WIP - July - Global Media Publishing Ltd. - UK.COM

WIP - July - Global Media Publishing Ltd. - UK.COM

WIP - July - Global Media Publishing Ltd. - UK.COM

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

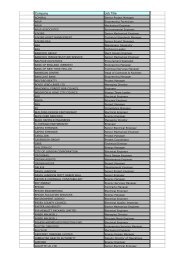

Editor:Aidan Turnbullpowereditorial@gmp.uk.comSales Director:Neb Saricnsaric@gmp.uk.comPublisher:Richard Teasdalerteasdale@gmp.uk.comJournal Assistant:Zoë Taylorztaylor@gmp.uk.comAccounts Division:Sally Gassonaccounts@gmp.uk.comFar East Sales:C H Park,Far East Marketing Incfemchp@unitec.co.krGerman/Danish/Swedish Sales:Mario Dobreskomdobresko@gmp.uk.comRussia Sales:Sergy Stanovkinstanovkin@dars.ruUS Sales & Subscriptions:Alex Carteracarter@gmp.uk.comAsia-Pacific Correspondent:John Gossjohn.goss@ceejay.com.hkContributorsChristopher Hopkins; Wartsila; GEEnergy Centrax; Man-Diesel; CumminsPower Generation; Siemens; BWE;Rolls Royce; ElectrawindsPublished by:<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong><strong>Global</strong> House, 13 Market Square,Horsham, West Sussex, RH12 1EU,<strong>UK</strong>. Tel: +44 (0)1403 220750Fax: +44 (0)1403 220751Website: www.gmp.uk.com© Worldwide Independent Power(ISSN 1468-7100).Subscription price £120 (<strong>UK</strong>),£180 (overseas) per year.Please send address changes toWorldwide Independent Power,<strong>Global</strong> House, 13 Market Square,Horsham, RH12 1EU, <strong>UK</strong>.Printed by Manor Creative, <strong>UK</strong>Auditors: ABC applicationapproved October 2006In the next issue• CHP & Cogeneration• Diesel/Gas Engine• Renewables Round Up• Gen-Sets & Loadbanks• Silencers/Insulation• UPS Systems/MaintenanceGMP<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong>J u l y 2 0 0 9C O N T E N T SAlternators 14Essentially, you want the greatest performance from analternator for the least cost, reports Steve Wells.CHP Systems 16Asko Vuorinen explains how modelling can help municipal CHPsystems to be optimised in terms of profit and efficiency.Gen-Set controls 18Roger Watterson looks at how generators and their controlsplay a vital role in network maintenance.Controls for Gen-Sets 20Larry Fetting and Lee Ann Duval unveil a new gen-set withPowerCommand software controls.Gas Turbines 22Malmo’s latest gas turbine driven plant has been completed byHitachi Power Europe, Olaf Lipinski reports.Heat Exchangers 24GEA Iberica has won an order for heat-exchange surfacecondensers for a new solar thermal power plant in Spain.Filtration 25US-based Westar Energy has saved US$231,000 over the lastthree years thanks to improved filtration from Pall.Blading 26There’s a new kind of abrasive tip material available forturbine blades, report Scott Wilson and Thomas Peters.Switchgear 27Linde Engineering’s project in Abu Dhabi depends on Siemens’gas-insulated 220-kV high voltage switchgear.Power Plant Review 28Profile of the Monsenergo Turnkey Project - PLUS we look atAustria’s Walsum 10 coal power plant in Westphalia [page30].R E G U L A R SPower news from around the world 6Sharewatch 12New Products, Contracts & Applications 32www.gmp.uk.com/powerPROMOTING ON-SITE POWER AND COGENERATIONWORLDWIDE INDEPENDENT POWERSwitchgear - the faceof the future?Heat exchangers destined for Spain.See Page 24.Our power portfolio includes:W O R L D W I D E I N D E P E N D E N T P O W E RJULY 2009Switchgearthe face ofthe futureSiemens Energy has produced advancedgas-insulated 220-kV switchgear for thepower supply to an air separation plantfor The Linde Group and ADNOC. [Pic:Linde’s Burghausen facility, Germany]More power for Malmo, Sweden.See Page 22.8-10 June - NEC - BirminghamIP&EE2010Independent Power & Energy EuropeM I D D L E E A S T P O W E R

www.iberinco.comWE HAVEMANAGED TOGO FURTHERTHANANYONE ELSE

EDITOR’S LETTERWEL<strong>COM</strong>EA warm welcome to this month’sissue of Worldwide IndependentPower - as always bringing youcloser to the stories and issuesaffecting on-site power andcogeneration around the world.For editorial comments, please donot hesitate to contact the editor.BIENVENUESoyez le bienvenu à cette issue deWorldwide Independent Power.Comme d'habitude, nous vousapportons toujours plus près dessujets qui affectent l'énergie et laco-generation sur place autour dumonde.N'hésitez pas contacter lerédacteur pour des commentaireséditoriaux.WILLKOMMENHerzlich Willkommen zur Ausgabedieses Monates von WorldwideIndependent Power. Wie immerbringen wir Sie näher heran an dieEreignisse und Geschichten derStromerzeugungsindustrie rund umdie Welt.Für redaktionelle Kommentare undAnregungen wenden Sie sich bittean den Autor.BIENVENIDOBienvenido a esta edición deWorldwide Independent Power.Como siempre, acercándolo a lostemas que afectan a la energía y ala cogeneración in-situ. No dudeen contactar con nuestro editorpara cualquier cuestión editorial.BENVENUTIBenvenuti a questa nuova edizionedi Worldwide Independent Power.Come sempre cercheremo dioffrirvi storie e questioniriguardanti on-site power ecogeneration a livello globale. Percommenti editoriali, si prega dicontattare l'editore.Aidan Turnbull- EditorThe mystery of renewablesHow are the renewable energy markets doing these days? If you believe all you read, it mightappear very well indeed. Europe is now said to be one of the best situated continents forusing renewable energy systems - such as sunlight, wind, rain, tides, geothermal heat andbiomass sources.In the <strong>UK</strong>, since 2000, we have established 70 wind farms, comprising more than 800 turbines intotal. As more become established costs have fallen, and the final cost of getting electricity fromthe wind has dropped considerably. The good news is that windfarms are growing every year at therate of 30%, with a worldwide installed capacity of 121,000 MW in 2008 and they have now becomewidely accepted in the US and Europe. In the latest media reports the experts have suggested thatthe potential of wind energy is five times our total current global energy production, or 40 timescurrent electricity demand.The truth is that potential does not equal viable potential. You'll often hear claims that windpower could generate much more electricity than we could possibly use. Unfortunately, theseclaims are generally based on silly assumptions, such as all land with wind potential could beconverted to wind farms. Yes, we could theoretically knock down Central London and build windfarms over the land, but not even the Greens feel this is a viable option.Sadly, apart from onshore wind, which is just about cost-competitive with conventional electricityproduction, renewables are an expensive way of generating electricity. Unless there are specialcircumstances - supply security considerations, environmental subsidies, or remote locations awayfrom the grid - meaning that any electricity supply from a central source would involve extension ofa grid network - renewables aren't really economically viable.One can argue that conventional fuels don't pay an economic rate for the clean-up of theenvironmental mess they make, and that on a level-playing field, renewables make more economicsense. But the fact is, nuclear energy aside, fossil fuels don't yet pay the full cost of clean-up,although there are attempts to move towards this with carbon trading.Put simply, the question people have to answer is this:"Do you want it cheap - or do you want it clean?"<strong>July</strong> has proved a fertile month for organisations promoting renewable energy issues. There is nowa body with worldwide reach called the International Renewable Energy Agency (IRENA) - made upof experts from 129 nations - which has agreed to establish a headquarters in Abu Dhabi from whereit will advise on renewable energy. <strong>Media</strong> reports have suggested that Australia and Japan addedtheir names to the document establishing IRENA just hours before its inaugural conference in Sharmal-Sheik on June 29th - so, clearly, this is viewed as an important development.IRENA’s aim is to offer advice to world governments on technical and financial issues linked torenewable energy and promote and encourage the introduction of this kind of technology acrossdeveloping countries.EUROPE ASIA-PACIFIC MIDDLE EASTAFRICAAMERICASW ORLDWIDE I NDEPENDENT P OWER • JULY 20095

