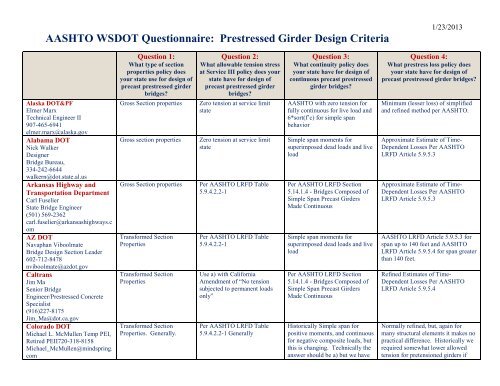

AASHTO WSDOT Questionnaire: Prestressed Girder Design Criteria

AASHTO WSDOT Questionnaire: Prestressed Girder Design Criteria

AASHTO WSDOT Questionnaire: Prestressed Girder Design Criteria

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

not been diligent with keeping ourdesign processes up. Also formany bridges it does not seem tomake any practical difference.1/23/2013lump sum methods were used sincethe lump sum methods of theStandard specifications sometimesdiffered drastically for the stressesand concrete strengths we used (atthe time these were high stresses,strengths, and prestressing levels).Personally I think the detail in thecode detailed method gives theimpression that the predictions aremore accurate than they are, andrequires information only known tothe actual fabricator for the girders,or perhaps not even then. (GIGO)The data set the code is based on isnot broad enough, and concrete andenvironmental conditions are not thatpredictable. When we have donesegmental structures the creep andshrinkage tests were not consistentenough from sample to sample to beof any use whatsoever. If precisionis required for the prediction ofmaterial properties, concrete is thewrong material.District of Columbia DOTKonjit Eskender, P.E. ProjectEngineer 202-671-4568Konjit.Eskender@dc.govFlorida DOTChristina Freeman / DennisGolabekStructures <strong>Design</strong> Engineer850-414-4190christina.freeman@dot.state.fl.usTransformed SectionPropertiesTransformed SectionPropertiesPer <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1When analyzing stresses ofsimple span beams, limitstresses in accordance withLRFD Table 5.9.4.1.2-1 withthe exception that for the outer15 percent of the design span,tensile stress at the top of beammay not exceed 12 x squareroot of f'ci at release. Fortransient loads duringconstruction the tensile stresslimit may be taken as 6 xsquare root of f'c. It is notnecessary to check tensilestresses in the top of simplePer <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast<strong>Girder</strong>s Made ContinuousFDOT policy is to use only posttensioningto splice beamsegments within simple spansand/or to establish continuitybetween adjacent spans.Furthermore, in the design ofpretensioned beams madecontinuous by field-applied posttensioning,the pretensioning shallbe designed such that, as aminimum, the followingconditions are satisfied:A. The pretensioning shall meetthe minimum steel provisions ofLRFD [5.7.3.3.2].Do not have a policy on timedependentlosses; but follow<strong>AASHTO</strong> (either a or b)Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3 For simplesupported beams

1/23/2013span beams in the finalcondition.B. The pretensioning shall becapable of resisting all loadsapplied prior to post-tensioning,including a superimposed deadload equal to 50% of the uniformweight of the beam, withoutexceeding the stress limitationsfor pretensioned concreteconstruction.C. The pretensioning force shallbe of such magnitude that theinitial midspan camber at release,including the effect of the deadload of the beam, is at least ½". Incomputing the initial camber, thevalue of the modulus of elasticityshall be in accordance with SDG1.4.1 for the minimum requiredstrength of concrete at release ofthe pretensioning force, and thepretensioning force in the strandsshall be reduced by losses due toelastic shortening and steelrelaxation.D. Anchorage zones of posttensioningducts, and beamlengths in which ducts deviateboth horizontally and vertically,require integrated drawings inaccordance with SDG 4.5.E. The limitation on thepercentage of debonded strands ofthe pretensioned strand group atthe ends of beams may beincreased to 37.5% provided posttensioningis applied to the beamsprior to casting the deck concreteand provided that the totalnumber of debonded strands isequal to or less than 25% of thetotal area of pretensioned andpost-tensioned strands at the timeof placement of the deckconcrete.Hawaii DOT Gross Section properties Zero tension at service limit Per <strong>AASHTO</strong> LRFD Section Either is accepted. An estimate is an

