Design of Deep Underground stations in soft soil ... - Royal Haskoning

Design of Deep Underground stations in soft soil ... - Royal Haskoning

Design of Deep Underground stations in soft soil ... - Royal Haskoning

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Design</strong> <strong>of</strong> <strong>Deep</strong> <strong>Underground</strong> <strong>stations</strong> <strong>in</strong> s<strong>of</strong>t <strong>soil</strong> conditions<br />

J. Herbschleb 1 , J.C.W.M. de Wit 2<br />

ABSTRACT<br />

The municipality <strong>of</strong> Amsterdam wish to<br />

reduce the level <strong>of</strong> car traffic with<strong>in</strong> the<br />

City Centre. As a consequence the public<br />

transport is to be extended by a new<br />

North/South Metro l<strong>in</strong>e. This paper will<br />

focus on the design philosophy <strong>of</strong> the deep<br />

station boxes. The excavations depths for<br />

the <strong>stations</strong> will exceed 30m and will be<br />

constructed <strong>in</strong> difficult s<strong>of</strong>t <strong>soil</strong> conditions.<br />

A further significant aspect is that the<br />

build<strong>in</strong>g pits are very near (3 to 5 m) to<br />

build<strong>in</strong>gs <strong>of</strong> historical importance. This is<br />

illustrated by the follow<strong>in</strong>g topics that are<br />

<strong>in</strong>vestigated.<br />

• Geology/Geotechnics<br />

• Structural design station box<br />

• Requirements/Impact surround<strong>in</strong>gs<br />

• FE-Modell<strong>in</strong>g<br />

• Additional test project diaphragm walls<br />

• Monitor<strong>in</strong>g dur<strong>in</strong>g construction<br />

INTRODUCTION<br />

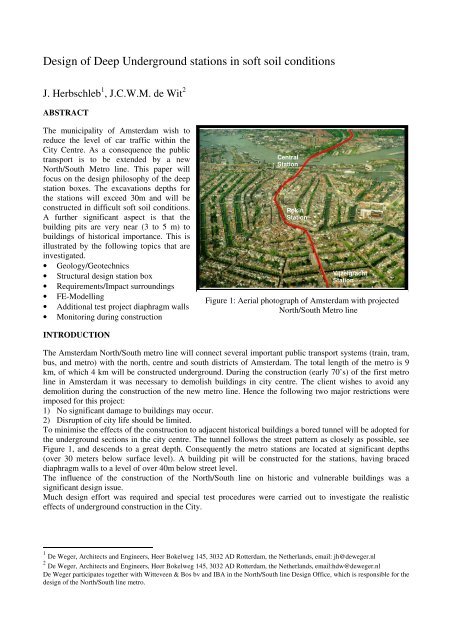

Central<br />

Station<br />

Rok<strong>in</strong><br />

Station<br />

Vijzelgracht<br />

Station<br />

Figure 1: Aerial photograph <strong>of</strong> Amsterdam with projected<br />

North/South Metro l<strong>in</strong>e<br />

The Amsterdam North/South metro l<strong>in</strong>e will connect several important public transport systems (tra<strong>in</strong>, tram,<br />

bus, and metro) with the north, centre and south districts <strong>of</strong> Amsterdam. The total length <strong>of</strong> the metro is 9<br />

km, <strong>of</strong> which 4 km will be constructed underground. Dur<strong>in</strong>g the construction (early 70’s) <strong>of</strong> the first metro<br />

l<strong>in</strong>e <strong>in</strong> Amsterdam it was necessary to demolish build<strong>in</strong>gs <strong>in</strong> city centre. The client wishes to avoid any<br />

demolition dur<strong>in</strong>g the construction <strong>of</strong> the new metro l<strong>in</strong>e. Hence the follow<strong>in</strong>g two major restrictions were<br />

imposed for this project:<br />

1) No significant damage to build<strong>in</strong>gs may occur.<br />

2) Disruption <strong>of</strong> city life should be limited.<br />

To m<strong>in</strong>imise the effects <strong>of</strong> the construction to adjacent historical build<strong>in</strong>gs a bored tunnel will be adopted for<br />

the underground sections <strong>in</strong> the city centre. The tunnel follows the street pattern as closely as possible, see<br />

Figure 1, and descends to a great depth. Consequently the metro <strong>stations</strong> are located at significant depths<br />

(over 30 meters below surface level). A build<strong>in</strong>g pit will be constructed for the <strong>stations</strong>, hav<strong>in</strong>g braced<br />

diaphragm walls to a level <strong>of</strong> over 40m below street level.<br />

