LED Lighting - Beriled

LED Lighting - Beriled

LED Lighting - Beriled

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

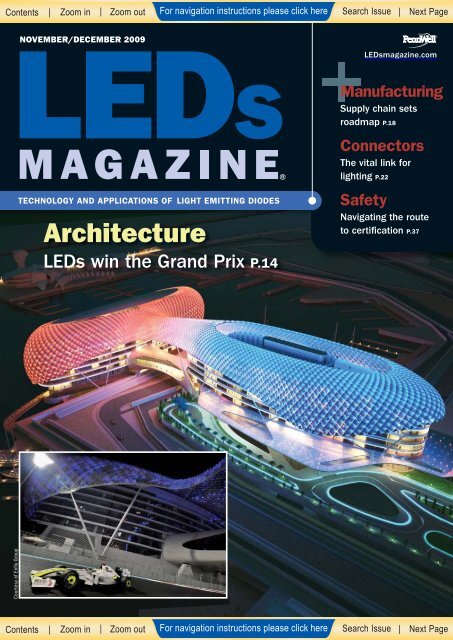

Contents | Zoom in | Zoom out For navigation instructions please click here Search Issue | Next PageNOVEMBER/DECEMBER 2009<strong>LED</strong>smagazine.comTECHNOLOGY AND APPLICATIONS OF LIGHT EMITTING DIODESArchitecture<strong>LED</strong>s win the Grand Prix P.14ManufacturingSupply chain setsroadmap P.18ConnectorsThe vital link forlighting P.22SafetyNavigating the routeto certification P.37Courtesy of Enfi s GroupContents | Zoom in | Zoom out For navigation instructions please click here Search Issue | Next Page

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSSuperb <strong>LED</strong> <strong>Lighting</strong> by X<strong>LED</strong>s, Korea<strong>LED</strong> MR 16 LAMP8WGA1607S8W12V280Lm440Lux<strong>LED</strong> MR 16 LAMP4W1605TL4W12V190Lm320Lux<strong>LED</strong> Desk Lamp10W3 Color ModeQ-20010W12V1400LuxDoHyeon B/D 4F #128-6 Nonhyeon-dong, Kangnam-Gu, Seoul Korea, www.exleds.comTel : 82-2-3443-5360 ext 309 Fax : 82-2-3443-5351 E-mail : info@daejindmp.co.krPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS________________________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSHigh Performance. Low Power.Energy-Efficient <strong>LED</strong> <strong>Lighting</strong> SolutionsNational’s new low-side, constant-current <strong>LED</strong> driver offers integrated thermal controlto increase system reliability. The thermal foldback feature of National’s LM3424 <strong>LED</strong>driver provides a more robust thermal design to extend the life of the <strong>LED</strong>s, making it anideal solution for a variety of outdoor, automotive, and indoor lighting applications.NominalCurrent<strong>LED</strong> CurrentTemperatureBreakpoint<strong>LED</strong> Temperature© 2009, National Semiconductor Corporation. National Semiconductor, , PowerWise, and WEBENCH are registered trademarks. All rights reserved.Thermal ManagementSince thermal design greatlyimpacts the light outputand lifetime of the <strong>LED</strong>s,a well-designed thermalsystem is critical. TheLM3424’s thermal foldbackfeature eliminates theneed for external thermalmanagement circuitry,allowing for a more robustand reliable thermal systemand extending the life of the<strong>LED</strong>s.Easy to UseWith National’s WEBENCH ®<strong>LED</strong> Designer online tool,designers can use theLM3424’s thermal foldbackfeature to visualize thedesign’s behavior at userselected<strong>LED</strong> temperaturebreakpoints for easy andquick development ofa thermal managementsystem.Flexible DesignNational’s LM3424 <strong>LED</strong>driver, with a wide inputvoltage range, can be easilyconfigured in buck, boost,buck-boost, and SEPICtopologies with minimaladjustments. Driving amaximum of 18 <strong>LED</strong>s inone string, the LM3424gives designers flexibilitywhile providing up to 96%efficiency and accuratecurrent regulation with lesspower and heat dissipation.national.com/ledPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSISSUE 30november/december2009Cover StoryFormula One World Champion JensonButton races past the Yas Hotel, AbuDhabi, which is covered with an <strong>LED</strong> netfrom Cooper and Enfi s (p.12).Photo credit: Enfi s Group plc.features18 MANUFACTURINGSupply chain maps a path to bringing down thecost of <strong>LED</strong> lightingPaula Doe, SEMI22 CONNECTORSConnectors provide the vital link for lightingsystem designRonald Weber, Tyco Electronics29 CONFERENCESRecent conferences in Asia highlight <strong>LED</strong> industryprogressBob Steele, Strategies Unlimited32 OUTDOOROutdoor <strong>LED</strong> lighting benefi ts from PG&E efforts,but health concerns are surfacingBrian Owen & Tim Whitaker4917columns/departmentsCOMMENTARY Tim WhitakerNights draw in, <strong>LED</strong>s lightthe road aheadNEWS + VIEWS<strong>LED</strong>s tower above Paris, LondonEquipment sales on the riseEpistar and Lynk Labs ink dealCree shows 102 lm/W <strong>LED</strong> A-lampEnfi s and Cooper provide<strong>LED</strong> veil for Yas HotelFUNDING + PROGRAMSEPA and DOE sign deal to endEnergy Star Wars sagaRogue lamp labels hit the shelves37 SAFETYNavigating the product safety certifi cation processfor solid-state lighting productsTodd Straka, Intertek40DESIGN FORUMPutting the Smart Phone in control: using apps inembedded systems to control <strong>LED</strong> lightingCarl Matthews, ML Electronics Ltd4344PRODUCT FOCUSLAST WORDReally Big <strong>LED</strong>s will enablethe next phase of <strong>LED</strong> lightingKeith Ward, Luminus DevicesPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGScommentaryNights draw in, <strong>LED</strong>slight the road aheadAutumn is here, the days are growingshorter and I’ve got my <strong>LED</strong> bike lightsout of the drawer. The conference schedulehas been packed in recent weeks, with theeconomy causing some events to struggle,while others such as Light Show West in LosAngeles were very well attended, with excellentfeedback. We’re pleased to say that nextFebruary’s Strategies in Light 2010 (SantaClara, CA) will be the largest in the show’shistory, and a strong conference programhas been announced (see __________www.ledsmagazine.com/news/6/10/28).Also in California,_______________utility Pacific Gas & Electric (PG&E) hasremoved a major roadblock for roadwaylighting by including <strong>LED</strong> technology in itsrate schedule (p.32). Put simply, PG&E hasacknowledged the energy-efficiency benefitsof <strong>LED</strong> technology, so that customers operating<strong>LED</strong> streetlights are charged less forPG&E’s services and power.In our last issue we wrote about the USDOE’s <strong>Lighting</strong> Facts program, which hasintroduced a label for lighting performancethat is similar to the Nutrition Facts labelscommonly seen on food products. A greatidea, but unfortunately it has been underminedfirst by Philips and then Osram Sylvania,who both circumvented procedures andprinted their own labels (p.17). Now we hearthe Federal Trade Commission is looking ata similar labeling program for all lamps, tohelp consumers understand exactly whatthey are buying. Hopefully this will get ridof some of the ridiculous comparisons thatare published on lamp packaging.Speaking of replacement lamps, it appearsthat the DOE’s Caliper program is doing itsjob. We hear that Costco, a major US store,has recalled certain <strong>LED</strong> lamps after theywere proven by Caliper testing to have vastlyinferior performance to the values claimedby the manufacturer.Positive news for replacement <strong>LED</strong> lamps:Cree has set new standards with its prototypeA-19 lamp which has an output of 969lm and efficacy of 102 lm/W. The 2800 Klamp has 91 CRI (p.12). In our last issue wewrote about the L Prize, which focuses onachieving performance targets for different<strong>LED</strong> lamp types. Philips has submitteda 60W-replacement prototype, which is nowbeing evaluated. In my view, it doesn’t makesense to award these lucrative prizes untilthe performance thresholds are reached bya lamp that is in full production. Customersdon’t buy prototypes. Also, the price pointneeds to be considered, since market transformationrequires high-performance lampsthat people can afford to invest in.Finally, as this issue was going to press,we heard that GE has acquired an <strong>LED</strong> moduletechnology from Journee <strong>Lighting</strong> (www.ledsmagazine.com/news/6/11/10). The modulecan be inserted into a luminaire with asimple twist-lock action, which makes therequired thermal and electrical connections.Crucially, this means the module canbe removed and replaced in case of failure ofthe <strong>LED</strong> source or drive circuitry, and it canalso be upgraded as <strong>LED</strong> technology continuesto evolve. As a major lighting player, GEhas struggled to penetrate the mainstreammarket with its <strong>LED</strong> offerings, but thesemodules could be just what the market islooking for.Speaking of false dawns, I’m going to goand buy a blue-<strong>LED</strong>-based light therapy boxto help combat the shorter autumn days.