Download PDF - TGW Logistics Group

Download PDF - TGW Logistics Group

Download PDF - TGW Logistics Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

www.tgw-group.com<br />

POP-UP ROLLeR TRAnSFeR<br />

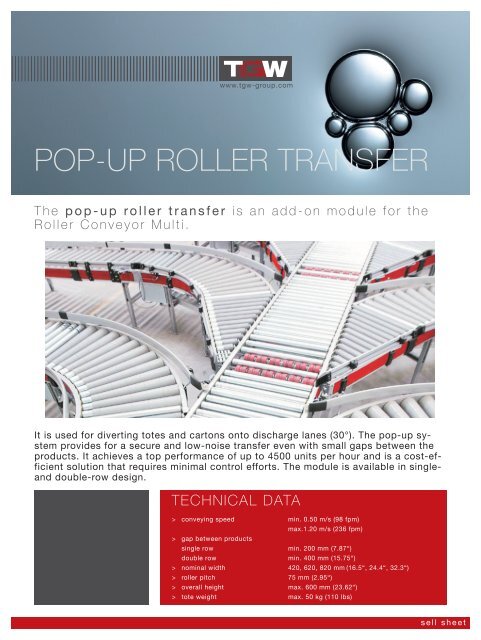

T h e p o p - u p r o l l e r t r a n s f e r i s a n a d d - o n m o d u l e f o r t h e<br />

R o l l e r c o n v e y o r M u l t i .<br />

It is used for diverting totes and cartons onto discharge lanes (30°). The pop-up system<br />

provides for a secure and low-noise transfer even with small gaps between the<br />

products. It achieves a top performance of up to 4500 units per hour and is a cost-efficient<br />

solution that requires minimal control efforts. The module is available in single-<br />

and double-row design.<br />

TechnicAL DATA<br />

> conveying speed<br />

> gap between products<br />

min. 0.50 m/s (98 fpm)<br />

max.1.20 m/s (236 fpm)<br />

single row min. 200 mm (7.87“)<br />

double row min. 400 mm (15.75“)<br />

> nominal width 420, 620, 820 mm (16.5“, 24.4“, 32.3“)<br />

> roller pitch 75 mm (2.95“)<br />

> overall height max. 600 mm (23.62“)<br />

> tote weight max. 50 kg (110 lbs)<br />

s e l l s h e e t

BeneFiT<br />

FeATUReS<br />

> high Performance<br />

> Low control effort<br />

> Flexibility in design, versatility to meet any application<br />

requirements<br />

> Minimised assembly effort<br />

> Transfer with little gaps and at high speed<br />

> Pop-up rollers are driven by main conveyor drive<br />

> Pneumatic or electro-mechanical swivel lift drive<br />

> simple design<br />

> Use in freezer applications<br />

> single and two-sided diverting possible<br />

T G W M e c h a n i c s , h e a d q u a r t e r e d i n W e l s , A u s t r i a , i s<br />

p a r t n e r f o r t h e e n t i r e e l e c t r o - m e c h a n i c a l e q u i p m e n t<br />

i n a u t o m a t e d i n t r a - l o g i s t i c s s o l u t i o n s .<br />

The leading manufacturer of automated material handling and storage systems covers all functional requirements<br />

of material handling and sortation as well as automated storage/retrieval of totes, cartons, trays and<br />

pallets. The company is part of <strong>TGW</strong> <strong>Group</strong> which has local offices in Germany, the United States, Spain,<br />

italy, the United Kingdom, Poland, France, Scandinavia and china generating annual sales revenues of<br />

€ 221,5 mil. ($ 307,2 mil) and employing about 1100 people worldwide.<br />

<strong>TGW</strong> MechanIcs GMbh, A-4600 Wels, collmannstraße 2, T+43.(0)7242.486-0, F+43.(0)7242.486-31<br />

e-mail: mechanics@ tgw-group.com, www.tgw-group.com<br />

<strong>TGW</strong> sysTeMs Inc., Spring Lake, Mi 49456-9652, 6870 Grand haven Road, USA, Phone +1.231.798.4547<br />

e-mail: usinfo@tgw-group.com, www.tgw-group.com<br />

© <strong>TGW</strong>, 2011. Version 08/2011<br />

s e l l s h e e t