Modules - Beriled

Modules - Beriled

Modules - Beriled

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

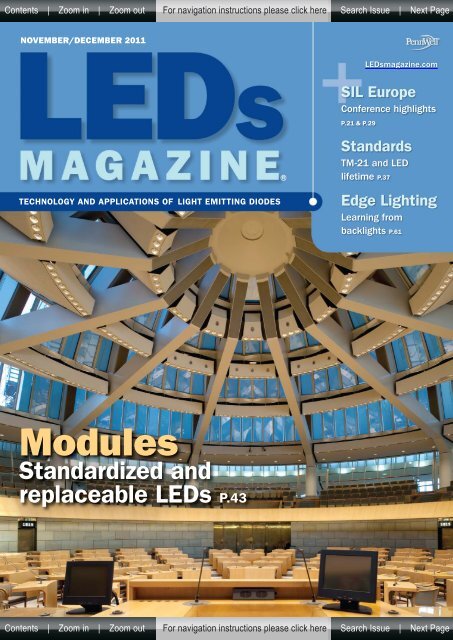

Contents | Zoom in | Zoom out For navigation instructions please click here Search Issue | Next PageNOVEMBER/DECEMBER 2011SIL EuropeConference highlightsP.21 & P.29LEDsmagazine.comTECHNOLOGY AND APPLICATIONS OF LIGHT EMITTING DIODESStandardsTM-21 and LEDlifetime P.37Edge LightingLearning frombacklights P.61<strong>Modules</strong>Standardized andreplaceable LEDs P.43Contents | Zoom in | Zoom out For navigation instructions please click here Search Issue | Next Page

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®___________________________________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®SpotlightsHong Kong Office:Rm. 223-231, 2/F., East Wing, TST Centre,66 Mody Road, TST East, Kowloon, Hong KongTel: (0755) 3309 3752 / (852) 2723 2302Fax: (852) 2722 1040E-mail: lighting@matrix.hk.comWorldwide Offices: N28650www.viribright.comwww.viribright.com.cn_________________________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®commentaryEuropean focus in aglobal LED industryIn early October, LEDs Magazine held itssecond Strategies in Light Europe conference,which featured a wide range ofpresentations on subjects relating to markettransformation and technology in theLEDs and lighting space (pages 21 and 29).The LED lighting market in Europe is predictedto grow at a CAGR of 41% from 2010 to2015, according to the market-research firmStrategies Unlimited. A key driver will be thegrowth in sales of LED retrofit lamps, drivenby the European directive that has alreadyphased out various types of incandescentlamps at 60W and above. As our article discusses,there are a number of other policyledactions that are promoting the adoptionof solid-state lighting throughout Europe.For example, 2 or 3 major demonstrationprojects are set to be announced shortly,and public procurement will be encouragedto lead by example by making use of energyefficientproducts and services.The European Commission has alsointroduced an EU Quality Charter,which is a voluntary set of criteria thatis intended to promote high-quality LEDlamp products and raise customer awareness.The criteria have been used by EUmember countries to develop their ownquality labels for LED lamps…but ultimatelythis might result in 27 differentlabels! Industry groups, notably the ELC,are calling for a standardized Europe-wideapproach to lamp labelling.Standardization provided a major discussionpoint at Strategies in Light Europe,with particular emphasis on the efforts bythe Zhaga Consortium to provide standardinterfaces for LED light engines (page 43).Three light-engine specifications have beenapproved to date, and Zhaga members arebusy designing products according to thesespecs, although non-members don’t haveaccess to the details. This is perhaps understandable,as Zhaga members want to protecttheir interests and gain a first-moveradvantage. However, this demonstrates asurprising feature of standardization efforts– in most cases, the organizations responsibledo a lousy job of telling industry andother interested parties when new standardsare finalized. TM-21, covering the projectionof long-term lumen maintenance of LEDlight sources (page 37), is a good example.This is hugely important for the LED lightingindustry, but there was little or no fanfarewhen it was finally published after yearsin development. And the IES charges $40 todownload a copy.Strategies in Light Europe also heard fromtwo organizations that are working on aglobal basis; the Global Lighting Forum, andthe IEA Annex on SSL (page 24). Both areexamples of how global cooperation is workingtowards harmonization of standards,and test and measurement protocols, whilealso building a strong consensus withrespect to the benefits of LED lighting.Another organization, the China-basedInternational SSL Alliance, has similar aims.And speaking of China, the recent announcementof a firm schedule for incandescentlamp phase-out (page 17) had a positiveeffect on the share prices of a number of USbasedcompanies with an interest in the LEDmarket, demonstrating again the globaldimension of the LED lighting industry.Tim Whitaker, EDITORtwhitaker@pennwell.comSENIOR VICE PRESIDENT Christine Shaw& PUBLISHING DIRECTOR cshaw@pennwell.comEDITOR Tim Whitakertwhitaker@pennwell.comASSOCIATE EDITOR Nicole Pelletiernicolep@pennwell.comSENIOR TECHNICAL Maury WrightEDITOR maurywright@gmail.comSENIOR TECHNICAL Laura PetersEDITOR laurap@pennwell.comMARKETING MANAGER Luba HrynykPRESENTATION MANAGER Kelli MylchreestPRODUCTION DIRECTOR Mari RodriguezSENIOR ILLUSTRATOR Christopher HippAUDIENCE DEVELOPMENT Jayne Sears-RenferEDITORIAL OFFICES PennWell Corporation,LEDs Magazine98 Spit Brook Road, LL-1Nashua, NH 03062-5737Tel: +1 603 891-0123Fax: +1 603 891-0574www.ledsmagazine.comSALES OFFICESSALES MANAGER Mary Donnelly(US EAST COAST) maryd@pennwell.comTel. +1 603 891 9398SALES MANAGER Allison O’Connor(US WEST COAST) allison@jagmediasales.comTel. +1 480 991 9109SALES MANAGER Joanna Hook(EUROPE) joannah@pennwell.comTel. +44(0)117 946 7262SALES MANAGER Masaki Mori(JAPAN) mori-masaki@ics-inc.co.jpTel: +81 3 3219 3641SALES MANAGER Mark Mak(CHINA & HONG KONG) markm@actintl.com.hkTel: +852 2838 6298SALES MANAGER Diana Wei(TAIWAN) diana@arco.com.twTel: 886-2-2396-5128 ext:270SALES MANAGER Young Baek(KOREA) ymedia@chol.comTel: +82 2 2273 4818CORPORATE OFFICERSCHAIRMAN Frank T. LauingerPRESIDENT AND CEO Robert F. BiolchiniCHIEF FINANCIAL OFFICER Mark C. WilmothTECHNOLOGY GROUPSENIOR VICE PRESIDENT Christine A. Shaw& PUBLISHING DIRECTORSENIOR VP OF AUDIENCE Gloria S. AdamsDEVELOPMENTSUBSCRIPTIONS: For subscription inquiries:Tel: +1 847 559-7330;Fax: +1 847 291-4816;e-mail: led@omeda.com;ledsmagazine.com/subscribeWe make portions of our subscriber list available to carefully screenedcompanies that offer products and services that may be important foryour work. If you do not want to receive those offers and/or informationvia direct mail, please let us know by contacting us at List ServicesLEDs, 98 Spit Brook Road LL-1, Nashua, NH 03062.Copyright © 2011 PennWell Corp (ISSN 2156-633X). All rightsreserved. Contents of this publication may not be reproduced in anyform without prior written consent of Publishers.4 NOVEMBER/DECEMBER 2011 LEDsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®GELightingFrom a Tiny Twist Grows a Full Revolution.The GE Infusion LED Module is more than flexible, it’s built for the future. As LED technology advances, you can twist in newergenerations of the Infusion module without replacing fixtures. And with a full line of lumen packages up to 3500, multiple colortemperatures, and CRI and dimming options, the energy efficient LED module paves the way for a revolution in lighting design.Explore the GE Infusion LED Module, luminaire options and a variety of applications online at www.gelighting.com/infusion© 2011 GEPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®Webcasts:LED Lighting Made Easy – A Modular SystemApproach to Designing FixturesDATE: October 2011PRESENTERS: Costa Politakis, FutureLighting SolutionsDan Sullivan, Philips LightingLight and Color - Methods of AchievingHigh CRI with LEDsDATE: October 2011PRESENTER: Marc Dyble, Osram Opto SemiconductorsEfficient Driving and Safe Monitoringof Multiple LED ArraysDATE: October 2011Creating Highly Efficient, Highly ReliableLighting Designs with Multiple LED StringsDATE: November 2011PRESENTER: Alexander Craig,Fairchild SemiconductorAn LED Luminaire Solution ForIndoor Area LightingDATE: November 2011PRESENTER: Valentin Kulilov, ON SemiconductorDiagnosing and Solving Thermal Challengesin Next-Generation LEDsDATE: November 2011PRESENTER: Boris Marovic, Mentor GraphicsVisit www.ledsmagazine.com/webcaststo access upcoming and archived presentations.FEATURED article| onlineChinese LED manufacturing – more than just LEDsSignificant investments and subsidies have enhanced Chinese companies’capabilities to produce not only LED chips and packaged devices, but also materialsand equipment used in LED manufacturing, as TOM HAUSKEN explains.www.ledsmagazine.com/features/8/11/1ADVERTISERS indexBeautiful Light Tech ............................27Cree, Inc. ................................... 23, C4CSA International ...............................25EBV Elektronik .............................. 40-41Evergreen International Corp. ............. 50Fin-Core Corp. ....................................31Fusion Optix ...................................... 48Future Electronics, Inc. ...................... 64GE Lighting Solutions ............................5Global Lighting Technologies .............. 63Helio Optoelectronics Corp. ................52Instrument Systems GmbH .................70Inventronics (Hangzhou) Co., Ltd. ....... 60Lambda Research Corp. .................... 