____Tim Whitaker, EDITORtwhitaker@pennwell.comGROUP PUBLISHER Christine Shawcshaw@pennwell.comEDITOR Tim Whitakertwhitaker@pennwell.comTel. +44(0)117 946 7262MANAGING EDITOR Carol Settinocarols@pennwell.comTel. +1 603 891 9234CONTRIBUTING EDITOR Brian OwenMARKETING MANAGER Luba HrynykPRESENTATION MANAGER Cindy ChamberlinPRODUCTION DIRECTOR Mari RodriguezSENIOR ILLUSTRATOR Christopher HippAUDIENCE DEVELOPMENT Debbie BouleyEDITORIAL OFFICES PennWell Corporation, <strong>LED</strong>s MagazineCorporate Offices98 Spit Brook Road, LL-1Nashua, NH 03062-5737Tel: +1 603 891-0123Fax: +1 603 891-0574www.ledsmagazine.comSALES OFFICESSALES MANAGER Mary Donnelly(USA) maryd@pennwell.comTel. +1 603 891 9398SALES MANAGER Joanna Hook(EUROPE) joannah@pennwell.comTel. +44(0)117 946 7262SALES MANAGER Manami Konishi(JAPAN) manami@ics-inc.co.jpTel: +81 3 3219 3641SALES MANAGER Mark Mak(CHINA & HONG KONG) markm@actintl.com.hkTel: +852 2838 6298SALES MANAGER Alice Chen(TAIWAN) alice@arco.com.twTel: +886 2 2396 5128 ext.206CORPORATE OFFICERSCHAIRMAN Frank T. LauingerPRESIDENT AND CEO Robert F. BiolchiniCHIEF FINANCIAL OFFICER Mark C. WilmothTECHNOLOGY GROUPSENIOR VICE PRESIDENT Christine A. ShawSENOIR VP OF AUDIENCE Gloria S. AdamsDEVELOPMENTVP INTERNET SERVICES Tom CintorinoSUBSCRIPTIONS: For subscription inquiries:Tel: +1 847 559-7330;Fax: +1 847 291-4816;e-mail: led@omeda.com;ledsmagazine.com/subscribeWe make portions of our subscriber list available to carefully screenedcompanies that offer products and services that may be important foryour work. If you do not want to receive those offers and/or informationvia direct mail, please let us know by contacting us at List ServicesMagazine Name, 98 Spit Brook Road LL-1, Nashua, NH 03062.Copyright © 2009 PennWell Corp. All rights reserved. Contents ofthis publication may not be reproduced in any form without priorwritten consent of Publishers.4 NOVEMBER/DECEMBER 2009 <strong>LED</strong>smagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSwww.osram-os.com<strong>LED</strong>s for General <strong>Lighting</strong> SolutionsOSRAM Opto Semiconductors empowers lighting solutions for today and tomorrowPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS<strong>LED</strong>s MAGAZINEonlineWebcastsOptimizing <strong>LED</strong> Performancethrough Heat ManagementORIGINALLY BROADCAST: October 2009PRESENTERS: Martin Schon, Sapa Extrusions; Mick Wilcox, NuventixSolid-State <strong>Lighting</strong>: Safety CertificationProcess and Performance TestingMeasurement TechniquesORIGINALLY BROADAST: September 2009PRESENTERS: Greg McKee, LabsphereTodd Straka, IntertekVisit www.ledsmagazine.com/webcasts to access upcomingand archived presentations.Web Exclusive ArticlesStrategically Speaking: Recent conferencesin Asia highlight <strong>LED</strong> industry progresswww.ledsmagazine.com/features/6/10/12High-efficiency lighting needs high-efficiency manufacturingwww.ledsmagazine.com/features/6/10/3Fitted Target Efficacy metric promotes discussionwww.ledsmagazine.com/features/6/10/2Featured CompaniesThe following have recently been added to the <strong>LED</strong>s Magazine site as FeaturedCompanies (see www.ledsmagazine.com/buyers/featured):High Power <strong>Lighting</strong> Corp. • Instruments Systems GmbHADVERTISERS indexAvago Technologies C3Citizen Electronics Ltd. 7Daejin DMPC2Edison Opto Corporation 13Elecosn HK 43Foxsemicon 43GE Lumination 43Genie Electronics 24GlacialLight 33Innovations in Optics 30Instrument Systems 24GmbHIntertek 8Kingbright Electronic 41Europe GmbHLabsphereC4Lambda Research Corp. 12MeanWell USA 25National Semiconductor 2OptoElectronix Inc. 43Osram Opto 5Semiconductors GmbHQuasar Light Co Ltd. 10Roal Electronics USA Inc. 43Semileds 26Seoul Semiconductor 11Co Ltd.Sichuan Jiuzhou Electric 1GroupSigncomplex Ltd. 21Specialty Coating 35Systems Inc.SphereOptics LLC 14Stockeryale 15Supertex Inc. 19Taitra 27The Bergquist Company 16Thomas Research 28ProductsUPEC 43USHIO 31FEATURED eventsStrategies in Light 2010February 10-12, 2010Santa Clara, California, USAAn expanded <strong>Lighting</strong> Track and a newsolid-state lighting Investor Forum will beamong the highlights of SIL 2010 — seewww.ledsmagazine.com/news/6/10/28for full program details. Register byDecember 11 for early-bird discounts.MORE: www.strategiesinlight.comO<strong>LED</strong> <strong>Lighting</strong> Design Summit 2009December 2-3, 2009Boston, MA, United StatesForum<strong>LED</strong>December 3-4, 2009Lyon, FranceWhite <strong>LED</strong>sDecember 13-16, 2009Taipei , TaiwanPhotonics West 2010January 23-28, 2010The Moscone Center, SanFrancisco, CA, United StatesThe ARC Show 2010February 03-04, 2010Earls Court, London, United Kingdom<strong>LED</strong> China 2010March 02-05, 2010Guangzhou, ChinaLight+Building 2010April 11-16, 2010Frankfurt am Main, Germany<strong>Lighting</strong> Japan: the 2nd <strong>LED</strong>/O<strong>LED</strong> <strong>Lighting</strong> Technology ExpoApril 14-16, 2010Tokyo Big Sight, JapanLightfair 2010May 12-14, 2010Las Vegas Convention Center, United States<strong>LED</strong> <strong>Lighting</strong> TaiwanJune 09-11, 2010Taipai, Taiwan<strong>LED</strong> Expo and O<strong>LED</strong> Expo 2010June 22-25, 2010KINTEX, South KoreaMORE: www.ledsmagazine.com/events6 NOVEMBER/DECEMBER ER/DECECEMBER 2009<strong>LED</strong>smagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS___________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSAnd the market said, “Let there be <strong>LED</strong>.”<strong>LED</strong> products are the future of lighting. They are also quite complex and rapidly evolving—which is why youneed a test lab like Intertek. No other lab in the world offers the same breadth of safety and performancetesting services. Plus, we have labs in Europe, North America and Asia, each with a commitment to ultra-fastproject turnarounds. And our engineers offer the kind of guidance that can make all the difference when itcomes to getting your product to market on time.Our industry leadership was established long ago by our founder, Thomas Edison. It’s his legacy that inspiresour team today as lighting reinvents itself,once again. For more information, whitepapersand webinars, please visit our website.1-800-WORLDLAB (967-5352)www.intertek.com/lightingIntertek offers product safety certification (ETL) as well as EMC, quality,performance, environmental and energy efficiency testing services.Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS____________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS_____________________news+viewsannounced plans to enter the AC <strong>LED</strong> marketwith single-chip AC <strong>LED</strong> technology. Lastyear, Epistar obtained a patent license fromITRI, the Taiwan-based Industrial TechnologyResearch Institute.• In September, Epistar raised US$351 millionin equity financing, and has settled adispute with Philips Lumileds over AlIn-GaP <strong>LED</strong> technology and products (www. ____ledsmagazine.com/news/6/9/23).• Also, Epistar says it has developed atechnology to enable high color renderingindex (CRI) and high efficacy for warm-white<strong>LED</strong>s. The company has combined its blueand red chips in different packages (www. ____ledsmagazine.com/news/6/11/4). ◀MANUFACTURINGSemi<strong>LED</strong>s increases capacity<strong>LED</strong> maker Semi<strong>LED</strong>s Corporation hasintroduced an Aixtron MOCVD system with7 × 4-inch configuration into its 4-inch <strong>LED</strong>wafer fab in Taiwan. Semi<strong>LED</strong>s has shiftedits mass production of its V<strong>LED</strong> productsto 4-inch wafers, which it says will greatlyincrease production capacity to meet strongdemand for high-end applications, such asstreet and domestic lighting. The fab willbe able to produce 10 million high-powerV<strong>LED</strong> chips per month when running atfull capacity. At the recent ChinaSSL conference,Semi<strong>LED</strong>s announced that its packagingcustomers, using I-core Mvp<strong>LED</strong> chips,have achieved 120 lm/watt for cool-white<strong>LED</strong>s running at 350mA. ◀MORE: www.ledsmagazine.com/press/20396REPLACEMENT LAMPSCree shows 102 lm/W <strong>LED</strong> A-lampCree has demonstrated an A-lamp <strong>LED</strong> lightbulb with an output of 969 lumens at 102lm/W efficacy, which the company claimsis the highest lumen output and efficacyreported in the industry (www.ledsmagazine.com/news/6/11/3).The light output is________________________equivalent to that of a 65W incandescentbulb, but Cree’s <strong>LED</strong> version uses only 9.5W.The demonstration A-19-style bulb featuresthe latest Cree production XLamp® XP-G<strong>LED</strong>s and TrueWhite Technology, a patentedmethod of delivering warm-white lightwith high color rendering and efficiency.The 2800 K warm-white lamp has 91 CRI.Cree said that all data was verified by thirdpartytesting under steady-state operatingconditions.The US government’s L Prize includes acategory for an <strong>LED</strong> replacement for a 60Wincandescent lamp. Light output shouldexceed 900 lm with energy consumptionof less than 10W, and efficacy of more than90 lm/W. CRI should exceed 90 with a colortemperature in the 2700–3000 K range.It remains unclear whether Cree may planto manufacture <strong>LED</strong> lamps in the future, orto license its technology and/or sell its <strong>LED</strong>sto an established lamp maker.• Cree’s revenue for <strong>LED</strong> products was arecord $156 million for the quarter endedSeptember 27, 2009, a14% increase over theprevious quarter.• Cree’s cool-white XLamp® XP-G <strong>LED</strong> isnow commercially available. It can produceup to 367 lm when driven at 1A, at a typicalefficacy of 111 lm/W. The highest-performingbin also has a standard minimum fluxat 350 mA of 139 lm. The XP package size is3.45 × 3.45 mm.