Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

'''''''"'"''''"'''''''"''''''''' '"''''000000 <

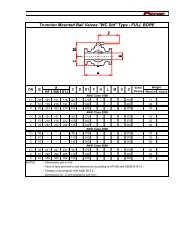

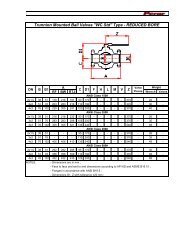

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVES!rAL 'vtfLDED BONNET TYPE GATE VALVESNO.PART NAMEI. BODY2. SEAT RING3. WEDGE4. STEM5. BONNET6. GLAND PARKING7. YOKE8. GLAND9. GLAND FLANGE10. GLAND NUTII. GLAND BOLT12. YOKE SLEEVE13. THRUST WASHER14. HAND WHEEL15. NAMEPLATE16. HAND WHEEL NUTA105,........ Fs·······: ........;;9............... F;·;A182............... F22 ..... f ...... F9~ ......:....... F3o4 .... )' ...... F31·;;· ... ·······;;;;;····...BODYA lOS I A182 i. A182 : A182 : A182 i A182 : A182 : A182 A182. -FS . -F9 -Fll : -F22 : -F9o : -F304 : -F316 -FSl••••••...•...............................••...•........•..••.......•..••...••..•..•.;..•••...............: ...................;.,,................:.................... = ....................:................... ~-- ... .. .. .. ... ..... ...................WEDGE A479-410+STL ~ 316SS : 316SS FSlA479-316+STL +STL ~ +STL +STLSEATR,NG - - ~:::: - - -T ~~ T ~~ :~;,+STL . +STL +STL................................................ ······························································································· · ············ · ··························~················ ..

I:..Sf;;IIN FORGE0 SiF6EI: VAit:'JESHIGH PRESSURE V~LVES/·,,' ' i .-'··..(',.,.-_. .. ~_....-..,.:.-.... 127 210 229 : 254. . .......................................•...................•......................... ... ?.~~ ... .l ........ ~~~ ..... l ... .. ~~· ···· · ·?.~~..... l16 16 ········ ·26.....;······.. 26 ... .........'32··· --:- ..··· ····46·····:·· ·······48... T160 ······································ .......224 253 317 ~ 377 377 : 458 : 510 : 510.,.......... .. ... .. ........... ................. ' ..................·:..... ... .. .... .... ................. .. ~ ...............· ·· · ~ ..................·........ 59 ·····5.o 1.o ....... 1 .~ : ~. :... ~ ....... 1 .8.:~.... ....... 1 .S.:~..... j ....... ~~P ....;... ...... ~~ .....l......... ~? .... ...~· ................. .. ...... ffiy~:~~Yi~' ....... i.o ~5 .......... 22 ~ 5.... 28.3 68.2 78.5 ~ 181 : 230 350mr8&S:21fi0lJzwQ.Q:I:230 250 300377 470 51012 16 528.0 11.0 45.0 5810.5 22.5 78.5 181 230 3505