NEWSIn brief...Sulzer Chemtechacquires SABSulzer Chemtech hassigned an agreement toacquire SAB TechnicalServices (India) for apurchase price of US$5.75million. SAB's annual salesare approximately US$4million. With thisacquisition Sulzer seeks toexpand its geographicalpresence as a leadingglobal field serviceprovider.Isolux in AfricaIngeteam T&D has justsigned a new contractwith Isolux to supply theelectrical equipment foran Ene power station inAngola. The contractincludes the supply of fivecomplete substations andprotection relays for foursubstations in differentprovinces of Angola.Ingeteam T&D is alreadylooking at the secondphase of the projectwhich includes theexpansion of several substations.This is thesecond contract thecompany has carried outin Africa since itsKuraymat project inEgypt.New filters for solarmodulesFirst Solar, one of thefastest-growingmanufacturers of solarmodules in the world, ismaking solar panels at anew plant in Frankfurt(Oder), Germany. Theseare being produced withan advanced thin-filmsemiconductor processkept clean by Camfil FarrHEPA filters.Infigen in US$25mdeal with B&BIInfigen Energy hasacquired Babcock &Brown International'sAustralian and NewZealand wind energyproject developmentassets for US$25m. It alsotakes over B&BI’s US windasset managementbusiness to enhanceInfigen's existing windfarm projects in the USand Germany.ABB wins US$24m order for <strong>UK</strong>ABB, the leading power andautomation technology group, hasbeen awarded a US $24 millioncontract by National Grid for a 400kV substation which will provide thegrid connection for a new powerstation in the north-west of England.The Carrington Power project is aCCGT (combined cycle gas turbine)plant located on the site of a formercoal-fired power station near the cityof Manchester. ESB International ofIreland is the majority shareholder inthe project. The new station,comprising two 430MW generatormodules, is expected to becompleted by 2013 and to produceenough power to meet the needs ofaround one million households.ABB's contract includes the supply offive bays of GIS (gas insulatedswitchgear) and associated systems.The switchgear will be housed in adedicated building elevated byaround 1.7 meters to ensurecontinued operation in the event of aflood. Future expansion by anadditional seven bays of GIS equipment has alsobeen allowed for."ABB's GIS solution, with its compact footprint, isideal for such applications," said Claudio Facchin,global head of ABB's substation business, a part ofthe company's Power Systems division. "We arepleased to support National Grid's efforts tostrengthen the reliability of the grid."Enfinity develops China powerA joint bidding team, initiated byEnfinity, has won the first 10 MWpsolar concession project whichinvolves developing China's largestPV power station. The DunhuangPV Project involves an investmentof 200 million yuan (27 mio euro),with an annual power productionof 16.37 million kWh, and afranchised operation term of 25years.In March 2009 the ChineseNational Development and ReformCommission (NDRC) initiated anopen tender to confirm theon-grid electricity price andtechnical solutions.A total of 13 enterprises,including major domestic powergiants, got the upper hand in thebidding, with tender pricesranging from 0.69 yuan/kWh(0.071 euro/kWh) to 1.9yuan/kWh (0.196 euro/kWh). Thejoint bidding team, which wasinitiated by Enfinity, has won theproject with the price of 1.09yuan/kWh. CGNPC and LDK Solarare the partners on the bid."The project is expected to startconstruction within 4 months andhas to be completed within the18 following months", commentedGino Van Neer, founder ofEnfinity. All PV systems will be PVtracker panels, installed on land.Enfinity is in the process ofsetting up the Dunhuang jointventure company and confirmingthe EPC contract. In the nearfuture Enfinity will develop atotal of 500 MWp of PVinstallations in the Dunhuangregion."Winning this bid is an importantmilestone for Enfinity'sinternational expansion strategyand it will act as an entranceticket towards the high potentialAsian market," says a very proudGino Van Neer.NDRC of China also intent to setup a bench mark FIT (Feed intariff) at 1.09 yuan/kWh thatEnfinity proposed. Enfinity - asthe only foreign player whoThe Carrington Power project.participated in the tender - hasattracted a lot of attention inAsia.Followed by the success of theDunhuang project, Enfinity iscontinuing the development inChina. Enfinity had its first selfdevelopedproject in Shizuishan(Ningxia province) approved bythe provincial level governmentrecently. The 10MWp project isready to be submitted to NDRCfor the FIT approval.6JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

NEWSIn brief...Botswana to getfluidised bed boilerplantThe AE&E Group - a leadingsupplier of power generationand environmentalsystems - has secured theengineering contract for thecombustion system of four150 MW circulating fluidisedbed boilers for theMorupule coal-fired powerstation in Botswana.German subsidiary AE&ELentjes won the order,worth almost EUR 10million, from generalcontractor China NationalEquipment Corporation. Theengineering design work isdue for completion by theend of 2009, and phaseddelivery of the boilers toend-user Botswana PowerCorporation is scheduled tobegin in 2011. AE&E Lentjeswill provide commissioningsupport services.Dresser-Rand andSamsung Techwinenter strategicallianceThe Dresser-Rand Company,an affiliate of Dresser-RandGroup Inc. and SamsungTechwin Co., <strong>Ltd</strong>. anaffiliate of Samsung Groupin Korea, have entered astrategic alliance. Thealliance calls for exclusivepackaging of Dresser-RandDATUM centrifugalcompressors and VECTRApower turbines for mechanicaland generator-driveapplications to supplyKorean-based shipyards andengineering companies, aswell as to supply the localKorean market.GEA supplies powerplant cooler to Chinafor 2010GEA received a EUR 22morder to design,manufacture and supply anAir Cooled Condenser forthe 1200 MW Guijao II coalfired power plant in theShanxi province in China. Itwill be delivered by 2010.The Air Cooled Condenserwill be equipped with ALEXAir Cooled Condenserbundles which will bemanufactured at GEA'sfactory in Langfang, China.Wood Group gets Sheringham wind farmWood Group Engineering (NorthSea) <strong>Ltd</strong> has been awarded thedesign and project managementof two offshore substations byAREVA T&D on the SheringhamShoal Offshore Wind Farm. The88-turbine 315 MW (220,000 homepotential supply) wind farm issited just inside the 12-mileterritorial limit of Sheringham onthe <strong>UK</strong>'s North Norfolk coast.Sheringham Shoal Offshore WindFarm will be developed by SciraOffshore Energy <strong>Ltd</strong> which isjointly owned by the Norwegiancompanies StatoilHydro andStatkraft.Power from the 88 wind turbineswill be captured by the twooffshore substations before beingsent to shore. Capturing energyvia unmanned offshoreJordan’s 65m€ gas turbinesIt's been 5 months since theFinmeccanica subsidiary AnsaldoEnergia, a leading provider ofcomponents and services forpower plants, signed two majorinternational contracts worth atotal of more than 65M€ withJordan. AE has already shippedsome systems to the Middle Eastas part of the deal.The agreement in Jordan wasoriginally reached with the Koreancompany Doosan. This involvesproviding two V94.2 gas turbinesin 2+1 configuration for thecombined cycle power station(450 MW in total) atAmman East.substations at source, prior tosending it to shore, is moreenergy efficient than usingonshore substations."Wood Group's move into therenewable energy sector is anatural progression from theservices it provides to the oil &gas and power sector," said LesThomas, Group Director forProduction Facilities."With 30 year's experience workingwith oil & gas operators in theEastern Hemisphere, WGENS iswell placed to apply its technicalexpertise to offshore wind farmdevelopments."In a recently announced paralleldevelopment, Wood Group's GasTurbine Services division has setup Wood Group Renewable EnergyServices, with offices in HoustonA long-term service agreementhas also been secured directlywith the AES/Mitsui consortium,which is acting as developer forthe project and is also responsiblefor the plant's operation andmaintenance.As a corollary to this order,Ansaldo Energia will supply a 280MW steam turbine and a 330 MVAair-cooled generator to theKorean company Posco, theworld's third-largest steel group,which will be acting asEPC contractor for theconstruction of a coal-fired plantat Nueva Ventanas, Chile, ownedby the US power company, AES.and Aberdeen, to provide a fullrange of asset managementsolutions for all industrial windturbines.Siemens expands gasturbine capacitySiemens is expandingproduction capacity at its gasturbine manufacturing plant inBerlin. Last month, thecompany opened a productionfacility in the Moabit districtin the presence of Karl-Theodor Freiherr zuGuttenberg, Federal Ministerof Economics and Technology,and Peter Löscher, Presidentand CEO of Siemens AG. Thisexpansion of productioncapacity will create 200 jobs,says Siemens.Almost one-third of the totalinvestment of EUR42 millionwas channelled into the newproduction facility. In thefuture it will be possible toeasily produce approximately14,000 gas turbine blades andvanes there every year. Its gasturbines are then sold topower plants around the globefor eco-friendly powergeneration."We are pleased that Siemensis sticking with the Berlin locationand not only securing jobsbut also creating new oneseven in these turbulent times,"Karl-Theodor Freiherr zuGuttenberg told <strong>WIP</strong>. Siemensis the major employer in theindustrial sector in Berlin.8JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

How can we get by with less when thewhole world keeps asking for more?Getting more and more energy from fewer and fewer resourcesis our never-ending mission.In addition to excellent availability and utmost reliability, efficiency is a key requirement when it comes to supplyingenergy for the world’s steadily growing megacities. Basically, it’s all about making best use of all resources. We apply thisprinciple across the entire energy conversion chain to take efficiency to totally new levels. Our new 800 kV transformer,for example, makes possible the efficient transmission of electric energy in the gigawatt range over distances of 1,000kilometers and more. And our new generation of gas turbines makes combined cycle power plants deliver a recordbreakingefficiency of more than 60 per cent. www.siemens.com/energyAnswers for energy.