• Cree expects to add 275 jobs in NorthCarolina during 2009 to serve the expansionof its <strong>LED</strong> manufacturing capacity andother staffing needs at its facility in Durham,NC. ◀ARCHITECTURALEnfi s and Cooper provide<strong>LED</strong> veil for Yas HotelAnyone who saw the recent Formula OneGrand Prix in Abu Dhabi could not fail tonotice the color-changing <strong>LED</strong> veil coveringthe Yas Hotel, which is unique as theonly hotel in the world to sit astride a racetrack. The building’s visual impact is greatlyenhanced by its exterior <strong>LED</strong> mesh, containing208,800 <strong>LED</strong>s, which resulted from a collaborationbetween two UK-based companies,Cooper <strong>Lighting</strong> and Enfis Group plc.The exterior consists of sweeping, curvilinearforms constructed of steel and over 5,300pivoting diamond-shaped glass panels whichare illuminated via the <strong>LED</strong> lighting system.Cooper used over 5,850 Enfis <strong>LED</strong> arrays inits lighting system. Primarily these wereEnfis 4-channel UNO Plus arrays and controldrivers integrated into custom-designed12 NOVEMBER/DECEMBER 2009 <strong>LED</strong>smagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS____________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSnews+viewsIP65-rated stainless-steel stanchions.The desert climate of Abu Dhabi can reach60°C in the summertime, creating problemsfor most light sources. Cooper said that theEnfis array/driver system was the only onethat passed the rigorous environmentalchamber trials. Enfis’ technology providesthe ability to control each <strong>LED</strong> array, aswell as two-way communication with eachdriver/array combination providing realtimemonitoring of fixture temperature,CCT and energy consumption. The RemoteDesk Management (RDM) DMX control systemwas supplied by e:cue. ◀MORE: www.ledsmagazine.com/news/6/11/2MANUFACTURINGLG invests in <strong>LED</strong>sLG Group, one of Korea’s largest display makers,plans to spend about 4 trillion won (about$3.34 billion) on a major plant for makingliquid-crystal display (LCD) glass substratesand <strong>LED</strong>s in Paju, Gyeonggi Province, Korea.The new, 840,000-square-meter manufacturingfacility will begin producing <strong>LED</strong> componentsand materials in 2010, and LCD glassin 2012, and will be critical in LG’s plans toexploit the sharply increasing demand fornext-generation display and lighting technologies.LG Innotek, the company’s <strong>LED</strong>subsidiary, will invest around 1 trillion wonthrough 2012, and will use the new facilityto produce <strong>LED</strong> BLUs and lighting components.The plant will eventually boostthe company’s production capabilities of<strong>LED</strong>s by four times the current level with afocus on <strong>LED</strong> backlighting units for use inLCD televisions and monitors produced byLG Display. ◀MORE: www.ledsmagazine.com/news/6/9/25BUSINESSTyntek to acquire UbiluxTyntek Corp, a Taiwan-based <strong>LED</strong> chipmaker, has obtained approval from its boardto acquire Ubilux Optoelectronics Corp., the<strong>LED</strong> chip manufacturing arm of PowerchipSemiconductor Corp, Taiwan’s secondlargestcomputer memory chipmaker. Theshare-swap deal is worth about NT$2.81billion (US$86.8 million). After the acquisition,Powerchip will become the biggestshareholder at Tyntek, and Tyntek will bethe third largest <strong>LED</strong> chip maker in Taiwan,after Epistar Corp and Optotech Corp. Thecompany has aggressive expansion plansand will increase the number of MOCVD systemsto 30 units by the end of next year. ◀MORE: www.ledsmagazine.com/news/6/10/24__________________________________________O<strong>LED</strong>STransparent low-profi leO<strong>LED</strong> lighting panelsOsram Opto Semiconductors has developedprototype large, transparent O<strong>LED</strong>panels, that measure 17 × 17 cm 2 and havea luminous area of 210 cm 2 . The panels areonly a few hundred micrometers thick,and do not need separate encapsulation.The test samples were developed as partof the TOPAS research project funded bythe Germany Ministry for Education andResearch (BMBF). The aim of the project is14 NOVEMBER/DECEMBER 2009 <strong>LED</strong>smagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSto produce 1 m 2 transparent O<strong>LED</strong> modules,and will run until 2011. Osram Optosays that in the O<strong>LED</strong> lighting marketthere is a clear demand for large, low-profiletransparent light sources. The O<strong>LED</strong>panels can be made transparent due tonew developments in electrode designand a new approach to thin-film technology.The current is distributed evenly overthe active surface, which in turn leads touniform luminance. Further developmentwork will lead to an even thinner carriermaterial, and therefore to even thinnerO<strong>LED</strong>s. The new technology also simplifiesthe manufacturing process, whetherO<strong>LED</strong>s are produced on a small moleculeor polymer basis. The next stage is to integratethe processes into a stable manufacturingoperation. ◀MORE: www.ledsmagazine.com/news/6/10/19LICENSINGAcuity joins Philips <strong>LED</strong>luminaires licensing programAnother major lighting company, AcuityBrands Inc, has signed up for Philips’ licensingprogram for <strong>LED</strong>-based luminaires. Acuitywill gain access to Philips’ patent portfoliofor <strong>LED</strong> systems and controls. The deal coversworldwide sales of <strong>LED</strong>-based luminairesfrom all of Acuity’s businesses. Acuity Brandsis one of the world's leading providers of lightingfixtures and related products, with brandsincluding Lithonia <strong>Lighting</strong>, Holophane,Peerless, Gotham and Mark Architectural<strong>Lighting</strong>. Philips has already signed licensingagreements with major players such as Osramand Zumtobel. ◀MORE: www.ledsmagazine.com/news/6/10/21<strong>LED</strong> PERFORMANCELumileds publishes LM-80 dataPhilips Lumileds is claiming to be the firstpower <strong>LED</strong> manufacturer to publicly publishnews+viewsLM-80 test report data, which describes thelumen maintenance characteristics of itswhite Luxeon Rebel <strong>LED</strong>s. The report, availablefrom its website, will be useful for luminairemanufacturers when evaluating themerits of using different <strong>LED</strong>s for their SSLproducts. Lumileds is encouraging other <strong>LED</strong>makers to follow its lead. ◀MORE: www.ledsmagazine.com/news/6/10/20Correction:Dialight installationIn our last issue we published an articlewritten by Linear Technology (<strong>LED</strong>sMagazine, Sept/Oct 2009, p. 49; ___ www.ledsmagazine.com/features/6/10/9).Figure 2, which shows a refi neryinstallation, as well as informationin the section entitled "Industriallighting," is taken without permissionor acknowledgement from a case studypublished by Dialight (www.ledsmagazine.com/press/17997). The article also claimsthat a Linear IC was used in Dialight'sfi xtures. According to Dialight, Linear'sIC is defi nitely not used in the luminairespictured in Dialight's installation photo,nor are any Linear ICs used in any Dialightluminaires. <strong>LED</strong>s Magazine apologizes toDialight for publishing this material._____________<strong>LED</strong>smagazine.com NOVEMBER/DECEMBER 2009 15Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSNEW T-CLAD ® PASTICKS IT TO HEAT.Peel and place thermal solution withstands the heat of solder reflow.Easier assembly, cooler <strong>LED</strong>s.Thermally conductive insulated metal substrateboards specifically configured for <strong>LED</strong> applications.Bergquist’s T-Clad with pre-applied Bond-Ply ® 450 allows you to adhere yourmounted <strong>LED</strong>s to a variety of heatsinks and surfaces while thermally optimizingyour application.This version of peel and place T-Clad canwithstand the high temperatures of solder reflow during<strong>LED</strong> assembly and then be positioned in the lightingapplication using its strong thermally conductive adhesive.Call or visit to qualify for your FREE sample.Call 1.800.347.4572 or visit www.bergquistcompany.com/preappliedFREE T-Clad ® PASample Board18930 West 78th Street • Chanhassen, MN 55317 • A ISO9001:2000 registered facility(800) 347-4572 • Phone (952) 835-2322 • Fax (952) 835-0430 • www.bergquistcompany.comThermal Materials • Thermal Substrates • Fans and BlowersPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSfundingprogramsEPA and DOE sign deal to endEnergy Star Wars sagaAt the end of September, the US Departmentof Energy (DOE) and the US EnvironmentalProtection Agency (EPA) signed a partnershipagreement that transfers the responsibilitiesfor the Energy Star program, includingsolid-state lighting, from DOE to EPA.The original joint announcement (www.ledsmagazine.com/news/6/10/1)stated that the_______________________EPA would be brand manager and Agencylead for the Energy Star products program,while DOE will provide technical support inareas such as product testing and verification.The statement also resolved to developan integrated approach to the Energy Starresidential lighting program that recognizesthe importance of both whole-fixture-basedand light-source-based approaches for measuringlighting energy efficiency.In mid-October, Jim Brodrick, lighting programmanager for the DOE, said that it is stillunclear whether the Energy Star SSL Programwill continue as introduced by DOE, or if significantchanges will be made by EPA (www. ____ledsmagazine.com/news/6/10/18). However,he said that, at the behest of the Next Generation<strong>Lighting</strong> Industry Alliance (NGLIA) andother industry stakeholders, an agreementhas been reached with EPA to continue thecriteria adoption process for outdoor lightingand replacement lamps.Brodrick commented that Energy Starplayed “only a minor role” in the DOE’s overallcommercialization support efforts forSSL, which he stressed would continue. “Weare in the process of expanding our Caliper,Gateway Demonstration, and <strong>Lighting</strong> Factsefforts as a way of broadening our commercializationsupport in an expanding industry.We will also be increasing stakeholdereducational efforts, especially for thosepotential buyers not totally familiar withsolid-state lighting,” he said.In early November, Alex Baker, EnergyStar lighting program manager for the EPA,provided an update to Energy Star lightingmanufacturing partners, energy efficiencyprogram sponsors and stakeholders (www. ____ledsmagazine.com/news/6/11/5). Baker saidthat no later than November 30, 2009, DOEand EPA will release a more detailed proposaloutlining anticipated Energy Star programenhancements for 2010, including a proposedapproach for integrating various elements ofthe Energy Star lighting program.