The <strong>in</strong>fluence <strong>of</strong> the construction <strong>of</strong> the North/South l<strong>in</strong>e on historic and vulnerable build<strong>in</strong>gs was a<br />

significant design issue.<br />

Much design effort was required and special test procedures were carried out to <strong>in</strong>vestigate the realistic<br />

effects <strong>of</strong> underground construction <strong>in</strong> the City.<br />

1 De Weger, Architects and Eng<strong>in</strong>eers, Heer Bokelweg 145, 3032 AD Rotterdam, the Netherlands, email: jh@deweger.nl<br />

2 De Weger, Architects and Eng<strong>in</strong>eers, Heer Bokelweg 145, 3032 AD Rotterdam, the Netherlands, email:hdw@deweger.nl<br />

De Weger participates together with Witteveen & Bos bv and IBA <strong>in</strong> the North/South l<strong>in</strong>e <strong>Design</strong> Office, which is responsible for the<br />

design <strong>of</strong> the North/South l<strong>in</strong>e metro.

GEOLOGY<br />

The subsurface <strong>of</strong> Amsterdam is<br />

composed <strong>of</strong> sediments, up to depths<br />

vary<strong>in</strong>g between 800 to 1000 meters<br />

below ground level. The sediments<br />

(sands, silts, clays and peat) have<br />

orig<strong>in</strong>ated from mar<strong>in</strong>e-, glacial-,<br />

eolian- and river deposits. In the<br />

upper 350 meters <strong>of</strong> sediments two<br />

ma<strong>in</strong> geological important units are<br />

dist<strong>in</strong>guished, namely Holocene<br />

(10.000 years - present) and<br />

Pleistocene (10.000 - 2.5 million<br />

before present) deposits, see Figure 2<br />

for a general lithological pr<strong>of</strong>ile <strong>of</strong><br />

Amsterdam.<br />

The oldest and deepest Pleistocene<br />

deposits are mar<strong>in</strong>e clays and f<strong>in</strong>e- Figure 2: Geological cross section <strong>of</strong> Amsterdam<br />

gra<strong>in</strong>ed sands, which extend to a level<br />

<strong>of</strong> 250- 350 meter below groundlevel<br />

With the second last (Saalien) ice age sediments were deposited on top <strong>of</strong> these river deposits. The ice cap<br />

came near to the South <strong>of</strong> Amsterdam and created the Amsterdam Bas<strong>in</strong>. Dur<strong>in</strong>g this period ma<strong>in</strong>ly glacial<br />

and melt water deposits were formed with<strong>in</strong> the bas<strong>in</strong>. After melt<strong>in</strong>g <strong>of</strong> the ice cap the Amsterdam Bas<strong>in</strong> was<br />

flooded with the sea and partially filled with mar<strong>in</strong>e sands and clays (Eemclay). Dur<strong>in</strong>g the last ice age<br />

(100.000 - 10.000 years ago), the ice cap did not extend to the south <strong>of</strong> Amsterdam. In that period the<br />

Netherlands experienced a tundra climate. The Amsterdam Bas<strong>in</strong> was filled with ma<strong>in</strong>ly sand. These sand<br />

layers are very important to foundation practice <strong>in</strong> Amsterdam and marks also the end <strong>of</strong> the Pleistocene.<br />

Holocene deposits (ma<strong>in</strong>ly peats and clays) were ma<strong>in</strong>ly formed under the <strong>in</strong>fluence <strong>of</strong> the sea. The ris<strong>in</strong>g<br />

sea (0.5m per century) reached the present location <strong>of</strong> Amsterdam 7000 year ago. A transgression started due<br />

to lower<strong>in</strong>g <strong>of</strong> the sea level, 5000 years ago. Dur<strong>in</strong>g the Holocene a river connection existed to the sea. This<br />

river produced erosion channels <strong>in</strong> the Pleistocene sand deposits. In these channels, sometimes with widths<br />

over 100m, th<strong>in</strong> sand and (s<strong>of</strong>t) clay layers were deposited.<br />

SITE INVESTIGATION<br />

Along the route <strong>of</strong> the North/South l<strong>in</strong>e a comprehensive <strong>soil</strong> <strong>in</strong>vestigation has been made. This <strong>soil</strong><br />

