Aging Studies and Stabilization of PBO Fiber - Polymer Science and ...

Aging Studies and Stabilization of PBO Fiber - Polymer Science and ...

Aging Studies and Stabilization of PBO Fiber - Polymer Science and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

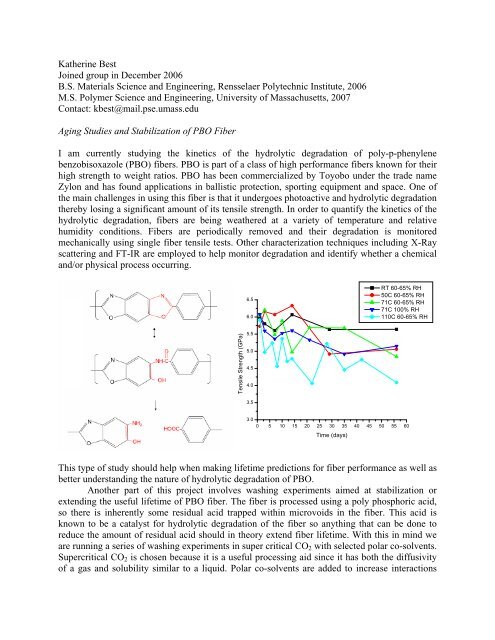

Katherine BestJoined group in December 2006B.S. Materials <strong>Science</strong> <strong>and</strong> Engineering, Rensselaer Polytechnic Institute, 2006M.S. <strong>Polymer</strong> <strong>Science</strong> <strong>and</strong> Engineering, University <strong>of</strong> Massachusetts, 2007Contact: kbest@mail.pse.umass.edu<strong>Aging</strong> <strong>Studies</strong> <strong>and</strong> <strong>Stabilization</strong> <strong>of</strong> <strong>PBO</strong> <strong>Fiber</strong>I am currently studying the kinetics <strong>of</strong> the hydrolytic degradation <strong>of</strong> poly-p-phenylenebenzobisoxazole (<strong>PBO</strong>) fibers. <strong>PBO</strong> is part <strong>of</strong> a class <strong>of</strong> high performance fibers known for theirhigh strength to weight ratios. <strong>PBO</strong> has been commercialized by Toyobo under the trade nameZylon <strong>and</strong> has found applications in ballistic protection, sporting equipment <strong>and</strong> space. One <strong>of</strong>the main challenges in using this fiber is that it undergoes photoactive <strong>and</strong> hydrolytic degradationthereby losing a significant amount <strong>of</strong> its tensile strength. In order to quantify the kinetics <strong>of</strong> thehydrolytic degradation, fibers are being weathered at a variety <strong>of</strong> temperature <strong>and</strong> relativehumidity conditions. <strong>Fiber</strong>s are periodically removed <strong>and</strong> their degradation is monitoredmechanically using single fiber tensile tests. Other characterization techniques including X-Rayscattering <strong>and</strong> FT-IR are employed to help monitor degradation <strong>and</strong> identify whether a chemical<strong>and</strong>/or physical process occurring.6.56.0RT 60-65% RH50C 60-65% RH71C 60-65% RH71C 100% RH110C 60-65% RHTensile Strength (GPa)5.55.04.54.03.53.00 5 10 15 20 25 30 35 40 45 50 55 60Time (days)This type <strong>of</strong> study should help when making lifetime predictions for fiber performance as well asbetter underst<strong>and</strong>ing the nature <strong>of</strong> hydrolytic degradation <strong>of</strong> <strong>PBO</strong>.Another part <strong>of</strong> this project involves washing experiments aimed at stabilization orextending the useful lifetime <strong>of</strong> <strong>PBO</strong> fiber. The fiber is processed using a poly phosphoric acid,so there is inherently some residual acid trapped within microvoids in the fiber. This acid isknown to be a catalyst for hydrolytic degradation <strong>of</strong> the fiber so anything that can be done toreduce the amount <strong>of</strong> residual acid should in theory extend fiber lifetime. With this in mind weare running a series <strong>of</strong> washing experiments in super critical CO 2 with selected polar co-solvents.Supercritical CO 2 is chosen because it is a useful processing aid since it has both the diffusivity<strong>of</strong> a gas <strong>and</strong> solubility similar to a liquid. Polar co-solvents are added to increase interactions

etween the acid trapped in the fiber <strong>and</strong> the solvent. The hydrolytic degradation <strong>of</strong> treated fiberswill then be monitored for changes in rate or behavior.Improving the Fracture Toughness <strong>of</strong> Optical Grade PC LensesMy second project is aimed at enhancing the fracture toughness <strong>of</strong> an optical gradepolycarbonate system in order to prevent slow crack growth. Epoxy has been chosen as theprimary toughening agent <strong>and</strong> three strategies are being employed to reach this goal:1. Epoxy/PC interpenetrating network2. Cross-linking <strong>and</strong> chain extending PC3. PC nanocomposite with reactive POSS particlesThe first strategy involves using a difunctional epoxide which can be cross-linked with severaldifferent amine curing agents to form a highly branched network within the PC. The secondstrategy involves using a multifunctional epoxide both to cross-link <strong>and</strong> chain extend the PCchains. A catalyst has been chosen which promotes the reaction <strong>of</strong> the epoxide with the chainend groups <strong>of</strong> PC. Currently work is being done to find the composition <strong>of</strong> this system whichoptimizes the toughness <strong>of</strong> the material. The third strategy relies on a similar concept <strong>of</strong> crosslinking<strong>and</strong> chain extending the PC via POSS particles which have been functionalized withepoxide groups. The POSS particles have been found to aggregate within the PC creating ananocomposite-like structure. This however, significantly decreases the transparency <strong>of</strong> the PC.