12Ledlink Optics Inc. ..............................19Linear Technology .............................. C3Lutron Electrics Co, Inc. ..................... C2Matrix Lighting Limited, Hong Kong .......1MeanWell USA ....................................16National Semiconductor..................... 45Nordson Asymtek .............................. 33Optotune AG .......................................67Optronic Laboratories .........................59Orb Optronix ...................................... 34Phihong USA ..................................... 20Philips Lighting BV ............. 9, 11, 13, 15Philips Lumileds ...................................2Farnell Danmark AS ............................42Proto Labs, Inc. ................................. 53Recom Distribution &Logistics Gmbh ..................................28Samsung LED America ...................... 35Seoul Semiconductor Co Ltd. ................7Shanxi Guangyu LedLighting Co Ltd. ..................................14Shenzhen RefondOptoelectronics Co., Ltd. ................... 46Sichuan Jiuzhou ElectricGroup Co Ltd. .................................... 49Signcomplex Ltd. ................................73Specialty Coating Systems..................47Stellarnet, Inc. ................................... 39Supertex Inc. ......................................77Thomas Research Products ............... 56Underwriters Laboratories ................. 36VS Optoelectronic GmbH & Co KG ...... 266 NOVEMBER/DECEMBER 2011 LEDsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®Fortimo LED <strong>Modules</strong>for today, for tomorrowNew!Fortimo LED SLM gen 2Future-proof, high quality andprogressive LED technology for retail.Designed to give you the best quality of white lightand easy design-in, now and in the future. Many leadingmanufacturers already use Fortimo as the trusted lightsource in their luminaires. See why at philips.com/fortimoPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®Fortimo LED <strong>Modules</strong>for today, for tomorrowFuture-proof, high quality andprogressive LED technology for hospitality.Designed to give you flexible warm white light, now andin the future. Many leading manufacturers already useFortimo as the trusted light source in their luminaires.See why at philips.com/fortimoPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®news+viewsHowever, Veeco’s third-quarter bookingswere $133 million, a decline of 57% sequentially.LED & Solar orders declined 59%sequentially to $112 million, with MOCVDorders at $103 million. “Veeco’s third-quarterorders were impacted by weak near-termLED industry demand, low MOCVD equipmentutilization rates in Asia, and decreasedbusiness activity in China,” commented JohnPeeler, Veeco’s CEO.Aixtron’s equipment order intake was alsodown sequentially by 77% to EUR 51.5 million($71 million) in Q3 of 2011, relative toEUR 222.2 million ($306.0 million) in Q2.Equipment order intake in the first 9 monthsof 2011 was down 11% year-over-year at EUR484.1 million ($666.8 million).Aixtron’s quarterly revenues decreasedby nearly half (49%) from EUR 175.6 million($241.9 million) in Q2 to EUR89.8 million($123.7 million) in Q3 2011. Revenues inthe first 9 months of 2011 decreased 16% toEUR 470.8 million ($648.4 million) from EUR558.1 million ($768.7 million) in the sameperiod last year. The cause was customerdelays in delivery dates and credit tighteningin Asia, said the company.Paul Hyland, president and CEO of Aixtron,described current market conditions as“difficult” but said: “There can be no doubt inanybody’s mind that the LED lighting investmentcycle will come and will be the biggestend-market opportunity this industry hasever seen. It is not a question of ‘if’ it is onlya question of ‘when’.” ◀MORE: www.ledsmagazine.com/news/8/11/3OUTDOORWelland switches to LEDsThe City Council in Welland, Ontario,Canada, has voted unanimously to completelyreplace the city’s street lights withLED fixtures. The Council approved anagreement with SSL Energy Solutions andAppalachian Lighting Systems Inc. (ALSI)to replace the existing street-lighting systemthroughout the city with ALSI’s ALLEDfixtures and ALLink control system.The capital cost of CAN$2.74 million willbe financed through a debenture, and paidback by utilizing the energy savings fromthe program. In year one, street-lightingenergy costs should be reduced by $221,553with a saving in maintenance costs of$159,250. Phase 1 of the project will includethe replacement of 4300 cobrahead HPSfixtures by April 2012. Phase 2 will consistof replacement of 2410 decorative fixtures,scheduled for completion in December2012.Welland estimates that the total cost ofoperating its current HPS-based lightingsystem would amount to almost $18 millionover 15 years, which is the “estimatedtrue cost of doing nothing.” By switching toLED lighting, the City will save $6.8 millionin operating costs. After paying the variouscharges including debt repayments, thecity will save $2.38 million in total over the15-year term of the agreement. ◀MORE: www.ledsmagazine.com/news/8/9/31Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®Fortimo LED <strong>Modules</strong>for today, for tomorrowFuture-proof, high quality andprogressive LED technology for outdoor.Designed to give you the best LED performancewith high quality of white light, now and in thefuture. Many leading manufacturers alreadyuse Fortimo as the trusted light source in theirluminaires. See why at philips.com/fortimoPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®news+viewsLED FABRICATIONOptogan opens LED chip fabOptogan GmbH has held an opening ceremonyfor its LED chip-production facilityin the German city of Landshut. The sitepreviously housed a Hitachi semiconductorfactory, with a clean-roomarea of 4000 m². Optoganhas invested tens of millionsof euros in the site,which will employ up to100 people. Initial capacitywill be over one billionLED chips per year.According to Optogan,the facility is Europe’s second-largestLED chip-productionsite. The largestis also in Germany, namely Osram OptoSemiconductors’ plant in Regensburg. TheOptogan Group, headquartered in Russia,opened a large LED packaging facility in St.Petersburg last year (www.ledsmagazine.com/news/7/11/29).“In Landshut, we have discovered theideal infrastructure for our future highvolumeproduction of LED chips,” saidHans Peter Ehweiner, managing director ofOptogan GmbH. “Our LED lamps and luminairesare on the way towards lighting upindoor, outdoor, and residential areas allover the world.” ◀MORE: www.ledsmagazine.com/news/8/10/14LED MATERIALSRubicon ships 200,000th6-inch waferRubicon Technology, Inc. (Nasdaq:RBCN) hasstated that it has shipped over 200,000 six-inchsapphire wafers to LED manufacturers worldwide.Rubicon had previously announced thatit had upgraded the crystal-growth furnacesin its three manufacturing facilities to allow8-inch sapphire wafer production. Rubiconhas production facilities in Bensenville, IL,Batavia, IL and Penang, Malaysia.Also, Rubicon says it has begun productionof aluminum oxide, the startingmaterial used to manufacture sapphire.On-site processing of aluminumoxide will allow better process controland the growth of higher-quality sapphirewith larger crystals. Some analystsexpect 8-in wafers to account for morethan 50% of the LED market by 2016.MORE: www.ledsmagazine.com/news/8/10/32_____________ _________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®Fortimo LED <strong>Modules</strong>for today, for tomorrowFuture-proof, high quality andprogressive LED technology for offices.Designed to give you the highest energy efficiency andcomfortable white light, now and in the future. Many leadingmanufacturers already use Fortimo as the trusted lightsource in their luminaires. See why at philips.com/fortimoPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®__________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®fundingprogramsEPA releases first draft ofEnergy Star Lamps specThe US Environmental Protection Agency(EPA) has published the first draft of theEnergy Star Lamps v1.0 specification atwww.energystar.gov/lamps. This is intendedto replace the existing Compact FluorescentLamps and Integral LED Lamps specifications.Comments or concerns about this firstdraft should be sent to lamps@energystar.govby December 9.The specification is described by the EPAas “technology-neutral” and includes a proposalto align lamp-life requirements acrosstechnologies by introducing a 10,000-hr minimumlifetime requirement (for LED lamps,this would be a 10,000-hr rated lumen maintenancelife).The specification is limited to lampsintended to be connected to the electricpower grid. It includes photometric performancerequirements, lumen maintenance andreliability requirements, luminous-intensitydistribution requirements, electrical performancerequirements, dimensional requirements,and lamp labeling and packagingrequirements for all lamp types included inthe specification.In December 2009, the EPA laid out a plan tointegrate