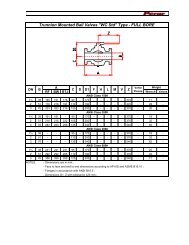

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESSEAL VVEWED BONNET TYPE GLOBE VALVESNO.PART NAMEI. BODY2. SEAT3. PAD4. DISC5. DISC NUT6. STEM7. BONNET8. GLAND PACKING9. YOKE10. GLANDI I. GLAND FLANGE12. GLAND NUT13. GLAND BOLT14. YOKE BUSH15. HANDWHEEL16. NAMEPLATE17. HAND WHEEL NUTA105A182. ... Fs ........ : ....... F9 ...... T ..... F11 ........ f ....... i=.22 ... .. T......F91 ..... T .... F304 .....]' ..... F31·6 ....,....... Fs1 ..... ..BODYA lOSA182 : A182 i A182 ! Al82 : A182 i Al82 : A182 i Al82-F5 : -F9 : -Fll . -F22 ~ -F91 : -F304 : -F316 : -F51SEATStellite on Body····oisc........ ......... ................................ ........ ........ ........ ........ A479:1P4i·a·i'TP3.i6 .. ............ ..... ......................... .. r. ......... .... .. ............... .. ..... ........ ................................. ... ..................;..................,;,.................. ~ ...................:................... ~-.................. :...................:........... .............. 3i.6ss····r ..... 3i.6ss .... :··;,··s3.iaa3····STL HARDFACING ~ +STL ! +STL ~ +STL' '' o''' o '''' "o 'o o' oo'''''' o '''II oo '' '' o '' '' '' '''' ' ' ' ' ' ''''''' ' ' '' oo ' '' ' ' '' '' ••o' ''' ' ' ''' ' O•' ' ' •• • • •• • • • •• • •• ''''''' ' '' ''' '''' ''' '''''' ''' ''''' '''' • ''' 0• ' '' ' ''' ' '''I''' •' ' ' • • '• O •' • • ' • ' ' ~· ' "' • ' '''''"'' "' ,, " ' ''"' ' " ' ' ' ".,, , ' " '' ' '' ' ' " ' ' ' ' " 'STEM A479-TP410/TP630 ~ 316SS ~ 316SS : S31803.........................................................................................................................................................................................,...................,...................,....................DISC NUT A479-TP410 I TP316 ! 316SS ! 316SS ~ S31803,................................................. .........................................................,.............................................................................. ( ...................,...................,....................,.,BONNET Al05 : A182 i Al82 : Al82 : Al82 i Al82 : Al82 : A182 : Al82............................................... .................................... ~ -F5 : -F9 ~ -Fll ~ -F22 ~ F91 ~ F304 : -F316 ~ -F51.;...................:................... :...................:...................:..................,...................,........................ ................YOKEAl05N.... ~~~~.O. .P.~.?.~~~·~· · · ······ · ··· ··· · ........... ................. ........... .......... ............... ~~9.P.~~!~. /. ~~?.P.~!!.~ .. ~ . ~0.~?.~~! .~.~~............................................................... ..... ~ ~~~.................................................. ·······································································································································-···························································GLAND A276-410 A276-304.................................................. .......................................................................................................................................-...........................................................GLAND FLANGEAl05N.................................................. ..................................................................................................................................................................... ...............................GLAND NUTA194-2H..................................................GLAND BOLT............................................................................................................................................................Al93-B7.............................. ............... :.?.~.~ .~~.s.~ ......................... ............ ............... .. .. ... ............................................. ~i9.~.!~~~i·~ - ~r9.~ ............... ................. .... .................. ....... .............. ....HANDWHEELAl97::::: ~~~~ : ~~~!E. :::::·::::::::::::::::: : ::::::::::::::: ::: : : ::: : :: ::::::::::::::: : ::::::::::::::::~i~;i~:i~:; : : : : : ::: ::: :: : : : : : : : : :: : : : : : : : ::: :: :: : :::::::: : :::::::::::I:: :>~ :~t~i~!~~:~t~:~~: :::::: :::: : : ::: : : : : · :: ::HANDWHEEL NUTA563A6

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVES[ CLASS 1500]VALVE SIZEL (mm)W(mm)H (mm)P (mm).........................WI (kg)Typical CvFactor3/4 1-1/41-1/2 2 2-1/2 3_IwL'[ CLASS 2500]VALVE SIZE 1/2L (mm)................. ..... ...W(mm).........................H (mm).........................P(mm)........... ..............WI (kg)..........................Typical CvFactor1-1/41-1/2 2 3w[CLASS 4500 (STANDARD-BUTT WELD ENDS)]VALVE SIZEL (mm)W(mm)H (mm)P(mm).........................WI (kg)···· typicai ·cv·· ·Factor7

..........................................................ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESf£AL VvfLDED BONNET TYPE Y-GLOBE VALVESNO.PART NAMEI. BODY2. SEAT3. PAD4. DISC5. STEM6. DISC NUT7. BONNET8. GLAND PACKING9. YOKE10. GLANDII. GLAND FLANGE12. GLAND NUT13. GLAND BOLT14. YOKE BUSH15. HAND WHEEL16. NAMEPLATE17. HAND WHEEL NUT~M DESIGNATIONPARTS -------BODYA105A lOSA182:······ F;;·

...................ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVES[ CLASS 1500 lVALVE SIZE 1/2 3/4 ~ 1-1/4 1-1/2 2 2-1/2 3L (mm) 110 : 127 . 155 210 , 210 . 229 . 254 . 280···· ·w ·(~~) · ···· ········;·40·····: ···· ··;-t

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESfEAL 1/1/ELDED BONNET TYPE UFT CHECK VALVESNO.PART NAMEI. BODY2. SEAT3. DISC4. CAP5. NAMEPLATE* OPTION:SPRING LOADEDNo. ~ ASTM DESIGNATIONPARTSBODY~A lOS, • 00 00 Fs. 0000.00.! 00 00.00 .F 00 0000 ooj 00 oo·. F. . 9 1 00 •• 00 ., 00 00 OOFA18222 .. 00•• : •• 0000 . Fs~ ·.. 00 ]' . 00 •• F ... 00. ]' 00 ••• F 304. .. 00316. j. oo .... F .... 00 ••51: A182 i A182 : A182 : A182 : A182 : A182 : A182 : A182: -FS -F9 ~ -Fll ~ -F22 : -F9a ~ -F304 ~ -F316 ~ -F51..................................................................................... .:. .................. i ................... : ................... : .................. .:.. .................. ; ................... : ................... : ................... .... ~ ...... ~.~.~! ... oo ........ oo.ooo .. oo .. oo ... ooooooooooo·oo·oooooooooooooooooooooooooo.oooo ..... oooo .. oo ... oo .. ooooo ... oooooooooo·~·'·-;:~I!~~ .?.~.~Y.oooooooooo ... oo.ooooo·oo:oo···oo··oo··oo·oooooooooooooooooo··· · ~·oo··oo·· · oooo • oo···A479-3 DISC A479-TP410 I TP316+STL A479-TP316+STL i S31803··4··00: +STL··c;.;P·····oo........ oo.oooooo···oo··· ·oooo·oooo..... oo .. oooo ... oo .. oo.oooioo .."Ai'82oooo·r·oo"Ai'82 ooooToo .."Ai'82 oo·oo:oo·oo"Ai.82····r·oo·"Ai.82··ooroo···"Ai.82 oooor····"Ai.82···· roo···"Ai·8·2·oo···................................................. .................................... A lOS N ~ -FS i -F9 : -Fll ~ -F22 ~ -F9a ~ -F304 ~ -F316 : -F51.:................... .;................... ;................... :...................:................... ~-.................. -~.................. ; ............... .....5 NAME PLATE Aluminium : 304 Stainless SteelI''''''' '''" • •" • •'"''''"'' '••''"" "' •'" •" • ••"' • .. ' •• ••'' .. ' .. ••''"' •'" •' •• ''" • • •"' ••'" • •'" •" • '''" "' "''"'"''" ...... ' .. ' • .... ' .. '' .... ' .. '' .. ' • .... '"'' "" • •• •" .. ~ .6 SPRI NG A276-304.1NCONEL 625" • •'" • •"" •"'' •" • • '•' • •" ' ' '" '• •' '" •' " ' ' '''' • • .. ' • '10