<strong>in</strong>vestigation consisted <strong>of</strong> a total <strong>of</strong> 125 boreholes and about 400 CPT’s each up to depths <strong>of</strong> 70 meters. As<br />

well as these bor<strong>in</strong>gs and CPT’s, special tests like Cone Pressure Meters (CPM) were also carried out.<br />

In the laboratory the samples <strong>of</strong> the bor<strong>in</strong>gs were classified and tested. The laboratory tests were used ma<strong>in</strong>ly<br />

to determ<strong>in</strong>e the strength and stiffness parameters <strong>of</strong> the <strong>soil</strong>s, specially the Pleistocene Mar<strong>in</strong>e Eemclay. The<br />

reason to concentrate the site <strong>in</strong>vestigation to the Eemclay is that very little geotechnical <strong>in</strong>formation was<br />

available for this layer prior to the North/South l<strong>in</strong>e project. Also this will be the first time a construction<br />

(both the bored tunnel and the deep build<strong>in</strong>g pits for the <strong>stations</strong>) is made <strong>in</strong> this clay.<br />

Table 1: Global overview <strong>of</strong> laboratory tests<br />

Soil layer Classification Sieve analysis Atterberg Triaxial Oedometer<br />

limits tests test<br />

Holocene 405 35 45 50 19<br />

Pleistocene Sand 260 80 38<br />

Pleistocene Eemclay 360 170 170 96 135<br />

Other layers 685 265 165 49 37<br />

Total 1710 550 380 233 191

GEOTECHNICAL DESIGN<br />

Geotechnical pr<strong>of</strong>ile<br />

The geotechnical data (CPT’s, boreholes) are each<br />

<strong>in</strong>terpreted to obta<strong>in</strong> a <strong>soil</strong> pr<strong>of</strong>ile. Instead <strong>of</strong> draw<strong>in</strong>g<br />

one geotechnical pr<strong>of</strong>ile along the centrel<strong>in</strong>e <strong>of</strong> the<br />

alignement <strong>of</strong> the tunnel it was decided to use a GIS.<br />

With the aid <strong>of</strong> a GIS a 3D block model, see Figure<br />

3, is constructed. The advantages <strong>of</strong> the 3D GIS<br />

block model are:<br />

1) A geotechnical pr<strong>of</strong>ile can be created <strong>in</strong> each<br />

direction and location.<br />

2) Updat<strong>in</strong>g the pr<strong>of</strong>ile is fast and easy when<br />

additional data becomes available.<br />

3) The ability to calculate the volumes <strong>of</strong> excavated<br />

<strong>soil</strong>s with a dist<strong>in</strong>ction <strong>in</strong> sands, clays, etc.<br />

The ma<strong>in</strong> disadvantage is that subjective<br />

<strong>in</strong>formation, such as possible filled-<strong>in</strong> channels, are<br />

more difficult to take <strong>in</strong>to consideration. The f<strong>in</strong>al<br />

geotechnical pr<strong>of</strong>iles are therefore corrected and<br />

adapted by hand.<br />

Geotechnical parameters<br />

The determ<strong>in</strong>ation <strong>of</strong> geotechnical parameters can<br />

not be seen apart from boundary conditions like:<br />

1) Calculations models<br />

2) Required safety<br />

Figure 3: Automatic Generation <strong>of</strong> pr<strong>of</strong>ile<br />

The calculation models and design <strong>of</strong> the build<strong>in</strong>g pit<br />

determ<strong>in</strong>e the type <strong>of</strong> geotechnical parameters.<br />

Advanced f<strong>in</strong>ite element programs with second order material models require different geotechnical<br />

parameters than analytical models. The careful selection <strong>of</strong> calculation (<strong>soil</strong>) models, the level <strong>of</strong> safety (risk<br />

analysis) and site <strong>in</strong>vestigation is the start <strong>of</strong> the determ<strong>in</strong>ation <strong>of</strong> the geotechnical parameters. In this project<br />

some <strong>of</strong> the important geotechnical parameters can be derived <strong>in</strong> several ways. In Table 2 a global overview<br />

is given <strong>of</strong> the applied <strong>in</strong>vestigation methods and the connection to some geotechnical parameters.<br />