the four existing Energy Star lightingspecifications into two, new, technologyneutralspecifications: Luminaires (light fixtures- www.ledsmagazine.com/news/8/5/23)and Lamps (light bulbs). EPA says that its goalwas “to better serve the consumer interest inidentifying energy-saving lighting products byensuring that performance requirements andtesting methods reward efficiency and quality,irrespective of technology.” In doing so, theEPA is also seeking to remove any overlap orcontradiction among specifications.For lamps, the EPA initiated a consultationprocess in March 2011, feedback from whichcan be viewed on the Lamps website (www. ____energystar.gov/lamps). This feedback focusedthe EPA’s attention on further improvementsto quality-related requirements rather thanincreases to the already-high efficiencyrequirements.The EPA has addressed consumer barriersto adoption by developing proposed improvementsto lamp start time, run-up time, colorconsistency, and reliability in high-heat andfrequent-switching applications. The EPA alsore-evaluated the lamp labeling and packagingrequirements in the existing specifications.The first draft also includes a proposal toalign lamp-life requirements across technologies,creating an “even playing field.” Specifically,the draft includes a proposal for a10,000-hr minimum lifetime requirement.The EPA says that product data shows thisrequirement to be readily attainable withCFLs. While the Integral LED Lamps specificationhas required a 15,000- to 25,000-hrminimum, “there are disadvantages to thisapproach which appear to be hindering adoptionof LED lamps,” said the EPA.Several lamps are excluded from the specificationincluding lamps that operate on anexternal ballast, driver or transformer; lampspowered by an internal power source, e.g.solar; lamps with other power-consuming featuresthat do not provide useful illumination;lamp technologies without industry-standardizedmethods of measurement; lampswith bases not detailed in ANSI standards;and Zhaga-defined LED modules. ◀China unveils plansfor incandescentlamp phase-outChina has unveiled its three-step planfor phasing out energy-inefficient incandescentlamps. The announcement onNov 4 caused a surge in the share price ofseveral LED companies, including Cree.According to the Xinhua News Agency,the phase-out will ban imports and salesof incandescent lamps in the followingcategories, as follows:• 100W and above: October 1, 2012• 60W and above: October 1, 2014• 15W and above: October 1, 2016Xie Ji, deputy director of the environmentalprotection department with China’sNational Development and ReformCommission (NDRC), said that the planshows China’s determination to pressahead in its efforts to save energy, reduceemissions and curb climate change.China is a major manufacturer andconsumer of lighting products and is theworld’s largest producer of both energysavinglamps (CFLs) and incandescentbulbs. In 2010, incandescent-lamp productiontotaled 3.85 billion units, anddomestic sales stood at 1.07 billion units,said Ji.Power consumption for lighting inChina accounted for 12% percent of thecountry’s total electricity use in 2010.The NRDC expects that the plan willenable China to save 48 billion kWh ofpower per year and reduce CO2 emissionsby 48 million tonnes annually.China’s phase-out ties in with legislationin other countries and regionsto stop using these products. Europe’sincandescent phase-out affected60W-and-higher lamps from September2011 (www.ledsmagazine.com/________news/8/9/1), while the US begins itsnationwide ban on 100W-and-aboveincandescent lamps from January 1,2012. ◀MORE: www.ledsmagazine.com/news/8/11/7 _______LEDsmagazine.com NOVEMBER/DECEMBER 2011 17Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®fundingprogramsLUMEN coalition launches websiteThe LUMEN (Lighting Understanding for a More Efficient Nation)coalition has launched a website (www.lumennow.org) dedicatedto informing US consumers regarding energy-efficient residentiallighting options. The coalition is led by the Alliance to SaveEnergy, the American Lighting Association (ALA) and the NationalElectrical Manufacturers Association (NEMA) and includes participantsfrom more than 40 nonprofit energy-efficiency advocacygroups, utilities, lighting manufacturers and trade associations.The coalition has estimated an annual energy saving per householdof up to $100 by replacing less-efficient bulbs with halogen,CFL or LED options. “Understanding which option is best for aspecific application is where LUMEN members can help the homeowner,”said Larry Lauck of the ALA.The website includes a guide to selecting replacement bulbs,frequently-asked questions, and news regarding energy-efficientlighting options. The website also explains the new FTC LightingFacts label, which will be required on all medium screw-basebulbs sold in the US as of January 1, 2012. ◀MORE: www.ledsmagazine.com/news/8/10/23The city of Stamford, CT, has installed over 1000 cobraheadLED fi xtures from GE, leading to an annual saving in energycosts of $146,000. Initially, LED street lights did not farewell in comparison with other products, but the newer GEproducts offered improvements in terms of a color temperatureof 4300K, better uniformity and reduced glare (www. ___ledsmagazine.com/news/8/10/33).DOE consortium publishes LEDstreet-lighting guidelinesThe DOE Municipal Solid-State Street Lighting Consortium hasposted specification templates for use by utilities and municipalitiesthat are evaluating or implementing LED street-lighting projects.The first draft of the Model Specification was posted in Apriland the revised specification takes into account feedback fromconsortium members and the wider community.The Model Specification contains two guidelines and is availableat www.ssl.energy.gov/specification.html. _________________________ The System Specificationoption for municipalities (Appendix A), is designed tomaximize application efficiency and incorporates site characteristicssuch as pole spacing and mounting height. Meanwhile, theMaterial Specification option for utilities (Appendix B), emphasizesluminaire efficiency and does not consider site characteristics.The flexible format of the guideline allows users to modifydefault values to fit their local design criteria, which typicallyvary from city to city, and even from application to applicationwithin a given city. ◀MORE: www.ledsmagazine.com/news/8/10/29_________________________Competition begins for NextGeneration LuminairesThe US DOE has announced that its Next Generation Luminaires(NGL) SSL competition has been separated into two competitions,for indoor and outdoor products, due to growth in participation.Each competition will have its own judging panel, and the datesare now staggered. The intent-to-submit deadline for indoor NGLsis December 16, while final online submissions are due by January13, 2012. Physical product samples are due by January 18, andwinners will be announced in May. The DOE will send out its callfor entries for the outdoor NGL competition in March 2012, withawards being presented in August 2012.The competition is jointly sponsored by the DOE, the IlluminationEngineering Society of North America (IESNA), and the InternationalAssociation of Lighting Designers (IALD). In the NGL SSLcompetition, the judges examine lighted samples in their intendedapplications, as well as photometric data and other documentation.Evaluation criteria include the quality and quantity of illumination,energy efficiency, and serviceability. ◀MORE: www.ledsmagazine.com/news/8/2/27DOE releases promising resultsfrom Round 13 Caliper testingThe US Department of Energy (DOE) has completed Round 13of product testing through its SSL Caliper program. Round 13included three types of products: LED and benchmark high-bayluminaires, LED wallpack luminaires, and LED and benchmark2x2-foot troffers. The summary report provides an overview ofphotometric performance results, compares the results withrespect to similar products that use conventional light sources,and can be downloaded at www.ssl.energy.gov/reports.html.On average, the round 13 LED luminaires showed a significantimprovement in efficacy over LED luminaires tested in 2009 and 2010,with a minimum efficacy close to the average observed in 2009-2010.In addition, the variation in performance across the Round 13 LEDluminaires was less than in 2009-2010 products; that is, there weresmaller differences between minimum and maximum efficacy. A similartrend was observed with other performance parameters includinginitial lumen output, CCT and CRI.MORE: www.ledsmagazine.com/news/8/10/1618 NOVEMBER/DECEMBER 2011 LEDsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®_______________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®Think Phihongenergy efficient LED drivers...or it’s lights out.Shouldn’t your LED driver last as long as your LEDs?Why spec LEDs with 40 – 50,000 hour life if your LED driver doesn’t make