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVES[ CLASS 1500]VALVE SIZE 1/2 3/4 ! ! 1-1/4 ! 1-1/2 ! 2 2-112 3L (mm) 110 . 127 ~ 155 . 210 ~ 210 ~ 229 . 254 . 280......................... ..................·:...... ......... ...·:..................·:................···:................···~··............... · ·~ .......... ........ -~............... ......H (mm) 81 ~ 94 ~ 116 ~ 147 ~ 147 ~ 176 ~ 206 ~ 235......................... ···················~···················~············ · ······~···················=···················~···················?···················~·····················P (mm) 12 ~ 16 ~ 20 ~ 26 ! 32 ~ 43 ~ 48 ~ 59... .........................................;...... .............; ...................;................···=...................;...................;...... ............ -~.....................Wt (kg) 2.0 ! 3.5 ! 6.0 : 13.0 : 13.0 : 19.0 ! 28 ~ 36····-ryi)icalcv:.... ·········2···2·······!......... 2···8······r······ .. 5···9·······:······· 1··3··· 8·······~···· ····1·6····7······:······· 2· · 2· · · 5··· ··· ·t· ···· · ··· · 3···7······:··· · · · ·····54· ·· ·· ···Factor · ~ · ~ · ~ · ~ · ~ · ~ :[ CLASS 2500]VALVESIZE 1/2 3/4 1-1/4 ! 1-1/2 2 ! 2-1 /2 3L (mm) 127 . 155 , 210 . 229 ! 229 , 235 ! 254 . 280.. ... .... .... ... .... ...................) .................. •).................. ·~...................;............ ....... ;..................•) .......... .... .... · ~ ...... ...............H (mm) 94 ! 116 ~ 147 ~ 176 ! 176 ! 195 ~ 216 ! 230......................... ................... ~ ................... ~ ................... ~ ................... ~ ............ ....... ~ ................... ~ ................... ~ .................... .P (mm) 11 ~ 13 : 18 ~ 23 ~ 26 ~ 35 ~ 40 ~ 52......................... ................... ! ................... ~ ................... ! ................... ~ ................... ~ ................... ~ ................... ~ .................... ....... ~~ ..(~~~ ······ ......... ~ :~..... 1 .........! :~..... lTy~~~~~~v 1.6 ~ 2.4 ~ 5.0 · 11.2 ! 13.8 ' 17.0 ~ 25 ~ 38....... 1 .~ :~ .... j ....... ~ 1 .:~ .... .t ....... ~ . 1 . P .... t ....... ~P .... l .......... ~~ ... .. l .......... ~ ..... .L[ CLASS 4500 ]VALVE SIZE 1/2 3/4 1-1/4 1-1/2 2 2-1/2 3L (mm) 155 , 210 . 229 , 235 . 235 . 254 . 280 . 320························· ···················t···················!···················!···················!···················t···················)•··················>·····················H (mm) 100 ! 120 ~ 150 ! 180 ! 180 : 210 ! 240 ! 268......................... ....................................... ; ................... ; ................. .. ; ................... ; ................... ) ................... ~ .................... .P (mm) 8 ! 10 ! 15 : 20 ! 22 ~ 30 ! 40 ! 52.. . . .. . . . .. . . .. . . .. . . . .. . . " ................ ~ ........ " ....... "! ................... : ................... : .............. ..... : ........ .......... -~ .. ................ ·? ................. ... .Wt (kg) 8.0 : 13 ~ 21 ~ 30 ~ 30 ~ 38 ! 49 ! 62. . . . . . . . . . . . . . . . . . . . . . . . . . ................ .. i .................. ,; ................... ~ .................. -~ ................... ; ................... ; .............. ' .... ; .................... .Typical Cv 1 2 : 1 5 : 3 ~ 8 ~ 9 ' 10 8 : 20 7 : 32 6Factor · : · : .4 ~ ~ ~ . : . : .11

