LOCTITE 392™ - Henkel

LOCTITE 392™ - Henkel

LOCTITE 392™ - Henkel

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

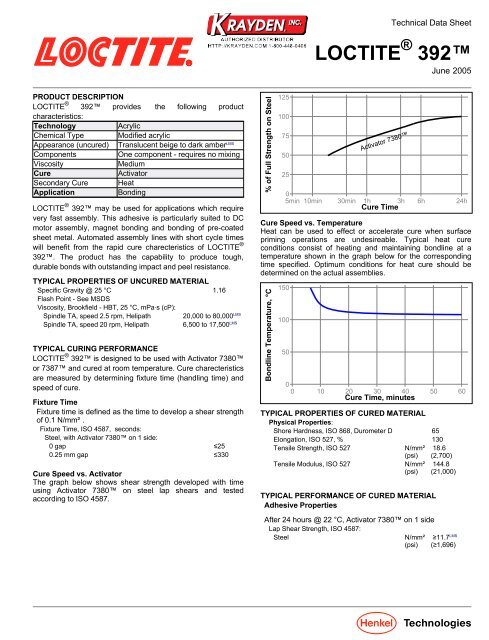

Technical Data Sheet<strong>LOCTITE</strong> ® 392June-2005PRODUCT DESCRIPTION<strong>LOCTITE</strong> ® 392 provides the following productcharacteristics:TechnologyAcrylicChemical Type Modified acrylicAppearance (uncured) Translucent beige to dark amber LMSComponentsOne component - requires no mixingViscosityMediumCureActivatorSecondary Cure HeatApplicationBonding<strong>LOCTITE</strong> ® 392 may be used for applications which requirevery fast assembly. This adhesive is particularly suited to DCmotor assembly, magnet bonding and bonding of pre-coatedsheet metal. Automated assembly lines with short cycle timeswill benefit from the rapid cure charecteristics of <strong>LOCTITE</strong> ®392. The product has the capability to produce tough,durable bonds with outstanding impact and peel resistance.TYPICAL PROPERTIES OF UNCURED MATERIALSpecific Gravity @ 25 °C 1.16Flash Point - See MSDSViscosity, Brookfield - HBT, 25 °C, mPa·s (cP):Spindle TA, speed 2.5 rpm, Helipath 20,000 to 80,000 LMSSpindle TA, speed 20 rpm, Helipath6,500 to 17,500 LMSTYPICAL CURING PERFORMANCE<strong>LOCTITE</strong> ® 392 is designed to be used with Activator 7380or 7387 and cured at room temperature. Cure charecteristicsare measured by determining fixture time (handling time) andspeed of cure.Fixture TimeFixture time is defined as the time to develop a shear strengthof 0.1 N/mm².Fixture Time, ISO 4587, seconds:Steel, with Activator 7380 on 1 side:0 gap ≤250.25 mm gap ≤330Cure Speed vs. ActivatorThe graph below shows shear strength developed with timeusing Activator 7380 on steel lap shears and testedaccording to ISO 4587.% of Full Strength on Steel125100755025Activator 738005min 10min 30min 1h 3h 6h 24hCure TimeCure Speed vs. TemperatureHeat can be used to effect or accelerate cure when surfacepriming operations are undesireable. Typical heat cureconditions consist of heating and maintaining bondline at atemperature shown in the graph below for the correspondingtime specified. Optimum conditions for heat cure should bedetermined on the actual assemblies.Bondline Temperature, °C1501005000 10 20 30 40 50 60Cure Time, minutesTYPICAL PROPERTIES OF CURED MATERIALPhysical Properties:Shore Hardness, ISO 868, Durometer D 65Elongation, ISO 527, % 130Tensile Strength, ISO 527 N/mm² 18.6(psi) (2,700)Tensile Modulus, ISO 527 N/mm² 144.8(psi) (21,000)TYPICAL PERFORMANCE OF CURED MATERIALAdhesive PropertiesAfter 24 hours @ 22 °C, Activator 7380 on 1 sideLap Shear Strength, ISO 4587:SteelN/mm² ≥11.7 LMS(psi) (≥1,696)

