Lambda sensors

Lambda sensors

Lambda sensors

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

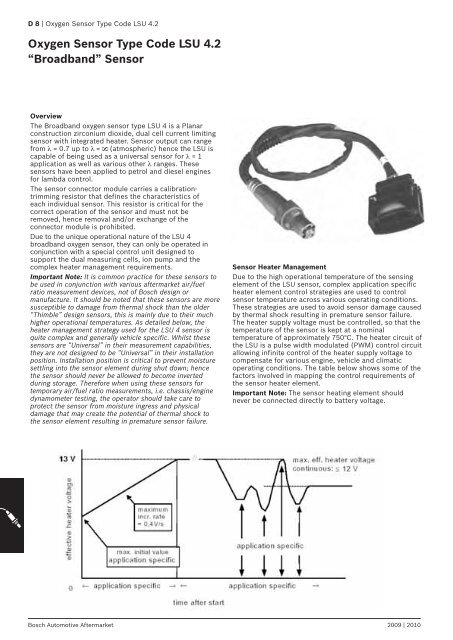

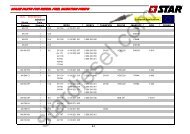

D 8 | Oxygen Sensor Type Code LSU 4.2Oxygen Sensor Type Code LSU 4.2“Broadband” SensorOverviewThe Broadband oxygen sensor type LSU 4 is a Planarconstruction zirconium dioxide, dual cell current limitingsensor with integrated heater. Sensor output can rangefrom λ = 0.7 up to λ = (atmospheric) hence the LSU iscapable of being used as a universal sensor for λ = 1application as well as various other λ ranges. These<strong>sensors</strong> have been applied to petrol and diesel enginesfor lambda control.The sensor connector module carries a calibrationtrimmingresistor that defines the characteristics ofeach individual sensor. This resistor is critical for thecorrect operation of the sensor and must not beremoved, hence removal and/or exchange of theconnector module is prohibited.Due to the unique operational nature of the LSU 4broadband oxygen sensor, they can only be operated inconjunction with a special control unit designed tosupport the dual measuring cells, ion pump and thecomplex heater management requirements.Important Note: It is common practice for these <strong>sensors</strong> tobe used in conjunction with various aftermarket air/fuelratio measurement devices, not of Bosch design ormanufacture. It should be noted that these <strong>sensors</strong> are moresusceptible to damage from thermal shock than the older“Thimble” design <strong>sensors</strong>, this is mainly due to their muchhigher operational temperatures. As detailed below, theheater management strategy used for the LSU 4 sensor isquite complex and generally vehicle specific. Whilst these<strong>sensors</strong> are “Universal” in their measurement capabilities,they are not designed to be “Universal” in their installationposition. Installation position is critical to prevent moisturesettling into the sensor element during shut down; hencethe sensor should never be allowed to become invertedduring storage. Therefore when using these <strong>sensors</strong> fortemporary air/fuel ratio measurements, i.e. chassis/enginedynamometer testing, the operator should take care toprotect the sensor from moisture ingress and physicaldamage that may create the potential of thermal shock tothe sensor element resulting in premature sensor failure.8Sensor Heater ManagementDue to the high operational temperature of the sensingelement of the LSU sensor, complex application specificheater element control strategies are used to controlsensor temperature across various operating conditions.These strategies are used to avoid sensor damage causedby thermal shock resulting in premature sensor failure.The heater supply voltage must be controlled, so that thetemperature of the sensor is kept at a nominaltemperature of approximately 750 º C. The heater circuit ofthe LSU is a pulse width modulated (PWM) control circuitallowing infinite control of the heater supply voltage tocompensate for various engine, vehicle and climaticoperating conditions. The table below shows some of thefactors involved in mapping the control requirements ofthe sensor heater element.Important Note: The sensor heating element shouldnever be connected directly to battery voltage.Bosch Automotive Aftermarket 2009 | 2010