it past 5K?Built on a tradition of high quality, high efficiency power products, Phihong’s high quality LEDdrivers support multiple strings with independent current control, a wide range of applications(3-200W) and feature dimming, IP67 rating for outdoor environments and UL and FCC certification.Phihong ships millions of OEM products every month with millions of hours DMTBF.Make sure your next LED product design keeps operating. Phihong LED drivers won’tleave you standing in the dark.New LED driversfrom PhihongFor complete technical information visitwww.phihong.com/LED or call 1.888.PHIHONG (744.4664)Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®conferences | STRATEGIES IN LIGHT EUROPEStrategies in Light Europe focuses onLED lighting and market transformationEurope-wide policies related to solid-state lighting, as well as standardization, lighting quality,product labels and global initiatives, were among the many subjects tackled at Strategies in LightEurope 2011. TIM WHITAKER reports.With more than 900 registeredparticipants, the second annualStrategies in Light Europe 2011conference and exhibition took place inMilan, Italy, on October 4-6, 2011. Onenew feature of this year’s event was theintroduction of parallel tracks on MarketTransformation and Technology: the latteris covered in a separate article on page 29.The LED lighting market in Europe isexpected to grow at a compound annualgrowth rate of 41% between 2010 and 2015,according to the Keynote presentation byVrinda Bhandarkar, Strategies Unlimited’sDirector of LED Lighting Research (Fig. 1).The replacement-lamps sector will growmost rapidly, as the impact is felt of Europewidelegislation to remove inefficient lampsfrom the market.Bhandarkar said that the global LEDlighting market had revenues of $5 billionin 2010, of which 21% was from replacementlamps and the remainder from luminaires.In general, performance is improving andprices are falling, but there are “huge issueswith low-quality, under-performing LEDproducts,” said Bhandarkar. She also saidthat standards setting is moving rapidly, butneeds consistency between regions. Productquality, labeling, and standardizationwere all themes taken up by other speakersat the conference. Module standards, forexample, were discussed by Andy Davies ofGE Lighting (see www.ledsmagazine.com/________news/8/10/10 and page 43 of this issue).Also in the Keynote session, DominikWee and Arthur Jaunich from McKinsey &Company covered the main points of theirrecent report entitled “Lighting the way:Perspectives on LEDs and the global lightingmarket” (www.ledsmagazine.com/features/8/9/13)._________A different perspective was provided bySimon Fisher, general manager EMEA forIndoor Luminaire Solutions with GE Lighting.Fisher, formerly an independent lightingdesigner, gave a talk entitled “Designingwith LEDs: Redefiningthe Lit Environment”but he was ($ Billion)Revenuekeen to stress that 7LEDs are not the6only game in town.“This is the Strategiesin Light con-5ference,” he said. 4“It’s important to3develop LED solutionsbut not ignore 2other technologies…1this is GE’s strategygoing forward.” 0Fisher advocateda holistic approachto product design,encompassing notonly the components and application design,but also system integration and quality andreliability. “We need to have a solution-orientatedapproach to customer needs,” he said.Focusing on modules, Fisher said that connectivityis the “design key.” While electricalcompatibility reduces losses, good thermalcontact sustains the LED lifetime and astrong mechanical connection maintains systemintegrity.From a client perspective, good opticalquality is key, said Fisher. Clients requirea choice of beam angles, high light-outputratio (LOR), and repeatable performance.He then discussed GE optics that are compatiblewith the company’s module products,and also revealed that GE will introducemodule-based luminaires for indooruse in Q3 2012.Fisher said that the lighting industryhas changed recently: “Five or six yearsago the discussion was mainly on capitalLED lighting market in EuropeCAGR 41%2010 2011 2012 2013 2014 2015ReplacementlampsLuminairesSource:Strategies UnlimitedFIG. 1. Market forecast for LED lighting product sales in Europe.cost, now return-on-investment is part ofthe discussion,” he said. “This is important,because we’re going to be asking people tospend more on their lighting than they doat present.”European SSL policies and actionsEU policies for the promotion of SSL werediscussed in detail by Paolo Bertoldi of theEuropean Commission (EC) Joint ResearchCentre (http://re.jrc.ec.europa.eu/energyefficiency).____ Energy efficiency, including lighting,is a key component for reaching Europe’s variousclimate and energy objectives by 2020.“Lighting is covered by many policies andactions, including the new strategy for SSLLEDsmagazine.com NOVEMBER/DECEMBER 2011 21Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®conferences | STRATEGIES IN LIGHT EUROPEunder the Digital Agenda for Europe,” saidBertoldi. Among the activities are energylabeling, public procurement, the Eco-Designdirective, and R&D programs in the currentFP7 and future FP8 programs. The generalaim is to support the most efficient technologies,and to introduce financial schemes thatcan overcome the barrier of high initial cost,a particular problem for SSL.For many years, Europe has used theenergy label, which grades appliances(including lamps) from A to G according toenergy usage. This is now under review andis due to be revised by May 2012. Also, by settingminimum energy-efficiency requirements,the Eco-Design Directive has alreadyhad a major impact on the lamp market inEurope: 60W incandescent lamps were effectivelyoutlawed from September 2011 (www. ____ledsmagazine.com/news/8/9/1). As Bertoldiexplained, the second phase of the Directive,covering directional lamps, is due tobe adopted by July 2012.Lighting is also part of the Energy Performancefor Building Directive, which is aimingto move towards “almost zero-energybuildings.” However, feeling the need for anew impetus, the EC has put forward a proposalfor a new Energy-Efficiency Directive(EED). One aspect would be to call on thepublic sector to lead by example, by purchasingproducts, servicesand buildings thathave high energy-efficiencystandards. Also,national energy-efficiencyschemes couldencourage utilities todistribute LED lamps toconsumers, which Bertoldidescribed as a “greatopportunity” for LEDs.SSL is a central partof the Digital Agenda forEurope, which focuses onways that informationand communicationstechnology (ICT) canstimulate the EU economyand benefit society.Specific SSL-relatedactions include a GreenPaper, to be published later this year, and thelarge-scale SSL demonstration projects thatshould start at the beginning of 2012 (www.___________FIG. 2. Module-based luminaires on the GE Lighting stand at SIL Europe.FIG. 3. Dekra’s certifi cation markfor LED products.___ledsmagazine.com/news/8/2/5).In R&D, the EC is currently funding variousprograms in LEDs and OLEDs to thetune of around EUR 90 million, said Bertoldi.He also gave a number of project examplesfrom the GreenLight program (www. ____eu-greenlight.org), an EC-lead voluntary initiativeto reduce lightingenergy use in commercialand industrial sectorsand in street lighting.Standards andCELMA guidelinesStandardization was acentral discussion topicat SIL Europe, and wascovered in detail by KayRauwerdink of CELMA,an organization that representsthe Europeanlighting industry for luminairesand components.CELMA has written aguidance paper on qualitycriteria for LED luminaireperformance thatfocuses on two PublicAvailable Specifications (PAS) documents thatwere recently published by IEC, the internationalstandards body. IEC/PAS 62717 coversperformance requirements for LED modules,while IEC/PAS 62722 covers LED luminaires,in both cases for general lighting.Rauwerdink said the industry needs totransition from “comparing apples andpears” when it comes to commercial products,and instead make apples-to-applescomparisons. “Evaluating performanceclaims from different manufacturers cannotbe done without using a standardizedset of quality criteria that are measured incompliance with appropriate standards,” hesaid. The CELMA guide suggests that usersof LED luminaires should request LED luminairespecifications that are measured incompliance with the new IEC documents.The documents were released simultaneouslyto ensure consistency between module-and luminaire-quality criteria. Thesecriteria include a large selection of metrics,including input power, luminous flux andefficacy; luminous intensity distribution;CRI and chromaticity coordinate values,both initial and maintained; rated life (inhours) and associated rated lumen maintenance(in lux); and failure fraction (Fy), correspondingto the rated life of the LED modulein the luminaire.The CELMA guide explains the best methodsfor measuring these criteria, and why22 