Hoover Dam Bypass - Aspire - The Concrete Bridge Magazine

Hoover Dam Bypass - Aspire - The Concrete Bridge Magazine

Hoover Dam Bypass - Aspire - The Concrete Bridge Magazine

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

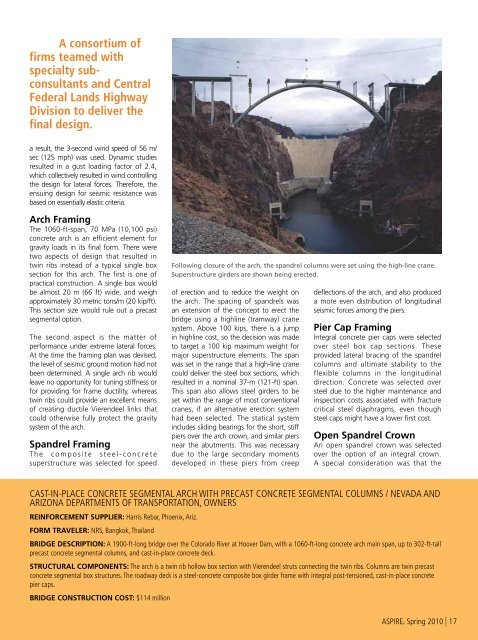

A consortium offirms teamed withspecialty subconsultantsand CentralFederal Lands HighwayDivision to deliver thefinal design.a result, the 3-second wind speed of 56 m/sec (125 mph) was used. Dynamic studiesresulted in a gust loading factor of 2.4,which collectively resulted in wind controllingthe design for lateral forces. <strong>The</strong>refore, theensuing design for seismic resistance wasbased on essentially elastic criteria.Arch Framing<strong>The</strong> 1060-ft-span, 70 MPa (10,100 psi)concrete arch is an efficient element forgravity loads in its final form. <strong>The</strong>re weretwo aspects of design that resulted intwin ribs instead of a typical single boxsection for this arch. <strong>The</strong> first is one ofpractical construction. A single box wouldbe almost 20 m (66 ft) wide, and weighapproximately 30 metric tons/m (20 kip/ft).This section size would rule out a precastsegmental option.<strong>The</strong> second aspect is the matter ofperformance under extreme lateral forces.At the time the framing plan was devised,the level of seismic ground motion had notbeen determined. A single arch rib wouldleave no opportunity for tuning stiffness orfor providing for frame ductility, whereastwin ribs could provide an excellent meansof creating ductile Vierendeel links thatcould otherwise fully protect the gravitysystem of the arch.Spandrel FramingT h e c o m p o s i t e s t e e l - c o n c r e t esuperstructure was selected for speedFollowing closure of the arch, the spandrel columns were set using the high-line crane.Superstructure girders are shown being erected.of erection and to reduce the weight onthe arch. <strong>The</strong> spacing of spandrels wasan extension of the concept to erect thebridge using a highline (tramway) cranesystem. Above 100 kips, there is a jumpin highline cost, so the decision was madeto target a 100 kip maximum weight formajor superstructure elements. <strong>The</strong> spanwas set in the range that a high-line cranecould deliver the steel box sections, whichresulted in a nominal 37-m (121-ft) span.This span also allows steel girders to beset within the range of most conventionalcranes, if an alternative erection systemhad been selected. <strong>The</strong> statical systemincludes sliding bearings for the short, stiffpiers over the arch crown, and similar piersnear the abutments. This was necessarydue to the large secondary momentsdeveloped in these piers from creepdeflections of the arch, and also produceda more even distribution of longitudinalseismic forces among the piers.Pier Cap FramingIntegral concrete pier caps were selectedover steel box cap sections. <strong>The</strong>seprovided lateral bracing of the spandrelcolumns and ultimate stability to theflexible columns in the longitudinaldirection. <strong>Concrete</strong> was selected oversteel due to the higher maintenance andinspection costs associated with fracturecritical steel diaphragms, even thoughsteel caps might have a lower first cost.Open Spandrel CrownAn open spandrel crown was selectedover the option of an integral crown.A special consideration was that theCAST-IN-PLACE CONCRETE SEGMENTAL ARCH WITH PRECAST CONCRETE SEGMENTAL COLUMNS / NEVADA ANDARIZONA DEPARTMENTS OF TRANSPORTATION, OWNERSREINFORCement SUPPLIER: Harris Rebar, Phoenix, Ariz.form traveler: NRS, Bangkok, ThailandBRIDGE DESCRIPTION: A 1900-ft-long bridge over the Colorado River at <strong>Hoover</strong> <strong>Dam</strong>, with a 1060-ft-long concrete arch main span, up to 302-ft-tallprecast concrete segmental columns, and cast-in-place concrete deck.structural components: <strong>The</strong> arch is a twin rib hollow box section with Vierendeel struts connecting the twin ribs. Columns are twin precastconcrete segmental box structures. <strong>The</strong> roadway deck is a steel-concrete composite box girder frame with integral post-tensioned, cast-in-place concretepier caps.BRIDGE CONSTRUCTION COST: $114 millionASPIRE, Spring 2010 | 17