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESmESSURE f£AL BONNET TYFf GLOBE VALVESNO. PART NAMEI. BODY2. DISC3. DISC NUT4. GAS KEf5. STEM6. YOKE7. LOCKNUT8. GLAND9. SPACER RING10. PACKING WASHERII. GLAND PACKING12. GLAND FLANGE13. GLAND BOLT14. GLAND NUT15. NEEDLE BEARING16. DISK SPRING17. HAND WHEEL18. SLEEVE19. HAND WHEEL NUT20. NAMEPLATE12

~ ..................•ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVES_l,. ' · ;-·,- ./[ CL~S_S 2500]VALVE SIZE 1/2 3/4 1 1·114 1·1/2 2 2·1/2 3 IL (mm) 127 . 155 , 210 . 229 . 229 235 . 254 . 280ooo ooooo.o o oo oo o "'•Uoo o o ''' 00 '' ''' 0 ' ''' ' ' ' •i' 0 ' ''' ' '' ''' ''' ''' '~' '''' 0 '' '' '' 0 0 0 0 '''! 0 '' '' ' '' '''' 0 ' ' ''' · ~• '' 0 '' 0 ' '' 00 0 00 • • • • • '' •• • •• • • • ••• • •• ·~ • •• •• • 0 • • •• •• • • •• ••) '' • • 0 '' • • •• •• • •• •• • ••W (mm) 160 i 200 : 230 : 250 i 250 300 i 356 i 356.................. -~ ...................:.................. -~.................. ...................: .................. -~ .....................H (mm) 320 : 320 ~ 370 : 460 ~ 460 490 : 560 ~ 5600 . •• • • .. • •• •• • • .. • .... • • .. • •••••••••••••••••• !··.. ··r; · ..... ...... 32o .....-r·····32a·····T·····37·a······:······460..··--r·····4·60...... f ...... 4.90·····-r··· .. 560 ........... 566········....... , ................. ................... ~................... ~ ................... : ................... ~ ................... ~ ................... ~ ..................................... ..P (mm) 8 i 10 : 15 i 20 [ 22 : 30 ~ 40 52• .. • .... • .. • .. •• • • .. • • • • • .................. : .................. ·: ................... : .................. ·.... tyt~~~~v .... ....... 8·> .................. ·~..................' .................. .Wt (kg) 12 ~ 17 : 26 i . 37 : 37 i 45 : 68 79. 6 .... T .. .. i.o . 8 ..····:··..·;·5·.·2......:..····i8·.·a······r··..·26.·Ci··· .. ·~···· ·3·3 ~5· ·· · ·:-··· ..···28....... ....... 44 ·······13

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESFLOW CALCUlATION WITH KV VALUE1. DefinitionThe equation of continuity is used for anideal flow without friction through across-sectionQ:AXVQ=FiowA = Cross-section of the pipev=Velocityfor incompressible media the followingapplies:~>.Pt V' and V =YI1-ThusQ=A · YI1-The following applies to actual folwsubject to friction1{2l:PQ=a·A VTthe folw coefficient a being in practice ameasure of the pressure loss due tofriction and vorticity occurring duringfolw through a valve, for exampleThe folw coefficient and area A of thenominal width of the valve are thevalve-specific calues which togetherwith a constant form the valvecharacteristic "Kv •The folw is therefore also1rt:iQ=Kv. rTif measurement is carried out with apressure drop and the medium water,the following is obtained:e:.p = 1 barp = 1kg/cm3=Q ·(-!;Q= Kv 1{4-Q= Kv 1+Q= KvHence the definition:The Kv value is the folw in m 3 /h ofwater at 5 to 30"C which folwsthrough the valve at a pressure lossof 1 bar:It must be remembered that:1. the Kv value is not a dimensionlessvalue. Therefore the Kv valuesindicated on our catalogue are onlysuitable for calculating the folw inm 3 /h;2. the equation indicated are not valueequation ; this means that theprevailing operating conditions mayonly be used in the units indicatedaccording to applied formulae;3. the valve is independent of the flowmedium, with suitable approximation.The Kv values are calculated for thedifferent valve designs in accordancewith the VDINDE-2173 guidelines, andare indicated in the data tables of thecatalogues as valve characteristics forthe efficiency of the <strong>valves</strong>.2. The importance of the Kv value forthe flow calculation:The exact function of <strong>valves</strong> in a systemrequires careful selection of the valvetype and an accurate valuedetermination of the valve cross-section.After the switching (connection)function and nominal pressure havebeen selected the following factorsdetermine the connection size:Type, density, viscosity and temperatureof the flow medium; flow; pressurebefore and after the valve, andpremissible pressure loss in the valve.The operating conditions, such as flow ofpressure loss, can be calculated for astationary flow by means of the Kv valueindicated for each valve, and on thebasis of the following applied formula.If the flow and pressure loss are known ina system, the total Kv value is obtained.1 = 1 + 1 +.... 1kv tot? kvl 2 kvi kvn 2in a parallel arrangement the individualKv values are added together, and theformula is as follows:kv tot. = kvl + kv2 + .... kvn3. Notes3.1 For liquid media:For viscosities of up to approx.v=20mm2fs(=20 cSt=3t)formulae indicated with the liquid mediacan be used. For a higher viscosity acorrection factor can be introduced onthe basis of the viscosity coefficient.14