NOVEMBER/DECEMBER 2011 LEDsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®®LIGHTING-CLASS LEDsXLAMP ML-B & ML-E LEDsOPTIMIZED FORSMOOTH-LOOK LIGHTINGLonger lifetime than backlighting LEDs(and the LM-80 data to prove it)Best color consistency with industry’ssmallest color binsXLAMP XP-E HEW LEDsOPTIMIZED FORNON-DIRECTIONAL LIGHTINGLowers the cost of high-efficiencyLED systemsLight optimized for your application—many CCT & CRI options availableXLAMP CXA2011 LEDsOPTIMIZED FORNON-DIRECTIONAL LIGHTINGSimple assembly—no solderingor connectors requiredWide lumen output range—upto 3500 lumensat 45W, 85°CCREE XLAMP LEDs ARE APPLICATIONOPTIMIZED FOR LOWEST SYSTEM COSTREVOLUTIONARY!Cree XLamp ® Lighting-Class LEDs arepurposefully designed to deliver theindustry’s best performance and optimizedspecifically for distinct applications.Our revolutionary product portfolio enablesyou to design brighter, more efficientluminaires with fewer LEDs or simply useless LEDs and save space. So whetheryou’re designing the next generation ofindoor downlights or lights that emulatethe look of fluorescent tubes, you canlower your system cost.Get samples of Cree XLamp LEDs orcontact a Cree Solutions Provider atcree.com or call us at 800.533.2583Get Cree reference designsfor non-directional applicationsat cree.com/refPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®conferences | STRATEGIES IN LIGHT EUROPEthey are important. The document furtherexplains the difference between lifetimeclaims based on lumen maintenance andluminaire lifetime claims that depend oncomponent reliability.LED Quality CharterWith the advent of the Eco-Design Directiveto remove inefficient lamps from theEuropean market, it was also deemed necessaryto establish an EU LED QualityCharter (EU-QC), which was discussed atSIL Europe by Casper Kofod of Energy Piano.The EU-QC is a voluntary set of criteria thatis intended to promote high-quality LEDbasedlamps, to raise consumer awarenessand confidence, and to support promotionand procurement campaigns. Organizationscan sign up to support the EU-QC, which isrestricted only to LED lamps (not modules orluminaires), and to the residential, not commercial,sector.Importantly, the EU-QC is not a qualitylabel, although individual EU member countriescan use the EU-QC to develop their ownenergy-efficiency labels, such as those introducedin the UK or in Kofod’s home countryof Denmark. The recommended criteria canby viewed by downloading the EU-QC documentfrom the Residential Lighting sectionof the JRC website (http://re.jrc.ec.europa._____________eu/energyefficiency/).Surprisingly, considering levels set byother similar programs, the EU-QC requirementfor power factor (PF) is a minimum of0.5. Kofod said that “the consumer has noadvantages of high PF requirement, but disadvantagesif an extra corrector-circuit isinstalled.” The disadvantages come in termsof additional size, consumption, cost andother factors. He also said that lighting iscurrently 15-17% of domestic consumption,but in the future, when LEDs predominate, itwill be only 2-4%. In this case, a high PF willonly provide a marginal advantage: “We’retalking about peanuts,” said Kofod.The Danish Energy Savings Trust (EST)has developed a quality label for lampsthat meet EU regulations and the requirementsof the EU-QC, explained Kofod. Thelamps are self-certified, but the EST mayperform random testing. Demark is at theforefront of green policy development, andrecently announced that renewable energysources would be required to cover all electricityand heat consumption by 2035, andall energy consumption by 2050. “There is agreat future for LEDs to help slash energyconsumption in Denmark,” said Kofod.However, not everyone agrees that EUmember states should use the EU-QC todevelop their own labels: one obvious potentialconsequence could be 27 different labelingschemes, one for each country. AfterKofod’s talk, Jürgen Sturm of the EuropeanLamp Companies Federation (ELC) saidthat the European lighting industry “favorsa Europe-wide approach, not fragmentationof labels on a country-wide basis.”Dekra performance markIn his presentation, Jacob Neusink ofDekra, a quality and safety service-provider,asked: “Is there a need for an LEDquality mark?” Not surprisingly, Neusink’sanswer was yes, giventhat Dekra has alreadyissued its own LED performancemark (Fig. 3) totwo Netherlands-basedmanufacturers, LemnisLighting and Ledned.In explaining why themark was introduced,Neusink quoted commentsfrom Dekra’s customers.He said thatinstallers ask: “How canI be sure that the claimsmy supplier makes aretrue and how do I knowthat the products I buywill perform?” Meanwhile,manufacturerssay: “I have a high-qualityproduct with good performance,and my customerdoes not believewhat I am saying.” Toaddress such comments,the Dekra mark sets performancelevels for LEDlamps, or modules, orluminaires.Neusink pointed outthat this is a “qualitymark,” where testingconfirms that the performancereaches or exceeds the requiredlevels set by Dekra, rather than a “truthmark,” which simply confirms that the figuresquoted by the manufacturer are accurate.It’s important to note that Dekra offersits mark on a commercial basis, as distinctfrom government-sponsored programssuch as the Danish EST label mentionedabove (www.dekra-certification.com/en/led-performance-mark).______________Global initiativesThe challenge of harmonizing SSL-relatedactivities on a global basis has been taken upby at least two new organizations. The mainaims of the International Energy Agency(IEA) Annex on SSL (http://ssl.iea-4e.org), asdescribed at SIL Europe by Marc Fontoynont(Fig. 4), are to develop SSL quality assurance,to harmonize SSL performance testing,and to promote standards and developFIG. 4. Marc Fontoynont of Aalborg University discussed theIEA Annex on SSL, which aims to increase confi dence in SSL,and to allow governments to prepare more ambitious policiesfor energy-effi cient lighting products, for example relating toregulation and labels.24 NOVEMBER/DECEMBER 2011 LEDsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ® ® Third-party certifi cation and verifi cation are nowENERGY STAR requirements. CSA International hasENERGY STAR TestingFacility and Certifi cation Body. That means today wecan meet all of your lighting product safety and energyeffi ciency testing needs with a single, seamlesslyeffi cient testing program that saves you timeand money.Look to CSA International to meet ENERGY STARrequirements for lighting products including:If you prefer to perform testing using your own testinglaboratory, we can qualify your lab facilities under ourTesting Laboratory program, then verify your test resultsContact us today and learn how much time andmoney a combined safety and energy efficiencytesting program with CSA International can save you.1-866-463-1785 cert.sales@csa-international.orgwww.csa-international.orgPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®conferences | STRATEGIES IN LIGHT EUROPE____________an accreditation infrastructure.Meanwhile, the lighting industry is representedby the Global Lighting Forum (GLF),a gathering of lighting organizations fromaround the world representing over 5,000lighting manufacturers and US$50 billionin annual sales. Jürgen Sturm, GLF generalsecretary, explained that the GLF aims toshare knowledge of global lighting trendsand legislative developments. It acts as anetworking forum, developing joint industrypositions and communicating these togovernment authorities and other stakeholders.One of its specific priorities is to “acceleratethe uptake of LED and OLED lightingsolutions,” he said.The benefits of SSL can be defined, saidSturm, in seven dimensions: energy, system,environmental, biological, business, designand quality. “The benefits over all otherlighting technologies are unique, as only SSLcombines all [these] dimensions,” he said. Inthe biological dimension, Sturm said that“biological effective lighting” can influenceour well-being and health, and that LEDtechnology can help to manage the effects ofdemographic change, particularly for agingpopulations. However, he described the biologicaldimension as a “research topic” thatoften “raises a lot of tension.”In terms of business, Sturm said that “thecharacteristics and benefits of LED-lightingtechnology will lead to a change in businessmodels in lighting.” Models based on recurringrevenues from replacement sales (i.e.lamps) will be superseded by models basedon revenues over life including energy savings,but these will require innovative financingmodels. Sturm also said that LED lampsales will peak in 2018 due to the growth insales of integrated lamps and systems.LED market in RussiaEvgeny Dolin, chairman of the Russiannational association for manufacturersof LEDs and LED-based systems (www. ____nprpss.ru), ______ said that the Russian LED marketexperienced very rapid growth of 50-60%in 2010. Even so, LED lighting fixtures wereonly about 