Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

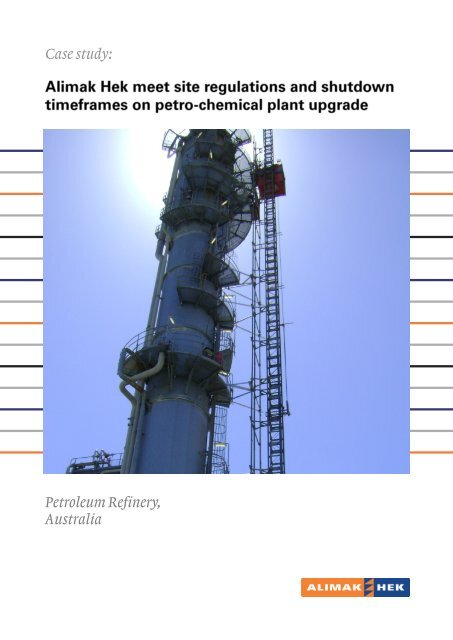

<strong>Case</strong> <strong>study</strong>:<strong>Petroleum</strong> <strong>Refinery</strong>,<strong>Australia</strong>

<strong>Case</strong> <strong>study</strong>:An Alimak Scando rack and pinion construction hoist wasinstalled at the petroleum refinery for use during theshutdown, refurbishment and reconditioning of thehydrogen production unit, known as the Reformer BHU.Given the highly flammable environment of thepetro-chemical plant, and the nature of the productsproduced, strict safety and operating conditions wereenforced on site. Working within facility requirements,Alimak Hek provided a temporary access solution thatallowed shutdown work to be completed within thedesignated timeframe.In order to complete necessary maintenance andupgrades to the facility on schedule, a means oftransporting men and materials to the upper levels of the43m steel Reformer Tower was required. An AlimakScando rack and pinion hoist proved the perfect solution,meeting size, weight, capacity and height requirementson site.Alimak Hek engineers designed and manufacturedunique brackets with extra long ties to fasten the mastsections to the tower’s irregular steel structure, inaccordance with petro-chemical plant safetyrequirements. In addition, extended landing platformswere fitted at the 33m and 37m landings, providing a safewalkway from hoist car to tower.Installation and dismantle of the temporary rack andpinion hoist was carried out in compliance with strict siteworking regulations, with Alimak Hek techniciansmonitoring the use of all power tools and completingwork within pre-arranged time frames.The Alimak temporary rack and pinion hoist remained onsite at the refinery for 4 weeks, providing men andmaterials with access to the 43m Reformer Tower duringrefurbishment works. Alimak Hek worked in compliancewith petro-chemical site regulations, working conditionsand timeframes, enabling shutdown work on the facilityto be completed on schedule.