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESIn the case the following must be used:Q in mJ/h, v in mm2/s(the relationshipbetween mm2/s, and E is:v[mm2fs]=v(cSt)=7.6. E for viscositygreater than 3• E).The correction factor K may bedetermined from the graph.The required Kv value is thanKv corrected = K · kv calculated3.2 for gaseous media:A distinction must be made betweensub-critical and supercritical ftowcondition:a) subcritical ftow conditioncharacterised in thatIn the supercritical ftow condition thethroughput therefore depends solelyon the pressure p1 before the valve.3.3 For steam:The required values must be taken fromthe steam tables.3.4 The ftow calculation bases on theKv value must be carried out allowingfor a deviation of approximately ± 10%For example, the folw through a valveis not wholly independent of thepressure behind the valve in thesupercritical ftow condition, as mighttheoretically be assumed, butincreases as the pressure behind thevalve decreases.The following value is sough:Correction factor KSolution using the graph:Starting by calculating the viscositycoefficient Z according to the followingformula:Viscosity lZ = 3845 ·Q Qi1 m'/h.v n nm•coefficient ~ sfrom the calculated viscosity coeffcientin the table, vertically upwards, to thecorrection curve.The point of intersection indicates thecorrection factor K by which the Kvvalue already determined must bemultiplied.Kv VALUE CORRECTION GRAPH FORQn =514 . Kv 1 ~:.p . PIPn· T1VISCOUS LIQUIDSCALCULATION EXAMPLE:Given:in this flow condition the throughput This graph is required for liquids whose Flow medium: Fuel oilthrough the valve depends on the viscosity is v > 20mm 2 /s. Flow coefficient: Kv=1.35pressure p 1 before and p2 behind theFlow:Q= 1m3/hvalve, e.g. the higher the pressure p2 In order to use this graph the following Kinematic viscosity: V= 1200mm2/sbehind the valve the lower thevalues must always be known: from Kv value correction graph:throughput.Correction factor K= 1.42Given : Flow coefficient KvSubstited in Kv corr = K/Kv givesb) supercritical ftow condition Flow Q in m3/h Kv corr = 1.35\ 1.42= 1.9charcterised in thatKinematic viscosity v in mm2/sin this flow condition sound velocitytheoretically occurs in the narrowestcross-section of the valve, so that thethroughput through the valve isconstant regardless of the pressurebehind the valve as long as it is lowerthan the critical pressure ~ 1 •~ 2.6 ••• ---- "' "' --- .. ------... ---- --- .... .... ., .... ---------- .. - -·----.... ----- .. , .. --------- .. .,1.... 1 I I I I IQ I I I I I I0 I I I I I I~ 2.4 ...... ...... ~ - ----- ...... -- ~---------- .. ~ - .. - ------------:--------- - --:-- --- ------ ~C I I I I I I0 I I I I I I:;:, 1 I I I I I~ 2.2 - - .... -- ~ - .. - .... -- .... .. - ~ ----- - - .... --~ -- ----- - ----.... -:-------- ----:--------- .. .. ~e I I I I I IQ I I l I I I0 2.0 -- -- -- ~-----------~---- 1 I ------ - ~--- I --- - - ---- - --~--- I - ---- - - -:----- I -- ---- ~ II : : : : :1.8 .. • • •"' •• I .......... • • • • • -:· • • • •••-•-• ~ -- ---- • • •• • • • • · :- • • • • • • • • • • · : · • • • • • • •-•- ~1 I I I I I1 I I I I I1.6 - ...... .. .... ~- .. --...... ...... ~ - .... - ............ .. ~-- .. - .. - .... ........ .... -:- .... -- .......... - -:---------- -~I : : : : :1.4 • • • • • • .. ~- • • • • • • • • •• -:•• I I I1.20 '0 '0 '0 00 '0 '1 .0.l:-----~:~_--:! : -::------::!.:-:-----=----=~:::====--:::30 50 1 00 200 500 1 000 2000Viscosity coefficient Z15

