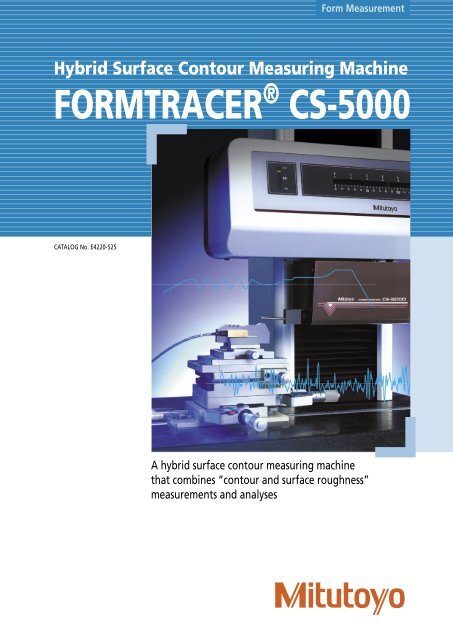

FORMTRACER CS-5000 - Mitutoyo Scandinavia AB

FORMTRACER CS-5000 - Mitutoyo Scandinavia AB

FORMTRACER CS-5000 - Mitutoyo Scandinavia AB

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

“Wide-range & high-resolution” detector!•Patent registered (Japan, U.S.A., England)•Patent pending (Japan, U.S.A., Germany, England)Employing Active Control Method, which reduces thevariation of the dynamic measuring force to improvetraceability and to thereby allow measurements withhigh-accuracy. The X- and Z- axes are equipped withthe Laser Holoscale, which boasts excellent narrowrangeaccuracy.Z-AXIS Newly Developed Detector•Measuring range [resolution]> Standard stylus:6mm (.24”) [0.002µm (.08µinch)]12mm (.47”) [0.004µm (.16µinch)]*> Double-length stylus:12mm (.47”) [0.004µm (.16µinch)]24mm (.94”) [0.008µm (.32µinch)]*•Measuring accuracy:> Standard stylus:±(0.2+|0.001H|)µm [(7.8+|H|)µinch]±(0.3+|0.02H|)µm [(12+|20H|)µinch]*> Double-length stylus:±(0.2+|0.005H|)µm [(7.8+|5H|)µinch]±(0.3+|0.02H|)µm [(12+|20H|)µinch]**<strong>CS</strong>-<strong>5000</strong>LX-AXIS• Measuring range [resolution]:200mm(8”) [0.00625µm (.25µinch)]• Measuring accuracy:±(0.2+0.001L)µm [±(7.8+L)µinch]2

Z-axis range6mm (.24”)Detectors of <strong>CS</strong>-<strong>5000</strong>Standard stylusDetectors of <strong>CS</strong>-<strong>5000</strong>LStandard stylusZ-axis range12mm (.47”)Measuring example“An analyzing program that integratescontour and surface roughness evaluations”•Patent pending (Japan)“FORMPAK-1000” and “SURFPAK-SV”, the popular contouranalysis program and surface roughness analysis program arecombined into FORMTRACEPAK!3

IntegrationToday in various industrial fields, where technologies are constantly advancing, even higher accuracy is requiredin measuring fine contours, as is seen in the machining industry and in fiber optics used in the information /communication equipment industries, to name a few.The <strong>CS</strong>-<strong>5000</strong> series Formtracer is a high-accuracy, hybrid surface contour measuring machine that offers the world’shighest level of accuracy and high-operability. It has been developed with the latest design engineering andproduction technologies of <strong>Mitutoyo</strong>, to answer the needs of these industries that employ the latest technologies.Body with high-rigidityX-axis drive unitEntire machine structureOptimal design using the FEM analysisIn pursuit of a machine with a highermeasuring accuracy, <strong>Mitutoyo</strong> combined thebase, column, and the X-axis drive unit, andusing a FEM structural-analytical simulation,the stress yielded in each member wasthoroughly analyzed. Measurements withhigh-accuracy were thus made possible bythe optimal structural design.X-axis guideDetectorX-axisdrive unitBaseColumnFWM structural analysisActive control detection systemThe newly developed detector> Traces the workpiece surface while detecting the surfaceroughness, with high-accuracy.> Offers high-traceability even on very steep inclined planes.> Prevents variation of the measuring force in the entire measuringrange of the Z-axis.•Patent pending (Japan, U.S.A., Germany, England)The resistance of the distortion gage changes when a displacement(vertical movement) of the stylus occurs, as shown in the figure onthe right. The Voice coil controls the vertical movement of the stylusto keep the resistance of the distortion gage constant.Structure outline of the <strong>CS</strong>-<strong>5000</strong>’sZ-axis detectorLaser HoloscaleVoice coilFrameConnectingmechanismStylusDistortion gage4

