Fabrics 101: Embroidering on Nylon

Fabrics 101: Embroidering on Nylon

Fabrics 101: Embroidering on Nylon

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

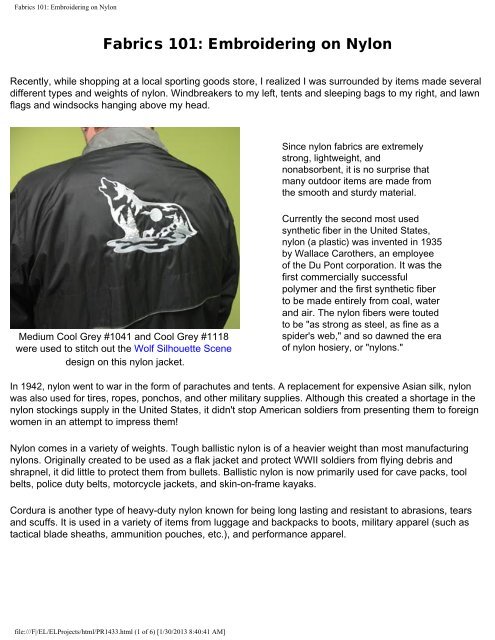

<str<strong>on</strong>g>Fabrics</str<strong>on</strong>g> <str<strong>on</strong>g>101</str<strong>on</strong>g>: <str<strong>on</strong>g>Embroidering</str<strong>on</strong>g> <strong>on</strong> Nyl<strong>on</strong><str<strong>on</strong>g>Fabrics</str<strong>on</strong>g> <str<strong>on</strong>g>101</str<strong>on</strong>g>: <str<strong>on</strong>g>Embroidering</str<strong>on</strong>g> <strong>on</strong> Nyl<strong>on</strong>Recently, while shopping at a local sporting goods store, I realized I was surrounded by items made severaldifferent types and weights of nyl<strong>on</strong>. Windbreakers to my left, tents and sleeping bags to my right, and lawnflags and windsocks hanging above my head.Since nyl<strong>on</strong> fabrics are extremelystr<strong>on</strong>g, lightweight, andn<strong>on</strong>absorbent, it is no surprise thatmany outdoor items are made fromthe smooth and sturdy material.Medium Cool Grey #1041 and Cool Grey #1118were used to stitch out the Wolf Silhouette Scenedesign <strong>on</strong> this nyl<strong>on</strong> jacket.Currently the sec<strong>on</strong>d most usedsynthetic fiber in the United States,nyl<strong>on</strong> (a plastic) was invented in 1935by Wallace Carothers, an employeeof the Du P<strong>on</strong>t corporati<strong>on</strong>. It was thefirst commercially successfulpolymer and the first synthetic fiberto be made entirely from coal, waterand air. The nyl<strong>on</strong> fibers were toutedto be "as str<strong>on</strong>g as steel, as fine as aspider's web," and so dawned the eraof nyl<strong>on</strong> hosiery, or "nyl<strong>on</strong>s."In 1942, nyl<strong>on</strong> went to war in the form of parachutes and tents. A replacement for expensive Asian silk, nyl<strong>on</strong>was also used for tires, ropes, p<strong>on</strong>chos, and other military supplies. Although this created a shortage in thenyl<strong>on</strong> stockings supply in the United States, it didn't stop American soldiers from presenting them to foreignwomen in an attempt to impress them!Nyl<strong>on</strong> comes in a variety of weights. Tough ballistic nyl<strong>on</strong> is of a heavier weight than most manufacturingnyl<strong>on</strong>s. Originally created to be used as a flak jacket and protect WWII soldiers from flying debris andshrapnel, it did little to protect them from bullets. Ballistic nyl<strong>on</strong> is now primarily used for cave packs, toolbelts, police duty belts, motorcycle jackets, and skin-<strong>on</strong>-frame kayaks.Cordura is another type of heavy-duty nyl<strong>on</strong> known for being l<strong>on</strong>g lasting and resistant to abrasi<strong>on</strong>s, tearsand scuffs. It is used in a variety of items from luggage and backpacks to boots, military apparel (such astactical blade sheaths, ammuniti<strong>on</strong> pouches, etc.), and performance apparel.file:///F|/EL/ELProjects/html/PR1433.html (1 of 6) [1/30/2013 8:40:41 AM]

<str<strong>on</strong>g>Fabrics</str<strong>on</strong>g> <str<strong>on</strong>g>101</str<strong>on</strong>g>: <str<strong>on</strong>g>Embroidering</str<strong>on</strong>g> <strong>on</strong> Nyl<strong>on</strong>Sport and ripstop nyl<strong>on</strong> are morecomm<strong>on</strong>ly found around the housethan the previously menti<strong>on</strong>edversi<strong>on</strong>s. Easy-care sport nyl<strong>on</strong> is asturdy fabric that is perfect foroutdoor items such as backpacks,tarps, outerwear, totes, outdoorflags, and banners. Last summer Imade the breezy windsock featuredto the left out of sport nyl<strong>on</strong> (clickhere or <strong>on</strong> the picture for projectinstructi<strong>on</strong>s).Ripstop is a lighter and silkier typeof nyl<strong>on</strong> that is woven with extrathreads in a pattern to help preventruns or tears. Wind-resistant (and iftreated with a durable finish, waterrepellant),ripstop nyl<strong>on</strong> is used forsleeping bags and tents. It's also agreat choice for light-weight jackets,p<strong>on</strong>chos, and wind pants.A pretty windsock, made of hearty nyl<strong>on</strong>, willperk up any patio.When embroidering <strong>on</strong> nyl<strong>on</strong>, I have found that applique designs work well <strong>on</strong> both ripstop and sport nyl<strong>on</strong>.Since applique designs have fewer stitches than "regular" or stitch-filled designs, puckering is not an issue.The sturdier sport nyl<strong>on</strong> is able to handle light to medium fill designs. If working with ripstop nyl<strong>on</strong>, Irecommend designs that have light fills.<str<strong>on</strong>g>Embroidering</str<strong>on</strong>g> <strong>on</strong> nyl<strong>on</strong> can be tricky, but I have some tips and techniques that should help you to achieveexcellent results. Below are results from my tests with ripstop nyl<strong>on</strong>, as well as tips for hooping, stabilizing,and embroidering.file:///F|/EL/ELProjects/html/PR1433.html (2 of 6) [1/30/2013 8:40:41 AM]