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESPRESSURE / TEMPERATURE RATING PER ASME 816.34SERVICE A105(2) A350-LF3{3) A182-F5A182-F316A182-F9TERMPERATURE A350-LF2(3) A352-LC2(3) A 182-F11 (4) A 182-F22(4) A182-F5aA351-CF3M(7)A217-C12(DEGREES) A216-WCB(2) A352-LC3{3) A217-WC9(S) A217-WC9(s) A217-C5 A351-CFBMF c psig Mpa psig Mpa psig Mpa psig Mpa psig Mpa psig Mpa psig Mpa-20 to 100 -20to38 1975 13.62 200) 13.79 200) 13.79 200) 13.79 200) 13.79 200) 13.79 1920 13.24200 93.5 1800 12.41 200) 13.79 J!m 13.10 1910 13.17 200) 13.79 200) 13.79 1655 11.41300 149 1750 12.07 1940 13.38 1795 12.38 1805 1245 1940 13.38 1940 13.38 1495 10.31400 204.5 1600 11.65 1880 12.96 1755 12.10 1730 11.93 1880 12.96 1880 12.96 1370 9.45500 260 1595 11.00 1775 12.24 1710 11.79 1705 11.76 1775 12.24 1775 12.24 1275 8.79600 315.5 1460 10.07 1615 11.14 1615 11.14 1615 11.14 1615 11.14 1615 11.14 1205 8.31650 343.5 1430 9.86 1570 10.82 1570 10.82 1570 10.82 1570 10.82 1570 10.82 1185 8.17700 371 1420 9.76 1515 10.45 1515 10.45 1515 10.45 1515 10.45 1150 7.93750 399 1345 9.27 1420 9.79 1420 9.79 1420 9.79 1420 9.79 1130 7.79800 426.5 1100 7.58 1355 9.34 1335 9.34 1325 9.14 1355 9.34 1105 7.62850 454.5 715 4.93 1300 8.96 1300 8.96 1170 8.07 1300 8.96 I~ 7.45900 482 460 3.17 1200 8.27 1200 8.27 940 6.48 1200 8.27 1050 7.24950 510 274 J.'XJ 1005 6.93 1005 6.93 fB5 4.79 985 6.79 1030 7.101000 538 140 0.96 595 4.10 715 4.93 510 352 780 5.38 970 6.1'B1050 565.5 365 252 530 3.65 375 259 505 3.48 960 6.621100 593.5 255 1.76 300 207 275 J.'XJ 300 2.07 860 5.931150 621 140 0.96 275 J.'XJ 185 1.28 200 1.38 735 5.071200 649 95 0.65 145 1.00 120 0.83 140 0.97 550 3.791250 676.5 485 3.342) Pennissible bUt not recommended for prolonged use above about 800F.1300 704.5 3) Not to be used over 6SOF(345C). 365 2521350 732 4) Pennissible but not recommended for prolonged use above about 1100F(595C). 275 J.'XJ1400 460 5) Not to be used over 1100F (595C). 200 1.381450 488 6) Not to be used over SOOF (425C). 155 1.071500 815.5 7) Not to be used over 850F (455C). 110 0.76Note: All other Sman Forged Steel Valves 1/4- - Z' (except Gate Valves to API602 and 606) have Pressure-Temperature ratilgs to 8-16.34STANDARD MATERIALS TO ASME 816.34TEMP.WORKING PRESSURE IN pslg BY CLASSES'F 150 300 : 600 900 1500 2500 4500100 285 740 1480 2220 3705 61 'X) 11110200 200 675 1350 2025 3375 5625 10120........... ~.Q!! ..........................?:W.............;............. ~~ .............:............ nu ............;............ .t.m ............:............ mQ ............;............ ~~ ............,............ ~~ ............400 200 : 635 : 12'Xl ; 1900 : 3170 : 5280 9505500 170 : 600 1200 : 1795 : 2995 : 49C.Xl 8980600 140 : 550 .··..·....·'650· ..·..·....· ........·..·· m· ........·..· ~-· ..·..· .... s:ir ........· 1005 : 1640 : 2735 : 4560 . 8210·:·........·..·iitir......·..·l"·..· ....··iii'io·....·......;....·..·..· 2685 ....·..·..·· t ··..·....· 4475 ..··..··....:·..·......·· 8655 ·..·..· ·...700 110 : 535 : !