NEWSIn brief...China success forTrinaTrina Solar Limited, aleading integratedmanufacturer of solarphotovoltaic products fromthe production of ingots,wafers and cells to theassembly of PV modules,has completed a deal witha key solar module glasssuppliers, Beijing Hua MeiDazheng Technology Co.<strong>Ltd</strong>. The two companieshave ratified an investmentagreement to build aproduction facility in theChangzhou TrinaPhotovoltaic Industrial Park.Micro wind turbinegenerators - theEogen solutionSmall wind turbines are oneof the most adaptable,flexible and easy to usetechnologies for generatingsustainable and cheapelectricity - that's thereason this market isbuoyant right now.Mecc Alte has designed anew series of alternatorfocused on this newapplication. The Eogenseries, ranging from 400Wto 5kW, has been designedwith the latest technologyavailable. Thanks to anoversized double bearingdesign, Eogen is said to bethe perfect solution bothfor vertical and horizontalwind turbines as it can beused as rotating hub for theblades, which results in abetter solution for theintegrator, reportsMeccAlte.Germans take onItalians at PortovayaGas Treatment PlantGermanischer Lloyd (GL)has signed a contract withMilan-based Siirtec NigiS.p.A. This is the largestAdvanced AdsorptionProcess Technology (ADAPT)contract that GL hassecured and will be for thelargest silica gel gasprocessing plant everconstructed. GL suppliesadsorption technologyservices for the newGazprom Portovaya GasTreatment Plant in Russia.Wind diesel power plant destined for BonaireThe Caribbean island ofBonaire has been chosen as theplace to establish the largestwind-diesel power generationfacility in the world. One of themajor companies in thedevelopment consortium is MANDiesel which will be ensuring thatthe island's needs for electricalpower can be covered fromrenewable sources for the next 15years.The project calls for theconsortium to construct andoperate wind and Diesel powergeneration facilities on the island.The generating facility will bebased on five 2.85 MW rated MANDiesel generator sets with thecapability of running on biofuel.The consortium is lead bysustainable energy solutionsprovider Econcern of Utrecht, theNetherlands and will beSolar power plant from ABBABB has completed delivery andcommissioning of the 1-megawatt(MW) Totana photovoltaic powerplant located in the region ofMurcia in Spain. In a year, Totanaproduces 2.2 gigawatt-hours ofgrid-quality electric power anddisplaces some 1,350 tons ofgreenhouse gas emissions.The turnkey solution wascompleted in a record time of fourmonths and is based on ABB'smodular concept for photovoltaicpower plants. It includes solartrackers, electrical balance ofplant, instrumentation andcontrols. The equipment isdelivered pre-assembled andfactory-tested to reduce on-sitework and time. The project scopealso covered installation andcommissioning, as well as theassociated civil works. The fasttrackdelivery enabled the plantowner, <strong>Global</strong> Capital Finance, tomeet the time criteria and qualifyfor the maximum feed-in tariff forphotovoltaic power plants.ABB's photovoltaic conceptincludes patented optimisationtechnologies that will help increasethe plant performance ratio tocompleted by Econcern subsidiaryoperating company Evelop andleading wind turbine and windpark specialist Enercon based inAurich, Germany.The project is trend-setting intwo ways. Firstly, it will enableBonaire to produce 100% of itselectrical power from renewablesources.Secondly, it makes the EcoPowerBonaire consortium both thebuilders and the owner/operatorsof the complete Bonaire electricalpower generation system.The plan to convert thecomplete electricity supplysystem of Bonaire to sustainablesources was devised by the Waterand Electricity Company ofBonaire (WEB - Water en EnergieBedrijf Bonaire).Its main elements involve theconstruction of an 11 MW windaround 80%, nearly 5% higher thanaverage industry standards for suchapplications. This clearly leads tohigher energy efficiency andtranslates into increased powerproduction and higher revenues forthe operator."Our ability to deliver a completeturnkey photovoltaic power plantin a remarkably short time andwith such high plant efficiencylevels is indicative of our technologystrength and executioncapabilities to serve the solarenergy business," says Franz-JosefMengede, head of the global PowerGeneration business, a part ofABB's Power Systems division.turbine park at Morotin onBonaire's northern coast and theconstruction near Bopec on thesouthern coast of a 14 MW Dieselpower plant.The wind turbines will have thecapacity to meet Bonaire'scomplete electricity supply whenwinds are strong enough.With its rapid start-upcapability, the diesel power plantwill serve as back-up duringperiods of low wind speeds andduring tropical storms, coverdemand peaks and stabilise thesystem.With a total capacity of 25MWthe project includes sufficient,carbon dioxide (CO2) neutralpower generation capacity tocope with growth in demand forelectrical power over the next 15years.GE Energy singledout by US GovtGE Energy's US-basedproduction facility in Slater,Mo., has received an awardfrom the U.S. Department ofLabor's Occupational Safetyand Health Administration(OSHA).It singled out the Slaterfacility for its outstandingcommitment to employeeprotection. OSHA's VoluntaryProtection Program (VPP)recognises businesses and worksites which demonstrateexceptional safety, health andenvironmental practices.A spokesman told <strong>WIP</strong>: “VPPparticipants comprise a selectgroup of facilities which havedesigned and implementedcomprehensive safety, healthand environmental programswhich go beyond normalcompliance with OSHAmandates to protect workersmore effectively,” he said.“VPP is OSHA's officialrecognition of the dynamicefforts of employers andemployees who have achievedexemplary occupational safety,health and environmentalperformance at their facility”.10JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

NEWSBiggest CFB from Foster Wheeler AGFoster Wheeler AG’s latest turnkeyproject has involved providing theworld's largest circulatingfluidised-bed (CFB) steamgenerator - which is also theworld's first supercritical CFB. Thishas successfully begun operatingat the Lagisza power plant, ownedby Polish utility companyPoludniowy Koncern EnergetycznySA (PKE).Foster Wheeler's <strong>Global</strong> PowerGroup provided the turnkey supplyof the boiler island, includingengineering and design, erection,civil work, start-up, andcommissioning.The new CFB replaces 1960s-erapulverised coal units at the powerplant and was built adjacent tothe old boilers.Many existing plant systems,including coal-handling and watertreatment, were renovated foruse with the new CFB unit.The Lagisza CFB produces 460MWe of electricity at an efficiencylevel well above that of typicalcoal plants.The unit incorporates a numberof advanced design features suchas compact solid separators,INTREX super heaters, and lowtemperatureflue-gas heatrecovery that captures valuableAUGUST* 3rd Renewable Energy India2009 Expo, 10th-12th August, NewDelhi, India.* COAL-GEN USA 2009, August19th - 21st, 2009, Charlotte, NC,USA.SEPTEMBER* Turbomachinery Symposium,September 14-17, 2009 at theGeorge R. Brown ConventionCenter, Houston, TX, USA.* ENERGTAB 2009 - 22nd PowerIndustry Fair, 15th-17thSeptember, Biala, Poland.OCTOBER* COAL-GEN EUROPE, 1st-4thSeptember, Katowice, Poland.* KIOGE 2009, KazakhstanInternational Oil & Gas Exhibitionand Conference, Almaty, October6-9th, 2009.* POWER-GEN Asia 2009, 7-9thheat that would otherwise be lost.The unit incorporates - for thefirst time ever in any CFB - highlyefficient BENSON vertical-tubesupercritical steam technology.The BENSON vertical tube is a newsteam technology which is moreefficient and reliable thanconventional supercriticaltechnology prevalent in themarket today.October, IMPACT ExhibitionCentre, Bangkok, Thailand.* AMPS POWER EXPO 2009 - inassociation with IP&EE, on 7th -8th October, London Olympia, <strong>UK</strong>.* ADNEC - Power Generation andWater Middle East 2009, 11-13th,2009, at the Abu Dhabi NationalExhibition Centre, Abu Dhabi.* Louisiana Gulf Coast OilExposition 2009 - October 27-29thin Lafayette Louisiana, USA. Nowin its 55th year.* Solar Power International '09on October 27th-29th, Anaheim,California, USA.NOVEMBER* Energy Show 2009 at ShanghaiNew Int'l Expo Centre, China,from 3rd - 7th November.* Algeria Electricity Expo, 3rd-5th November, 2009.* Vietnam Forum & Energy Expo,"This CFB represents aculmination of 30 years of designevolution for developing areliable, fuel-flexible technologyfor utility scale electricityproduction," Jaroslaw Mlonka,President and Chief ExecutiveOfficer for the Polish subsidiary ofFoster Wheeler's <strong>Global</strong> PowerGroup, told <strong>WIP</strong>.Energy industry teams raise £174,000A record number of teams fromthe energy industry took part inthe <strong>UK</strong>'s BG Energy Challenge2009 held in <strong>July</strong>, overcomingthree days of gruelling physicaland mental challenges and raisingmore than £174,000 for charity.The largest industry networkingand fundraising event of its kindsaw over 260 participants descendon Bangor, Wales to competeagainst each other and raisemonies in aid of nominatedcharities CARE International andSparks.The annual event, hosted byglobal natural gas business BGGroup, included teams from BGGroup, Amec, CB&I, Centrica,Fugro Robertson, Hess, KPMG,Nexen Petroleum, Petro-Canada,Energy Conference & exhibition dates for 2009Schlumberger, Weatherford andVenture Production. The outrightwinner was Team 7 BG GroupStrategy from the company'sReading-based headquarters.Hanoi, Vietnam, 4th-7thNovember, 2009.* Gas Turbine Users International(GTUI) Annual Conference onNovember 8th 13th, 2009 inCalgary, Canada, at the GrandHyatt Hotel.* India Energy, 13th-15thNovember, Mumbai ExhibitionCentre, Mumbai, India.* Energy Day In Croatia,November 20th, Zagreb.--------------------------------------DON’T FORGET JUNE 2010* IP&EE (Independent Power &Energy Europe), 8th - 10th June,NEC Birmingham, <strong>UK</strong>, will runconcurrently with Electrex 2010,one of the <strong>UK</strong>'s top industry tradeshows. Both highly-regardedexhibitions are being organised by<strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> <strong>Ltd</strong>.More info? Visit: www.gmp.uk.comIn brief...AUMUND Asia opensdistribution centre inHong KongThe need for a fast andreliable supply ofmaterials & fuels for theenergy sector hasencouraged AUMUND toestablish a new distributioncentre in Hong Kong. Thisadds to its establisheddistribution centres inRheinberg, Germany, and inAtlanta, USA. Two morecentres are in the pipelinein India and Brazil.Siemens wins £multimillionordersTwo important multi-millionpound orders from Rio TintoAlcan will bring additionalwork into Siemens'Newcastle facility later thisyear. The latest contractawards cover refurbishmentand outage work at theAlcan aluminium smelter atLynemouth inNorthumberland. Work willcommence on the Unit 1 IP(Intermediate Pressure)Steam Turbine Modulefollowed by the refurbishmentof the Unit 2 IP in thesummer of 2010. Siemens isalready undertaking arolling lifetime extensionprogramme at Rio TintoAlcan's 'captive' powerstation in Northumberland,as well as manufacturing IPturbine rotor and innercylinders for the powerstation, which uses threeParsons steam turbinegenerators to generate theelectricity for thealuminium smelter.India Contract forMeggitMeggitt PLC has won acontract award for a fullcondition-monitoringsolution from Relianceenergy for the new 600 MWHissar power station inHaryana state. Thisbuilds on Meggitt's previousaward of the YamunagarPower project, also inHaryana. Meggitt's latestoffice, which opened inBanglaore, will be used as aplatform from which tomarket Meggitt's sensingsystems products to India'scoal-fired power plants.W ORLDWIDE I NDEPENDENT P OWER • JULY 200911

