Instruction Manual (English) - Service - Dewalt.no

Instruction Manual (English) - Service - Dewalt.no

Instruction Manual (English) - Service - Dewalt.no

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

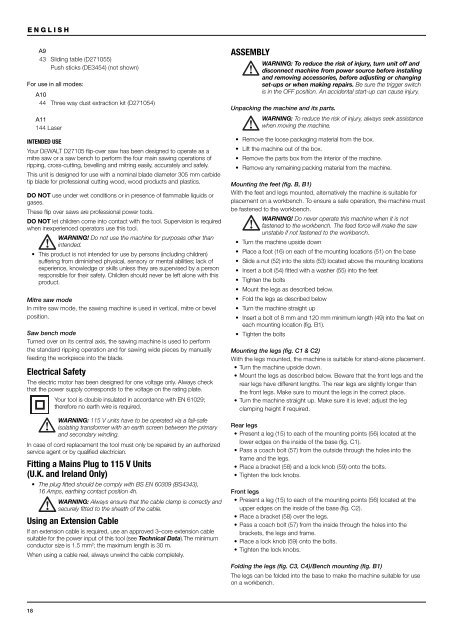

ENGLISHA943 Sliding table (D271055)Push sticks (DE3454) (<strong>no</strong>t shown)For use in all modes:A1044 Three way dust extraction kit (D271054)A11144 LaserINTENDED USEYour DEWALT D27105 flip-over saw has been designed to operate as amitre saw or a saw bench to perform the four main sawing operations ofripping, cross-cutting, bevelling and mitring easily, accurately and safely.This unit is designed for use with a <strong>no</strong>minal blade diameter 305 mm carbidetip blade for professional cutting wood, wood products and plastics.DO NOT use under wet conditions or in presence of flammable liquids orgases.These flip over saws are professional power tools.DO NOT let children come into contact with the tool. Supervision is requiredwhen inexperienced operators use this tool.WARNING! Do <strong>no</strong>t use the machine for purposes other thanintended.• This product is <strong>no</strong>t intended for use by persons (including children)suffering from diminished physical, sensory or mental abilities; lack ofexperience, k<strong>no</strong>wledge or skills unless they are supervised by a personresponsible for their safety. Children should never be left alone with thisproduct.Mitre saw modeIn mitre saw mode, the sawing machine is used in vertical, mitre or bevelposition.Saw bench modeTurned over on its central axis, the sawing machine is used to performthe standard ripping operation and for sawing wide pieces by manuallyfeeding the workpiece into the blade.Electrical SafetyThe electric motor has been designed for one voltage only. Always checkthat the power supply corresponds to the voltage on the rating plate.Your tool is double insulated in accordance with EN 61029;therefore <strong>no</strong> earth wire is required.WARNING: 115 V units have to be operated via a fail-safeisolating transformer with an earth screen between the primaryand secondary winding.In case of cord replacement the tool must only be repaired by an authorizedservice agent or by qualified electrician.Fitting a Mains Plug to 115 V Units(U.K. and Ireland Only)• The plug fitted should be comply with BS EN 60309 (BS4343),16 Amps, earthing contact position 4h.WARNING: Always ensure that the cable clamp is correctly andsecurely fitted to the sheath of the cable.Using an Extension CableIf an extension cable is required, use an approved 3–core extension cablesuitable for the power input of this tool (see Technical Data).The minimumconductor size is 1.5 mm 2 ; the maximum length is 30 m.When using a cable reel, always unwind the cable completely.ASSEMBLYWARNING: To reduce the risk of injury, turn unit off anddisconnect machine from power source before installingand removing accessories, before adjusting or changingset-ups or when making repairs. Be sure the trigger switchis in the OFF position. An accidental start-up can cause injury.Unpacking the machine and its parts.WARNING: To reduce the risk of injury, always seek assistancewhen moving the machine.• Remove the loose packaging material from the box.• Lift the machine out of the box.• Remove the parts box from the interior of the machine.• Remove any remaining packing material from the machine.Mounting the feet (fig. B, B1)With the feet and legs mounted, alternatively the machine is suitable forplacement on a workbench. To ensure a safe operation, the machine mustbe fastened to the workbench.WARNING! Do never operate this machine when it is <strong>no</strong>tfastened to the workbench. The feed force will make the sawunstable if <strong>no</strong>t fastened to the workbench.• Turn the machine upside down• Place a foot (16) on each of the mounting locations (51) on the base• Slide a nut (52) into the slots (53) located above the mounting locations• Insert a bolt (54) fitted with a washer (55) into the feet• Tighten the bolts• Mount the legs as described below.• Fold the legs as described below• Turn the machine straight up• Insert a bolt of 8 mm and 120 mm minimum length (49) into the feet oneach mounting location (fig. B1).• Tighten the boltsMounting the legs (fig. C1 & C2)With the legs mounted, the machine is suitable for stand-alone placement.• Turn the machine upside down.• Mount the legs as described below. Beware that the front legs and therear legs have different lengths. The rear legs are slightly longer thanthe front legs. Make sure to mount the legs in the correct place.• Turn the machine straight up. Make sure it is level; adjust the legclamping height if required.Rear legs• Present a leg (15) to each of the mounting points (56) located at thelower edges on the inside of the base (fi g. C1).• Pass a coach bolt (57) from the outside through the holes into theframe and the legs.• Place a bracket (58) and a lock k<strong>no</strong>b (59) onto the bolts.• Tighten the lock k<strong>no</strong>bs.Front legs• Present a leg (15) to each of the mounting points (56) located at theupper edges on the inside of the base (fi g. C2).• Place a bracket (58) over the legs.• Pass a coach bolt (57) from the inside through the holes into thebrackets, the legs and frame.• Place a lock k<strong>no</strong>b (59) onto the bolts.• Tighten the lock k<strong>no</strong>bs.Folding the legs (fig. C3, C4)/Bench mounting (fig. B1)The legs can be folded into the base to make the machine suitable for useon a workbench.18