Paul SantoBridge <strong>Design</strong> Engineer 808-692-7611paul.santo@hawaii.govIdaho Transportation DepartmentLuis Zarate Technical Engineer2208-334-8545luis.zarate@itd.idaho.govIllinois DOTJohn CicconeSenior Standards Engineer217-782-9111John.Ciccone@Illinois.govIndiana DOTRandy StrainINDOT Bridge StandardsEngineer317-232-3339Gross Section Properties,have allowed the use ofTransformed SectionPropertiesGross Section propertiesGross section properties ascalculated in LEAPConspanstatePer <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1 In accordance withthe code5.14.1.4 - Bridges Composed ofSimple Span Precast <strong>Girder</strong>sMade ContinuousWe design continuous prestressedgirder bridges as simple spans forall loads, but then addreinforcement over the piers tocontrol cracking. We do use5.14.1.4 to design the positivemoment connection at the pier.We also allow the girder to bedesigned fully continuous for liveload and superimposed dead withapproval.Generally IDOT follows 5.14.1.4however some of the particularswere modified based on ourexperience. These are noted inour in house manuals and designguides. For example IDOT choseto adopt a 45 day rule instead ofthe 90 day rule specified in5.14.1.4. Our 45 day rulerequires the fabricator to hold abeam at the yard for 45 daysbefore shipping. When youconsider deck forming afterdelivery we estimate 60 daysbefore a beam is locked into thestructure. The reinforcement usedto handle the positive restraintmoments is designed for aminimum capacity of 1.2 Mcr.This reinforcement has beenstandardized for the sections weuse and is either 2 or 3 - #8hooked bars. Detailed calculationfor creep and shrinkage are notrequired.<strong>Girder</strong>s Made Continuous Per5.14.1.4 and detailed perStandardsestimate!1/23/2013Approximate Estimate for I girderbridges designed with compositedeck. b) for everything else.Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3 Unless thereare unique design requirements thisrequirement is per code.

strain@indot.in.govIowa DOTKenneth F. DunkerTransportation EngineerSpecialist515-233-7920kenneth.dunker@dot.iowa.govKDOTJohn JonesBr. Manual Engineer785-368-7175jjones@ksdot.orgTransformed section forservice, camber, anddeflectionGross Section propertiesTable 5.9.4.1.2-1 for transfer,Table 5.9.4.2.2-1 for servicePer <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Generally 5.14.1.4, simple forservice and strength, continuousfor deflection and substructureloadsSimple span moments forsuperimposed dead loads and liveload1/23/2013Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3Louisiana DOTJenny FuAssistant Bridge <strong>Design</strong>Administration225 379 1321Zhengzheng.fu@la.govMaryland State HighwayAdministrationJeff Robert Senior ProjectEngineer410-545-8327jrobert@sha.state.md.usMichigan DOTJohn LazarTransportation Engineer 14 LicSpl517-335-3381lazarj@michigan.govMinnesota DOTDave Dahlberg Bridge <strong>Design</strong>Manual and Policy Engineer651.366.4491dave.dahlberg@state.mn.usMississippi DOTNick Altobelli, PEState Bridge Engineer601-359-7200nalto@mdot.state.ms.usTransformed sectionpropertiesTransformed SectionPropertiesGross Section propertiesGross Section propertiesTransformed SectionPropertiesPer <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Zero tension at service limitstatePer <strong>AASHTO</strong> LRFD Table5.9.4.2.2-£)Simple span moments forsuperimposed dead loads and liveloadPer <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast <strong>Girder</strong>sMade ContinuousSimple span moments for positiveLive Load and SuperimposedDead Load moments andContinuous for negative Live loadand Superimposed Dead Loadmoments over the piers.All precast prestressed girderbridges are designed as simplespan for all loads. The deck iscast continuous over the pierswith additional top mat rebarincluded in the vicinity of thepier. The deck is saw cut partialdepth and sealed at the pier to“guide” the anticipated crack inthe deck.Per <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast<strong>Girder</strong>s Made ContinuousBoth Approximate Estimate andRefined Estimates of Time-Dependent Losses are allowed.Approximate method is typicallyusedRefined Estimates of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.4Approximate Estimate from Article5.9.5.3Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3