Table 2: Global overview <strong>of</strong> Geotechnical parameters<br />

Investigation Type Phi E’50 Eoed E’ur<br />

Atterberg limits Laboratory C C<br />

Triaxial test (load<strong>in</strong>g) Laboratory X X<br />

Traixial test (unload<strong>in</strong>g) Laboratory X<br />

CPT In-situ C C C<br />

CPM In-situ X X<br />

Oedometer test Laboratory X X<br />

Void ratio Laboratory C C<br />

C Correlation<br />

X Direct measurement<br />

By careful selection <strong>of</strong> the samples and the characterisation it was possible to dist<strong>in</strong>guish a set <strong>of</strong> geological<br />

layers. When study<strong>in</strong>g these parameters further it was concluded that the variations found <strong>in</strong> the values <strong>of</strong> the<br />

stiffness parameters were not only caused by the different test methods (laboratory, <strong>in</strong>-situ), stress path, etc.<br />

But ma<strong>in</strong>ly due to differences <strong>in</strong> the stra<strong>in</strong> levels <strong>of</strong> the tests. With an <strong>in</strong>-situ test (CPM) low (10 -4 ) stra<strong>in</strong><br />

levels are <strong>in</strong>troduced <strong>in</strong> the <strong>soil</strong>, the result<strong>in</strong>g E’ur is therefore much higher than <strong>in</strong> an Oedometer test where<br />

high (10 -1 ) stra<strong>in</strong> levels are <strong>in</strong>troduced to the <strong>soil</strong> samples. This has led to the conclusion that when<br />

determ<strong>in</strong><strong>in</strong>g the design values <strong>of</strong> the geotechnical parameters it is necessary to derive the stiffness values <strong>in</strong><br />

the range <strong>of</strong> the expected stra<strong>in</strong> level. With careful <strong>in</strong>terpretation <strong>of</strong> all tests eventually a geotechnical<br />

parameter set that meets the above mentioned requirements was derived.

DESIGN PHILOSOPHY<br />

The design philosophy <strong>of</strong> the station boxes was to determ<strong>in</strong>e an acceptable balance between the safety<br />

requirements and construction costs. The guidel<strong>in</strong>es for the design, both for the build<strong>in</strong>g pits and the bored<br />

tunnel, are the predicted deformations <strong>of</strong> the adjacent build<strong>in</strong>g foundations. The deformations depend on the<br />

follow<strong>in</strong>g:<br />

a. Geotechnical behaviour (parameters)<br />

b. Calculation models (F<strong>in</strong>ite Element or Analytical)<br />

c. Construction design<br />

Knowledge <strong>of</strong> the optimal geotechnical parameters allows the <strong>soil</strong> behaviour to be determ<strong>in</strong>ed. However<br />

because it is not possible to derive the geotechnical parameters exactly from laboratory-or <strong>in</strong>-situ tests, a<br />

certa<strong>in</strong> safety marg<strong>in</strong> is <strong>in</strong>troduced. The larger the safety marg<strong>in</strong> the more secure but also the more costly. To<br />

calculate the deformations mathematical <strong>soil</strong> models are used. By us<strong>in</strong>g the latest validated FE models and<br />

technology the most accurate predictions <strong>of</strong> the deformations can be assessed. Apart from the geotechnical<br />

behaviour, the deformations depend also on the design <strong>of</strong> the build<strong>in</strong>g pit.<br />

The ma<strong>in</strong> objective is not to cause any significant damage to the adjacent build<strong>in</strong>gs, the criteria (allowable<br />

deformations <strong>of</strong> ground level and foundations) are assessed a conservative manner. In Figure 7 all the<br />

<strong>in</strong>volved elements are illustrated <strong>in</strong>clud<strong>in</strong>g their <strong>in</strong>teractions.<br />

UNDERGROUND STATIONS<br />

Four underground <strong>stations</strong> will be built <strong>in</strong><br />

the city centre <strong>of</strong> Amsterdam as a part <strong>of</strong><br />

the North/South l<strong>in</strong>e metro. For the<br />

construction <strong>of</strong> the underground <strong>stations</strong>,<br />

a build<strong>in</strong>g pit will be constructed hav<strong>in</strong>g<br />