OOO•• • ••••• J.OO00 000 00 00 0 003536'0'5886""0""io585""0...ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESWORKING PRESSURE IN psig BY CLASSES'F 150 300 600 900 1500 2500 4500100 290 750 1500 2250 3750 6250 11250200 '}ffJ 715 1430 2150 3580 5%5 10740ooO oooooooom. oooooooo oOO o oOOOOOOOOOO OO~O OOOOOOoO OOo O'O OOooOO O O oo~?~OOO OOOHOOOOO,OOOOOooo ,, .1)~~ oo ooo•oOOOOO ooo oo ,,,'1!)7!./,,,,,,,, 3385 : 5640 ooOoOo oo ooo ooo OoOoo 10105~ D ' ~ ' ~ 00 ······~ ···· · ······r······· ~ ··~··· · ···· · ··500 rn ~ ' ~ . ~ m ~ . ~.... H ... 600 ... H ................ ..... Hl! ............. t ............ @. ............. l ............ m() .. ..... .. L ........... J8.J~ ............. l ....... ... ms ............ t .......... .. W ........... .. t ........... 9.w.OH ..........650 125 : 590 : 1175 : 1765 : 2940 : 4905 : 8825700 110 570 ~ 1135 : 1705 2840 4730 8515.......... ~ ......................... ~ ............. l ............ m ............ l ........... ~ ........... i ............ ~ ........... l ........... ~ ........... l ........... g .......... l ........... ~ ....... ...800 80 : 510 : 1015 : 1525 : 2540 : 4230 : 7610850 65 : 485 : 975 . 1461 : 2435 : 400) ~ 7305........... $.®. ........................... ~ ............. 1. ........... 4.~ ............ i. ............ 9W ............;......... .. ..l.~~......... ...;........... J245 ...........,..... .. ~7~~ ... ......... !............ ~749.950 35 : 380 755 1130 1885 3145 . 56601000 20 . 270 535 805 1340 2230 4010ooooooHoolOSU .... ,,.,.,. , " ' "'"H""' ~ '"""'"" ' 'L ' D ""'" '"'"' " 400 'H"'' "' ' ''' ' "'"'""' ~~L .. , ,.,.,.; .. H""""'99? ...... , .. ,,. ,; .... ,. , ..... .l.@. .. ..... .... ; .... ,,, .. , .. ~ .. , .. H•OO OO1100 20 115 225 . 340 : 565 ~ 945 ~ 17001150 105 205 3IO 515 sro 15451200 55 110 165 275 461 825Safe use to 11 OO"FWORKING PRESSURE IN psig BY CLASSES'F 150 300 600 900 1500 2500 4500100 290 750 1500 2250 3750 6250 11250200 '}ffJ 750 1500 2250 3750 6250 11250300 230 . ~ . ~ . ~ . - . ~ : ~........... 400 .......................... i00 ............,............ 705 ............ ~ ............. i4'i6'""'" ' ' "~··"·""''' 2i'i5'''''"''''''' " ''''"''' 353() '"'''"'''~"'"'""' '588(i'' '' "' ' ""'"' ' "'''"'i0585 '''"'''"'500 170 . 665 : 1330 : 1995 . 3325 . 5540 . 9965........... ®.P .......................... J .W............. i ............. ®? .............:............ .I.~W............:............ .I.~J.~............ i ............ ~ ............:.. .......... ~ ............ L ........... m9 ............650 125 : 590 ~ 1175 : 1765 : 2940 : 4905 : 8825700 110 . 570 : 1135 1705 2840 ~ 4730 8518...... ..... 750 ............. ............. . 95 ......... .... 1.. ........ .. s30 ......... ... i ............t065............:............ .t59.5............).......... . m ..... .. ..... i .... ...... M3.0 ........ ....)............ 7.97.0 ............800 80 ' 500 · m ' ~ · • : ~ : ~850 65 440 880 . 1315 : 2195 . 3660 : 6585........... 9011 ........................... 50 ............. ~ ............. 3.55 .............).............705.............;............ 1060 ............;............ nns .. ..........;.. ......... ms ............;............ 5300 ............950 35 : '}ffJ . 520 ~ 780 : 1305 ~ 2170 : 39101000 20 . 190 . 385 ~ 575 ' 9ro : Ifill 2880..........1050........................ ~JL ......... l .......... .. l40 ............. L ........... ~ ............. i ............ A20 ............. i. ........... .705............. i. ........... U7.0 ... ......... i. ... ........ W.O ............1100 20(1) ~ 105 · 205 ~ 3IO · 515 : sro : 15451150 20(1) : 70 140 : 205 345 570 . 1030,1200 20(1) 45 90 135 225 370 670Note: (!)For Welding end Valves only, Flanged end ratings terminate at IOOO"FTEMP.WORKING PRESSURE IN psig BY CLASSES'F 150 300 600 900 1500 2500 4500100 290 750 1500 2250 3750 6250 11250200 '}ffJ 750 1500 2250 3750 6250 11250300 230 .H ,.730 : 145500 000'"765" OO OOOOOO ..,.. ... Hi4'i6: 2185 :00° ..... , . OOO OO 2i'i5' OO H OO OOO ~-- : (IJIO . 1092500OO OO OO OO OO ,.. OOOOOO.. oOO ~ O '"400' OOOO OOO OOOOO OOO .... OO OOO '2.00 OOO OO OOO O........ , ....0000500 rn . 665 ~ · ~ ' ~ ~ 9965.W............. l .... ....... ®? ............. i. .......... ..l.~J.Q...........:............ .1.~.1.~............ ~ ........... ~ ......................... ~ ............!............ Cf.f!.Q .. ............. ~ ........................... I .650 125 : 590 : 1175 : 1765 ~ 2940 ~ 4905 ~ 8825700 110 570 ~ 1135 1705 . 2840 : 4~ ~ 8515.......... ~ ......................... ~ ............. l ........... ~ ............ l ..... .... ~ ...........:............ ~ .... ~ ~ ~ ~ ~ ~800 80 : 510 : 1015 . 1525 ...... ~ ............ 2540 ............ ~ ............ 4236""" ..... ~ ............ 76'16""""""850 65 · 485 ~ m ~ u ' 400l ~............ ~ ............. L ........... U~ ............ J ....... .... ~~ ............ L .......... ~?~~ .. ....... ~749 ....................... 9.00 ........................... ~ ............. ). .... ~~ .. H950 35 . 370 : 740 . 1110 . 1850 . 3085 55551000 25 290 ~ 585 875 1560 2430 4370.......... ~-~~ ·····................... ~:} ...........;.............}~ ··..........;............. ~ ............;....... ..... ~ ............;...... ... .. ~ ............;.............'JI§..·· .. ~ ... .... .. ~~ ...........1150 20(1) 75 150 225 380 630 11301200 20(1) 50 105 155 '}ffJ 430 770Note: (I)For Welding end Valves onlY. Flanged end ratings terminate at tOOO"F17