5% of the total lighting market in2010, with revenues of US $67 million. Thesefigures are expected to increase to 15% and$333 million by 2015.Dolin said that the Russian government issupporting energy efficiency and promotingthe use of LEDs, while the biggest corporationsare starting investment programs forLED lighting. One example is Russian Railways,which invested EUR 13 million in 2010,and EUR 24 million in 2011. Russia is tryingto derive maximum benefit by switchingdirectly from incandescent lamps to LEDlamps, skipping the move to compact-fluorescentlamps (CFLs) that has been prevalentelsewhere in Europe.Dolin’s organization is of course involved instandards work, and he said that Russia hasadopted the LED color-coordinates specifiedin the ANSI C78.377 standard. Also, October2011 saw a national requirement come intoplay for a minimum efficacy of 50 lm/W forLED lighting. In the case of retrofit lamps, theminimum is between 50 lm/W and 70 lm/Wdepending on color temperature.Dolin said that the organization is workingto harmonize Russian measurement laboratorieswith international efforts. He pointedout that it is difficult for Russia to use USdevelopedstandards without modifications,due to differences such as climate, and thenature of the electrical grid.Business developmentOne member of the Russian LED manufacturers’association is Optogan, which has amajor production facility in St. Petersburgand also recently opened an LED chip productionfacility in Landshut, Germany (page14). Optogan’s Markus Zeiler spoke abouthow the company has set about enablingfast adoption of LED lighting. One strategyis to set up a network of “technological andregional champions,” he said, enabling eachcompany to stay focused on its own technologicalareas of strength. One example is atechnical cooperation on AC-LEDs betweenOptogan and Lynk Labs.Another strategy is product modularity.“We need to reduce complexity and keep itsimple for our customers,” said Zeiler, offeringa preview of a scalable chip-on-board (COB)concept which he said was analogous to Legobricks. Finally, he discussed new sales channelsand the value of franchising via remotebusiness owners with regional know-how, asan alternative to setting up branch offices.“This keeps investment low, but enablesglobal branding,” he said.26 NOVEMBER/DECEMBER 2011 LEDsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®___________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®LED DriversBuck/Boost LED Drivers - From 1W to 100W.5 Year WarrantyHighest EfficiencyDimming down to 0%TRIAC DimmingAC or DC InputFor Application Support contact yourlocal RECOM sales contact or go to:www.recom-power.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®conferences | STRATEGIES IN LIGHT EUROPESIL Europe technology track focuseson design, from optics to luminairesThe technology track at Strategies in Light Europe featured several presentations specifi cally aimedat selecting the right materials, optics, drivers and luminaire designs to best take advantage of LEDtechnology, writes LAURA PETERS.The Strategies in Light (SIL) Europeconference and exposition was heldin Milan, Italy on October 4-6 andfeatured two days of discussion regardingthe technological developments thatgo into solid-state lighting (SSL) products.A key message of these presentationsrings true: LED lighting has matured to thepoint where luminaire design, whether itis for street lights, recessed downlights orintegral replacement lamps, must bringtogether optimized drivers, optics andthermal design to best take advantage of allthat LED technology has to offer. SIL Europealso featured parallel sessions in the MarketTransformation track (page 21).Luminaire designHans Laschefski, a consultant with AlanodAluminium-Veredlung GmbH in Ennepetal,Germany, discussed a trend toward multiplereflectors as a means to control glarewith high-power arrays of packaged LEDs.As the industry moves to smaller, denserarrays, glare increases and must be managedto provide an acceptable user experience.“When evaluating glare, people oftentalk about the average luminance, but sinceLEDs are spot-light sources, we should evaluatethe spot illuminance, which is unfortunatelydifficult since the necessary measurementequipment is not typically available,”he explained.Laschefski showed several advancedreflector designs, all of which do not uselenses directly on the packaged LEDs butrather have the LEDs facing angled mirrorsand reflectors. This helps to improve the lightLAURA PETERS is a Senior Technical Editorwith LEDs Magazine.distribution, achieve bettercolor mixing, andreduce glare. One of theadvantages to havingvery-high reflectivityfrom aluminum-basedalloys (95-98% reflectancewith Alanod'sMiro and Miro Silverreflectors) is that multiplereflections can eliminate the observationof a point-light-source by a person lookingdirectly at the luminaire. For instance, inthe Deflecto luminaire street light by AriannaLEDof Padova, Italy (Fig. 1), the multiplereflections sufficiently scatter the light. “Inthese designs, you cannot even tell the lightMultiple reflector light patternFIG. 1. Defl ecto street lights utilize multiple refl ections toeliminate point-light-source glare. Inset: Light distributionpattern from luminaire (source: AriannaLED).source is an LED,” Laschefski said.Laschefski stated that by separating theLEDs from the optics, the problem of lensaging can be controlled. He explained thatwhen LEDs are closely coupled to optics inan air-tight environment, volatile organiccompounds (VOCs) used in LED assemblyLEDsmagazine.com NOVEMBER/DECEMBER 2011 29Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®conferences | SIL EUROPEmay permeate the silicone dome. Light exposurecauses the VOCs to oxidize, creating adiscoloration of the silicone. If, instead, theLED emitters are not contained in an airtightenvironment, VOCs have a chance todiffuse out and not interfere with the opticaltransmission.The importance of visual comfort with LEDluminaires was also emphasized by GiorgiaTordini, an optical designer with Philips ProfessionalLighting Solutions, who presented“The visual barrier: Designing the nightappearance of an LED product.” She definednight appearance as a person's visual perceptionwhen a light is first switched on in itsapplication. Very high luminance from LEDlight (108 cd/m²) can cause glare, which is anuncomfortable reaction to brightness. Tordininoted that glare is different from photobiologicaldamage, which is caused mainly bylight in the UV realm.Tordini described the optical system ofPhilips’ DayZone luminaire for office lighting,which has a task light in the middle anda separately-controlled outer ring-light forambient lighting. The luminance of the outerring is 3x smaller than that of the inner portion.The luminance limit for work spaces,according to British Standard EN-12464,is 1000 cd/m² at a 90-degree to 65-degreeangle from the vertical axis.Tordini explained that the optical designuses primary optics at the LED level (whichis a multi-LED package) to convert the lightdistribution into a controlled beam. Theplastic optics consists of a microlens arrayfabricated from polymethylmethacrylate(PMMA). This serves to minimize chromaticaberration due to first-order interference,while enhancing scattering to allow auniform visual appearance of light. Transmittancethrough the PMMA film is 92%.This patterned film is available in roll-torollsheets and therefore is flexible to applyin different shapes and sizes. Beyond thisprimary optic, a secondary optic, consistingof a hollow prism ring, modifies the light distributionand controls the light level transmittedto the target surface.Achieving omni-directionalityMarkus Hofmann, a senior developmentengineer with Osram GmbH of Munich,Germany, presented the pros and consof four different approaches to achievingomni-directionality with integral lampsfor residential applications. He said thatomni-directionality can be achieved usinglight guides, reflectors, a remote phosphoror a three-dimensional (3D) arrangementof LEDs.The key advantage of using light guidesOmni-directional lamp in base-up positionRepeat measurements invertical 45° and 90° planesfrom initial planeEnergy Star program requirements for integral LED lamps180°is that an incandescent-like bulb in appearancecan be achieved. However, there isgreat light loss and low efficiency associatedwith this approach, and meetingEnergy Star specifications (Fig. 2) is verydifficult. As a result, light-guide approachesare currently limited to low-lumen-output,design-driven applications.Meeting Energy Star requirements ismuch more practical if reflectors are usedinside the bulb to direct the light. Anotheradvantage is that a classical bulb designis possible. Hofmann said that reflectorsinside retrofit lamps currently work bestfor lamps with medium lumen output.When it comes to achieving high lumenoutput, the remote phosphor approach issuitable because light losses are low andthe phosphor is compatible with externalaluminum fins that function as the heatsink. The downside, particularly in today’smarket according to Hofmann, is the highcost of remote phosphors that contain rareearthmaterials. Assembly of the bulbs isalso a more complex process, he said, butEnergy Star requirements can be met.0°At least 5% of total flux (lm)in 130°-180° zone135°Luminous intensity (cd) at any anglein the 0°-135° zone shall not differfrom the mean intensity for the entire0°-135° zone by more than 20%.Source: OsramFIG. 