1.2m thick braced diaphragm walls.<br />

These walls reach down to approx. NAP -<br />

35 m/ -40 m, see figure 4. The m<strong>in</strong>imum<br />

distance between the build<strong>in</strong>g pit and the<br />

historical build<strong>in</strong>gs is about 3 m. The<br />

build<strong>in</strong>g pit will be excavated <strong>in</strong> the dry<br />

after the water level <strong>in</strong>side the pit has<br />

been lowered. This can be done without<br />

<strong>in</strong>fluenc<strong>in</strong>g the water level outside the pit<br />

because the build<strong>in</strong>g pit walls cont<strong>in</strong>ue<br />

down <strong>in</strong>to the seal<strong>in</strong>g Eemclay at a depth<br />

<strong>of</strong> 20-25m. The excavation depth varies<br />

per station and will be between 26-32m<br />

below street level. With a dry excavation<br />

the vertical equilibrium <strong>of</strong> the build<strong>in</strong>g-<br />

pit base must be considered. For the<br />

deepest build<strong>in</strong>g pits safety aga<strong>in</strong>st<br />

vertical equilibrium cannot be achieved<br />

by the weight <strong>of</strong> the seal<strong>in</strong>g ground<br />

stratum (Eemclay) alone. Additional<br />

measurements are to be taken by<br />

excavat<strong>in</strong>g the deep part <strong>of</strong> the build<strong>in</strong>g<br />

pit under compressed air conditions.<br />

When the build<strong>in</strong>g pit is excavated the<br />

concrete structure can be built. The<br />

re<strong>in</strong>forced concrete diaphragm wall, which<br />

Depth [NAP + m]<br />

0<br />

-10<br />

-20<br />

-30<br />

3.0 to 9.0 m 24.5 m<br />

3.0 to 9.0 m<br />

Plaxis 2D<br />

predictions<br />

-40<br />

-40 -20 0<br />

Horizontal deformation [mm]<br />

Excavation NAP -10.0m<br />

Excavation NAP -15.0m<br />

Excavation NAP -25.3m<br />

Groutstrut<br />

Figure 4: <strong>Design</strong> Rok<strong>in</strong> Station<br />

-60<br />

0 10 20<br />

qc [MPa]<br />

30<br />

is orig<strong>in</strong>ally the reta<strong>in</strong><strong>in</strong>g wall, will be <strong>in</strong>tegrated <strong>in</strong> the permanent body. This was so decided because a<br />

composite structure <strong>of</strong> the diaphragm wall and a cast-<strong>in</strong>-situ <strong>in</strong>ner wall results <strong>in</strong> the m<strong>in</strong>imum depth <strong>of</strong> the wall<br />

structure and therefore a maximum distance between the build<strong>in</strong>g pit and the adjacent build<strong>in</strong>gs.<br />

0<br />

-10<br />

-20<br />

-30<br />

-40<br />

-50<br />

Depth [NAP + m]

INFLUENCE ON THE SURROUNDINGS<br />

In consider<strong>in</strong>g the environmental impact <strong>of</strong> construct<strong>in</strong>g these <strong>stations</strong> the follow<strong>in</strong>g elements require closer<br />

exam<strong>in</strong>ation:<br />

1. Excavation <strong>of</strong> diaphragm wall trench, which <strong>in</strong>troduces a 3D stress stra<strong>in</strong> behaviour <strong>in</strong> the <strong>soil</strong> layers.<br />

2. The self weight <strong>of</strong> the wall and the applied deck which can cause settlement <strong>of</strong> the wall.<br />

3. Excavation <strong>of</strong> the build<strong>in</strong>g pit which causes horizontal deformation <strong>of</strong> the diaphragm wall and a<br />

relaxation <strong>of</strong> the Pleistocene Eemclay which forms the bottom <strong>of</strong> the build<strong>in</strong>g pits.<br />

Some <strong>of</strong> the described mechanisms can cause settlements <strong>of</strong> nearby pile foundations, others may result <strong>in</strong><br />

heave. Also the deformation behaviour <strong>of</strong> the <strong>soil</strong> layers (clay) is time dependent due to consolidation and<br />

creep effects. This means that the f<strong>in</strong>al situation is not necessarily the critical situation, and that the entire<br />

construction process should be taken <strong>in</strong>to account. To obta<strong>in</strong> a complete picture <strong>of</strong> deformations ,it is<br />

necessary to use a FEM program, <strong>in</strong> which the full construction sequence is considered.<br />

Settlement risk assessment studies were carried out to predict the risk and degree <strong>of</strong> settlement <strong>in</strong>duced<br />

damage to adjacent structures. The specific surround<strong>in</strong>g conditions <strong>of</strong> the Amsterdam city centre necessitated<br />

the application <strong>of</strong> analytical and numerical studies to <strong>in</strong>vestigated this risk. The study results were used to<br />

def<strong>in</strong>e boundary conditions for the historical masonry build<strong>in</strong>gs and the requirements for the settlement<br />

<strong>in</strong>duc<strong>in</strong>g construction activities (Kaalberg et al).<br />