MoDOTGregory Sanders StructuralDevelopment and SupportEngineer573.526.0245gregory.sanders@modot. Mo.govMontana DOTJeff Olsen, P.E Bridge AreaEngineer – Billings District406-444-7610 jolsen@mt.govNCDOTTodd M Garrison, PEAdvanced Engineer(919) 707-6538tgarrison@ncdot.govNebraska Department OfroadsFouad JaberAssistant State Bridge Engineer402-479-3967fouad.jaber@nebraska.govNHDOTDavid L. ScottIn-House <strong>Design</strong> Chief(603) 271-2731dscott@dot.state.nh.usNJDOTEric KraehenbuehlManager609-530-2552eric.kraehenbuehl@dot.state.nj.usNMDOTZann Jones Civil EngineerAdvanced(505) 827-5583zann.jones@state.nm.usNV DOTTodd StefonowiczAss’t Chief Structures Engr775.888.7550tstefonowicz@dot.state.nv.usTransformed SectionPropertiesWe use gross properties as astandard, but may usetransformed on a case-bycasebasisGross Section properties(routinely used)Transformed SectionProperties (used whenbeneficial)Gross Section propertiesTransformed SectionPropertiesGross Section propertiesGross Section propertiesNet section propertiesPer <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1 (for <strong>AASHTO</strong>girders and modified bulb tees)b) Zero tension at service limitstate (for cored slab and boxbeam units, and for all girdersin corrosive environments)Our present policy is to use0.095sq.rtf’c and rate for0.19sq.rtf”cZero tension at service limitstateZero tension at service limitstatePer <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast <strong>Girder</strong>sMade ContinuousPer <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast <strong>Girder</strong>sMade ContinuousSimple span moments forsuperimposed dead loads and liveloadPer <strong>AASHTO</strong> LRFD 5.14.1.4NH has not done a continuousprecast prestressed girder bridgesince prior to LRFDimplementation. When we designour next one, our first attempt willbe option A.Per <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast <strong>Girder</strong>sMade ContinuousPer <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast <strong>Girder</strong>sMade ContinuousPer <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast <strong>Girder</strong>sMade Continuous1/23/2013Refined Estimates of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.4We use the approximate method withgross section properties and therefined method if we are using thetransformed section properties.a) Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3b) Refined Estimates of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.4We don’t have a policy but in generalwe use the approximate methodApproximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3Refined Estimates of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.4Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3

NYS DOTRajesh TanejaAssistant Director, Bridge <strong>Design</strong>Bureau518-457-2595rtaneja@dot.state.ny.usOhio DOTSean MeddlesBridge Standards Engineer614-466-2464Sean.Meddles@dot.state.oh.usOklahoma DOTRoland Sison<strong>Design</strong>er(405) 325-4140rsison@odot.orgOregon DOTCraig ShikeInterim Bridge StandardsManaging Engineer503-986-3323Craig.L.SHIKE@odot.state.or.usGross Section PropertiesComposite with slab.Gross Section propertiesGross Section propertiesGross Section propertiesOregon does not permit theprestress gain due to liveload to be included in theprestress loss calculation.Therefore, use oftransformed sectionproperties is not permittedsince it would automaticallyinclude the prestress gaindue to live load.Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1 (for HL-93 LiveLoad)1. For NYSDOT <strong>Design</strong>Permit Vehicle stress limitis 0.14√f’c (for other thansegmentally constructedbridges)2. All bridges in NYS aresubjected to severecorrosion conditions.Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Simple spans –0.0948*sqrt(f’c). This is 50%the tension allowed in LRFD.This level of allowable tensionwas selected after a study ofdesigns prepared using thestandard specifications with0.0948*sqrt(f’c) for HS25loading and no tension forHS20 loading. Precastprestressed concrete slabs,boxes and girders form themajority of Oregon’s bridgeinventory. When LRFD wasintroduced, Oregon did notwant to begin building newSimple span moments forsuperimposed dead loads and liveloadWe also design the slab joint overthe pier for superimposed deadloads & live load.ODOT requires designers toconsider two loading conditions:1. Simple span for noncompositeloadings andcontinuous for live load andcomposite dead loadincluding an allowance forfuture wearing courses.2. Simple span for all noncompositeand compositeloadings excluding anallowance for future wearingcourses.Simple span moments forsuperimposed dead loads and liveloadOregon follows Section 5.14.1.4,but also requires bridges to beevaluated as if they were simplysupported with the tension nearmidspan limited to 0.19*sqrt(f’c).1/23/2013Refined Estimates of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.4We use Commercial Software, LEAPsoftware from Conspan andVirtis/OpisApproximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3Refined Estimates of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.4Oregon believes the refined estimateof losses per 5.9.5.4 provides the bestaccuracy. Before this method wasavailable, Oregon used a methodwhich provided similar estimates.Oregon has never seen a prestressedmember with noticeable momentcracks. For this reason, we believethe refined method provides asatisfactory level of conservatism.

