General Utility Service, Needle Valves, GU Series, (MS ... - Eoss.com

General Utility Service, Needle Valves, GU Series, (MS ... - Eoss.com

General Utility Service, Needle Valves, GU Series, (MS ... - Eoss.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

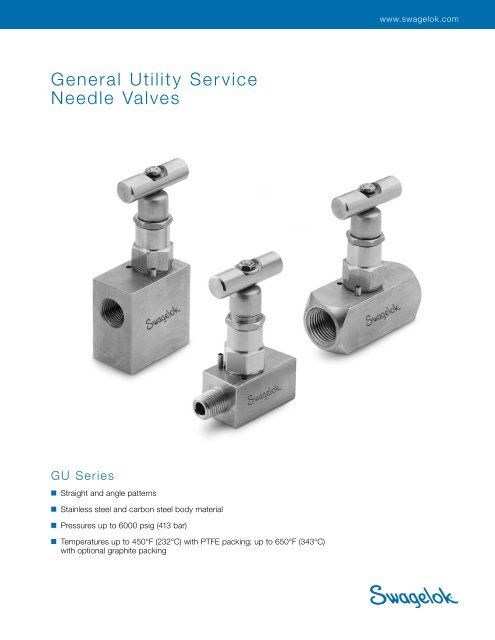

www.swagelok.<strong>com</strong><strong>General</strong> <strong>Utility</strong> Ser vice<strong>Needle</strong> <strong>Valves</strong><strong>GU</strong> <strong>Series</strong>■ Straight and angle patterns■ Stainless steel and carbon steel body material■ Pressures up to 6000 psig (413 bar)■ Temperatures up to 450°F (232°C) with PTFE packing; up to 650°F (343°C)with optional graphite packing

<strong>General</strong> <strong>Utility</strong> <strong>Service</strong> <strong>Needle</strong> <strong>Valves</strong>Features<strong>GU</strong> series needle valves are for use in general-purposeapplications to isolate or vent system media. Thehardened stainless steel, nonrotating needle promotesleak-tight shutoff and long service life. The valve stemthreads are isolated from the media.■ Compact design■ Stainless steel stop pin■ High-temperature packing and bonnet seal optionavailable■ Antitamper and lockable handle features available■ Suitable for sour gas service; materials are selected inaccordance with NACE MR0175/ISO 15156.Stainless steel handlewith square drive stemand lock nut to ensurepositive actuationStem threads are coldrolled for high strengthand smooth operationTwo-piece knucklejoint provides nonrotatingneedle feature. Jointis located above thepacking, protected fromsystem mediaStainless steel shroudprotects stem threadsagainst ingress of dirtand dustStem threads abovepacking, protected fromsystem mediaNonrotating, hardenedneedle for positive shutoffSafety back-seating needleseals in fully open position

<strong>General</strong> <strong>Utility</strong> <strong>Service</strong> <strong>Needle</strong> <strong>Valves</strong>Materials of ConstructionComponentBodyBonnet<strong>Needle</strong>Packing,bonnet sealsLubricantBonnet seal ring,gland nut, shroud,stem, gland, handle,handle lock nut,handle washer,locking pin,gland lock nutStainless SteelValve Body MaterialCarbon SteelMaterial Grade/ASTM SpecificationZinc plated➀316 SS/ carbon steel/A479AISI 1018316 SS/A479S17400 SS/A564Condition H1150DCarbon/glass-filled PTFE orgraphiteFluorinated base with PTFEand tungsten disulfide316 SSWetted <strong>com</strong>ponents listed in italics.➀ Bodies with weld end connections receive a rust-preventive coatinginstead of zinc plating.Flow DataFlow Coefficient at Turns OpenAnglePatternFlow Coefficient (C v )8<strong>GU</strong> <strong>Series</strong>4<strong>GU</strong> <strong>Series</strong>Number of Turns OpenPressure-Temperature RatingsTemperature, °F (°C)–20 (–28) to 0 (–17)0 (–17) to 100 (37)00 (93)00 (148)400 (204)450 (232)500 (260)600 (315)650 (343)PTFEPacking MaterialGraphiteWorking Pressure, psig (bar)—6000 (413)5160 (355)4680 (322)4260 (293)4110 (283)———6000 (413)6000 (413)5160 (355)4680 (322)4260 (293)4110 (283)3960 (272)3780 (260)3660 (252)StraightPatternFlow Coefficient (C v )16<strong>GU</strong> <strong>Series</strong>8<strong>GU</strong> <strong>Series</strong>TestingEvery Swagelok <strong>GU</strong> series needle valve is factorytested with nitrogen at 1000 psig (69 bar). Seats have amaximum allowable leak rate of 0.1 std cm 3 /min. Shelltesting is performed to a requirement of no detectableleakage with a liquid leak detector.Cleaning and PackagingEvery Swagelok <strong>GU</strong> series needle valve is cleanedand packaged in accordance with Swagelok StandardCleaning and Packaging (SC-10), <strong>MS</strong>‐06‐62.4<strong>GU</strong> <strong>Series</strong>Number of Turns Open