2D & 3D FE MODEL<br />

The vertical load<strong>in</strong>g <strong>of</strong> the diaphragm wall, as well as the excavation and unload<strong>in</strong>g <strong>of</strong> the Eemclay are<br />

analysed with a 2D FE model. The excavation <strong>of</strong> the diaphragm wall trench however is more complicated.<br />

This is due to 3D stress/stra<strong>in</strong> effects, therefore a 3D FE model is used. The 2D FE model is furthermore<br />

used to estimate the deformations, at ground- and foundation level, dur<strong>in</strong>g the several stages <strong>of</strong> the<br />

excavation <strong>of</strong> the deep build<strong>in</strong>g pits. Three FE s<strong>of</strong>tware programs were tested <strong>in</strong> order to select the one most<br />

suitable for the construction <strong>of</strong> the station box. Eventually Plaxis was selected ma<strong>in</strong>ly because <strong>of</strong> the<br />

extensive <strong>soil</strong> mode library. After research, both <strong>in</strong>ternally and by the University <strong>of</strong> Stuttgart, the Harden<strong>in</strong>g<br />

Soil model <strong>of</strong> Plaxis appeared to a most suitable model for very large (unload<strong>in</strong>g ) excavations <strong>in</strong> sand and<br />

clay.<br />

Harden<strong>in</strong>g Soil model<br />

The Harden<strong>in</strong>g-Soil model represents a much more advanced model than the Mohr-Coulomb model. In the<br />

Harden<strong>in</strong>g Soil model the limit<strong>in</strong>g states <strong>of</strong> stress are described by means <strong>of</strong> the friction angle, φ, the<br />

cohesion, c, and the dilatancy angle, ψ. The <strong>soil</strong> stiffness is described much more accurately by us<strong>in</strong>g three<br />

different <strong>in</strong>put stiffnesses: the triaxial load<strong>in</strong>g stiffness, E50, the triaxial unload<strong>in</strong>g stiffness, Eur, and the<br />

oedometer load<strong>in</strong>g stiffness, Eoed. In contrast to the Mohr-Coulomb model, the Harden<strong>in</strong>g-Soil model also<br />

accounts for stress-dependency <strong>of</strong> stiffness moduli. This means that all stiffnesses <strong>in</strong>crease with pressure.<br />

Build<strong>in</strong>g sequence<br />

The build<strong>in</strong>g sequence as implemented <strong>in</strong> the FE model<br />

is more or less as follows:<br />

1) Installation <strong>of</strong> diaphragm wall (stresses only)<br />

2) Installation <strong>of</strong> deck<br />

3) 6 excavation phases up to NAP -32m.<br />

a) lower water table <strong>in</strong>side pit<br />

b) dry excavation<br />

c) plac<strong>in</strong>g struts<br />

d) consolidation (2-4 months)<br />

4) Installation <strong>of</strong> concrete and structure<br />

Sometimes special build<strong>in</strong>g steps are <strong>in</strong>cluded to model<br />

excavation under air-pressure or the <strong>in</strong>stallation <strong>of</strong> groutstruts<br />

before excavation. Includ<strong>in</strong>g steps for numerical<br />

stability more than 100 calculation steps are used to<br />

model a s<strong>in</strong>gle excavation.<br />

harden<strong>in</strong>g<br />

shear locus<br />

cap with<br />

compression<br />

harden<strong>in</strong>g<br />

Figure 5: Plaxis Harden<strong>in</strong>g Soil model

FE MODEL VALIDATION<br />

The ma<strong>in</strong> objective <strong>of</strong> the FE calculations is to create a frame <strong>of</strong> reference for the expected deformations. For<br />

this reason a large amount <strong>of</strong> sensitivity calculations were made after which a set <strong>of</strong> new calculations was<br />

created. In this new set <strong>of</strong> calculations the <strong>soil</strong> parameters (lower, average and upper limit value) were varied<br />

such that special features like maximum horizontal bend<strong>in</strong>g <strong>of</strong> diaphragm wall could be calculated.<br />

The 3D FE model is validated with the results <strong>of</strong> a special test project. This test project was conducted to<br />

ga<strong>in</strong> more <strong>in</strong>sight <strong>in</strong> the deformations that occur dur<strong>in</strong>g <strong>in</strong>stallation <strong>of</strong> a diaphragm wall <strong>in</strong> Amsterdam <strong>soil</strong><br />

conditions.<br />

After validation <strong>of</strong> the 3D FE model the total deformations, <strong>in</strong>stallation <strong>of</strong> diaphragm wall (3D FE model)+<br />

excavation <strong>of</strong> build<strong>in</strong>g pit (2D FE model) are calculated.<br />