Hight-resolutionEquipped with Laser holoscale •Patent pending (Japan, U.S.A., Germany, England)The X-axis and Z-axis detectors are equipped with the Laser Holoscale, a scale that use the interference of diffracted light, and boastsexcellent accuracy in wide and narrow ranges. The Laser Holoscale offers the highest level of resolution in the world: X-axis 0.00625µm(.25µinch), Z-axis 0.002µm (.079µinch).Principale ofLaser HoloscaleMirrorDetectorBeam splitterMirror[a]Laser beam[b]Laser HoloscaleLaser diodeMirrorBeam splitterMirrorScaleGlassplateInterferencefringe0.5m (.02inch)What is the Laser Holoscale?The laser Holoscale uses intersecting laser beams [a] and [b] to create an interference fringe, which is recorded on the glass plate (scale).This means that the wavelength of the light is transferred directly onto the scale, allowing the scale pitches in order and the entire scalelength to be exposed altogether. Thus, extremely high cumulative accuracy and linear accuracy with uniform pitches can be achievedat the same time, unlike with the Step & Repeat method, which produces uneven pitches, in the lithographic process using an originalreduction exposure.X-axis guide with high-rigidity and high-accuracyCeramic guide •Patent pending (Japan, U.S.A., Germany, England)The X-axis employs a square pillar guide made of ceramics.The slider is attached by a wire at the center of gravity of the frictional force generated by a sliding motion, to reduce the transmission of thevibration caused by the drive motor, thus minimizing hysteresis` and thereby allowing high-accuracy traversing straightness of the drive unit.To accommodate this driving mechanism, the guide is shaped in a special form.*Hysteresis: a phenomenon in which the load and distortion that occur in a one-way travel do not mach those of the return travel.Straightness Standard stylus: (0.05+0.0006L)µm [(2+0.5L)µinch] (0.1+0.0015L)µm [(4+1.5L)µinch]*Long stylus: (0.1*0.0006L)µm [(4+0.5L)µinch] (0.2+0.0015L)µm [(8+1.5L)µinch]*Measuring accuracy ±(0.2+0.001L)µm [(12+2L)µinch] *<strong>CS</strong>-<strong>5000</strong>LCompensation technologyUltra-high accuracy> X-axis measuring accuracy compensation•Patent pending (Japan, U.S.A., Germany, England)The scale that is built-in in the column detects the height of the X-axis drive unit to compensate for a microscopic“distortion of the column”, which occurs depending ton the detector position on the X-axis.(X-axis accuracy of (0.2+0.001L)µm [(7.8+L)µinch] is guaranteed at any detector position on the (vertical) column.)>Temperature compensationEach of the X- and Z-axis scales are equipped with a built-in temperature sensor, which detects the ambienttemperature as well as the workpiece temperature to allow temperature compensation.(Allows contour measurements without the influence of workpiece and ambient temperatures.)TemperaturesensorColumn withbuilt-in scale5

High-accuracy three dimensional topographySupports three-dimensional surface texture measurement and analysis> <strong>CS</strong>-<strong>5000</strong>-3D / <strong>CS</strong>-<strong>5000</strong>L-3D provides a variety of graphics methods and evaluation parameters forvarious surface texture evaluations from the three-dimensional topography data.> A desired topographic profile can be analyzed two-dimensionally, thus allowing the evaluation of finecontour and fine texture at the same time.Y-axis table + three-dimensionalauto-leveling tableDimensionsUnit: mm (inch)Min.100(3.94")Wall630 (24.8")940 (37.01")1710 (67.32")1430 (56.3")1130 (44.49")620 (24.41")7