<strong>General</strong> <strong>Utility</strong> <strong>Service</strong> <strong>Needle</strong> <strong>Valves</strong>Ordering Information and DimensionsDimensions are for reference only and are subject to change.AnglePatternAStraightPatternACopenCopenBDBEDAngle PatternEnd ConnectionsOrificeOrdering NumberDimensions, in. (mm)Type Size C v in. (mm) Stainless Steel Carbon Steel A B C D E1/4 in.SS-4<strong>GU</strong>F4-A S-4<strong>GU</strong>F4-A0.85 (21.6)1.50 (38.1) 1.00 (25.4)0.203.20 (81.2)3/8 in. 0.55SS-4<strong>GU</strong>F6-A S-4<strong>GU</strong>F6-A 1.75 (44.5) 1.10 (27.9) 1.75 (44.5) 1.25 (31.8)(5.0)1/2 in. SS-4<strong>GU</strong>F8-A S-4<strong>GU</strong>F8-A 1.23 (31.2) 3.33 (84.6) 2.00 (51.0) 1.31 (33.3)Female NPT1/2 in.SS-8<strong>GU</strong>F8-A S-8<strong>GU</strong>F8-A1.23 (31.2) 3.87 (98.3) 2.00 (51.0) 1.38 (35.1)0.313/4 in. 1.60SS-8<strong>GU</strong>F12-A S-8<strong>GU</strong>F12-A 2.00 (51.0)3.98 (101) 2.50 (63.5) 1.50 (38.1)(8.0)1.60 (40.6)1 in. SS-8<strong>GU</strong>F16-A S-8<strong>GU</strong>F16-A 4.25 (108) 2.76 (70.0) 1.75 (44.5)