“Among other things,” said Baker’s letter,“it is EPA’s intention to streamline the qualificationprocess and paperwork related toEnergy Star qualification of lighting products,as part of the process of integratingpotentially duplicative and overlappingspecifications.”Baker also said that EPA intends to retainkey elements of the DOE-developed EnergyStar specifications for Solid State <strong>Lighting</strong>and Integral <strong>LED</strong> Lamps, including testingaccording to the IES LM-79 standard, asappropriate.“The process to integrate the lighting specificationswill be consistent with Energy StarGuiding Principles, and open to partner andstakeholder review through a series of publiccomment periods resulting in final version(s)that go into effect after sufficient transitiontime,” said Baker’s letter. “Until this task iscomplete, partners will continue to be ableto qualify products using existing specificationsand contracting support to the EnergyStar program.” ◀Rogue lamp labelshit the shelvesIn September, we reported that severalPhilips <strong>LED</strong> lamps were on sale in theUSA with unauthorized versions of the<strong>Lighting</strong> Facts label on their packaging(www.ledsmagazine.com/news/6/9/21).The <strong>Lighting</strong> Facts label is part of the USDepartment of Energy’s voluntary SSLQuality Advocates program, via which<strong>LED</strong> luminaire makers can “demonstratetheir commitment to accurate and consistentreporting of product performanceclaims,” to quote the DOE. Blaming aninternal procedural error, Philips hurriedlyjoined the program and submittedthe required performance data.In October, it emerged that Osram Sylvaniahad also made its own <strong>Lighting</strong>Facts label for its 4W PAR16 <strong>LED</strong> lamp(www.ledsmagazine.com/news/6/10/14).________________________This particular label lacks the standardportrait format and other features of theauthorized version.In between the Philips and Osram Sylvaniaincidents, the DOE commented onthe <strong>Lighting</strong> Facts label program, sayingthat it will take “immediate action” toinvestigate any violations and insist onconformity with the program requirements.The DOE said anyone “who doesnot play by the rules” should expect tohear from DOE lawyers and the FederalTrade Commission. We have yet to hearof any outcome in this direction, butthe DOE also correctly said that roguelabels undermine the very nature of theprogram, which is designed to protectthe consumer from "getting burned" byproducts whose performance falls shortof manufacturers’ claims.Equally important, but not coveredby the <strong>Lighting</strong> Facts program, is theissue of invalid and inappropriate comparisonswith existing technology. TheOsram Sylvania 4W <strong>LED</strong> lamp is statedto be a replacement for a 25W lamp (ofunspecified type). However, the <strong>LED</strong>lamp produces only 110 lumens—whichwould be pretty shoddy performance forany 25W lamp.<strong>LED</strong>smagazine.com NOVEMBER/DECEMBER 2009 17Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS<strong>LED</strong>s | MANUFACTURINGSupply chain maps a path to bringingdown the cost of <strong>LED</strong> lightingSignifi cant reductions could be achieved in the cost of producing <strong>LED</strong>s, particularly if the supplychain can collaborate on an industry-wide roadmap, writes PAULA DOE of SEMI.It should be possible to achieve about a70% reduction in production costs for <strong>LED</strong>lighting by 2015. This was one conclusionreached by attendees at two US Departmentof Energy (DOE) workshops that looked atways to improve solid-state lighting (SSL)manufacturing (see “SSL Manufacturingworkshops”). A big part of that potentialdecline is projected to come from a reductionof about 85% in the cost of the packaged<strong>LED</strong>, which now accounts for some 40% ofthe cost of the luminaire.However, achieving those aggressivepotential reductions will likely depend, inpart, on sector cooperation on an industryroadmap—and a realistic common-costmodel—so those within the supply chain canfigure out where to best focus their efforts.Such pre-competitive collaboration has beenused effectively by the semiconductor andflat-panel display industries in the past todrive more rapid improvement in processtechnology.DOE recently released an initial roadmapfor HB-<strong>LED</strong> and O<strong>LED</strong> manufacturingtechnology. The roadmap is based onthe stakeholder discussions at the workshops,and represents industry consensuson the expected evolution of SSL manufacturing,best practices, and opportunities forimprovement and collaboration. “We cameto some consensus on where the principalcosts are, which gives us a better sense ofwhat needs work,” says Fred Welsh, RadcliffeAdvisors, consultant to the DOE and one ofthe organizers.DOE plans to update the roadmap nextyear, and also to continue work on developinga cost-of-ownership model, to betterRelative manufacturing cost1.00.80.60.40.20.0identify where the best gainsfrom investments in improvingmanufacturing processwould be. Such a model wouldallow the community to identifyequipment and processeslying on the critical path andoffer a more quantitativeassessment of the beneficialcost impact of addressingeach issue. The equipmentand materials industry associationSEMI, which has facilitatedsimilar efforts in othersectors, also welcomes inputon how it can best help supportthese efforts, says Tom Morrow, SEMIVP of global exhibitions and marketing.EQUIPMENT: Suppliers see2–3x potential reductionsSemiconductor equipment makers say thereare real options for making big improvementsin process yields and productivity tobring down SSL costs, by applying learningsfrom other thin film manufacturing sectorsand designing equipment specifically suitedto this sector, with the kinds of process controland volume throughput that are nowrequired.“We think overall epitaxial processingcost has to come down 3×, and we seea path to be able to do that,” says Jim Jenson,VP of marketing for the MOCVD businessat Veeco Instruments, Inc. (Plainview,NY). He notes that progress has been madeon improving the complex, multi-hourepitaxial process that grows most of the keydevice layers. This has included developmentPAULA DOE covers Emerging Markets for SEMI (www.semi.org), the global industry associationserving the manufacturing supply chains for the microelectronic, display and PV industries.OpticsAssemblyPower suppliesThermal & metal bending<strong>LED</strong> devices2009 2010 2012 2015FIGURE 1. Projected luminaire cost, and potential forreduction. Source: DOE Manufacturing Workshop.of better uniformity and repeatability, optimizedflow geometries, better temperaturecontrol, faster processing time, improvedsystem architecture and optimized batchsizes, though it could take a few years for allthese developments to get into high-volumeproduction.Another more radical option being consideredby both established and potentialnew suppliers is to divide the epitaxial processinto separate chambers, each optimizedto the different requirements of the differentlayers. Typically this would use hydridevapor phase epitaxy (HVPE) for the thickGaN, though HVPE reactors will need to bemade into high-volume tools. Oxford Instrumentsplc (Yatton, UK) recently announcedthe first multiwafer HVPE reactor (see____www.ledsmagazine.com/press/18664).Applied Materials, Inc. (Santa Clara,CA) reports it’s making progress on possibleMOCVD solutions as well. “We see techniquesfrom IC processes used for decadesthat would apply,” says Pat Lamey, strategicmarketing and new business developmentfor the energy and environmental solution18 NOVEMBER/DECEMBER 2009 <strong>LED</strong>smagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS<strong>LED</strong>s | MANUFACTURINGgroup. He notes that Applied’s developmentfocus is now getting feedback from customers,and is based on a combination of commonlyused MOCVD processes and “sometechnology that’s been written about fordecades but never brought to production.”Lamey also says that better process controlis key to improving overall <strong>LED</strong> yieldsand costs, because it’s crucial to overallthroughput and performance. “We’re seeinga segment of the