE11900 Pulau Pinang, PenangTél. +6 04 642 6562 / 642 6563Fax +6 04 642 6561malaysia.contact@tornos.comwww.tornos.comComplies with current CE/CEM safety directivesThis document is based on information available at the time of publication. Although every effort has been made to ensure that the content is as accurate aspossible, TORNOS S.A cannot accept responsibility for ensuring that all details regarding the equipment and software is correct, nor can it foresee all eventualities.TORNOS S.A. does not provide any guarantee nor assume any liability for the accuracy and volume of the information contained in this manual. The content ofthis manual remains the property of TORNOS S.A, who reserves the right to change, add to or correct this at any time.OCTOBER 2009 edition