SHAREWATCHThe renewable energy questionJohn Sauven, Greenpeace's executive director, looks at the <strong>UK</strong> Government’s policytowards renewables while<strong>WIP</strong>’s Christopher Hopkins reports on shares prices.<strong>July</strong> has proved an interesting monthfrom an energy point of view. The <strong>UK</strong>Government published two WhitePapers entitled: ‘The <strong>UK</strong> Low CarbonTransition Plan’ and ‘The <strong>UK</strong> RenewableEnergy Strategy 2009’. In these theGovernment has set out a number ofmilestones which it believes will beachieved by 2020. It projects that 1.2million+ people will be in green jobs andthat approximately 40% of electricity willbe from low carbon sources such asrenewables and nuclear. The Governmentalso includes coal with carbon-capturetechnology in this category. Clean coalemits less NOx and SOx but the only wayto avoid carbon emissions is to use carboncapture technology when burning it.In theory, theGovernment has pledgedthat the <strong>UK</strong> will be retiring 45% of itsenergy generating capacity by 2020 –more than any other European nation.The Transition Plan sets out how the <strong>UK</strong>will attempt to meet the cut in emissionsin the budget of 34% on 1990 levels by2020. This is the reduction laid out in theClimate Change Act 2008 (which wasadopted into the <strong>UK</strong> statute books inNovember 2008). The Transition Planstates that a 21% reduction has alreadybeen delivered, equivalent to cuttingemissions entirely from four cities the sizeof London.John Sauven, Greenpeace's executivedirector, commented: "The Governmentmust prioritise renewable energy andenergy efficiency over everything else inthe sector. If they do this, Britain couldlead the fight against climate change,whilst providing hundreds of thousands ofjobs. Anything less would be a failure."The Government envisages that 50% ofelectricity will be derived from lowcarbon sources by 2025. Amongst 'lowcarbon sources' the Government includesan unknown amount of fossil-fuelledelectricity with carbon capture andstorage as well as nuclear energy.Funding for such <strong>UK</strong> projects - availablefrom the European Investment Banks - isrumoured to be significantly less than the£4bn announced in the last budget. Onthe plus side, the economic effects ofsuch developments are likely to includesmarter delivery and planning reform,Company(Currency)Monthlyshare price52 weekhigh/lowABB (CHF) 17.08 11.29/29.73Ansaldo (EUR) 13.12 7.71/13.18Atlas Copco (SEK) 69.75 40.70/91.00Caterpillar (USD) 33.04 21.71/75.87Chloride (GBX) 151.25 107.25/270.00Cummins (USD) 35.21 17.70/75.98Doosan HeavyIndustries (KRW)Foster Wheeler(USD)61,300 37,300/104,00023.75 12.73/75.00better grid connections and more dynamicelectricity transmission and distributionnetworks.<strong>WIP</strong>Change overmonthChangeover yearChange sinceJan. 2008-2.29% -41.90% -38.78%+10.34% +37.34% +51.85%+2.95% -13.08% -20.96%-6.82% -55.20% -53.96%-0.66% -41.83% -14.67%+8.57% -45.28% -24.99%-16.26% -38.08%-10.44% -67.24% -66.92%GE (USD) 11.72 5.73/ -13.06% -55.37% -67.59%John Deere (EUR) 1,500 1,450/ 0.00% +2.04% +21.46%Kirloskar (INR) 82.05 31.50/101.60MAN (EUR) 43.70 26.37/74.49Mitsubishi (JPY) 1,788 923.00/3,650MTU (EUR) 23.23 12.87/27.92Internet linkwww.gmp.uk.com/power-8.83% -5.20%+1.42% -38.02% -46.53%+18.69% -47.83% -30.18%-0.61% -48.91% -34.26%Rolls-Royce (GBX) 361.50 231.14/ +10.21% +5.86% -25.66%404.79Siemens (EUR) 49.16 33.05/ -4.43% -30.65% -45.01%79.80Volvo Penta (SEK) 47.60 29.10/ -1.86% -35.68% -46.96%83.00Wärtsilä (EUR) 23.77 15.53/ -6.08% -40.05% -45.08%41.49Monthly figures taken at the end of June 200912JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

Rotor bolt tensioningfor GT compressorsBoltight bolt tensioners are designed to tensiongas turbine compressor rotor through bolts. Thetools are ideal for new manufacture and serviceenvironments, offering accurate and repeatablebolt loading.OUTSTANDING!AC & DC Generators 5 - 85KVA4/2 Pole 1/3 Phase Industrial/Marine/AgricultureGENCO EEC LTDUnits 7 & 8 Ketton Business Estate Pit Lane, Ketton, Nr StamfordLincolnshire, PE9 3SZ, United KingdomTel: (+44) 01780 - 721619 Fax: (+44) 01780 - 721385e mail: generators@gencoeec.co.uk www.gencoeec.co.ukKey features▲ Compact size▲ Lightweight▲ Easy to use▲ Fast and reliableEmail rotors@boltight.comor call +44 870 7744661www.boltight.comBOLTIGHTRHYDRAULIC BOLT TENSIONINGNeed tomanage agas engine plant?The Delomatic offersan integrated heatand power managementsolution. Itscapabilityofcompletesystem management ent ensureshassle-free operationof your entire combinedheat andpowerplant(CHP) – regardless of your type of gas: bio, natural, landfillor other.Additionalfeaturestoensureeasyoperationinclude atouchpanel PCandthepossibilityofremote operationvia networkorinternet (TCP/IP) connection. Agraphicdisplayofheating,cooling and fuel circuits is also an available option.Delomatic features:• Easy,configurable setup• Gen-set control and protection• Gas mixer control• Heating and cooling watercircuit control•HMI with animated diagramsHMIThe DEIF Group – Head office in Denmark with subsidiaries in Germany,Norway,<strong>UK</strong>, France, China, USA, Brazil and IndiaDEIF A/S·Frisenborgvej 33·DK-7800 Skive·Tel.: +45 9614 9614 ·Fax: +45 9614 9615 ·info@deif.com ·www.deif.com

ALTERNATORSAlternators - what to look forEssentially, you want the greatest performance from an alternator for the least cost andwithout creating difficulties, explains Steve Wells of Mecc Alte <strong>UK</strong> <strong>Ltd</strong>.Selecting an alternator for a givenapplication is something often overlooked,writes Steve Wells.Even some very well-known hirecompanies will generally oversize agenerator to ensure that there are noproblems encountered at site. Probablythis is quite right as there are major costsinvolved in shipping generators around thecountry.For fixed generator applications theload, present and future is usually knownat the start, and such loads are becomingincreasingly more complex. It is still quitelikely that a specification for a generatingset will have 80% written around theengine and systems, but little left for thealternator. Alternators are important withregards to the load, to economy and toreliability and should command morethought.Different alternator manufacturers havediffering priorities, whether group-led orsimple design philosophies. Generallyspeaking, you want the most performancefrom the alternator for the least cost andwithout creating difficulties.The higher the efficiency, the less fuel isburned for a given power output. Here,there are differences betweenmanufacturers that are quite marked - upto 5% difference in efficiencies in somecomparisons.Although not directly proportional tofuel saving, it is in fact a fuel-saving usingthe higher efficiency machines. This is anod to the 'greens', and also for thoseseeking optimum power from the gensetto give them an edge in a tender, or touse the slightly lower power engineoption.Again, for optimum sizing and winning oftenders, the transient ability of thealternator could result in a smallermachine. Some projects will need to sizethe gen-set based upon the transient andnot the continuous load. In these casesLV alternator from Mecc Alte <strong>UK</strong> <strong>Ltd</strong>.the steady state condition means it is avery lightly loaded genset with all theconsequential problems encountered withengines and then ultimately its reliability.The alternator does not give a jot aboutlight loads, although if it has an goodoverload ability - 'current forcing' thenyou can have a smaller machine to thesame job. Systems exist now with theMecc Alte 'MAUX', the CGT's 'PMG/EBS' andthe Leroy Somer's 'AREP/PMG', but not allof theses are standard fixtures so bewareof the cost penalties.Some loads will create currentharmonics and affect the waveformproduced from the alternator and alsoadd to the heating effects in thealternator windings. Some loads arevariable peed motor drives, UPS systemsand furnaces. Here it is important tounderstand the level of harmonicsproduced by the load and the amount ofvoltage distortion the load will allow.Factors to consider when sizing themachine will include:- The AVR should have a dedicatedpower supply which is either separate tothe main power windings or derived froma differing vector. These will include theMecc Alte 'MAUX', the CGT's 'PMG/EBS' andthe Leroy Somer's 'AREP/PMG'.- Ideally, the regulator shouldsense on all three phases to get an overallpicture of what is happening to themachine - because it will still be sensingthe distorted output waveform from thestator.- Oversize for either heatingand/or to reduce output voltagedistortions.- The oversizing has the effect ofreducing the sub-transient reactance (x"d)of the machine. The lower the value thebetter the machine will cope with thedistorted loads. Some manufacturers havemachines with a low x"d across most ofthe range which means less oversizing -smaller machine, more compact, less cost- win tenders.Not all manufacturers have the samephilosophy - to provide all of this in acompact, reliable and proven package ata competitive price. So look around atwhat is on offer from the most popularmanufacturers. Do not follow like sheepto the 'perceived' best - because they maynot be the best at all.<strong>WIP</strong>Internet linkwww.meccalte.co.uk14JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