solid-state businesswith potential for significant improvementin the next half decade, and the sooner wecan bring the production techniques andcontrols known from our other technologiesand products, the faster it will move into themarket place,” says Lamey. “A roadmap willbe particularly helpful, especially since the<strong>LED</strong> industry is transitioning from two-inchsubstrates to 100mm substrates.”Likely to propel the biggest jump in manufacturingproductivity, however, could be theentry of some big silicon chip makers whoare accustomed to doing very controlled productionin very high volumes. “The customerbase is evolving as new players from the ICSSL ManufacturingworkshopsThe DOE held two SSL Manufacturingworkshops in 2009 (April 21–22 inFairfax, VA, and June 24–25 in Vancouver,WA), as the start of a new initiative toenhance product consistency and quality,and to accelerate cost reductions throughmanufacturing improvements. Morethan 350 participants—chip makers,fi xture and component manufacturers,and others—examined underlying issuesrelated to materials, equipment, andother factors that infl uence SSL productquality and cost. The Fairfax workshopattendees identifi ed key barriers andrecommendations toward lower-cost,higher-quality SSL products, and a draftroadmap was reviewed at the Vancouverevent. The fi nal version of the roadmaprepresents industry consensus on theexpected evolution of SSL manufacturingand is available at www.ssl.energy.gov/projects.html. ◀________industry enter the field,” saysLamey. “Their entry will havea huge impact on manufacturingtechnology.”KLA-Tencor Corp. (Milpitas,CA) sees another potential2× cost reduction fromimprovements in defectinspection and defect sourceanalysis, says Richard Solarz,KLA-Tencor senior directorof technology, as the <strong>LED</strong>industry currently lacksboth appropriate inspectionequipment to find the criticaldefects and efficient systems►Relative manufacturing cost1.00.80.60.40.20.0to figure out what’s causing them. Toolsdeveloped to inspect finer features on siliconfor the IC industry find a lot of defects thatdon’t matter for <strong>LED</strong>s, and can’t find othersthat do. For example, they can’t differentiatethe problematic micropits or threadingdefects in sapphire from the particles thatdon’t matter, and they can’t bin the finisheddie by the qualities of2009 2010 2012 2015Wafer processingEpitaxySubstratePhosphorBack endFIGURE 2. Projected packaged <strong>LED</strong> cost, and potentialfor reduction. Source: DOE Manufacturing Workshop.Supertex HV9910B and HV9961 <strong>LED</strong> Drivers:Switching Converters Optimize <strong>LED</strong> Performancein Municipal <strong>Lighting</strong>Efficient - Simple PFC implementation meets or exceeds most municipalpower efficiency requirements (PFC > 90%, THD < 20%)► Durable - <strong>LED</strong> driver lifetime extended by elimination of the needfor electrolytic capacitors►►interest. And laserbasedbare wafer/film surface analysistools in the frontend,developed forthe hard-disk industry,can’t talk to theimage-based patterned-waferinspectiontool in the backend,developed toinspect wafer-levelchip packaging. Thismakes it difficult toquickly track defectsback to their source.“Now that weunderstand the keydefect needs of manyof the <strong>LED</strong> manufacturers,we have identifiedkey changes weneed to make in ourtools to isolate thesedefects. And we needto overlay the defectmaps from the tools,”says Solarz. “Workingwith our customers,we believe that we can reduce manufacturingcost in many cases by as muchas a factor of two.” He sees other potentialfor improved yields, but only if the industryagrees on what is needed. One example,he notes, is the difference in opinionabout the need for a color-quality monitor.“The answers range from solid 'yes' to solidModular and Scalable - One driver can control multiple <strong>LED</strong> strings,or add more to easily scale to different power levelsEasy to design - Simple output current programming and no needfor loop compensationTo learn more about the Supertex Switching Converter <strong>LED</strong> Driver ICs, visit:www.supertex.comSupertex inc.1235 Bordeaux Drive, Sunnyvale, CA 94089 ♦ (408)222-8888 ♦ E-mail: mktg@supertex.com<strong>LED</strong>smagazine.com NOVEMBER/DECEMBER 2009 19Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS<strong>LED</strong>s | MANUFACTURINGFIGURE 5. Freestanding GaN foil.(Courtesy of Goldeneye)Technologies (Raleigh, NC). “But the worlddoesn’t have much experience in making it,so we’re still coming down the volume learningcurve. But in the meantime there’s a drivingforce for an intermediate solution.”The first intermediate solution now apparentlygetting a serious look is patterned sapphire.Texturizing the surface with differentschemes of wet or dry etch improvesthe quality of the epi layers grown on top,for better light extraction efficiency, thoughwhy this works and how best to do it remainto be worked out. Also a possibility is addingan aluminum nitride (AlN) layer on top ofthe patterned sapphire, with initial resultsreportedly showing increased brightnessand wavelength uniformity. “We stronglysuspect this may bring down costs too,”says Evans, “since it can eliminate some ofthe MOCVD steps.” The AlN-coated sapphirecan be ramped more quickly to the appropriatetemperature and needs no buffer layer,so the epi process can skip straight to hightemperaturedeposition of the GaN, improvingthroughput of the reactor. Deliveries ofthese substrates are expected in 2010.Then there’s the more radical alternativeof putting a GaN surface on the sapphire,then taking away the sapphire and using justthe freestanding GaN foil alone as the substratefor growing the <strong>LED</strong> layers. Goldeneye(Carlsbad, CA) grows a 30-micron layer ofGaN by HVPE, then removes it by laser liftoff.These thin GaN foils measuring a centimetersquare (see Fig. 5) can be very quicklyramped to growth temperature and cooledback down, allowing an epi growth cycle asfast as 30 minutes, claims Scott Zimmerman,Goldeneye VP of technology. The companyhas just taken delivery of its first reactorredesigned specifically for this kind ofrapid cycling.The European semiconductor researchconsortium IMEC, meanwhile, is workingon controlling thermal mismatch of GaNgrown on silicon, by monitoring the growthin situ and doing careful stress engineering.“GaN on Si is the option that offers thebest cost reduction possibilities in the endcompared to any other choice,” argues MarianneGermain, GaN program manager forIMEC. “Si is the only substrate that allowsfor large wafer diameters and lower substratecost.” IMEC claims to have reduceddefects to about the same level as on sapphire,by using several intermediate layersof AlGaN and silicon nitride (SiN) betweenthe Si and the GaN.________________<strong>LED</strong>smagazine.com NOVEMBER/DECEMBER 2009 21Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSlighting | CONNECTORSoperate at higher voltages, contacts arespaced further apart to meet agency separationrequirements.Housings and environmental concernsThe connector housing provides a numberof very important functions. Fundamentally,the housing provides environmental protectionand electrical insulation between adjacentcontacts and between the contact andthe outside world. This insulation is usuallyverified and stated as a voltage in theDielectric Withstand Voltage (DWV) ratingfor the connector.A properly-designed housing holds thecontacts in one half of a connector in correctrelationship with the contacts in themating half to provide trouble-free matingand unmating. It also fixes the spacingbetween contacts and defines the creep(electrical tracking distance over surfaces)and clearance (linear “line-of-sight” distance)between contacts.The environmental protection provided bythe housing can preventcontaminants(both solid and liquid)from getting into theconnector interface,and also preventsinadvertent physicalcontact with the electricalcontacts. TheMini-CTconnectionContactcarrierconnector’s level of sealing typically adheresto the well-recognized IP levels (see Fig. 3).When dealing with elevated voltages (usuallyabove 48 volts), most safety standardsrequire design features to prevent accidentalphysical contact with the electrical contact.In this case, contacts are recessed to someextent and often shrouded as a mechanicalbarrier to contact.Choosing a connectorElectrical, mechanical, and environmentalperformance requirements must be identifiedand considered to select the best connectorfor an application. Electrically, theHeat sink<strong>LED</strong>RetentionclipOptional lensand lenscarrierFIGURE 4. High-intensity <strong>LED</strong> holder combines thermal,mechanical, and electrical management into a single, easy-tousesystem.connector must be compatible with thecontinuous levels of current and voltage. Inaddition, transient and surge conditions thatmay occur over the life of the product needto be identified.Mechanical considerations include formfactorissues such as physical size, matingdirection, and how the connectors are heldtogether after mating. The connector mustalso be evaluated for the degree in which itcan withstand mechanical abuse, such asvibration, shock, and the like.Environmentally, the connector mustwithstand both application temperatureranges and processing temperatures (suchWe bring quality to light.