2. Omnidirectionality is one of the more diffi cult requirements of Energy Star.Alternatively, a 3D arrangement of theLEDs can meet high-lumen-output needsand also meet Energy Star requirements.Hofmann stated that 60W-equivalent (850lm) and 75W-equivalent (1060 lm) lampsthat meet Energy Star requirements withgood CRI, CCT and lifetime have been fabricatedusing 3D approaches. “Realizationof 100W-equivalent lamps with 3DLED arrangements will be coming soon,”he added.Another presentation in the same sessionrevealed a less-traditional approach tofabricating and marketing retrofit lamps.Martijn Dekker, CTO of Lemnis Lighting,an LED lamp maker based in the Netherlands,announced that Lemnis has enteredinto a multiyear commitment with a largeretailer to develop and market cost-effectiveLED lamps. The first products are 400-lm and 200-lm lamps, which will be introducedin European stores soon. Althoughnot confirmed by Dekker, the retailer isthought to be Sweden-based Ikea. WhileDekker noted that the lamps do not meetEnergy Star requirements and have ashorter lifetime rating (20,000 hours) thanmost replacement lamps, the overridinggoal in development was achieving acceptableconsumer price points while deliveringquality lamps.“The price target for these lamps was lessthan €9.99 ($13.77) for the 45W-replacementlamp and €6.99 ($9.64) for the 25W-replace-30 NOVEMBER/DECEMBER 2011 LEDsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®conferences | SIL EUROPENormalized system efficacy (%)120100ment,” explained Dekker. The 400lm lamp offers a CCT of 2700Kand a CRI above 85. The LEDdesign combines two red LEDswith four phosphor-convertedblue LEDs, but the company plansto move to a phosphor-only arrayin 2012 products.Dekker referred to the novelbusiness agreement with Lemnis’partners as a virtual verticallyintegratedcompany involvingthe retailer, the lighting manufacturer,an LED fabrication partnerin India and other supply partners.These companies are sharingthe project risk to achieve long-termvolume sales of LED lamps priced at $8/klmat the lamp level. “A non-integrated supplychain leads to a stacking of profit marginsthrough the supply chain,” he said, whichlimits the industry’s ability to hit low commercialprice points.80604020LEDsystem efficacyCFLsystem efficacyHIDsystem efficacy00 20 40 60 80 100Input power (%)Source: Harvard EngineeringFIG. 3. System effi cacy of various technologies when dimmed.Optimizing opticsAmong all retrofit lamps, perhaps the LEDbasedMR16, because of its small size, is one ofthe more difficult to design. Mike Bean, headof design and development at Carclo TechnicalPlastics (CTP), a designer and manufacturerof optical components based in London, UK,described the MR16 halogen lampas a tough act to follow. “MR16design using LEDs is quite a challenge…despitethe fact that thereare several commercially-availablereplacement lamps, most donot come close to the 50W halogenin performance,” said Bean.According to the US Departmentof Energy’s (DOE’s) Caliper testingof LED-based MR16 lamps, while50W-equivalent performance isthe goal, typical measurementsare closer to those of 25W- or35W-equivalent lamps (Fig. 3).To achieve the required centerbeamintensity and a narrow overall beamangle, one key to the lamp design is to combinesmaller LEDs with focusing optics.Smaller LEDs and total internal reflection(TIR) optics allow the beam angle to bereduced from 40 to 27˚, while still delivering2250 cd at 27˚. In this design, the 30-mm-__________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®conferences | SIL EUROPEIntensity (cd)8000700060005000400030002000diameter optic was optimallyplaced 15 mm above the multichipLED source, allowing thereflector to fit within the specifiedgeometry of the MR16 lamp(per ANSI C78.24 specification).Bean said that in addition tohelping with the beam angle, themulti-chip LED approach alsoaffords more driver options,including serial or parallel operation.The reference design useda Diodes 1.5A driver, a Cree MT-GLED package and a Carclo TIRoptic to deliver an initial outputof 611 lm at 10.1W (61 lm/W).SIL presentations alsoaddressed luminaire design elementsrelated to product life. Klaus Reinartz,director of the global LED programat Bayer MaterialScience LLC (BMS) inLeverkusen, Germany, explained howadvanced polycarbonate materials can50Wequilvalent35Wequilvalent20Wequilvalent50W reference design1000Round-11 Caliper results00 10 20 30 40 50 60Beam angle (°)offer increased transparency in a thinneroptical lens with a much smaller yellownessindex than previous-generation materials.The company’s Makrolon products are stableagainst 90-degree LED light with anSource: CTPFIG. 4. Energy Star center-beam intensity targets for MR16lamps, showing seleted Caliper results and reference design.intensity of 46 lm/cm², and thecompany is currently performingtrials at higher temperaturesand light intensities.Advanced polycarbonatematerials can be injectionmoldedinto a wide variety ofshapes and sizes to meet LEDlight transmission, shapingand diffusing needs. One of thenewer developments that Reinartzdescribed is thermally conductivegrades of polycarbonate(up to 40W/m∙K), which canbe custom-molded to act as alighter, more flexible heat sinkthan aluminum options.Driver and dimmer designRasib Khan, an engineering managerwith Harvard Engineering plc, based inWakefield, UK, presented a comparisonof dimming system efficacy among LED,Complex componentsneed reliable protection.When you need to precisely spray and dispense liquid coatings and materials, the SCS Precisioncoat selectivespray and dispense coating system provides maximum accuracy and flexibility. The 3-5 axes system offersa wide array of industry-leading optional features to meet any production requirement, includingprogrammable tilt and rotate, needle calibration, vision system, offline programming and a barcode reader.The new SCS Precisioncoat potting platform automates the potting process to increase production accuracyand efficiency. The PC-controlled system allows users to precisely control the volume of material dispensed,can be configured with one head or multiple heads, and can dispense one or two-part materials.Contact SCS to find out more about our innovative solutions for your advanced technologies.World Headquarters (US): 317.244.1200www.scsequip.com32 NOVEMBER/DECEMBER 2011 LEDsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®Ultra-PreciseDispensingEssential for manufacturingSide-View LEDs for smartphones,tablets and e-readersConsistent weight every timeTight color qualityMore units per hourAutomatic closed-loop controlFind out more about Jet Dispensingat www.NordsonASYMTEK.com/LEDsWithNordson ASYMTEKjetting systems, 0.1 to 0.2 mmdots of silicone phosphor areeasily dispensed tofill the 0.4 mm cavity.The Spectrum Series jetting system automatically maintainsconsistent shot weight for improved process capability (CpK) whileensuring higher UPH. Using CPJ+, available only from NordsonASYMTEK, process variability is reduced to maintain a constant Takttime. The system is easy to program and adjustments are not requiredafter set-up, keeping your process under machine control.Email: info@nordsonasymtek.comUSA: +1.760.431.1919China, Shanghai: +8621.3866.9166China, Beijing: +8610.8453.6388China, Guangzhou: +8620.8554.0092Europe: +31.43.352.4466India: +91.44.4353.9024Japan: +81.3.5762.2801Korea: +82.31.765.8337S.E. Asia/Australia: +65.6796.9514Taiwan: +886.2.2902.1860nordsonasymtek.