<strong>CS</strong>-<strong>5000</strong> StylusStandard accessoriesOptional accessoriesUnit: mmStandard stylusLength of stylus tip: 6.5mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5mDouble-length stylusLength of stylus tip: 12.5mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5mDouble-length ball stylusLength of stylus tip: 12.75mmTip material: sapphireRadius of tip curvanture:ø0.5mm ballø0.5mm ball12.512.751401ø1.235.956.5ø4ø4ø1.235.95ø454.51 34.5 (19)ø1.24025.9510674.5(30.5)65.95(8.6)(8.8)(2.6)10674.5(30.5)65.9512AAC26112AAC26212AAC263Small hole stylusLength of stylus tip: 15mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5mø1.240A40A0.654.134.51554.51 34.5ø1.8ø1.225.9525.9525.95(19)53.90.4 34.5 (19)1040ø4ø4(19)55.52 34.5(19)ø4ø4ø0.60.40.60.6Extra small hole stylusLength of stylus tip: 10mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5m0.4Deep groove stylusLength of stylus tip: 26mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5m6626 1.21.6AAø4(2.5)(2.5)(22)12AAD64712AAD64812AAD649Eccentric stylusLength of stylus tip: 6.5mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5m6.540˚ø1.2(2.5)SkidDetector1525.9512AAD6508

<strong>CS</strong>-<strong>5000</strong>L StylusStandard accessoriesOptional accessoriesUnit: mmStandard stylusLength of stylus tip: 12.5mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5m12.51ø1.2ø674.5107ø4(31.5)Length of stylus tip: 15mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5m0.60.615106.674.5 (31.5)ø6ø4Ball stylusLength of stylus tip: 12.75mmTip material: SapphireRadius of tip curvanture:ø0.5mm ball25401ø1.2ø6(19)ø0.5mm ballDouble-length stylusLength of stylus tip: 25mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5m115.95145.954012.75154.51187ø1.235.9535.9565.95ø674.565.95(6.5)(6.8)10712AAD543ø4(31.5)12AAD544ø4(31.5)12AAD545ø1.2ø0.60.40.640AExtra small hole stylusLength of stylus tip: 10mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5m0.440AEccentric stylusLength of stylus tip: 12.5mmTip material: diamondTip form: 40˚ coneRadius of tip curvanture: 5m1.61.212.535.951035.95ø1.265.95106.4ø6ø6ø4 ø41871154.5(31.5)ø6ø616664Aø40.4A3(1.1)(1.1)(6.5)35.9565.9574.5 (31.5)65.9510912AAD65112AAD65274.5 (31.5)12AAD653Double-length ball stylusLength of stylus tip: 25.25mmTip material: diamondRadius of tip curvanture: ø0.5mm ballø0.5mm ball25.25ø1.2(19.3)115.95145.9512AAD546SkidDetector9

Optional AccessoriesCross travel table218-003Rotary vise (two-slide jaw)218-041 (metric)218-051 (inch)Rotary vise (two-slide jaw)218-041 (metric)218-051 (inch)V-block998291Rugged table218-002Rotary table172-196Holder with clamp176-107Swivel center support172-197Large size auto-leveling table178-028•Patent registered (Japan)Auto-leveling table178-027•Patent registered (Japan)Center Support172-142Center Support riser172-142V-block with clamp172-234V-block with clamp172-378V-block set182-902 (mm)182-901 (inch)Step reference specimen178-611 (mm)178-612 (inch)Roughness referencespecimen178-601 (mm)178-602(inch)Three-axis adjustment table178-047•Patent registered (Japan)XY leveling table with swivel178-042-1 (metric)178-052-1 (inch)(standard accessory)10

62.000303 (2) CPR, Printed in Japan<strong>Scandinavia</strong> <strong>AB</strong>Släntv. 4 • Box 712SE-194 27 Upplands VäsbyTel: 08-594 109 50Fax: 08-590 924 10info@mitutoyo.sese