Grand Haven High School, MI - Dectron International, Inc.

Grand Haven High School, MI - Dectron International, Inc.

Grand Haven High School, MI - Dectron International, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

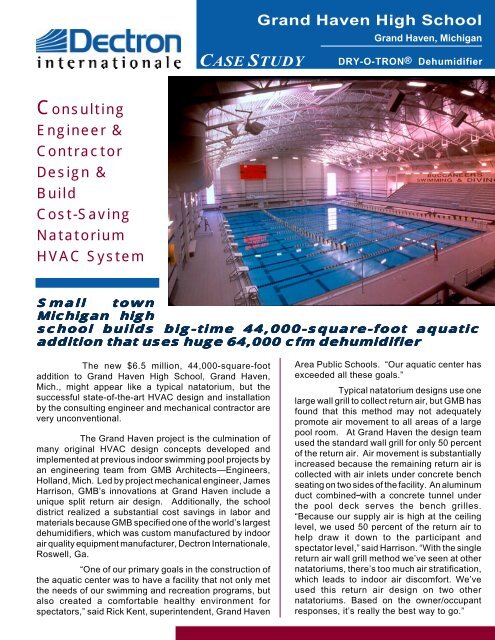

CASE STUDY<strong>Grand</strong> <strong>Haven</strong> <strong>High</strong> <strong>School</strong><strong>Grand</strong> <strong>Haven</strong>, MichiganDRY-O-TRON® DehumidifierConsultingEngineer &ContractorDesign &BuildCost-SavingNatatoriumHVAC SystemSmalltownMichighigan an highschool builds big-time 44,000-square-fe-foot oot aquaticticaddition that t uses huge e 64,000 cfm dehumidifierierThe new $6.5 million, 44,000-square-footaddition to <strong>Grand</strong> <strong>Haven</strong> <strong>High</strong> <strong>School</strong>, <strong>Grand</strong> <strong>Haven</strong>,Mich., might appear like a typical natatorium, but thesuccessful state-of-the-art HVAC design and installationby the consulting engineer and mechanical contractor arevery unconventional.The <strong>Grand</strong> <strong>Haven</strong> project is the culmination ofmany original HVAC design concepts developed andimplemented at previous indoor swimming pool projects byan engineering team from GMB Architects—Engineers,Holland, Mich. Led by project mechanical engineer, JamesHarrison, GMB’s innovations at <strong>Grand</strong> <strong>Haven</strong> include aunique split return air design. Additionally, the schooldistrict realized a substantial cost savings in labor andmaterials because GMB specified one of the world’s largestdehumidifiers, which was custom manufactured by indoorair quality equipment manufacturer, <strong>Dectron</strong> <strong>International</strong>e,Roswell, Ga.“One of our primary goals in the construction ofthe aquatic center was to have a facility that not only metthe needs of our swimming and recreation programs, butalso created a comfortable healthy environment forspectators,” said Rick Kent, superintendent, <strong>Grand</strong> <strong>Haven</strong>Area Public <strong>School</strong>s. “Our aquatic center hasexceeded all these goals.”Typical natatorium designs use onelarge wall grill to collect return air, but GMB hasfound that this method may not adequatelypromote air movement to all areas of a largepool room. At <strong>Grand</strong> <strong>Haven</strong> the design teamused the standard wall grill for only 50 percentof the return air. Air movement is substantiallyincreased because the remaining return air iscollected with air inlets under concrete benchseating on two sides of the facility. An aluminumduct combined with a concrete tunnel underthe pool deck serves the bench grilles.“Because our supply air is high at the ceilinglevel, we used 50 percent of the return air tohelp draw it down to the participant andspectator level,” said Harrison. “With the singlereturn air wall grill method we’ve seen at othernatatoriums, there’s too much air stratification,which leads to indoor air discomfort. We’veused this return air design on two othernatatoriums. Based on the owner/occupantresponses, it’s really the best way to go.”

