Araldite LY 8615R Resin Aradur 8615H Hardener - Krayden, Inc.

Araldite LY 8615R Resin Aradur 8615H Hardener - Krayden, Inc.

Araldite LY 8615R Resin Aradur 8615H Hardener - Krayden, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

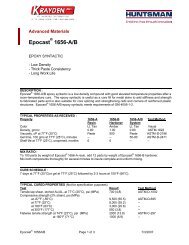

TYPICAL CURED PROPERTIESNEAT SYSTEM*Cured for 24 hrs at 77°F (25°C) plus 2 hrs. at 250°F (121°C) + 3 hrs. at 350°F (177°C). Tested at 77°F (25°C)unless otherwise noted.Test Value Test-MethodSpecific Gravity 1.06 ASTM D-792Cubic <strong>Inc</strong>h per Pound 26 ASTM D-792Hardness, Shore D 87 ASTM D-2240Ultimate Flexural Strength, at 77ºF (25°C), psi (MPa) 9,995 (69) ASTM D-790Flexural Modulus, at 77°F (25°C), psi (MPa) 429,672 (2,963) ASTM D-790Tg by DMA, E’ onset, dry, °F (°C) 422 (217) ASTM D-4065Compressive Strength, at 77°F (25°C), psi (MPa) 36,439 (251) ASTM D-695Compressive Modulus, at 77°F (25°C), psi (MPa) 320,851 (2,213) ASTM D-695* NOTE: All properties are for the neat product form (non-composite).LAMINATE SYSTEMTYPICAL CURED PROPERTIES*Test Value Test-MethodHardness, Shore D 92 ASTM D-2240Ultimate Flexural Strength, at 77ºF (25°C), psi (MPa) 100,837 (695) ASTM D-790Flexural Modulus, at 77°F (25°C), psi (MPa) 6.22x10 6 (42,896) ASTM D-790Tg by DMA, E’ onset, dry, °F (°C) 422 (217) ASTM D-4065Tg by DMA, E’ onset, wet, °F (°C) 373 (189) ASTM D-4065% weight gain** 0.698Ultimate Compressive Strength, at 77°F (25°C), psi (MPa) 62,366 (430) ASTM D-695Compressive Modulus, at 77°F (25°C), psi (MPa) 11.3 x10 6 (77,931) ASTM D-695* Tested at 77°F (25°C) unless otherwise noted.** Hot/wet conditioning is 48 hours in tap water boiling at 208°F to 216°F (98°C to 102°C). Sample weightmeasured before and after sample boils to determine % weight gain.LAY-UP PROCESSPanel Type:Approximately 3 ft. x 2 ft. (0.92m x 0.61m) flat panelCloth Type:8 layers, 1581 glass clothCloth Rotation: 0, 90°Procedure:Vacuum bagged, flat panelLaminate <strong>Resin</strong> Content: 32.3%NOTE : The <strong>Araldite</strong> ® <strong>LY</strong> <strong>8615R</strong> / <strong>Aradur</strong> ® <strong>8615H</strong> epoxy system will self-support during curing after 8 hours at125°F (52°C) minimum cure after infusing material. The material will cure hard after 48 hours at room temperature,however, the 125°F (52°C) minimum cure should be used for self support. Postcure can then be continuedpartially supported off the master or foam model used.Provisional product information is provided on experimental products. Samples were tested at roomtemperature unless otherwise noted. All samples were cured for 24 hours at room temperature plus six hoursat 250°F (121°C), plus six hours at 400°F (204°C). Composite samples were from a room-temperatureinfused, 14 in. x 14 in. (35.6cm x 35.6cm) flat panel. The lay-up was 8 layer, 0° rotation, TPI style #4114, Lot#7027, 5HS carbon fabric, 12 in. x 12 in. (30cm x 30cm), T-300-6K-309 yarn. Samples were cut and tested inthe warp (lengthwise) direction.<strong>Araldite</strong> ® <strong>LY</strong><strong>8615R</strong>/<strong>Aradur</strong> ® <strong>8615H</strong> System Page 2 of 8 October 2010