CHP SYSTEMSOptimising municipalCHP systems for usersDrawing on CHP modelling, Asko Vuorinen, General Manager, managing Director ofModigen <strong>Ltd</strong>, explains how municipal CHP systems can be optimised in terms ofprofit and efficiency.Municipal power systems aredesigned to provide an area of acity with electricity and heat. Asan example, let's take Finland - the mostnorthern of the EU countries. Thepossibilities for CHP generation here aregreater than for almost anywhere else inEurope because of the heating needs ofits cities.Let's consider the electrical loadduration curve of a model city in Finlandwith, say, 100,000 inhabitants. The peakelectricity load would be 250 MW, or 2.5kW/capita. The electricity consumption is1,200 GWh, or 12 MWh/capita. The fullpower hours in the system are 4,800 h/a(1200 GWh/250 MW).The peak load of heat consumption is400 MW, or 4 kW/capita. Annual heatconsumption is 1,200 GWh, and is thesame as electricity consumption. Thus,the annual full power hours in the heatsystem are 3,000 h/a (=1200 GWh/400MW). Heat is distributed via a districtheating network which has an inlettemperature of 90°C and a returntemperature of 50°C.In the case being considered all of theelectricity will be purchased from thenational system, and all of the heat willbe produced with hot water boilers.Alternative municipal power plantsinclude a gas engine (GE) plant, adualfuel combined cycle (DFCC) plant,and a coal-fired CHP plant.The typical gas engine plant (GE-32/32)has four 8 MW engines. It can produce 32MW of electricity and 32 MW of heat forthe district heating network.The dual-fuel combined cycle plant, onthe other hand, (DFCC-67/61) has four 16MW dual-fuel engines and one 3 MW backEngine room of a major CHP project in Hungary [pic. courtesy of Wartsila]pressure steam turbine. It can produce 67MW of electricity and 61 MW of heat. Wecan evaluate the heat balances ofalternative power plants using anevaluation program. In the first place, wecan study each alternative, one-by-one,and try to find the alternative offeringthe best profitability as measured insimple payback time of the marginalinvestment costs.Investment costs riseIn decentralised or centralised powerplants we can assume that the investmentcosts for power plants are rising at anexponent of 0.9, in line with theincreasing size of the power plant. Thus,large plants mean, on average, lowerinvestment costs per invested kilowatt ofpower.However, the costs of energy distributionsystems rise with the size of powerplants. Therefore, there is always anoptimum size for the system, where thegeneration and distribution costs are at aminimum level. Investments needed inthe electricity and heat distribution networksshould total less than the savingsrealised from the construction costs of alarge plant. However, this largely dependson the type and size of the area served bythe power plants.If the area served is large, and there areseveral local consumption centres, itcould be more economical to build localplants in each centre.There are also security aspects involved.If the plants are all on one site, a singlefailure of the system caused by, say, afallen tree or corrosion in the districtheating pipes, could result in the entirecity being blacked out. Such failures canbe limited by having at least two sites, sothat should a network failure occur, only50% of the system will be affected.In general, a modern power and heatsystem should be planned to manage asingle failure criterion, whereby singlefailures cannot black out the whole city.There should, therefore, be reserve power16JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

CHP SYSTEMSGyor in Hungary: 55% of the peak demand for heat is covered by the CHP plant.plants and heat boilers included in thesystem.If a single unit power plant produces100% of the heat load of a city, it wouldneed a 100% backup boiler. If a powerplant has been constructed using sevenunits, then the backup boiler requirementwould be only 15% of the total capacity.The costs of the additional reserve boilercapacity should be included when makingthe cost evaluation.In Finland, 2.4 million inhabitants live inhouses heated by district heating systems.This corresponds to 46% of the totalpopulation of 5.2 million.In the 30 largest cities the totalelectrical output of CHP plants in thosecities is about 3,500 MW, and the averagecapacity calculated per district heatingcustomer in those cities is 1.7 kW/capita.Very few cities have less than anestimated 1 kW/capita. The cities ofEspoo, Jyväskylä and Hämeenlinna havethe largest potential for new CHPcapacity. Espoo could triple its capacityand build plants generating 250 MW.Jyväskylä and Hämeenlinna couldincrease their capacities by 50% - 100%.Jyväskylä could build a 50 - 100 MW plantand Hämeenlinna a 30 - 60 MW plant.Combined heat and power plants offerthe lowest cost in the power system andthere should be more of them.In the north, where the heating season islong, CHP plants can generate 100% of thecities' electricity needs. The largest citiescan, with the right planning, beindependent of outside electricity.Instead, they can have gas engine andcombined cycle plants, which have apower-to-heat ratio of one or more.A city can then build CHP capacity of 2.4kW/capita. Smaller cities can be almostindependent of outside power, if a majorityof the people are living in houses heatedby district heating. With gas engineplants, capacity can reach 2.0 kW/capita.The CHP plants are profitable investments.The costs of power generation arelower because of the high total efficiency,which is 80 - 90%. Maximisation of theCHP capacity can be achieved by buildingCHP plants which have the highest heatto-powerratios or alpha values.Local power plants can also be built tobe independent of the national grid.Thus, if the grid has a disturbance, thelocal power system can be separated fromthe grid. Under this scenario, the localsystem should be built using smallerpower plants that can meet the singlefailure criterion.This scenario was experienced inNovember 2006 during the blackout of theWestern UCTE-system. Several cities werethen without power, but Barajas Airport inMadrid had no interruption, because thesix Wärtsilä 6 MW dual-fuel engines wereautomatically switched for island modeoperation. This type of multi-unit powerplant is also capable of generating enoughpower should one unit be out of operation,or if gas pipelines are broken.Asko Vuorinen's book "Planning OptimalPower Systems" is available for internetorders atwww.optimalpowersystems.com.Internet linkwww.wartsila.comwww.wartsila.com/usa<strong>WIP</strong>Solar Taurus T60MOBILE GEN SETS5.2 MW• Solar Maintained• 7 Units (Gen 1) & (Gen 2)• All Natural Gas• Mobile PCR U.G. Switch gear• Low Nox 25 ppm• 60 Hz • 13.8 kV• 50 Hz Conversion Available205-590-3505 Tel205-590-3885 FaxWesley: wtuggle@maegen.comArt: asigler@maegen.comGreg: gposey@maegen.comKeith: kcoleman@maegen.com