<strong>LED</strong> Test and MeasurementMeasure all optical and electricalparameters of single <strong>LED</strong>s, highpower<strong>LED</strong>s and <strong>LED</strong> modulesin conformity to internationalstandards accurately and withinseconds. With equipment fromInstrument Systems – the worldleader in <strong>LED</strong> metrology.Ï Luminous intensity (candela)Ï Luminous flux (lumen)Ï Dominant wavelength (nm)Ï Color coordinates (x, y, z)Ï Spatial radiation patternÏ Thermal behaviorQuality that your customers can rely on!RoHS assemblyCustom functional testAutomated Optical Inspection0402BGA and X-Ray AnalysisMicrochip authorized designQuick turn prototypesGenie ElectronicsCompany, Inc.www.genieelectronics.com1087 Valley View Road, York, PA 17406717.840.6999 717.757.0194 (fax)light measurementPhone: +49 89 45 49 43 0 · info@instrumentsystems.com · www.instrumentsystems.com24 NOVEMBER/DECEMBER 2009 <strong>LED</strong>smagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSVisit www.FutureElectronics.com/Meanwellto see our world class <strong>LED</strong> driver offering______________www.FutureElectronics.com/Meanwell1-800-FUTURE-1Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSlighting | CONNECTORSas those experienced during reflow solderingof surface-mount connectors). The applicationenvironment will define additionalneeds, such as sealing, ability to withstandsolvents or salt spray, high altitudes, or otherextremes. In outdoor applications, UV exposurecapability is critical to reliable, longtermconnector performance.Thermal considerationsWhile signal applications typically do notrequire thermal management, power contactshave a maximum current rating, usuallybased on a 30°C temperature rise on thecontact. In high-intensity <strong>LED</strong> applications,the <strong>LED</strong>s themselves generate enough heatto require careful consideration to thermalmanagement. Integrating thermal managementinto a system often poses unique systempackaging challenges since most of thenew high-intensity <strong>LED</strong>s are small and areoften packaged as surface-mount devices(SMD). Integrating the connector system inamong the <strong>LED</strong>s, circuit boards, optics andthermal devices is often quite challengingif left to the end of the design process. Earlyevaluation of the interconnect options providesfor a more tightly integrated, optimizedsolution that can make assembly and,if needed, repair much more efficient.New interconnections must also addressthe special needs of solid-state lighting,including higher operating temperaturesand the ability to provide housings in specificcolors so the connector blends intothe visible parts of the lighting designer’sfixture. It is often very desirable to usecircuit board-mounted connectors withsoftened edges to minimize shadowingand the possibility of partially occludingthe light output of the low-profile surfacemount<strong>LED</strong>s.The next step in connectorsCurrent <strong>LED</strong> lighting design methodologyusually incorporates one or more <strong>LED</strong>sonto a circuit board, usually metal-cladfor thermal reasons, since it is well knownthat <strong>LED</strong>s perform better when operatingat lower temperatures. This assembly isthen integrated into the lighting fixture.However, throwing out conventional logicthat mandates a circuit board in the system,one could combine a heat sink into theelectromechanical design of the connectorto create a thermoelectric connector thatmates directly to the <strong>LED</strong>.An example is the high-intensity <strong>LED</strong>holder that Tyco Electronics designed for usewith a high-intensity <strong>LED</strong> (see Fig. 4). Theholder combines a small footprint and lowprofile with a snap-together contact systemfor both direct electrical and thermal connectionsdirectly to the <strong>LED</strong>. Without theneed for solder, thermal adhesives, or metalcladPCBs, application is simple, cost effective,and expands mounting options beyondthe planar constraints of circuit boards. Asan added benefit, replacement of a faulty____________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS_______________________________________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSlighting | CONNECTORS<strong>LED</strong> or changing colors is equally straightforwardsince all it entails is removing theretention clip, removing the <strong>LED</strong>, and replacingit with a new one. The basic holder kitincludes a contact carrier and an <strong>LED</strong> retentionclip used to secure the <strong>LED</strong> to the carrier.The module-to-cable interface is a standardtwo-position Tyco Electronics’ Mini CTpost and receptacle connection that furtherfacilitates plug-and-play operation.Standards and approvalsNaturally, any connector must meet agencyrequirements for any region of the world inwhich it is used. Regulatory agencies like ULand CSA in North America and IEC, TUV, andVDE in Europe have requirements to providefor safe application of a product. Selectingcomponents that have already gone throughthe approval process speeds design and simplifiesapproval of the final product. Giventhe global nature of the lighting market, thedesigner must confirm components meet allregional or local requirements. Being cognizantof the connector agency requirements,as well as those needed by the end application,is critical to the successful selectionand integration of the appropriate connectorsystem.CostThe acquisition cost of the connector isone thing, yet applied cost is quite another.Newer generations of application-specificconnectors for lighting can reduce the costof engineering, manufacturing, warrantyand maintenance. One key to realizing thesesavings is to understand connector basicsand to integrate connector selection intothe overall design process.New solid-state lighting systems withtheir inherent longevity demand equallyrobust connector systems. The <strong>LED</strong>s, thermalsolution, optics, and packaging comprisea considerable part of the overall costof the lighting system. The connector is usuallya small part of the overall cost and isoften specified without adequate considerationand balancing of cost versus performance.It makes little sense to scrimp onthe one component that your entire fixturerelies on for power. Without a reliable andappropriate connector system, the lightingfixture, however well designed and estheticallypleasing it is, becomes a dull, static(and unlit) non-functional object d’art.A checklist of requirements can be usefulwhen selecting a connector. The full text ofthis article includes a detailed checklist (seewww.tycoelectronics.com/products/lighting).Keep in mind that connector manufac-__turers typically have product specificationsas well as application specifications available,so be sure to ask the supplier for helpin your selection process. Spend some timeand consideration selecting the appropriateproven connector system for the application,even if it costs a little more. It will pay dividendsin the long run.____________________28 NOVEMBER/DECEMBER 2009 <strong>LED</strong>smagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSconferences | JAPAN & CHINAStrategically Speaking: Recent conferencesin Asia highlight <strong>LED</strong> industry progressTwo recent <strong>LED</strong> conferences—one in Japan and the other in China—illustrate how the <strong>LED</strong> industrycontinues to move forward, even in the midst of a worldwide recession that has caused substantialdownturns in other industries, writes BOB STEELE.<strong>LED</strong> Japan/Strategiesin Light, organized byStrategies Unlimited andPennWell, was held inYokohama on September16-17. The most pleasantsurprise at this eventwas the growth in attendanceover last year’sevent, held in October inTokyo. Total attendance(including the conferenceand associated exhibits)nearly doubled, from 2,700 in 2008 to 5,300in 2009. Likewise the number of exhibitorsincreased from 45 to 67 (more details atwww.ledsmagazine.com/news/6/10/3). Thisoccurred in a year in which the GDP of Japandeclined in the first half by 7.95% from 2008.Clearly something interesting is happeningto attract this kind of attendance in a verydepressed economic environment.Although Japan has long been a majorcenter of HB <strong>LED</strong> component manufacturing(accounting for 44% of world supply in 2008),it is a relative latecomer in the adoption of<strong>LED</strong> lighting, compared to, say, the US,Europe and China. However, that situationis beginning to change, as a number of major(and many smaller) companies in Japanenter the market with well-engineered andwell-designed lighting products.The <strong>LED</strong> lighting pioneer in Japan hasbeen Panasonic Electric Works (formerlyknown as Matsushita Electric Works), awell-established supplierof lighting products. Thecompany introduced itsfirst <strong>LED</strong> lighting productsseveral years ago, and in2009 is still the largestsupplier. More recentlyToshiba <strong>Lighting</strong> and Sharphave entered the marketwith a wide variety of <strong>LED</strong>luminaire products as wellas replacement