<strong>Grand</strong> <strong>Haven</strong> Therapy Pool RoomGMB broke tradition on other natatorium HVACdesign concepts as well. Typically, an indoor pooldehumidifier is in a mechanical room or rooftop location. At<strong>Grand</strong> <strong>Haven</strong> however, the dehumidifier is located outside atground level to save upwards of $30,000 in mechanical roomsquare footage and eliminate what may have resulted in anunsightly installation on the facility’s aesthetic, barrel-shapedroof. Since part of the return air is underground in the poolarea, Rite-Way Plumbing & Heating, <strong>Grand</strong> Rapids, Mich.,kept the return ductwork underground for aesthetic purposesen route to the dehumidifier. The underground return airenters the dehumidifier via a base configuration and curbplenum—a custom modification specified by GMB. Thechallenge with an underground duct installation, accordingto Larry Heemstra, project manager, Rite-Way Plumbing &Heating, is digging the trench deep enough and thenstructurally supporting the walls to protect workers againstdangerous cave-ins.Typically a project of this size requires severaldehumidifiers working in tandem. However GMB brokeconvention again by taking advantage of <strong>Dectron</strong>’s custommanufacturing skills. GMB specified one of the largestdehumidifiers ever manufactured by <strong>Dectron</strong>, aDRY-O-TRON ® RS-362 with airflow of 64,000 cfm and amoisture removing capacity of 377 lbs./hr. GMB ’s designalso provides ½-cfm outside air per square foot of deck andpool area, which is sufficient for the natatorium’s 1,000-spectator capacity. The huge 32-foot-long unit saved theschool district thousands of dollars versus the costs ofinstalling, piping, and ducting two or three units, not tomention saving limited ground area outside the natatorium.“I approached Paul McWatters (sales engineer atMacAire <strong>Inc</strong>., a <strong>Grand</strong> Rapids, Mich.-based manufacturer’srepresentative for <strong>Dectron</strong>) to see if <strong>Dectron</strong> could custombuild one really large unit and they came through,” saidHarrison.GMB also designed a supply air distribution systemthat is visually unnoticeable because it follows the contoursof the natatorium’s architectural, barrel-shapedceiling. While the ductwork adds an aesthetictouch, sheet metal subcontractor, SuperiorSheet Metal, Rockford, Mich., found itchallenging to install. Manufactured byEastern Sheet Metal, Cincinnati, thegalvanized and epoxy-coated spiral ductworkneeded dozens of elbows ranging from 15 to22-degrees to maintain a constant 12-inchgap along the contoured ceiling. “Installingthe ceiling ductwork was very challenging andrequired super accurate field measurements,”said Jerry Marculis, estimator/coordinator,Superior Sheet Metal.While the DRY-O-TRON ®dehumidifies and heats the pool water, it alsoreduces the space heating load in winter viaefficient heat recovery from the exhaust airand preheating of the outdoor air. Spaceheating is handled by the building's hot waterheating system comprised of a two LochinvarCorp., Nashville, Tenn. 2,618 mbh input boilersthat supply a Taco <strong>Inc</strong>., Cranston, R.I., 1,575mbh, 158 gpm secondary heat exchanger viaa 1.5 hp. Taco pump.Besides the main pool, the facilityalso has a separate 2,000-square-foot therapypool room that features a 15-foot-high,25-foot-wide wall of windows. Keeping thewindows free of condensation was anotherdesign challenge for GMB. Neither the areabetween the ceiling and the windows nor apool deck diffuser system would provide amplewindow coverage. Instead, air was suppliedfrom two 12-inch round column ducts thatappear aesthetically as support columns oneach side of the windows.Even though <strong>Grand</strong> <strong>Haven</strong> is asmall town of 15,000 people, it now has a bigtime pool that attracts many local swimmingprograms and competitions.FOR MORE INFORMATION ON A SPECIFICAPPLICATION, PLEASE CONTACT YOUR LOCALREPRESENTATIVE OR DECTRON.DECTRON, INC.10935 Crabapple Rd.Suite 202-ARoswell, Georgia30076Tel.: (770) 649-0102Fax: (770) 649-0243USA & CANADA1-800-676-2566www.dectron.com