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®conferences | SIL EUROPECFL and high-pressure sodium (HPS) lightsources. The greatest energy savings areassociated with using LEDs and appropriatedimming levels. As a comparison, HPSsources can only be dimmed to approximately40% of their maximum lumen outputand system efficacy is compromised withall levels of dimming (Fig. 4). In other words,higher input power is required to producethe same lumen output. For example, a 60WCosmo luminaire with Harvard DALI ballastat a 50% light-output level requires approximately67% of input power.System efficacy is better with CFLs, wherehigh efficacy is maintained down to about40% lumen output levels. For a typical fixture,30% lumen output requires approximately35% input power. However, below a40% dimming level, CFLs suffers from cathodeand driver inefficiencies.LEDs are easier to dim and hypotheticallycan be dimmed readily to as low as1%. System efficacy is excellent from 100%LM-80 / LM-79 TEST SERVICESSetting the Standard for LED MeasurementORBoptronix>DဒϬ>DϳဓdĞƐƟŶŐ^ĞƌǀŝĐĞƐKƌďKƉƚƌŽŶŝdžŝƐƚŚĞĮƌƐƚŝŶĚĞƉĞŶĚĞŶƚϯ ƌĚ ƉĂƌƚLJ/^KϭϳϬϮϱĐĐƌĞĚŝƚĞĚh^>ĂďŽƌĂƚŽƌLJŽīĞƌŝŶŐĐŽŵƉůĞƚĞ>DဒϬ>ƵŵĞŶDĂŝŶƚĞŶĂŶĐĞdĞƐƟŶŐEZ'z^dZWZĞĐŽŐŶŝnjĞĚK>ŝWZ^^>>ƵŵŝŶĂŝƌĞdĞƐƟŶŐĚĚŝƟŽŶĂů^ĞƌǀŝĐĞƐ>LJĞ^ĂĨĞƚLJǀĂůWƌŽĚƵĐƚdĞƐƟŶŐĨŽƌZŝƐŬ'ƌŽƵƉůĂƐƐŝĮĐĂƟŽŶdK>ŚĂƌĂĐƚĞƌŝnjĂƟŽŶ^ĞƌǀŝĐĞETO-S20-P6-HPAETO-TEC-100to around 20% of light output. For instance,a 50W-equivalent luminaire with Harvard700 mA DALI driver at 50% light outputonly requires 44% input power. With currenttechnology, system efficacy becomesimpacted by driver efficiency below 20% oflight output.According to Khan, simple analogswitch dimming (0-10V) works well on asmall scale, but requires too much cable forlarge-scale implementations. More expensivecontrol options such as DALI can providegreatwer flexibility for projects of allsizes and are re-configurable. However,DALI and other approaches require furtherwork to fully maximize control efficiencyand power factor over the control range.Ultimately, Khan expects the industry tomove to wireless intelligent control systemscapable of plug-and-play operation.Also in the drivers session, Steve Roberts,technical manager at Recom, Austria,discussed the significant impact that&RPSOHWH6(59,&(6&RPSOHWH6ŚĂƌĂĐƚĞƌŝnjĂƟŽŶ^LJƐƚĞŵƐddĞŵƉŽŶƚƌŽůǁŝƚŚdƐdĐdũDŽŶŝƚŽƌŝŶŐ,ŝŐŚůLJĐĐƵƌĂƚĞ>^ƉĞĐƚƌĂů&ůƵdžDĞĂƐƵƌĞŵĞŶƚƐĂŶĚWtDWŽǁĞƌ^ƵƉƉůLJŽŶƚƌŽůƐE/^ddƌĂĐĞĂďůĞůĞĐƚƌŝĐĂůdŚĞƌŵĂůKƉƟĐĂůĂƚĂƵƚŽŵĂƚĞĚĂƚĂĐƋƵŝƐŝƟŽŶĂŶĚŶĂůLJƐŝƐdŽŽůƐϰtŝƌĞsŽůƚĂŐĞĂŶĚƵƌƌĞŶƚDĞĂƐƵƌĞŵĞŶƚƐ,ĂƌĚǁĂƌĞ^ŽůƵƚŝŽŶƐŝŶĐůƵĚŝŶŐZĞƚƌŽĨŝƚŽƌƵƐƚŽŵ25%237521,;,1&6DOHV#2UE2SWURQL[FRP3OHDVHYLVLW2UE2SWURQL[FRPIRUDIXOOOLVWRISURGXFWV _____________VHUYLFHVhigh temperature can have on luminairereliability. He made several design recommendationsfor minimizing temperatureincreases in LED luminaires includingmounting the LEDs so that they havelow thermal impedance to the heat sinkand mounting the driver away from theLEDs and heat sink. The heat sink shouldbe designed for the most efficient size/efficiencyratio. Thermal derating can be usedto reduce the LED current if the junctiontemperature approaches specification limits.Roberts further recommends limitingthermal cycling and allowing for a singleLED failure in multiple LED installations.Input-output voltage transients can bemanaged by using spike protection as wellas short input cables with relatively-longeroutput cables.Regarding triac dimmers, Roberts recommendsthat engineers consider the timingof triggers and the effect on the driverelectronics. Rather than separate AC/DCballasts, a centralized DC-power-distributionapproach should be used with a largeAC/DC power supply feeding multiple DC/DC LED drivers. Finally, Roberts recommendsconsideration of the reliability ofevery component in the luminaire system.Designing power-distribution networksA presentation by Marc Ottolini of iSoteraLtd of Hoddesdon, UK, considered the utilityof DC-power-distribution networks forSSL. Ottolini compared four scenarios –the legacy architecture, a centralized DCStar approach where one AC/DC supplyfeeds DC/DC drivers, a DC grid where lowvoltageDC leaves the AC/DC supply, or acentralized high-frequency AC (HFAC) busapproach. For each approach, he looked atsimplicity of installation, cost, safety, reliabilityand controllability.He concluded that there is no compellingbenefit to implementing a full-DC-powerdistributionsystem for LED lighting. However,a centralized (bulk) power processingapproach can be advantageous if up anddown (2-stage) conversion can be made efficientenough, which depends on the diversityof the LED load. He finalized with thestatement that energy-efficiency benefitsalone (2-5%) do not provide enough impetusto begin setting new standards.34 NOVEMBER/DECEMBER 2011 LEDsmagazine.comPrevious Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®RELY ON ULAs lighting technology evolves, so does UL. In addition to product safetycertification, we also provide industry-leading performance testing,environmental programs and robust training initiatives.UL is widely known for our dedication to quality, technical expertise andbeing a symbol of trust. From code authorities to specifiers and consumersto retailers, our 100-year history of advancing safety demonstrates ourcommitment to protecting people, products and places.When you rely on UL for your lighting product needs, your future is bright.VISIT WWW.UL.COM/BRIGHT___________________Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®

Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM | Next PageqqM qMMQmagsTHE WORLD’S NEWSSTAND ®standards | TM-21The elusive “life” of LEDs:How TM-21 contributes to the solutionThe newly-introduced TM-21 document presents a method for lumen-depreciation projection basedon LM-80 data, enabling LED lifetime extrapolations beyond 6000 hours, says ERIC RICHMAN.In August 2011, the IlluminatingEngineering Society (IES) published theTM-21 document entitled “Lumen degradationlifetime estimation method for LED lightsources.” TM-21 is the IES-recommendedmethod for projecting lumen degradation ofan LED package, array or module based ondata collected according to LM-80.The lighting community expects TM-21 tobecome the standard method for projectinguseful LED lighting product life at realisticoperating temperature. This article presentsthe development process behind TM-21, andclarifies how and when to apply the lifetimeextrapolation method to arrive at reasonableand useful estimations.Lumen output(%)Typical "life" of standard lighting technologies10510095908580LED75INC FL HID706560551,000 11,000 21,000 31,000 41,000 51,000 61,000Hours of operationRepresentative only - not to scaleFIG. 1. Lumen degradation and failure behavior for incandescent (INC), fl uorescent(FL), high-intensity discharge (HID), and LED lamps.Why TM-21 and why now?We are all familiar with the very real butsometimes exaggerated long-life attributesof LED technology. Not the least of theseis the potential for very long life that helpsmake it an attractive design choice. Thetrick has been and continues to be how tomeasure or estimate this longevity to provideassurance to users of this technology’sreliability (life) compared to other options.We also understand that the overall reliabilityof a complete LED lighting fixturecan be affected by the reliability of individualproduct components (driver, lens, etc.)and should be accounted for in lifetimeestimations.The useful life of standard lighting technologiesis defined as the time to filamentor cathode failure. For most of these lamps,the time period prior to failure exhibitsacceptable levels of light output, as shownERIC RICHMAN (eric.richman@pnnl.gov) is a Senior Research Engineer with Pacific NorthwestNational Laboratories and follows standards development for the DOE SSL program (www.ssl.energy.gov). PNNL (www.pnl.gov) is a research laboratory of the US Department of Energy.______with the solid lines in Fig. 1. This makes iteasy to determine when to replace the lamp.However, LEDs do not have filament burnoutthat conveniently announces the endof life (dashed line in Fig. 1). Further, therapid development of the technology andthe desire to bring products to market ina timely manner does not allow for actualtesting verification of the long lives claimed(100,000 or even 35,000 hours). As a result,the industry has come to accept a definitionof the end of the useful life of an LED as thepoint when it no longer provides a specifiedlevel of light output.And finally, the life and performance ofLED lighting products depends greatly onexcess heat retained at the diode. This is whyLEDs require testing at multiple temperaturessuch that when a source is installed ina luminaire, its actual operating temperaturecan be measured and lumen depreciationof the product can be derived.Therefore, to serve the solid-state lightingindustry, the Technical Procedures Committee(TPC) of the IES proceeded to developappropriate tests for use in rating LED productlongevity. The initial need was a measureof the basic lumen degradation of LEDsource components identified by a module,package, or array of diodes and this came inthe form of LM-80. Importantly, LM-80 onlyspecifies how to measure lumen depreciationto a minimum of 6000 hours (but recommendstesting to 10,000 hours or longer).LM-80 stops short of using that data to estimateany depreciation after that, which iswhere TM-21 comes in.The TM-21 working group (WG) as partof the IES TPC was formed to develop thelumen depreciation projection methodand spent over three years exploring manyoptions. The WG evaluated various projectionoptions starting with an analysis of variousmathematical, engineering-based modelsto provide effective depreciation fit and auseful projection method.LEDsmagazine.com NOVEMBER/DECEMBER 2011 37Previous Page | Contents | Zoom in | Zoom out | Front Cover | Search Issue | SubscribeqMqM qMM MQmags| Next Page q qTHE WORLD’S NEWSSTAND ®