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESTEMP.WORKING PRESSURE IN psig BY CLASSES'F 150 300 600 900 1500 2500 4500100 Z75 7lfJ 1440 2160 3IDl ............:............:i

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESSPECIFICATION OF FORGED VALVE MATERIALSBODY & BONNET, GLAND FLANGE, WEDGE-DISC-SEAT (FORGED VALVES)DESCRITIONASTMDESIGNATIONCARBON STEEL2) 2)A 105N A350 -LF21·1/4 Cr·112Mo jA182- F11ALLOY STEEL2·1/4 Cr-1 Mo : 5%CrA182 A182-F22 -F59%CrA182-F9A182-F316STAINLESS STEEL316A182-F316l' Carbon 0.35 max. . 0.35max. .. ..... ~·I .. ~~o ....... : ..... ~·.IS.!n.ax: ..... : ........ ....... _O,I~ _nJ .......:........:........: ........;..... ••:................:........;........ ~ ..... ··'·· ......: •• ......;........: ........ .......:........ ••HeatTreat. Anneal ' QJench ..................... ~ ......................;.......:............... J:Il: ..... : .... ~~Iut i()~-~al ....... L ................ ..!\~.~~.. ................... teiisiie.iisiiii ii: ............ 7o.irii .... 1'65:00>·:.... 1o.fJXJ- ~ 90.cro- ~ 1o,fJXJ- , ss.fJXJ 90,fJXJ- , 1o.fJXJ , 1o.fJXJ , 75,(JJJ 11o.cro 130,(JJJ. . : . ~ ~................. ........ ... .... .. ......... ..!........ ~~~ ....... 9.!J.(X_XJL ..... 1 .I~iX:U. :........ ~.(X_XJ_( ....................... 1 1 _5~~.:................;.................:................................. .................~~· ~ : ~ ~ ~ ~ ~ ~ : ~ ~ ~ : ~ : ~ ~..· ei9ri9: ·•i~·.niii:· ..·..·..· · ·..· 22 · ·..· r ·..·24· · · · ····..·iii·······:····..·1s· · ..··:·..·..·iii....·.. ~· ....· iii ..·..·· ..·.. ·~·s· ..· ..:· ·..·':io· · · r .... · 3ii · · ·:·..· ··25·..·..·· ....· ..· ·..·· ..·.. i% · · ..:::~ : :~~~:~~ :~:~~ : ::::::::::: ::::::~s. ::::::r:::::: J.s::::::: :::::::~~ :::::::t::::::J.s: :::: : :: : :: :: ::Jr:::::;:: : ::: ~ :::::: ::::::: 3iJ: :::::I::::::>:::::::r:::::::~::::::::r::::::~::::::: :::::::::::::::: :::: ::::::::::::Hardness HB ... 1&:7_1113J(: .. :_. _ l~_ lll3X: ..... _2(}7 _~ :... l .. ~ I? ·~ ·... j ... 2(}7.•113X: ...:.} 1?.1113J(: .... }2:1. :.~ l .. j ........ ~ ....... l. .._I&:7_1T13J(·... L .. ~~-lll:ax: ... .. ~ -~:...._39.!> :.4~ 1_ ..... Piirtii........................ BODIFS-BONNEJ'S-LARGEDISCS DISC ' BODIFS-BONNEI'S DISCS DISC lll'-2" DISCI!l'-2"619

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESTHREADS· ASME 81.20.1L2------,I-- L1~Aush by HandTolerance on ProductIL2,>-,'---

ILSHIN FORGED STEEL VALVESHIGH PRESSURE VALVESF"g 1 ur e NoCLASSTYPEMATERIALII8 A 05 A 15 sII~ ENOSAPI TRIM NO.C on t ro IN 0PORT & BONNETCLASS TYPE MATERIAL8 800# A GATE 05 A105N1 150# B GLOBE F2 LF23 300# c Y·GLOBE 11 F116 600# 0 STOP CHECK 22 F22E PISTON CHECK F5 F59 900#F SWING CHECK 51 F5115 1500# F9 F9G BALL CHECK16 1690# 91 F91H Y·PISTON CHECK25 2500#04 F304(LIH)J PLUG26 2680# 16 F316(LIH)K BELLOWS GATE17 F317(L)45 4500#L BELLOWS GLOBE 21 F321 (H)M BELLOWS Y·GLOBE 47 F347(H)N BALL VALVE MN MONEL0 ANGLE HS HASTELLOYIC INCONELAL ALLOY20OT OTHERSPor·t & Bonnet API Trim NO. EndsA Reduced Port Bolted Bonnet 5 13 CrHF s swB Reduced Port Welded Bonnet 8 13 Cr N NPTc Reduced Port Extended Bonnet 9 Monel X SWXNPT0 Full Port Bolted Bonnet 11 Monel· HF B B.WE Full Port Welded Bonnet 15 304 SSHF F FlangeF Full Port Extended Bonnet 16 316 SSHF17 347 SSHFG Reduced Port Pressure Seals Special AlloyH Full Port Pressure Seal