Diaphragm wall test<br />

The ma<strong>in</strong> objectives for the full-scale test on a construction site <strong>in</strong> Amsterdam are:<br />

• Expand<strong>in</strong>g the knowledge on this subject, so that design if necessary can be made <strong>in</strong> advance.<br />

• Validation <strong>of</strong> 3D- FE model based on the test results.<br />

• Ga<strong>in</strong>ed <strong>in</strong>sight <strong>in</strong> the specific execution aspects <strong>of</strong> diaphragm wall <strong>in</strong>stallation <strong>in</strong> Amsterdam <strong>soil</strong>.<br />

The test project <strong>of</strong> the diaphragm wall <strong>in</strong>stallation consists <strong>of</strong> three parts:<br />

1. Prediction <strong>of</strong> the impact with a 3D FE model<br />

2. Full scale test at a construction site <strong>in</strong> Amsterdam<br />

a. Measurement <strong>of</strong> vertical and<br />

horizontal deformations <strong>of</strong><br />

the <strong>soil</strong> adjacent to the<br />

excavated trench, see<br />

figure 6.<br />

b. Settlement <strong>of</strong> loaded piles<br />

c. Impact on bear<strong>in</strong>g capacity<br />

<strong>of</strong> piles, due to excavation<br />

and concret<strong>in</strong>g <strong>of</strong><br />

succeed<strong>in</strong>g diaphragm wall<br />

panels.<br />

3. Validation <strong>of</strong> 3D FE model based<br />

on the test results that have<br />

become available.<br />

At this moment the validation <strong>of</strong> the<br />

3D model is f<strong>in</strong>alised. Nevertheless<br />

the follow<strong>in</strong>g conclusions can be<br />

taken:<br />

• The test results show that the<br />

<strong>in</strong>stallation <strong>of</strong> a diaphragm wall<br />

on this project has a m<strong>in</strong>or effect<br />

on the surround<strong>in</strong>gs and no<br />

significant impact on the piles <strong>of</strong><br />

nearby foundations (de Wit, et<br />

al, 1999).<br />

• The prediction by means <strong>of</strong> a 3D<br />

FE model proved, apart from<br />

consolidation effects, to be able<br />

to predict the deformations<br />

caused by the succeed<strong>in</strong>g stages<br />

<strong>in</strong> the <strong>in</strong>stallation <strong>of</strong> the<br />

diaphragm wall. In general the<br />

FE predictions result <strong>in</strong> larger<br />

deformations than monitored at<br />

the test program.<br />

60 m<strong>in</strong>utes<br />

Horizontal Deformation Incl<strong>in</strong>ometer dur<strong>in</strong>g<br />

concret<strong>in</strong>g <strong>of</strong> diaphragm wall [mm]<br />

45 m<strong>in</strong>utes<br />

20 m<strong>in</strong>utes<br />

10 m<strong>in</strong>utes<br />

Figure: 6 Results <strong>of</strong> <strong>in</strong>cl<strong>in</strong>ometer measurements<br />

Depth [NAP +m]

MONITORING<br />

To anticipate ground movement and damage to build<strong>in</strong>gs dur<strong>in</strong>g construction and to enable timely and<br />

appropriate actions, an effective monitor<strong>in</strong>g concept has been designed. Build<strong>in</strong>gs will be monitored us<strong>in</strong>g a<br />

fully automatic system <strong>of</strong> total <strong>stations</strong> and sensors. This on-l<strong>in</strong>e system will provide direct data for<br />

<strong>in</strong>terpretation <strong>in</strong> the design <strong>of</strong>fice. A system <strong>of</strong> partly automatic and partly manual monitor<strong>in</strong>g will be carried<br />

out dur<strong>in</strong>g the construction activities for the <strong>stations</strong>:<br />

• vertical ground deformations on surface level (outside the pit) with precise levell<strong>in</strong>g po<strong>in</strong>ts and on<br />

deeper levels (<strong>in</strong>side and outside the pit) with extensometers;<br />

• horizontal ground deformations with <strong>in</strong>cl<strong>in</strong>ometers;<br />

• horizontal and vertical deformations <strong>of</strong> the diaphragm wall (precise levell<strong>in</strong>g po<strong>in</strong>ts and <strong>in</strong>cl<strong>in</strong>ometer);<br />