lamps.Regarding the latter, itseems that these companies are beginningto target the consumer market (in additionto the professional lighting market, which isthe focus of most <strong>LED</strong> lighting suppliers atpresent). In Akihabara, the Tokyo electronicsretail district, a large number of shopsprominently display retrofit lamps fromSharp and Toshiba, claiming light outputequivalent to 40W and 60W incandescentlamps. Retail prices are in the neighborhoodof $40.Other Japanese companies active in the<strong>LED</strong> lighting market including Ushio, oneof the country’s largest lamp manufacturers,as well as Odelic, Daiko Electric, YamadaShomei, Yamagiwa, Iwasaki Electronics,and several others that are just beginningto enter the market in 2009.As a country with high electricity prices,as well as a strong focus on energy efficiencyand the need for reduction in greenhousegas emissions, it is not surprising thatBOB STEELE is Director of the Optoelectronics Program with Strategies Unlimited (MountainView, CA), part of PennWell’s <strong>LED</strong> & <strong>Lighting</strong> Media Group. Tel. +1 650-941-3438.Web: www.strategies-u.com. Strategically Speaking: Insights Into <strong>LED</strong>s & <strong>Lighting</strong> is a regular<strong>LED</strong>s Magazine column from Strategies Unlimited. See www.ledsmagazine.com/strategies.Japan has begun the move to solid-statelighting in earnest. Because the countryalready has wide adoption of highly efficientfluorescent lighting, it is understandablethat it has waited until the efficiency of<strong>LED</strong>s has reached the point where they arecompetitive with fluorescent sources tobegin the adoption of <strong>LED</strong> lighting.There are a number of regulatory movesunder way to promote the adoption of <strong>LED</strong>lighting, although the details are not yetclear (at least to an outsider). The focusis on facilities that use lighting on a24-hour-per-day basis, such as factories,convenience stores, gas stations, andthe like. As one example, a Lawson’sconvenience store in central Tokyo hasconverted all of its overhead fluorescentlighting to <strong>LED</strong>s.ChinaSSLThe 6th China International Forum on Solid-State <strong>Lighting</strong> (ChinaSSL 2009), held inShenzhen on October 14-16, showed similarattendance trends to <strong>LED</strong> Japan. Attendanceincreased from 621 in 2008 to 1,087 in 2009.Organized by the China Solid-State <strong>Lighting</strong>Alliance (CSA), and supported by the ChinaIlluminating Engineering Society, the ChinaAssociation of <strong>Lighting</strong> Industry, and theMinistry of Science and Technology, amongother organizations and government ministries,this is arguably the most important<strong>LED</strong>-related conference among the manyheld in China each year.China’s enthusiasm for solid-state lightingseems to only increase from year to year. Asteady stream of new companies is enteringthe market, at all levels of the supply chain,from epitaxy and chips to lighting fixtures,<strong>LED</strong>smagazine.com NOVEMBER/DECEMBER 2009 29Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSconferences | JAPAN & CHINAPanasonic has introducedthe Everleds range ofreplacement <strong>LED</strong> lamps.LumiBrightmostly funded by privateinvestment, but with somegovernment support as well.The most recent statistics,reported by Wu Ling, GeneralSecretary of the CSA, andothers at the conference, thereare now more than 1,000 <strong>LED</strong>packaging companies in China(although many of them are• UNPRECEDENTED INTENSITY• ULTRA HIGH BRIGHTNESSLumiBright LS line of <strong>LED</strong> Line Source Modules• For the Machine Vision market• Unprecedented intensity in range of wavelengths UV to NIR• Accessories include power/control and cooling fan modulesLumiBright LE series of OEM Light Engines• Incorporate ultra high brightness (UHB) <strong>LED</strong>s• Primary collection optics, thermistor and photo-sensor options forreal-time feed back or monitoring• One to three wavelengths UV to NIR and phosphors availableThree newly released LumiBright LE modules• Now available with glass optics for long life and high flux UVoperation• New high brightness white Endoscope Illuminator Module toreplace 300 Watt Xenon Lamps.www.innovationsinoptics.com • 781.933.4477very small, with more than 80% of them having investment of lessthan RMB 10 million (US$1.4 million). Perhaps more surprising isthe number of epitaxy and chip companies, estimated to numbermore than 60 by the end of 2009.Equally impressive is the figure of approximately 240MOCVD reactors expected to be installed (or at least on order)by the end of 2009. However, looking at the number of epi/chipcompanies relative to the number of reactors results in a figureof approximately four reactors per company. Compared withthe more massive reactor populations installed or planned bycompetitors in the US, Europe, or elsewhere in Asia,it seems likely that some consolidation among thevarious Chinese chip companies will be required toachieve economies of scale and to refine large-volumemanufacturing processes, as has happened over thepast few years in Taiwan.In addition to the chip and packaging companies, thereare also several thousand <strong>LED</strong> application companies inChina. The exact number is hard to determine, and infact it is growing on a weekly basis. According to CSAdata, the total <strong>LED</strong> applications revenue in China in2008 was RMB 45 billion (US$ 6.5 billion), up 50% over2007, with the largest applications being architecturallighting and display.In addition to this domestic market, Chinese system companiesare also active in production for the export market as well. Thisprovides and important market opportunity for foreign HB <strong>LED</strong>suppliers, as the Chinese exporters are becoming more sensitive toquality, especially for lighting products, and thus many of them areusing imported <strong>LED</strong>s from Cree, Lumileds, Osram and other foreignsuppliers to achieve performance and reliability levels that are notavailable from domestic <strong>LED</strong> manufacturers.<strong>LED</strong> streetlights continue to be a focus of the Chinese nationalsolid-state lighting effort. In the past, individual cities have taken thelead, installing many thousands of streetlights per city in a numberof cases (the best estimate of the cumulative total through the endof September 2009 is 200,000). Vendors were usually chosen from thelocal region, and product quality was often poor, with many earlyfailures reported.A new streetlight program, initiated at the national level, willinvolve 21 cities, each of which is expected to install at least 10,000<strong>LED</strong> streetlights. There will be a much greater emphasis on quality,and performance standards will have to be met as part of the biddingprocess. While in the past suppliers were all based in mainlandChina, in the new program bidding will be open to suppliers fromTaiwan as well.The total potential number of streetlights that could be installedunder this program could be up to 1 million. However, the timeframeover which this could happen is still uncertain. At this point theprogram is still in the discussion phase, and no installations have yettaken place. In the meantime, many cities continue to install <strong>LED</strong>streetlights on their own, and a dozen others are clamoring to jointhe program.30 NOVEMBER/DECEMBER 2009 <strong>LED</strong>smagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS____________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSlighting | OUTDOOROutdoor <strong>LED</strong> lighting benefits from PG&Eefforts, but health concerns are surfacingThe California utility PG&E has added <strong>LED</strong> lighting to its rate schedule, but people are starting todiscuss whether cool-white lighting is a great idea. BRIAN OWEN and TIM WHITAKER report.Asignificant obstacle to the adoptionof <strong>LED</strong> street lighting has been overcomethrough the efforts of PacificGas & Electric (PG&E), the California-basedutility. PG&E has removed a major roadblockfor roadway lighting in its new rate schedule,which recognizes and acknowledges thefinancial benefits of <strong>LED</strong> technology. TheElectric Schedule “LS-2 – Customer-OwnedStreet and Highway <strong>Lighting</strong>” (see www.pge._____________com/tariffs/ers.shtml) lists the rates chargedby PG&E for different lamp types, and is thesum of the facility charge and the energycharge. Monthly facility charges include thecosts of owning, operating and maintainingthe various lamp types and size. Crucially,because LS-2 now lists <strong>LED</strong>s at a separatelamp type, it reflects the energy savings of<strong>LED</strong> compared to other lighting technologies.LS-2 is applicable to lighting installationswhich illuminate streets, highways,and other outdoor ways and places wherethe customer is a governmental agency andowns the lighting fixtures, poles and interconnectingcircuits.Although LS-2 was effective May 1, 2009,there was no mention of it at September’sIES Street and Area <strong>Lighting</strong> Conference(SALC), where the announcement wouldhave surely captured the attention of all inattendance, since everyone in the industryhas recognized this as a major barrier.PG&E leadership has set an example forutilities across North America and createda path for municipalities to follow. It alsooffers a vehicle for dialogue and discussionin dealing with their local utility when considering<strong>LED</strong> street lighting, especially whenattempting to derive the associated financialbenefits that demonstrate that <strong>LED</strong> makes“financial sense” in order to develop a realisticpayback scenario.Mary Matteson Bryan, lighting portfoliomanager for PG&E’s Emerging Technologies(ET) group, explained to <strong>LED</strong>s Magazine howthe new schedule was developed: “As part ofPG&E’s Customer Energy Efficiency department,the ET group performed a numberof assessments of <strong>LED</strong> street lighting from2007 to 2009. Evaluations of energy savingsand lighting performance were positive.