TDS <strong>LOCTITE</strong> ® 392, June-2005After 48 hours @ 22 °C, Activator 7380 on 1 sideLap Shear Strength, ISO 4587:Steel :0 gap N/mm² 17.2(psi) (2,500)0.25 mm gap N/mm² 15.8(psi) (2,300)0.5 mm gap N/mm² 14.5(psi) (2,100)Aluminum :0 gap N/mm² 11(psi) (1,600)Zinc dichromate :0 gap N/mm² 11(psi) (1,600)TYPICAL ENVIRONMENTAL RESISTANCEAfter 48 hours @ 22 °C, Activator 7380 on 1 sideHeat AgingHeat aged for 2000 hoursLap Shear Strength, ISO 4587:Steel:@ 93°C N/mm² 13.1(psi) (1,900)@ 121°C N/mm² 9(psi) (1,300)@ 150°C N/mm² 3.4(psi) (500)Humidity ResistanceConditioned in 50°C condensing humidityLap Shear Strength, ISO 4587:Steel:1 week N/mm² 13(psi) (1,900)2 weeks N/mm² 9.3(psi) (1,350)4 weeks N/mm² 3.4(psi) (500)Chemical/Solvent ResistanceAged under conditions indicated and tested @ 22 °C.% of initial strengthEnvironment °C 720 hAir reference 87 100Water/glycol 50/50 87 30Gasoline 87 10Motor oil (MIL-L-46152) 87 100Directions for use1. For best performance bond surfaces should be clean andfree from grease.2. To ensure a fast and reliable cure, Activator 7380 or7387 should be applied to one of the bond surfaces andthe adhesive to the other surface. Parts should beassembled within 15 minutes.3. The recommended bondline gap is 0.1mm. Where bondgaps are large (up to a maximum of 0.5 mm), or fastercure speed is required, Activator 7380 or 7387 shouldbe applied to both surfaces. Parts should be assembledimmediately (within 1 minute).4. Excess adhesive can be wiped away with organic solvent.5. Bond should be held clamped until adhesive has fixtured.6. Product should be allowed to develop full strength beforesubjecting to any service loads (typically 24 to 72 hoursafter assembly, depending on bond gap, materials andambient conditions).Loctite Material Specification LMSLMS dated January-3, 2003. Test reports for each batch areavailable for the indicated properties. LMS test reports includeselected QC test parameters considered appropriate tospecifications for customer use. Additionally, comprehensivecontrols are in place to assure product quality andconsistency. Special customer specification requirements maybe coordinated through <strong>Henkel</strong> Quality.StorageStore product in the unopened container in a dry location.Storage information may be indicated on the product containerlabeling.Optimal Storage: 8 °C to 21 °C. Storage below 8 °C orgreater than 28 °C can adversely affect product properties.Material removed from containers may be contaminated duringuse. Do not return product to the original container. <strong>Henkel</strong>Corporation cannot assume responsibility for product whichhas been contaminated or stored under conditions other thanthose previously indicated. If additional information is required,please contact your local Technical Service Center orCustomer Service Representative.Conversions(°C x 1.8) + 32 = °FkV/mm x 25.4 = V/milmm / 25.4 = inchesµm / 25.4 = milN x 0.225 = lbN/mm x 5.71 = lb/inN/mm² x 145 = psiMPa x 145 = psiN·m x 8.851 = lb·inN·m x 0.738 = lb·ftN·mm x 0.142 = oz·inmPa·s = cPGENERAL INFORMATIONThis product is not recommended for use in pure oxygenand/or oxygen rich systems and should not be selected asa sealant for chlorine or other strong oxidizing materials.For safe handling information on this product, consult theMaterial Safety Data Sheet (MSDS).<strong>Henkel</strong> Loctite Americas+860.571.5100<strong>Henkel</strong> Loctite Europe+49.89.9268.0<strong>Henkel</strong> Loctite Asia Pacific+81.45.758.1810For the most direct access to local sales and technical support visit: www.loctite.com

TDS <strong>LOCTITE</strong> ® 392, June-2005NoteThe data contained herein are furnished for information onlyand are believed to be reliable. We cannot assumeresponsibility for the results obtained by others over whosemethods we have no control. It is the user's responsibility todetermine suitability for the user's purpose of any productionmethods mentioned herein and to adopt such precautions asmay be advisable for the protection of property and of personsagainst any hazards that may be involved in the handling anduse thereof. In light of the foregoing, <strong>Henkel</strong> Corporationspecifically disclaims all warranties expressed or implied,including warranties of merchantability or fitness for aparticular purpose, arising from sale or use of <strong>Henkel</strong>Corporation’s products. <strong>Henkel</strong> Corporation specificallydisclaims any liability for consequential or incidentaldamages of any kind, including lost profits. The discussionherein of various processes or compositions is not to beinterpreted as representation that they are free fromdomination of patents owned by others or as a license underany <strong>Henkel</strong> Corporation patents that may cover suchprocesses or compositions. We recommend that eachprospective user test his proposed application before repetitiveuse, using this data as a guide. This product may be coveredby one or more United States or foreign patents or patentapplications.Trademark usageExcept as otherwise noted, all trademarks in this documentare trademarks of <strong>Henkel</strong> Corporation in the U.S. andelsewhere.® denotes a trademark registered in the U.S.Patent and Trademark Office.Reference 0.4<strong>Henkel</strong> Loctite Americas+860.571.5100<strong>Henkel</strong> Loctite Europe+49.89.9268.0<strong>Henkel</strong> Loctite Asia Pacific+81.45.758.1810For the most direct access to local sales and technical support visit: www.loctite.com