You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

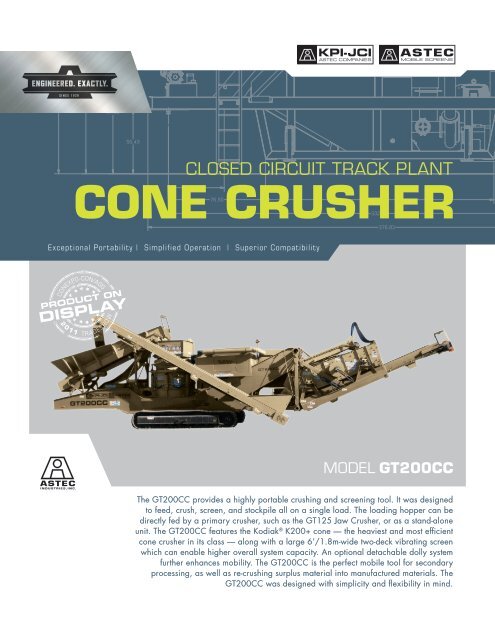

Closed CirCuit traCk plant<br />

Cone Crusher<br />

Exceptional Portability | Simplified Operation | Superior Compatibility<br />

model GT200CC<br />

The GT200CC provides a highly portable crushing and screening tool. It was designed<br />

to feed, crush, screen, and stockpile all on a single load. The loading hopper can be<br />

directly fed by a primary <strong>crusher</strong>, such as the GT125 Jaw Crusher, or as a stand-alone<br />

unit. The GT200CC features the Kodiak ® K200+ <strong>cone</strong> — the heaviest and most efficient<br />

<strong>cone</strong> <strong>crusher</strong> in its class — along with a large 6’/1.8m-wide two-deck vibrating screen<br />

which can enable higher overall system capacity. An optional detachable dolly system<br />

further enhances mobility. The GT200CC is the perfect mobile tool for secondary<br />

processing, as well as re-crushing surplus material into manufactured materials. The<br />

GT200CC was designed with simplicity and flexibility in mind.

P1<br />

P2<br />

Cone Crusher<br />

5 cu. yds/3.8m 3<br />

Loading Hopper<br />

P E R F O R M A N C E<br />

Mobility<br />

The GT200CC can be deployed<br />

and put back into operation within<br />

minutes, minimizing down-time.<br />

Capacity<br />

The GT200CC provides the most<br />

productive <strong>cone</strong> <strong>crusher</strong> and<br />

largest screen in its class.<br />

S1<br />

OperatiOn MOde<br />

KODIAK 200+ CONE CRUSHER<br />

Designed for quarry applications, the K200+<br />

is the heaviest and most efficient in its class.<br />

www.kpijci.com<br />

PART OF THE GLOBAL TRACK SYSTEM ®<br />

Combine with the GT125 Jaw Crusher and the<br />

GT145S Screen for a portable crushing and<br />

screening system.<br />

36” wide/91.44cm wide<br />

Belt Feeder<br />

P2<br />

E1<br />

E2<br />

P1<br />

6’ x 12’ (183 x 366cm)<br />

2 Deck Screen<br />

E A S E - O F - U S E<br />

Simplicity<br />

Electronics are kept to a minimum<br />

ensuring that maintenance and<br />

troubleshooting is easy to perform,<br />

anywhere.<br />

Hydraulics<br />

User-friendly hydraulic controls make<br />

set-up/tear-down and operation<br />

a breeze for users who may be<br />

unfamiliar with screening equipment.<br />

D1 D1<br />

E2<br />

VIBRATING SCREEN<br />

The GT200CC is the only closed-circuit <strong>cone</strong><br />

plant to offer a 6’ wide screen on tracks.<br />

Up to 385 TPH (349 MTPH)<br />

Plant Capacity<br />

D U R A B I L I LT Y<br />

mOdEl GT200CC<br />

Rugged Components<br />

<strong>KPI</strong>-<strong>JCI</strong> <strong>cone</strong> <strong>crusher</strong>s and screens are<br />

legendary for their robust construction<br />

and longevity.<br />

S A F E T Y<br />

Minimize Exposure<br />

Once positioned, the operator can feed the<br />

plant from the safety of the loading device.<br />

TRACK MOBILITY<br />

Tracks provide both jobsite mobility as well as<br />

the foundation required to isolate plant vibration.<br />

Because <strong>KPI</strong>-<strong>JCI</strong> & Astec Mobile Screens may use in their catalog & literature, old photographs of its products which may have been modified by the owners, products furnished by <strong>KPI</strong>-<strong>JCI</strong> & Astec Mobile Screens may<br />

not necessarily be as illustrated therein. Also continuous design progress makes it necessary that specifications be subject to change without notice. All sales of the products of <strong>KPI</strong>-<strong>JCI</strong> & Astec Mobile Screens are subject<br />

to the provisions of its standard warranty. <strong>KPI</strong>-<strong>JCI</strong> & Astec Mobile Screens do not warrant or represent that their products meet any federal, state, or local statutes, codes, ordinances, rules, standards or other regulations,<br />

including OSHA and MSHAGATOR, covering safety pollution, electrical, wiring, etc. Compliance with these statutes and regulations is the responsibility of the user and will be dependent upon the area and the use to<br />

which the product is put by the user. In some photographs, guards may have been removed for illustrative purposes only. This equipment should not be operated without all guards attached in their normal position.<br />

Placement of guards and other safety equipment is often dependent upon the area and the use to which the product is put. A safety study should be made by the user of the application, and, if required, additional guards,<br />

warning signs and other safety devices should be installed by the user, wherever appropriate before operating the products. NOTE: SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE REV. 1 03/11<br />

E1<br />

SERVICE MADE EASY<br />

D1<br />

S1<br />

Because we’re dedicated to keeping you up and running, we’ve provided two<br />

resources for quality O.E.M. parts and 24/7 service. <strong>KPI</strong>-<strong>JCI</strong> and Astec Mobile<br />

Screens parts and service are available from your local dealer and/or representative.<br />

Find the dealer or representative nearest you at www.kpijci.com.