• strut monitor<strong>in</strong>g<br />

An area <strong>of</strong> about 70 m around the build<strong>in</strong>g pit will be monitored. The monitor<strong>in</strong>g activities for the<br />

North/South L<strong>in</strong>e are divided <strong>in</strong>to three stages:<br />

a. Base monitor<strong>in</strong>g: Base monitor<strong>in</strong>g is carried out before construction works starts and will determ<strong>in</strong>e the<br />

natural settlement behaviour and seasonal (temperature) effects on the deformations <strong>of</strong> the build<strong>in</strong>gs.<br />

b. Process monitor<strong>in</strong>g: Process monitor<strong>in</strong>g is carried out dur<strong>in</strong>g construction and results will be provided<br />

on-l<strong>in</strong>e. The sample rate depends on the process (bored tunnel/build<strong>in</strong>g pit).<br />

c. Close out monitor<strong>in</strong>g: Closeout monitor<strong>in</strong>g cont<strong>in</strong>ues after build<strong>in</strong>g activities have ended and register<br />

long-term settlement behaviour.<br />

The monitor<strong>in</strong>g <strong>in</strong>formation is analysed and processed <strong>in</strong> such a way that dur<strong>in</strong>g the construction period<br />

changes to the design/process can be made. This approach has been used to some success <strong>in</strong> several projects<br />

<strong>in</strong> the UK and is usually called the Observational method [Anon 1996].<br />

Settlement Risk Management with GIS<br />

Settlement risk management is a important tool <strong>in</strong> controll<strong>in</strong>g the effects <strong>of</strong> construction activities on the<br />

surround<strong>in</strong>gs. It is implemented by a special developed Geographic Information System (GIS). The GIS has<br />

various modules that are used <strong>in</strong> the settlement risk management :<br />

• <strong>Design</strong><br />

• data <strong>of</strong> defect surveys<br />

• settlement predictions by FE modell<strong>in</strong>g <strong>of</strong> <strong>stations</strong>’ construction;<br />

• damage classification system by 3D numerical risk assessment studies on typical masonry structures<br />

us<strong>in</strong>g settlement predictions;<br />

• build<strong>in</strong>g classification based on damage classification system and settlement predictions<br />

• mitigat<strong>in</strong>g measures for locations with unacceptable damage risk<br />

• Construction<br />

• monitor<strong>in</strong>g data<br />

With<strong>in</strong> the design phase GIS is used to comb<strong>in</strong>e settlement predictions and build<strong>in</strong>g classifications along the<br />

station <strong>in</strong> order to confirm or adjust the <strong>stations</strong>’ design or to design mitigat<strong>in</strong>g measures. Dur<strong>in</strong>g<br />

construction the GIS allows for rapid <strong>in</strong>terpretation <strong>of</strong> the monitor<strong>in</strong>g data us<strong>in</strong>g the <strong>in</strong>formation from the<br />

design modules. If necessary back analyses can be carried out and be implemented <strong>in</strong> the GIS. In this way a<br />

early decision can be made about active measures.<br />

CONCLUSIONS<br />

Extensive parametric studies were carried out tak<strong>in</strong>g <strong>in</strong>to account the upper and lower bound values <strong>of</strong> both<br />

geotechnical parameters as well as material properties <strong>of</strong> the concrete structure. The result is a<br />

range/envelope <strong>of</strong> deformations <strong>in</strong> the sub<strong>soil</strong> that represents the impact <strong>of</strong> construction on the surround<strong>in</strong>gs<br />

and that will have to meet the boundary conditions <strong>of</strong> the masonry build<strong>in</strong>gs. This is achieved with both<br />

passive as well as active measures <strong>in</strong> the <strong>stations</strong> design. Passive measures are taken <strong>in</strong> advance e.g. six or<br />

seven strut levels, a deep jet grout strut etc. An active measure is taken dur<strong>in</strong>g construction and based on<br />

relation between numerical analysis results and monitor<strong>in</strong>g results dur<strong>in</strong>g construction (observational<br />

method). Active measures can be the pre-stress<strong>in</strong>g level <strong>of</strong> the struts or <strong>in</strong>creas<strong>in</strong>g the compressed air. This<br />

means that the design must be suitable to this possible active measures. In a complex project like the

excavation <strong>of</strong> a build<strong>in</strong>g pit (dimensions :<br />

lxhxw=120mx30mx20m) <strong>in</strong> a busy city very close<br />

(