PennDOTTom Macioce Chief BridgeEngineer717.787.2881tmacioce@pa.govSouth Carolina DOTBarry Bowers Structural <strong>Design</strong>Support Engineer803-737-4814bowersbw@scdot.orgGross Section Properties areused for all stiffnessanalysis and DL stressanalysis. TransformedSection Properties used forLL stresses analysis.PSLRFD usestransformed sectionproperties for LL stressanalysis only (not forstiffness analysis). Seethe attached pages for thePSLRFD UM. Thetransformed sectionproperties take intoaccount the transformedeffects of the prestressingstrands (mild steelneglected). This is inaccordance to DM-Gross Section propertiesbridges under the LRFD codewhich would have less loadcapacity than those already inour inventory. The tensionlimitation of 0.0948*sqrt(f’c)ensures LRFD bridges willnever be a weak link on theOregon highway system.When continuous for live load,0.0948*sqrt(f’c) and verifytension due to positive momentdoes not exceed 0.19*sqrt(f’c)when spans are considered toact as simply supported.Always use 0.0948 √f’cTensile stress limits for fullyprestressed concretemembers shall conform tothe requirements for "OtherThan SegmentallyConstructed Bridges" inLRFD Article 5.9.4. Projectslocated in Beaufort,Berkeley, Charleston,For <strong>Prestressed</strong> concrete beambridges made continuous forsuperimposed dead load and liveload, all structure components aredesigned for the more criticalcondition of full continuity or thecomplete loss of continuity at thediaphragms over the interiorsupports. Positive moment steelin the continuity diaphragm(s) isnot required since the structuredesign is not predicated onensuring continuity.Where practical, multiple spanbridges composed of precast,prestressed concrete girdersshould be detailed ascontinuous with continuitydiaphragms at interior supportsto eliminate expansion jointsin the deck slab. When precast,prestressed concrete girders1/23/2013Refined Estimates of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.4In analyzing stresses and/ordetermining the required length ofdebonding, stresses shall belimited to the values in LRFDArticle 5.9.4. Projects located inBeaufort, Berkeley, Charleston,Colleton, Dorchester,Georgetown, Horry, and JasperCounties shall be designed using

Colleton, Dorchester,Georgetown, Horry, andJasper Counties shall bedesigned using the stresslimits for severe corrosiveconditions. Projects locatedin all other counties shall bedesigned using the stresslimits for moderate corrosionconditions.are detailed as continuous forlive load and superimposeddead load, the following apply:• All structural componentsshall be designed for the morecritical condition of eitherassuming a fully effectiveconnection at the continuitydiaphragm (fully continuousspan) or assuming completeloss of continuity (simplespans).• Restraint moments caused bygirder creep and shrinkagemay be neglected.• A positive momentconnection shall be providedwith a factored resistance,

Texas DOTGregg A. Freeby, P.E. StateBridge Engineer512 416-2192Gregg.freeby@txdot.govUtah DOTJoshua J Sletten Structures<strong>Design</strong> Manager801-633-6314jsletten@utah.govVirginia DOTJulius Volgyi, JRAssistant State Structure andBridge Engineer804 786-7537Julius.volgyi@vdot.virginia.govWashington State DOTBijan KhaleghiBridge <strong>Design</strong> Engineer360 705-7181khalegb@wsdot.wa.govWisconsin DOTDavid KiekbuschStructural Development Engineer608-266-5084david.kiekbusch@dot.wi.govGross Section propertiesInitial tension in the amount of0.24*sqrt (f’ci) is allowed.Based on TxDOT experience,additional bondedreinforcement is not required.Final tension in the amount of0.19*sqrt(f’c) is allowed.Tension in the amount of0.24*sqrt(f’c) is allowed forchecking concrete stressesduring deck and diaphragmplacement.across a continuity diaphragm.TxDOT does not designcontinuous precast prestressedgirder bridges. All girders aresimple span. The slab iscontinuous over the interiorsupports but this is neglected ingirder design.Gross section properties <strong>AASHTO</strong> LRFD <strong>AASHTO</strong> LRFD girders madecontinuousGross Section propertiesGross Section propertiesGross Section propertiesper <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Zero tension at service limitstatePer <strong>AASHTO</strong> LRFD Table5.9.4.2.2-1Per <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast<strong>Girder</strong>s Made ContinuousSimple span moments forsuperimposed dead loads and liveloadPer <strong>AASHTO</strong> LRFD Section5.14.1.4 - Bridges Composed ofSimple Span Precast <strong>Girder</strong>sMade Continuous1/23/2013TxDOT method is to use <strong>AASHTO</strong>LRFD Bridge <strong>Design</strong> Specifications2004, 3rd. Ed., Article 5.9.5 Loss ofPrestress.A & B are acceptableA. Approximate Estimate of Time-Dependent LossesB. Refined Estimates of Time-Dependent LossesApproximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3VDOT do not include gainsRefined Estimates of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.4Approximate Estimate of Time-Dependent Losses Per <strong>AASHTO</strong>LRFD Article 5.9.5.3