<str<strong>on</strong>g>Fabrics</str<strong>on</strong>g> <str<strong>on</strong>g>101</str<strong>on</strong>g>: <str<strong>on</strong>g>Embroidering</str<strong>on</strong>g> <strong>on</strong> Nyl<strong>on</strong>I wanted to find whichcombinati<strong>on</strong> of fabric andstabilizer gave the bestresults.For the first test, I hooped apiece of ripstop nyl<strong>on</strong> with apiece of medium weight (2.5oz.) cutaway stabilizer.After embroidering thedesign, I examined theoutcome. The results werenot up to my standards. Doyou see how there arepuckers in the fabric? Nyl<strong>on</strong>is such a slippery fabric -- itpulled away from the sides ofthe hoop when the hoop wasmoving around. The designthat I'm working with is a lightand-breezydaisy, but eventhose light stitches arecausing the fabric to pull outof the hoop.Trying again, I used the samemedium weight cutawaystabilizer. This time I had afew tricks up my sleeve andfelt c<strong>on</strong>fident I would achievebetter results.First, I sprayed the stabilizerwith temporary sprayadhesive (I used GunoldKK100) and smoothed theripstop nyl<strong>on</strong> over it. Theadhesive will prevent thefabric from shifting while thedesign sews.file:///F|/EL/ELProjects/html/PR1433.html (3 of 6) [1/30/2013 8:40:41 AM]

<str<strong>on</strong>g>Fabrics</str<strong>on</strong>g> <str<strong>on</strong>g>101</str<strong>on</strong>g>: <str<strong>on</strong>g>Embroidering</str<strong>on</strong>g> <strong>on</strong> Nyl<strong>on</strong>Although the fabric now feltsecure, another step willeven further prevent shifting.I next added water-soluableW<strong>on</strong>der Tape to the bottomsides of the inner hoop, butnot to the corners. Now, thenyl<strong>on</strong> will not pull away fromthe sides of the hoop. Thetape will last through a fewhoopings and can easily bewashed away when you arefinished.I then hooped the fabric andstabilizer using a techniquethat I have found to work well- hoop the fabric somewhatloosely and then hand tightenthe screw until the hoop istight.Finally, the last step that Itook to secure the nyl<strong>on</strong> is toadd pieces of rubber shelfmat to the bottom sides of theinner hoop, <strong>on</strong> top of theW<strong>on</strong>der Tape. This is a trick Ilearned from Anne Campbelland Joan Warr a few yearsago.I cut strips of the rubber matabout 1 1/2" wide and as l<strong>on</strong>gas the sides of the hoop.Then I aligned <strong>on</strong>e of thel<strong>on</strong>g sides of the tape withfile:///F|/EL/ELProjects/html/PR1433.html (4 of 6) [1/30/2013 8:40:41 AM]

<str<strong>on</strong>g>Fabrics</str<strong>on</strong>g> <str<strong>on</strong>g>101</str<strong>on</strong>g>: <str<strong>on</strong>g>Embroidering</str<strong>on</strong>g> <strong>on</strong> Nyl<strong>on</strong>the inner edge of the hoopand press in place. Thecorners of the hoop were leftopen.Next, I tightly hooped thefabric and stabilizer together.The rubber mat strips gave agreat hold, and prevented thefabric from pulling away fromthe sides of the hoop.I stitched out the very samedesign, and as you can see,the results are fantastic! Thenyl<strong>on</strong> remained flat and didnot pucker. And, all parts ofthe design are lined upperfectly. Any marks left <strong>on</strong>the hoop will disappear in acouple of hours or they canbe ir<strong>on</strong>ed out using a lowtemperature setting and apressing cloth.file:///F|/EL/ELProjects/html/PR1433.html (5 of 6) [1/30/2013 8:40:41 AM]

<str<strong>on</strong>g>Fabrics</str<strong>on</strong>g> <str<strong>on</strong>g>101</str<strong>on</strong>g>: <str<strong>on</strong>g>Embroidering</str<strong>on</strong>g> <strong>on</strong> Nyl<strong>on</strong>Nyl<strong>on</strong> is relatively easy to care for. I would recommend washing <strong>on</strong> the gentle cycle with warmwater and a cool rinse. Using a fabric softener will reduce static problems. Tumble dry nyl<strong>on</strong> ata low temperature setting and press at a cool temperature setting, or line dry.Stitching tips for nyl<strong>on</strong>:NeedleStabilizerDesign Choice75/11 sharp needleCutaway (2.5 ounce)Choose designs with light to medium complexity; applique is also agreat choice.Click here for a printable versi<strong>on</strong> of this article.You'll need to have Adobe Acrobat Reader installed <strong>on</strong> your computer. If you d<strong>on</strong>'t have it, youcan download a free copy by clicking <strong>on</strong> the ic<strong>on</strong> below.file:///F|/EL/ELProjects/html/PR1433.html (6 of 6) [1/30/2013 8:40:41 AM]