- Page 1 and 2: THE PRODUCTCATALOGUEProductoverview

- Page 3 and 4: WELCOME...to OsbornThe No. 1 in sur

- Page 5 and 6: SERVICES... exclusively for youComp

- Page 7 and 8: TÜV/SAFETYCertified brand-name too

- Page 9 and 10: METRE PERFORMANCEWhy only metre per

- Page 11 and 12: PRODUCT OVERVIEWThe fastest way to

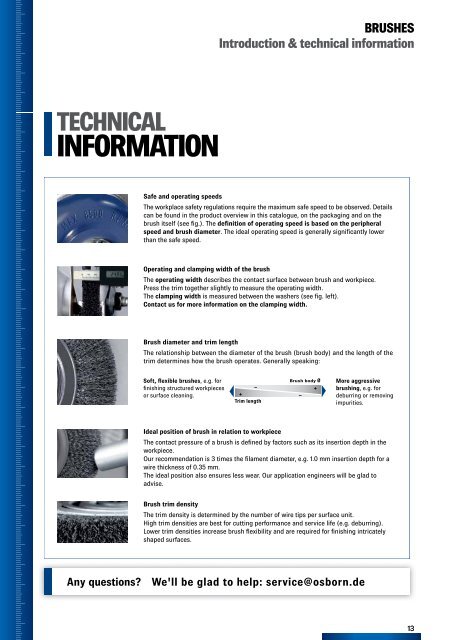

- Page 13: BRUSHESIntroduction & technical inf

- Page 17 and 18: BRUSHESAngle grindersBRUSHES FOR AN

- Page 19 and 20: BRUSHESAngle grindersWheel brushesk

- Page 21 and 22: BRUSHESAngle grindersWheel brushesa

- Page 25 and 26: BRUSHESAngle grindersCup brushesabr

- Page 27 and 28: BRUSHESPower drillsBRUSHES FOR POWE

- Page 29 and 30: BRUSHESPower drillsWheel brusheskno

- Page 31 and 32: BRUSHESPower drillsWheel brushescri

- Page 33 and 34: BRUSHESPower drillsWheel brushescri

- Page 35 and 36: BRUSHESPower drillsCup brushescrimp

- Page 37 and 38: BRUSHESPower drillsEnd brushescrimp

- Page 39 and 40: BRUSHESPower drillsEnd brushesabras

- Page 41 and 42: BRUSHESPower drillsTube & internal

- Page 43 and 44: BRUSHESPower drillsEnd brushescrimp

- Page 45 and 46: BRUSHESPower drillsEnd brushesabras

- Page 47 and 48: BRUSHESHigh-speed machinesBRUSHES F

- Page 49 and 50: BRUSHESHigh-speed machinesWheel bru

- Page 51 and 52: BRUSHESHigh-speed machinesEnd brush

- Page 53 and 54: BRUSHESHigh-speed machinesEnd brush

- Page 55: BRUSHESHigh-speed machinesEnd brush

- Page 58 and 59: BRUSHESStationary machinesImportant

- Page 60 and 61: BRUSHESStationary machines4-M adapt

- Page 62 and 63: BRUSHESStationary machinesWheel bru

- Page 64 and 65:

BRUSHESStationary machinesAxle plat

- Page 66 and 67:

BRUSHESStationary machinesF-adapter

- Page 68 and 69:

BRUSHESHand brushesImportant user i

- Page 70 and 71:

BRUSHESHand brushesHand scratch bru

- Page 72 and 73:

BRUSHESHand brushesHand scratch bru

- Page 74 and 75:

BRUSHESHand brushesHand scratch bru

- Page 76 and 77:

BRUSHESHand brushesHand scratch bru

- Page 78 and 79:

BRUSHESHand brushesButchersbrushwoo

- Page 80 and 81:

BRUSHESHand brushesButchersbrushwoo

- Page 82 and 83:

BRUSHESHand brushesBroomswooden bod

- Page 84 and 85:

BRUSHESHand brushesBroomswooden bod

- Page 86 and 87:

BRUSHESHand brushesBroomsplastic bo

- Page 88 and 89:

BRUSHESHand brushesSqueegeemmLpcs.3

- Page 90 and 91:

BRUSHESHand brushesPaint brushespla

- Page 92:

BRUSHESHand brushesPaint brushesmmT

- Page 95 and 96:

POLISHING/SATINISINGAngle polishers

- Page 97 and 98:

POLISHING/SATINISINGIntroduction &

- Page 99 and 100:

POLISHING/SATINISINGAngle polishers

- Page 101 and 102:

POLISHING/SATINISINGAngle grinders/

- Page 103 and 104:

POLISHING/SATINISINGIntroduction &

- Page 105 and 106:

POLISHING/SATINISINGAngle grinders/

- Page 107 and 108:

POLISHING/SATINISINGAngle grinders/

- Page 109 and 110:

POLISHING/SATINISINGStationary mach

- Page 111 and 112:

POLISHING/SATINISINGIntroduction &

- Page 113 and 114:

POLISHING/SATINISINGStationary mach

- Page 115 and 116:

POLISHING/SATINISINGPolishes & comp

- Page 117 and 118:

POLISHING/SATINISINGPolishes & comp

- Page 119 and 120:

GRINDINGAngle grindersGRINDING TOOL

- Page 121 and 122:

GRINDINGAngle grindersAbrasive disc

- Page 123 and 124:

GRINDINGPower drills/High-speed mac

- Page 125 and 126:

GRINDINGPower drills/High-speed mac

- Page 127 and 128:

GRINDINGSatinisersGRINDING TOOLS FO

- Page 129 and 130:

GRINDINGSatinisersFleece roller bru

- Page 131 and 132:

SPECIALSPECIAL TOOLS FOR DIFFERENT

- Page 133 and 134:

SPECIALBrushes for wood grainingmm

- Page 135 and 136:

SPECIALRoller brushesNatural Fibrem

- Page 137 and 138:

SPECIALRadiator brushesmmØ A L G p

- Page 139 and 140:

SPECIALFace brushesflat wiremmØ G

- Page 141 and 142:

SPECIALHandlefor face brushesmmØ L

- Page 143 and 144:

SPECIALChimney setpcs.1RRPOrder-No.

- Page 145 and 146:

SPECIALNozzle cleaning brushesWire/

- Page 147 and 148:

SPECIALSewer cleaning brushesElasto

- Page 149 and 150:

POSInformation & concepts for deale

- Page 151 and 152:

POSInformation & concepts for deale

- Page 153 and 154:

POSInformation & concepts for deale

- Page 155 and 156:

POS1. Brushes on display cardsOrder

- Page 157 and 158:

POS3. Sales module (specialist)Comp

- Page 159 and 160:

INDEXOrder-No.PageOrder-No.PageOrde

- Page 161 and 162:

INDEXOrder-No.PageOrder-No.PageOrde

- Page 163 and 164:

INDEXOrder-No.PageOrder-No.PageOrde

- Page 165 and 166:

OUR OTHER PRODUCT RANGESREQUEST INF

- Page 167 and 168:

General terms and conditions of pay