CONTROLS & MONITORINGGen-set controls & network outagesGen-sets and their controls play an important role in network maintenance and in thecontinuity of supply for end users, explains Roger Watterson, MD for DEIF <strong>UK</strong> <strong>Ltd</strong>.It is vital that outages are planned asmuch as possible and the supplymaintained. Many would say this shouldhappen at any cost - but, of course,safety remains a paramount concern,reports Roger Watterson.In the real world network operators havea gen-set supplier who can usuallyprovide correctly-trained and authorisedpersons to ‘back synch’ to the grid withsophisticated equipment in the safestpossible way.The ‘DEIF way’, for example, involvesusing a Remote Maintenance Box (RMB)which can be connected to a gen-set andthen the RMB can be moved up to 300metres away.This allows the operator to work somedistance from the gen-set, but still have avisual and audible indication of thestatus of the gen-set and its readiness tooperate in synchronisation.Coupled with a display indication of allgen-set readings, this makes for the safestpossible situation.Removing the fuse must be done at thecorrect time to avoid the obvious dangersof arcing due to operation whilst ‘out ofsynch’.The control unit is extremely fast, andstable synchronisation ensures maximumsafety when removing the fuse.The RMB can be positioned within easyreach of the operator, enabling him/herto stop the gen-set, synchronise the genset,deload the mains and go into island.The RMBfrom DEIF.At this point he can remove the RMB if itis required elsewhere, leaving the gen-setnow happily being supplied as the mainsfrom the customers’ point of view.This means that not only can one RMBbe used for a number jobs, but gen-setfitted with a standard AGC controller canbe also be used for any ‘normal’application at any time, thus allowing formaximum utilisation.This is the ultimate goal in the currentclimate for any operation manager, assetowner or business person.Safety remains a key factor and,therefore, operators have to be equippedwith the correct personal protectionequipment to suit this application alongwith the correct testing equipment.This includes specialist gloves andfaceguard along with the usual obviouspersonal protective equipment.The operators also have to be ‘approved’Inside the RMB.to be able to complete this necessarywork and would generally have networkengineers also in attendance. However,the RMB is designed to be very simple tocontrol.The step-by-step sequencer offers anintuitive user interface which makes theoperation extremely simple and servicevery easy. This leaves the operator toconcentrate on the many other technicalissues he has to consider.When the distribution network operatoris ready for the mains to be restored, theoperator simply plugs in the RMB andpicks up where he left off. Then, theSafety is of paramount importanceduring maintenance operations.operator moves to the next position onthe switch ‘synchronise to mains’ and theset will automatically synch to the mainswith the operator moving through thenext steps of ‘Deload Mains’ and ‘Stop’.This will complete the operation.The RMB can be unplugged duringoperations, stored away or used on thenext site awaiting planned outage.Once the operation has been completed,the gen-set can be moved to its next job,for instance, a rental situation such asAutomatic Mains Failure, peak lopping,load sharing with other gen-sets, etc. Thisensures the rental operator is maximisinghis costly assets.As the networks also have a wide rangeof older and existing installations to workwith, the RMB is designed to be flexible tofit in with this.It can cater for single or three-phasesupplies with very simple menu changes.Internet linkwww.deif.com<strong>WIP</strong>18JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

PUTTING YOU IN CONTROL ›››› AUTOMATIC GENERATOR CONTROLS › AUTOMATIC PARALLELING› LOW VOLTAGE SWITCHBOARDS › MOTOR CONTROL CENTRES› AUTOMATIC TRANSFER SWITCH PANELS › MAINS PARALLELINGIt isn’t possible to tellyou all about us inthis much space.www.controlandpower.co.ukTelephone: +44 (0)1723 871112Fax: +44 (0)1723 870625control and powerat your finger tipsVISIT OUR WEBSITE:Control & Power Systems <strong>Ltd</strong>. 3D Burniston Industrial EstateScarborough, North Yorkshire YO13 0HG

CONTROLS & MONITORINGControl systems for gen-setsLarry Fetting of Cummins Power Generation <strong>Global</strong> Rental, and Lee Ann Duvall,product manager, reflect on a new gen-set with PowerCommand® software controls.This new1500 kW Rental Power unit hasbeen designed to provide from 35 kW to2 MW for prime, emergency, standby anddistributed generation applications. Butthe PowerCommand control systemmakes it truly special.Asmart system control approach fromCummins Power Generation Inc isembodied in a new Rental Powergen-set. This is said to provide versatilityin a complete pre-integrated controlsystem with increased fuel capacity andbetter fuel economy than competitivemodels. <strong>WIP</strong> has the latest information onthe product.This 1500 kW Rental Power unit has beendesigned to provide from 35 kW to 2 MWfor prime, emergency, standby, peaksharing and distributed generationapplications. It features the workhorseCummins QSK50 diesel engine withCummins Generator Technologies'Stamford alternator.Larry Fetting, general manager, CumminsPower Generation <strong>Global</strong> Rental segmentexplains."This complete pre-integrated systemrequires reduced installation time andprovides higher system reliability for ourRental Power customers," Fetting said.Lee Ann Duvall, product manager, notedthat the user interface has been designedfor simplicity."We take into account that many of ourRental Power customers are not experts inoperating power generation equipment,"Duvall said. "This integrated gen-setprovides precise frequency and voltageregulations using message displays and analarm message system in one easy-tooperatecustomer interface."Some of the new product's key benefitsinclude:* Climate tolerance - a temperaturetolerantcooling system provides reliableoperation in ambient temperatures to 113degrees F (45 degrees C), enabling thegenerator set to operate at maximum loadwithout derating in a range of demandingclimates.* Fuel capacity - the exceptionally largefuel tank, ideal in remote locations, isdesigned to hold approximately 1,600gallons of fuel for a run-time of 22 hoursat prime power (75% load) beforerefuelling. This translates to fewerrefueling trips, lower operating costs anda smaller carbon footprint.* Environmental responsibility - the newRental Power unit meets Tier 2 emissionrequirements and can be fuelled with B20biodiesel fuel. For operation inenvironmentally-sensitive areas, the unitprotects against fuel spills with a dualwallfuel tank and 110% enginecompartment fluid containment. Theunit's sound attenuation (74 dBA at 7metres at full load) also is ideal for awide range of applications where noiseordinances are in place, Duvall added.PowerCommand controls cansimultaneously operate the engine fuelsystem, directly control the alternatorexcitation system and monitor up to 150other nodes, says Cummins.Internet linkwww.cumminspower.comPROBLEMI get a startingSOLVEDWhere canresistor for mytrolley bus?CressallIf anyone can help, Cressall can

Engine andgeneratorcontrollersENGINE PROTECTIONCONTROLLERSVersions with power keyswitch, LCD display for hourcounting and Hz/Rpmreadings, communication portfor easy and fast set-up.STAND ALONE GEN-SETCONTROLLERSPowerful controllers for standalone Gen-Set, with fullmetering facilities built in,communication port for easyand fast set-up, expandibleavailable also with analoginputs.LOVATO ELECTRIC S.P.A.CONTROL SOLUTIONSFOR INDUSTRYVIA DON E. MAZZA, 1224020 GORLE (BG) ITALYTel.: +39 035 4282111Fax: +39 035 4282400E-mail: info@LovatoElectric.comAUTOMATIC MAINSFAILURE (AMF)GEN-SET CONTROLLERSComplete series of AMF units,from the low cost RGAM10 tothe most sophisticated RGK60,providing remote supervision,expandibilty, CANbus-J1939interface.www.LovatoElectric.com

GAS TURBINESGas turbines in Malmö, SwedenAugust 2009 is a milestone month for Sweden's Öresundsverket Project, Malmö's newgas turbine-driven power plant developed by Hitachi Power Europe. The new plant isone of the most advanced in Europe, reports Olaf Lipinski.It's big, it's Swedish and it representsthe ultimate in 21st Century powerstations and - best of all - it startsproducing power next month. Malmö'sÖresundsverket Project represents a totalinvestment over €300, includinginfrastructure for the connection ofelectricity, gas and district heating.Olaf Lipinski, Technical Project Head forthe Öresundsverket Project told <strong>WIP</strong>: "Thiscombined-cycle gas and steam powerplant, located in the southern Swedishport of Malmö, is one of the most modernof its kind. Its capacity amounts to 440MW for power and 250 MW for heat andunder combined operations the energy ofthe fuel gas is used to 89 % efficiency."In 2006 HPE and GE Energy obtained theorder to build the plant, with HPE takingon responsibility for the balance of powerplant equipment, overall plant design,constructional planning, implementation,erection and startup management. GEEnergy's contribution to the project wasits powertrain and instrumentation andThis is one of the most hi-tech CHPplants in Europe, says HPE.Malmo's new 440 MWe / 250 MW plant goes operational next month.control technology. The construction ofthe combined cycle plant presented theplanners with real challenges.On the one hand the key components -gas turbine set, steam turbine set, heatrecovery boiler - had to be integrated intothe existing building of a 1950s coal-firedpower plant.On the other, there were a number ofproblems associated with the state of thebuilding noticed by the HPE staff. Whenwork first commenced in September 2006the engineers reported problems withwater ingress and insubstantialfoundations."The supports in the turbine shop, forinstance, had insufficient bearing capacityand had to be revamped at considerableexpense. Moreover, hundreds of tons ofadditional steel girders were needed toprop up floor elements," reveals Lipinski.Its proximity to the port and the highgroundwater level caused furtherdifficulties. Site engineers had to positionsheet pile walls and pump water out toenable the foundation and piling work toproceed.At peak periods around 70 Hitachi Poweroffice staff and a workforce numbering500, including construction managementpersonnel on the site, were involved withthe building of the combined-cycle powerplant. The original intention had been forthe plant to be operating commercially atthe beginning of 2009 but instead therewas an eight-month delay."The difficulties had an effect on theschedule - the completed plant willeventually be handed over to E.ONVärmekraft Sverige AB next month, inAugust," Björn Ahrendt, CommercialProject Head involved with the Malmöfacility, tells <strong>WIP</strong>.Once the combined cycle power plant isfully operational it will not only besupplying electricity and district heat forMalmö but will also be making a majorcontribution to climate protection. This isbecause the power plant is part of arolling programme to replace existingcoal-fired stations in Scandinavia.According to the authorities, thisprogramme is projected to reduce carbondioxideemissions by approximately onemillion tons a year.Facts at a glance:Project Öresundsverket - CHP Malmö* 440 MWe / 250 MW plant commencescommercial operations August 2009* Total investment over 300m€ includinginfrastructure for connection ofelectricity, gas and district heating* The project used some of the olderfacilities at Öresundsverket* Maintenance (LTSA) - main supplier;operation - E.ON Värme* Built and equipped by Hitachi PowerEurope and GE Energy.Internet linkwww.hitachi-eu-power.com<strong>WIP</strong>22W ORLDWIDE I NDEPENDENT P OWER • JULY 2009

