Case study: Patrick Stevedore Operations, Port of Melbourne ...

Case study: Patrick Stevedore Operations, Port of Melbourne ...

Case study: Patrick Stevedore Operations, Port of Melbourne ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

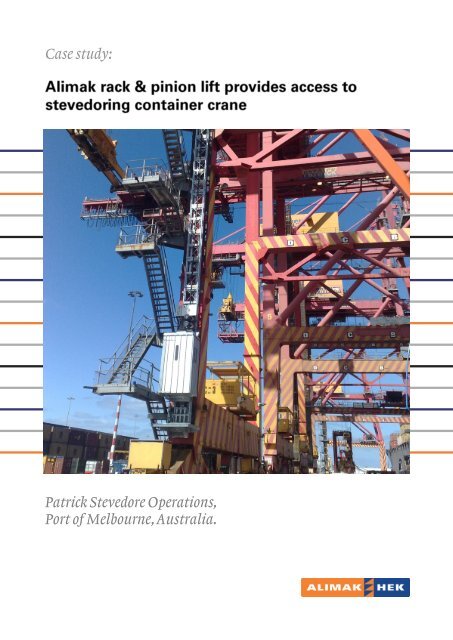

<strong>Case</strong> <strong>study</strong>:<strong>Patrick</strong> <strong>Stevedore</strong> <strong>Operations</strong>,<strong>Port</strong> <strong>of</strong> <strong>Melbourne</strong>, Australia.

<strong>Case</strong> <strong>study</strong>:Founded in 1919, <strong>Patrick</strong>’s <strong>Port</strong>s and Stevedoringspecialize in infrastructure management and the efficientmovement <strong>of</strong> cargo throughout Australian and NewZealand ports. The <strong>Patrick</strong> facility, located at Webb DockEast in Victoria’s <strong>Port</strong> <strong>of</strong> <strong>Melbourne</strong>, boasts three berths, aquay line <strong>of</strong> 780m and acts as one <strong>of</strong> the major frontlinesin Australian trade.<strong>Patrick</strong>’s <strong>Melbourne</strong> facility makes use <strong>of</strong> a CM06container crane to assist in the movement <strong>of</strong> complexproject cargo, including the loading and unloading <strong>of</strong>steel products, containers and heavy machinery. Untilrecently, this crane was fitted with an Electruck Easiriserindustrial lift, providing operators with vertical access tothe crane cabin.Given the obsolete nature <strong>of</strong> the Electruck lift, theresult <strong>of</strong> company closure in 2001, <strong>Patrick</strong>’s found itincreasingly difficult to have the Easiriser serviced andrepaired. A lack <strong>of</strong> available spare parts, absence <strong>of</strong>manufacturer support and difficulties in certifying thelift for operation left <strong>Patrick</strong>’s with little choice but tohave the lift removed and replaced.Alimak Hek worked closely with container cranespecialists, Inver Engineering, to execute the completedismantling and removal <strong>of</strong> the outdated lift, and theinstallation <strong>of</strong> the replacement Alimak SE industrial rackand pinion lift.Inver Engineering’s dismantling expertise enabledthe swift removal <strong>of</strong> the Electruck lift, full-height meshlift shaft and major support beams. Alimak Hek werethen able to install the SE industrial lift on site withoutdisrupting the use <strong>of</strong> the container crane, while InverEngineering installed necessary screening on lift landingsand stairs.The addition <strong>of</strong> the Alimak industrial lift has improvedthe efficiency <strong>of</strong> stevedoring operations at the <strong>Melbourne</strong>facility and relieved <strong>Patrick</strong>’s lift servicing andmaintenance concerns. Working closely with InverEngineering allowed Alimak Hek to complement theirown lift supply and installation expertise with Inver

<strong>Case</strong> <strong>study</strong>:Engineering’s experience in the difficulties <strong>of</strong> containercrane lift removal.Alimak Hek were able to provide <strong>Patrick</strong>’s with asingle contract for the complete removal and installationprocess, combining the expertise <strong>of</strong> two companies in theone contract to achieve best project results.The Alimak SE 500 industrial rack and pinion lift hasbeen in operation at the <strong>Patrick</strong> <strong>Port</strong> <strong>of</strong> <strong>Melbourne</strong>facility, providing operators with vertical access to thecontainer crane, since April 2010. This is now one <strong>of</strong> threeAlimak industrial lifts in operation at the <strong>Melbourne</strong>operations. Alimak industrial lifts have been used byglobal port authorities since 1971, and are installed ascrane elevators in more than 100 countries worldwide.