Download our Product Catalog - StormTech

Download our Product Catalog - StormTech

Download our Product Catalog - StormTech

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

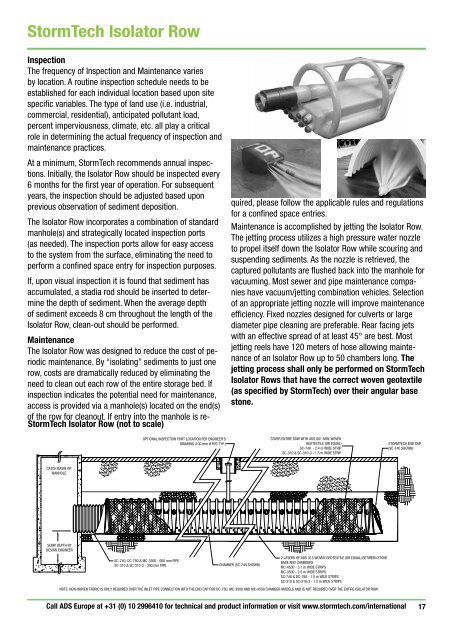

<strong>StormTech</strong> Isolator RowInspectionThe frequency of Inspection and Maintenance variesby location. A routine inspection schedule needs to beesta blished for each individual location based upon sitespecific variables. The type of land use (i.e. industrial,commercial, residential), anticipated pollutant load,percent imperviousness, climate, etc. all play a criticalrole in determining the actual frequency of inspection andmaintenance practices.At a minimum, <strong>StormTech</strong> recommends annual inspections.Initially, the Isolator Row should be inspected every6 months for the first year of operation. For sub sequentyears, the inspection should be adjusted based uponprevious observation of sediment deposition.The Isolator Row incorporates a combination of standardmanhole(s) and strategically located inspection ports(as needed). The inspection ports allow for easy accessto the system from the surface, eliminating the need toperform a confined space entry for inspection purposes.If, upon visual inspection it is found that sediment hasaccumulated, a stadia rod should be inserted to determinethe depth of sediment. When the average depthof sediment exceeds 8 cm throughout the length of theIsolator Row, clean-out should be performed.MaintenanceThe Isolator Row was designed to reduce the cost of periodicmaintenance. By “isolating” sediments to just onerow, costs are dramatically reduced by eliminating theneed to clean out each row of the entire storage bed. Ifinspection indicates the potential need for maintenance,access is provided via a manhole(s) located on the end(s)of the row for cleanout. If entry into the manhole is re-<strong>StormTech</strong> Isolator Row (not to scale)quired, please follow the applicable rules and regulationsfor a confined space entries.Maintenance is accomplished by jetting the Isolator Row.The jetting process utilizes a high pressure water nozzleto propel itself down the Isolator Row while sc<strong>our</strong>ing andsuspending sediments. As the nozzle is retrieved, thecaptured pollutants are flushed back into the manhole forvacuuming. Most sewer and pipe maintenance companieshave vacuum/jetting combination vehicles. Selectionof an appropriate jetting nozzle will improve maintenanceefficiency. Fixed nozzles designed for culverts or largediameter pipe cleaning are preferable. Rear facing jetswith an effective spread of at least 45° are best. Mostjetting reels have 120 meters of hose allowing maintenanceof an Isolator Row up to 50 chambers long. Thejetting process shall only be performed on <strong>StormTech</strong>Isolator Rows that have the correct woven geotextile(as specified by <strong>StormTech</strong>) over their angular basestone.Call ADS Europe at +31 (0) 10 2996410 for technical and product information or visit www.stormtech.com/international 17