®BS EN ISO 9001-2000Reg. No. FM38224Heat exchanger manufacturersl Exhaust gas heat exchangersl Header tank heat exchangersl Tubular heat exchangersl Oil coolersl Fuel coolersE. J. Bowman (Birmingham) <strong>Ltd</strong>. Chester Street, Birmingham B6 4AP, <strong>UK</strong>.Tel: +44(0)121 359 5401 Fax: +44(0)121 359 7495 email: info@ejbowman.co.uk www.ejbowman.co.ukCrestchic Loadbanks ensure you getMAXIMUM POWER everytime!LOADBANKS Available for Sale or HireCrestchic have been satisfying world markets with the design, manufacture and sale of Loadbanks for over 20 years.Designed to satisfy the load testing requirements of the power industry in all types of environments and markets.Crestchic Loadbank Rental now offers a complete solution to your load test requirements, 100MVA major projects down to 30kW one day hire installed by our trained personnel.• AC Loadbanks• Packaged Transformer Units•• AC Medium Voltage Loadbanks• Switchgear• DC Loadbanks• Neutral Earth ResistorsEnsure your power-plant will operate at maximum power every time, contact Crestchic today.MANUFACTURERENTALCLCrestchic <strong>Ltd</strong>, Second Avenue, Centrum 100, Burton upon Trent, Staffordshire DE14 2WF, <strong>UK</strong>Crestchic LoadbanksWORLDWIDE LOADBANK SPECIALISTSSales and Rental Offices in: North America, Singapore, Netherlands and DubaiLV and MV Cables• Installation Service• Engineer/OperatorT: +44 (0)1283 531645 F: +44 (0)1283 510103 E: sales@crestchic.co.uk www.crestchic.co.uk

HEAT EXCHANGERSHeat exchangers for solar thermalsGEA Ibérica has received an order to design, manufacture and supply seven surfacecondensers for new solar thermal power plants in Spain, <strong>WIP</strong> reports.The great advantage of solar thermalpower plants is probably the factthat they can continue to run duringthe night with heat stored during daylightoperation, enabling solar thermal powerplants to contribute to the base load ofgrids.Worth about 6 million Euros, this latestorder has been placed by SiemensIndustrial Turbomachinery AB of Finspong,Sweden. The surface condensers will bemanufactured at the GEA Caldemon site inSantander, Spain. GEA Ibérica, which ispart of the Energy and Farm Technologysegment, has recently acquired the site toenhance its production range. This factoryhas been the supplier for heat exchangersto GEA Ibérica before and is scheduled todeliver before the end of 2010.Ramon Rodriguez, Managing Director ofGEA Ibérica, told <strong>WIP</strong>: "GEA Ibéricaalready supplied the surface condensersto the PS10 and PS 20 projects, as well asto Andasol 1 & 2, Extresol 1 & 2, Ibersol-Puertollano as well as others."With these projects, GEA Ibérica hasgained vast experience in the field ofsurface condensers for the solar thermalpower generation. This new orderconfirms our experience and shows thatwe are well-prepared to face theBird's eye view of the GEA Caldemon site in Santander, Spain.GEA Ibérica is scheduled to deliver heat exchangers like this one before the end of2010. Each unit has an aggregate capacity of 350 MW.challenges of this fast-growing area withinthe power generation business."Jürg Oleas, CEO of GEA Group, added:"The order rewards our strategic focus onthe growing solar thermal power industry.To gauge the vast market potential of thisproven technology, consider the recentlyreportedinitiative of several big industrialand utility companies, such as Siemens,Eon and RWE. They are looking for wayshow to turn the Club of Rome's 'Desertec'vision into reality and to extensively relyon solar thermal energy for future powergeneration," he observed. GEA Ibérica, isa subsidiary of GEA's Thermal EngineeringDivision which has a history of supplyingsurface condensers to solar thermal powerplants in Europe.Growing demand is expected in the,especially from North Africa and the US,says GEA Ibérica. To safeguard economicdevelopment and to cover the risingenergy needs without threatening thequality of life of future generations,energy must be generated economically,safely and in an environmentallyacceptable manner.In the coming years a large proportion ofthe coal-fired power stations in Europeand the USA must inevitably be replacedby new technology, concludes GEA.<strong>WIP</strong>Internet linkwww.gegroup.com24JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

FILTRATIONFiltration - the key to profitabilityIn line with most power plant operators US-based Westar Energy had sought a way toreduce its clean water costs. Amazingly, investment in a microfiltration system hasgenerated savings of US$231,000 over the last three years, reports the facility.Westar Energy is the largestelectrical energy provider inKansas, USA, delivering reliablepower to more than 675,000 customers.Sitting on 600 acres in the northern edgeof town, Westar's 71-year-old LawrencePower plant had relied on 'city water' asits makeup water source. For the years2004-2006, the plant spent US$625,000 onwater, about 87% of which could becategorised as 'city water'.The plant had been relying on sandfilters and clarifiers for its own source,but was not getting the results it needed.In late 2006, the plant took the bold stepof installing a Pall Aria AP-4microfiltration system. A spokesman told<strong>WIP</strong>: "This was designed specifically totreat surface water like the water theplant was pulling from the Kansas River -and the system performed very well. Afterincorporating a clean water flush beforeevery shutdown, the plant has enjoyedexcellent reliability.""Currently, the Pall Aria system continuesPic: © Pall Corporation.to provide high purity water withminimum intervention and greater degreeof flexibility for the plant. The Pall Ariasystem has handled all the seasonalchanges in the water and has performedwell," a spokesman commented.Vince Avila, Plant Engineer for theWestar Lawrence Plant commented:"Typically, we run for five days and shutdown for two days, and we flush themembranes with city water each time weshut down."He points out: "The system has handledall the seasonal changes in the water andhas performed very well."According to Avila, the plant has savedmore than US$77,000 on water on anannual basis since 2007. "Expensive citywater used to be a staple," he says. "Nowwe've gotten it where it should be - as anemergency measure."Perhaps the greatest test of the systemcame in May 2007 when the Pall Aria MFsystem was subjected to heavy rain andsevere flooding in the Kansas River. TheThis Pall Aria AP-4 filterswater for Westar’s PowerPlant in Kansas, US.Filters help theplant to saveUS$77,000 peryear.plant, which by now was now takingalmost all of its water from the river,recorded turbidity, normally in the 25-30range with an average 470 NTU for theentire month, with turbidity spikes reaching2,200 NTU."Every piece of debris from the banksended up in the river," explains Avila. "Wewouldn't have been surprised if thesystem had ground to a halt. But it stayedin operation the entire time."In addition to its ruggedness, personnelat the plant say they have been impressedwith the user-friendly nature of the Pallunit. With only two lab technicians onstaff for the entire plant at any one time,the technology has to save on man-hours."The system has performed very well forus," concludes Avila. "We take a set ofreadings in the morning and, if everythingis OK, the system requires very littleinteraction."A spokesman told <strong>WIP</strong>: "Filtration iscritical to the success of a watertreatment system in meeting purity goals,and traditional filtration methods such assand and granular mixed-media are ofteninefficient, labour-intensive, and costly.This one really works though.”<strong>WIP</strong>Pall Aria is a trademark of Pall Corporation.Internet linkwww.pall.com/power.aspPic: © Pall Corporation.W ORLDWIDE I NDEPENDENT P OWER • JULY 200925

BLADINGTurbine blade advancesIn power generation, aggressive targets have been set for reduced CO2 and nitrogenoxide emissions from gas turbines. This means using a new kind of abrasive tip materialtechnology for turbine blades, says Scott Wilson and Thomas Peters of Sulzer Innotec.Current abrasive tip technologyavailable in the market place isbased primarily on the use of cubicboron-nitride abrasive particles which arebonded to the blade tip in an oxidationand creep-resistant matrix alloy, usingproprietary alloy deposition technology,write Scott Wilson and Thomas Peters.Cubic boron-nitride is one of the hardestmaterials known, next to diamond, and isan excellent abrasive material. However,it has one drawback; it oxidises rapidlywhen exposed to temperatures above900°C and lasts less than 100 hours in theaverage turbine environment.Several alternative abrasives to cubicboron-nitride were investigated in the EUfundedABRATIP program (AdvancedAbradables and Tip coatings for gasturbines), with participation from SulzerInnotec, Sulzer Metco and severalaerospace OEMs. The only candidatewhich exhibited equivalent cuttingperformance against ceramic abradableswas silicon carbide, which has excellentResearch has suggested that a siliconcarbideabrasive solution could beprovided to OEMs for their bladetipping needs.The rotor of a huge gas turbine repaired by Sulzer Turbo Services after a severeoutage in a combined-cycle power plant. The repair was faster and cheaper than areplacement.high temperature oxidation resistance incomparison to cubic boron-nitride.However, it too has an inherent thermodynamicinstability when brought incontact with turbine blade nickel-basedalloys. It will react with these alloys athigh temperature and disintegrate.R&D activities have continued todevelop an effective silicon-carbideabrasive solution which could be providedto OEMs for their blade tipping needs.Ceramic barrier coatings were applied tosilicon-carbide particles, but with onlylimited success as these tended to crackarising from thermal and elastic mismatchstrains at sharp corners. Additional effortswere made to find a more compliantbarrier coating.Then came an idea to use a reactivemetal layer such as chromium toneutralise the reactivity of a siliconcarbide surface. A more thermodynamicstable chromium-silicon-carbide barrier isformed when chromium is brought intocontact with silicon carbide at elevatedtemperatures.A chromium barrier coating was thenapplied to silicon-carbide abrasiveparticles successfully, which were thenused in blade tipping trials.Sulzer Innotec embarked on feasibilitytrials to fix the chromised SiC ontostandard turbine blade alloys using adedicated laser-weld deposition process.Good results were obtained where theparticles were successfully embeddedwithout serious damage to either particleintegrity or the chromised layer near thelaser beam heat input.Incursion tests using tipped bladesagainst ceramic abradable coatings,provided good results, report the authors.The program has progressed far enough tobe slowly moving out of the developmentstage and advancing toward marketopportunities. A series of developmentactivities are now underway inpartnership with Sulzer business unitsand its customers, says the company. <strong>WIP</strong>.Internet linkwww.sulzerts.com26W ORLDWIDE I NDEPENDENT P OWER • JULY 2009