“In a collaborative effort between PG&E’sET group, its <strong>Lighting</strong> Energy Efficiency programstaff, and the PG&E Street and Area<strong>Lighting</strong> group, PG&E began efforts toincorporate <strong>LED</strong> street lighting as a productoffering to customers. In the summerof 2008, the team started strategizing onhow to develop a tariff for customer-owned<strong>LED</strong> street lights. Street lights are billed aflat monthly fee based on the lamp size andwattage and an assumed 11 hours per nightof operation.“The initial issue identified was that <strong>LED</strong>street lights do not come in standard wattagesor sizes. The team developed the idea touse ‘wattage categories’ for the <strong>LED</strong> streetlights(for instance 50–55W category). Thenext issue was how to validate the power(watts) of the street light in order to assign itBRIAN OWEN is a contributing editor of <strong>LED</strong>s Magazine and Program Advisor to greenTbiz,which facilitates the <strong>LED</strong> City Toronto initiative and is an Energy Star partner. He is activelyinvolved in the development and operation of energy conservation programs for government,municipalities and utilities. Email: brian@greenTbiz.org.An evaluation study of solar-powered,<strong>LED</strong>-based outdoor luminairesby the <strong>Lighting</strong> Research Centershowed positive results. More: ___ www.ledsmagazine.com/news/6/10/4.to the correct rate schedule category. The ETteam identified the recently adopted IESNALM-79 test procedure as a means of providinga consistent, verifiable method for measuringthe power of the entire <strong>LED</strong> streetlightfixture for use in assigning to a rateschedule category.“With these basic parameters, the <strong>LED</strong>Street and Area <strong>Lighting</strong> group developedthe detailed wattage categories and monthlybilling rates for amendment to the currentrate schedule. The rates were subsequentlyapproved by the California Public UtilitiesCommission (CPUC).”Dark-Sky says boo to blue lightThe rapidly expanding use of bluish-whiteoutdoor lighting threatens visibility at32 NOVEMBER/DECEMBER 2009 <strong>LED</strong>smagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSlighting | OUTDOORnight and jeopardizes the nocturnalenvironment worldwide, according toa statement (www.ledsmagazine.com/news/6/10/8) ________ released by the InternationalDark-Sky Association (IDA).The statement says that developers oflight sources should be required to refinetheir products to limit blue-light emissionat wavelengths shorter than 500 nm. TheIDA also discourages the use of bluish-whitelamp sources with a correlated color temperatureabove 3000 K. The IDA is a US-basednot-for-profit organization aiming to preserveand protect the night-time environmentthrough environmentally responsibleoutdoor lighting.The advisory notes that the “laudable”demand for energy-efficient lighting hasresulted in a new generation of electriclight sources such as <strong>LED</strong>s and inductionlamps that emit a cold, bluish-white light.Although <strong>LED</strong> lighting is mentioned specifically,<strong>LED</strong>s Magazine was told by PeterStrasser, IDA managing director, that IDA isnot taking an adverse position toward anyspecific technology.IDA states that the bluish-white light canhave significant environmental impact,causing light pollution and sky glow, as wellas glare and the compromising of humanvision in the aging eye. “In addition, bluelight has a greater tendency to affect livingorganisms through disruption of theirbiological processes that rely upon naturalcycles of daylight and darkness, such as thecircadian rhythm,” says the statement.IDA published a graph showing the photopicsensitivity curve of the human eye,which peaks at 555 nm. Light in the blueportion of the color spectrum below 500 nm,such as that produced by a phosphor-converted“blue-rich” <strong>LED</strong>, has a limited usefulnessto the human eye. This blue light alsofalls within the circadian-rhythm sensitivitycurve, which peaks at around 470 nm. (Itis important to note that the human eye usesscotopic vision under low-light conditions,and mesopic vision in intermediate conditions.The peak sensitivity for scotopic visionoccurs at around 520 nm.)The IDA claims that some manufacturersand government agencies are “misrepresentingthe visual effectiveness of these bluishwhitelight sources, and the environmentalimpacts are not being considered.” Becauseof this, the IDA is encouraging governmentand other concerned parties to support additionalscientific research on this subject,stating “Research will help to understandfully the impact of bluish-white light, andguide the evolution of lighting technologyto protect human health and the nocturnalenvironment while providing safe and efficientoutdoor lighting.” An IDA white paperon this subject is expected soon.LRC’s Unified System of PhotometryResearchers at the <strong>Lighting</strong> Research Center(LRC), Troy, NY, have demonstrated in multiplefield tests that, by using what they describeas a Unified System of Photometry, a streetlighting system can be designed to reduce<strong>LED</strong> <strong>Lighting</strong>GL - MR /BR / SP Series /T8 Tube / Lihgt Bar /<strong>LED</strong> Driver(PFC)_____________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGSDistribution Date:March 2010Ad Close: 2/1/10Mat’l Due: 2/8/10<strong>LED</strong> SuppliersDirectory 2009Suppliers Directory 2010Integrated Advertising 24/7, 365 Days a Year!Keep Your Message in Front of <strong>LED</strong>s Magazine’sDecision Makers for a Full 12 Months:•Recognized as an invaluable reference manual•Delivered to 31,506* global buying professionalsas the March 2010 issue of <strong>LED</strong>s Magazine•Company Directory includes an A-Z listing of more than900 key suppliers in the <strong>LED</strong> industry•Extensive coverage of 10 major product sections, including<strong>LED</strong> Packages & Chips, Networks & Distributors, <strong>LED</strong> Displays& Signs, Test & Measurement, <strong>LED</strong> <strong>Lighting</strong> and more•Detailed company contact and product data for hundredsof organizations•Bonus distribution at major <strong>LED</strong>s and lighting events andconferences throughout 2010The <strong>LED</strong>s Magazine Suppliers Directory 2010 is a comprehensiveproduct guide and vendor directory reaching buyers of <strong>LED</strong>components and lighting and display products. Advertiserswho take advantage of our Suppliers Directory integrated printand online advertising will reach key decision-makerswith their product messaging.Book YourAd Early &(Nov. 30, 2009)Lock in‘09 Rates!DISPLAY ADVERTISINGRATES AND SPECIFICATIONRATES: USD USD2009 2010Enhanced Entry $ 685 935Priority Entry $ 1315 1565Two page profi le or ad $ 7300 8030DISPLAY ADVERTISINGAs an advertiser, you’ll receive:•FREE company directory listing - both print and online•FREE unlimited product guide listings.•FREE listing cross references to your ad page.•FREE bold entries for each of your listings.DIRECTORY ENHANCEMENT OPTIONSContact your sales representative to learn more about thefollowing listing enhancements and advertising upgrades!Enhanced Listing• Logo and 75 words of text in Company Directory section• Logo alongside company name in all Product Guide sectionsPriority Listing• All enhanced listing benefits above• Entry in Company Directory section is highlighted in a shaded box• In Product Guide listing, logo is highlighted in a shaded box• In Selection Charts, the Priority Entries are highlighted• Priority Entries listed on page 1 of the Directory and highlighted in theonline Buyer’s GuideEnchancement Ad Close Date: February 1, 2010Material Due Date: February 8, 2010USD USD2009 2010Full page profi le or ad $ 4180 45981/2 page ad $ 2510 27611/3 page ad $ 2050 22551/4 page ad $ 1670 1837*Publisher’s Own DataQUESTIONS: Please contact one our sales representatives for assistance.USAMary DonnellyTel: +1 603 891 9398maryd@pennwell.comEUROPEJoanna HookTel: +44(0)117 946 7262joannah@pennwell.comJAPANManami KonishiTel: +81 03 3219 3641konishi-manami@ics-inc.co.jpCHINA/HONG KONGMark MakTel: +852 2838 6298markm@actintl.com.hkTAIWANAlice ChenSales Manageralice@arco.com.twTAIWANVicky KungSales Managervicky@arco.com.twwww.ledsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | Subscribe | Next PageABE FMaGS