SWITCHGEARSwitchgear for power supplyYou'd expect the latest gas-insulated 220-kV high-voltage switchgear (GIS) for a powersupply plant to be ‘hot stuff’ - and it certainly is. It will serve an air separation plantcurrently being built by Linde Engineering Division in Abu Dhabi.Siemens Energy is currently supplyinggas-insulated 220-kV high-voltageswitchgear (GIS) on a turnkey basisfor power supply to an air separationplant for nitrogen production. This facilityis currently being built by LindeEngineering Division in Abu Dhabi.Scheduled for completion in late 2010,the Linde Group and the Abu DhabiNational Oil Corporation (ADNOC) willthen - through their joint venture Elixier -produce nitrogen for gas recovery in theUnited Arab Emirates.Key to the technology is the latest gasinsulated220-kV high-voltage switchgear,120/140-MVA power transformers,auxiliary power systems, and protectionand instrumentation & control systems forthe substation.The contract also includes all civilengineering services including ventilation,air conditioning and fire protectionequipment, logistics, installation andcommissioning. The order is worth in theregion of EUR60 million.Hydrogen production plant built byLinde in the Burghausen facility.Heat exchanger installed by the Linde Group.Siemens Energy will install the turnkey220-kV switchgear for power supply to anair separation plant where the nitrogen isproduced. In addition to the highreliability of the technology, the space--saving design of GIS plays a decisive rolein this industrial solution.Siemens Energy will also supply twolarge compressors for the air separationplant. The compressors increase thepressure of the air to be fractionated to8.5 bar to enable efficient recovery of thenitrogen. The value of the order for thetwo compressors alone is more thanEUR25 million.Just two months ago Siemens Energy &Automation released its latest switchgearfamily of Power Mod line of ModularMetering Products with QuickSystem.According to the company, Power Modfeatures a unique combination of laboursaving features to aid the contractorwhile installing the product. Siemensmodular metering is available for singlephase, three wire, 120/240VAC; threephase, four wire 120/208Y applications,and three phase in/out, 240Volt max deltasystems. The cross bus that connects thedevices is aluminum and has a 1200 ampcontinuous current rating. A spokesmantold <strong>WIP</strong>: “One of the key features of thenew product line is QuickSystem. ThisQuickSystem encompasses every step ofinstallation of the product, from mountingthe product on the wall to plugging in thetenant circuit breaker.”Special features engineered to decreaseinstallation time include:* QuickBolt: Here spring loaded, captivebolts provides faster and easierconnections between modules andhardware.* QuickConnect: A redesigned single boltjoint allows for easier, faster and moresecure enclosure connection in a modularlineup.* QuickPhase: Field phaseable socketsstreamline ordering and phase balancing.* QuickTorque: Proper torque has beensimplified with a breakaway nut design.Power Mod also features a premiermounting system, including an exclusiverolling mount design with the security ofextended mounting tabs.Internet linkwww.linde.comwww.siemens.com<strong>WIP</strong>W ORLDWIDE I NDEPENDENT P OWER • JULY 200927

TURNKEYMonsenergo MoscowA 420MW power generation facility in Moscow, built under a €280m turnkey EPCcontract, goes into full commercial production this month. <strong>WIP</strong> takes a first look.Moscow is hungry for energy and thenew Monsenergo project is key tomeeting the needs of the capital'sexpanding power network. It has evenbeen designed fulfil the power and heatneeds within the local region too.Alstom, along with its Russian partner, aPower Engineering Group known as theEnergomachinostroitelny Alliance(EMAlliance), has been working on theMosenergo contract since 2005. It beginscommercial operations this month(<strong>July</strong>/August 2009).The turnkey 420MW power generationpackage is worth €170m to Alstom, out ofa total €280m value for the project.The company has supplied componentsincluding a multishaft combined cycle unitcomprising a GT 26-gas turbine, steamturbine, two generators, one heatrecovery steam generator and the controlsystem for the entire facility."The plant has 280MW of gas turbinecapacity, making it one of the first plantsto have that capacity in Russia," said aspokesman. As early as April 2007,Mosenergo began construction of the PSU-The COORETEC research programme, running in Europesince 2006, is producing data to help achieve anticipatedextra capacities required amongst power stations from2010 onwards. Alstom has worked with the DLR Institute ofCombustion Technology in Stuttgart to develop the nextgenerationof gas & steam turbine power stations. [Below]Monsenergo features a multishaft combined cycle unit comprising a GT 26-gasturbine, steam turbine, two generators and one heat recovery steam generator.420 steam power unit and unit 8 PGU-420CHP-26. With an installed capacity of420MW and thermal power of 265MW, thenew plant is expected to be 59% efficientin condensation mode.The 280MW of gas turbine capacitymakes Mosenergo one of the first plantsto have that capacity in Russia. A mechanicaldraft water cooler is used for thecooling system and the turbine usesnatural gas with liquid fuel as a backup.A cooling tower, electrical equipment,heat exchangers and piping for thedistrict heating system have beenprovided by EMAlliance which has alsomanaged civil works and constructionissues.Alstom CEO and chairman, Patrick Kron,told <strong>WIP</strong>: "Alstom is proud to help Russiameet its fast-growing need for power withthe most up-to-date combined cyclepower generating technology.“This turnkey project has no equivalentin the Russian power industry. It willproduce electricity at a high-efficiencyrate, thus dramatically reducing CO2emissions in comparison with other powerplants."Internet linkwww.poweralstom.com<strong>WIP</strong>28JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

POWER PLANT REVIEWAustria’s Walsum 10 celebratesA major international celebration took place at Austria’s Walsum coal power plantfollowing its first successful boiler pressure test. <strong>WIP</strong> has the story.Amilestone has been reached withthe successful conclusion of theboiler pressure test at Austria’snew Walsum10 coal power plant.It’s taken two and a half years to buildat a cost of EUR 820 million to thepurchasers - Evonik Industries AG, theindustrial concern from Essen, and EVNAG, energy supplier from Lower Austria.Despite the fact the plant won’t be fullyfunctionaluntil 2010, both companies,along with Hitachi Power Europe GmbH(HPE), celebrated with a formal ceremonyin Duisburg-Walsum this month.A power plant with a 45%+ efficiency,Walsum features a 106-metre high utilitysteam generator (boiler), the mostcomplex single component of the facility.Coal power plants in Germany generallyhave an average of 38% efficiency andacross the world is it is only 30% perplant, making Walsum a very special siteindeed.2010 will see extremely hot steam (over600°C) under a very high pressure(approximately 274 bar) being generatedin the utility steam generator. This steamwill then flow into a turbine with angenerator converting the moving energyinto electrical power. The boiler pressuretest now officially endorses the ability ofthe boiler to withstand the high pressures.Christa Thoben, Economics Minister for North-Rhine Westphalia, took part in aceremony this month to mark the successful boiler pressure test at Walsum 10.The new Walsum 10 - designed to reduce overall CO2 emissions in North-RhineWestphalia by 2020.Around 9,900 tons of steel have been usedin the project. The piping has a totallength of approximately 450 kms and35,000 welds had to be welded at thepressure part. Modern materials areresponsible for the high efficiency. They,in turn, allow higher temperatures andpressures to be created in the boiler, saysHitachi.More than 300 guests, including ChristaThoben, Economics Minister for North-Rhine Westphalia (NRW), participated inthe official ceremony. "There is no alternativeto highly efficient, ultra-moderncoal power plants such as Walsum" saidThoben."Highly efficient and resource-conservingplants such as Walsum 10 enable us touphold our responsibility in climateprotection matters", said Dr. Klaus Engel,Chairman of the Executive Board ofEvonik Industries AG.“Because of the higher degree ofefficiency Walsum needs less fuel for thesame output compared with today's powerplants.,” he concluded.<strong>WIP</strong>Internet linkwww.hitachi-power.com30JULY 2009 • WORLDWIDE I NDEPENDENT P OWER

Invitation to Participate...Sales Agents:For Further Details, please contact:Neb Saric or Richard Teasdale at <strong>Global</strong> <strong>Media</strong> <strong>Publishing</strong> Limited<strong>Global</strong> House, 13 Market Square, Horsham, West Sussex, RH12 1EU, <strong>UK</strong>Tel: +44 (0) 1403 220750 Fax: +44 (0) 1403 220764E-mail: power@gmp.uk.com