Ordering Information and DimensionsDimensions are for reference only and are subject to change.Straight Pattern<strong>General</strong> <strong>Utility</strong> <strong>Service</strong> <strong>Needle</strong> <strong>Valves</strong>End ConnectionsOrificeOrdering NumberDimensions, in. (mm)Type Size C v in. (mm) Stainless Steel Carbon Steel A B C D1/4 in.SS-4<strong>GU</strong>F4S-4<strong>GU</strong>F42.13 (54.1)0.45 0.20 (5.0)1.75 (44.5) 0.50 (12.7) 3.20 (81.2)3/8 in. SS-4<strong>GU</strong>F6 S-4<strong>GU</strong>F6 2.25 (57.2)Female NPTMale NPT/female NPTFractional tubesocket weldFractional pipesocket weldMetric tubesocket weld1/2 in.3/4 in.1 in.0.45 0.20 (5.0) SS-4<strong>GU</strong>F8 S-4<strong>GU</strong>F8 1.75 (44.5)3.33 (84.6) 2.63 (66.8)0.63 (16.0)1.20 0.31 (8.0) SS-8<strong>GU</strong>F8 S-8<strong>GU</strong>F8 2.00 (51.0) 3.87 (98.3) 2.76 (70.0)1.20 0.31 (8.0) SS-8<strong>GU</strong>F12 S-8<strong>GU</strong>F12 2.00 (51.0) 0.75 (19.1) 3.98 (101) 3.00 (76.2)2.25 0.43 (11.0) SS-16<strong>GU</strong>F12 S-16<strong>GU</strong>F12 3.00 (76.2) 0.88 (22.4) 5.24 (133) 3.25 (82.6)1.20 0.31 (8.0) SS-8<strong>GU</strong>F16 S-8<strong>GU</strong>F16 2.00 (51.0)4.25 (108) 3.50 (88.9)1.00 (25.4)2.25 0.43 (11.0) SS-16<strong>GU</strong>F16 S-16<strong>GU</strong>F16 3.00 (76.2) 5.35 (136) 4.02 (102)1/4 in.SS-4<strong>GU</strong>M4-F4 S-4<strong>GU</strong>M4-F40.45 0.20 (5.0)3/8 in. SS-4<strong>GU</strong>M6-F6 S-4<strong>GU</strong>M6-F61/2 in.3/4 in.1 in.1.75 (44.5) 0.50 (12.7) 3.20 (81.2) 2.38 (60.5)0.45 0.20 (5.0) SS-4<strong>GU</strong>M8-F8 S-4<strong>GU</strong>M8-F8 1.75 (44.5)3.33 (84.6) 2.76 (70.0)0.63 (16.0)1.20 0.31 (8.0) SS-8<strong>GU</strong>M8-F8 S-8<strong>GU</strong>M8-F8 2.00 (51.0) 3.87 (98.3) 3.00 (76.2)1.20 0.31 (8.0) SS-8<strong>GU</strong>M12-F12 S-8<strong>GU</strong>M12-F12 2.00 (51.0) 0.75 (19.1) 3.98 (101) 3.13 (79.6)2.25 0.43 (11.0) SS-16<strong>GU</strong>M12-F12 S-16<strong>GU</strong>M12-F12 3.00 (76.2) 0.88 (22.4) 5.24 (133) 3.50 (88.9)1.20 0.31 (8.0) SS-8<strong>GU</strong>M16-F16 S-8<strong>GU</strong>M16-F16 2.00 (51.0)4.25 (108) 3.50 (88.9)1.00 (25.4)2.25 0.43 (11.0) SS-16<strong>GU</strong>M16-F16 S-16<strong>GU</strong>M16-F16 3.00 (76.2) 5.35 (136) 4.02 (102)1/4 in.SS-4<strong>GU</strong>SW4T S-4<strong>GU</strong>SW4T0.45 0.20 (5.0)3/8 in. SS-4<strong>GU</strong>SW6T S-4<strong>GU</strong>SW6T1/2 in.3/4 in.1 in.1.75 (44.5) 0.50 (12.7) 3.20 (81.3) 2.00 (50.8)0.45 0.20 (5.0) SS-4<strong>GU</strong>SW8T S-4<strong>GU</strong>SW8T 1.75 (44.5) 0.50 (12.7) 3.20 (81.3) 2.25 (57.2)1.20 0.31 (8.0) SS-8<strong>GU</strong>SW8T S-8<strong>GU</strong>SW8T 2.00 (51.0) 0.63 (16.0) 3.87 (98.3) 2.63 (66.8)1.20 0.31 (8.0) SS-8<strong>GU</strong>SW12T S-8<strong>GU</strong>SW12T 2.00 (51.0) 0.63 (16.0) 3.87 (98.3) 2.63 (66.8)2.25 0.43 (11.0) SS-16<strong>GU</strong>SW12T S-16<strong>GU</strong>SW12T 3.00 (76.2) 0.88 (22.4) 5.24 (133) 3.25 (82.6)1.20 0.31 (8.0) SS-8<strong>GU</strong>SW16T S-8<strong>GU</strong>SW16T 2.00 (51.0) 0.75 (19.1) 3.98 (101) 2.63 (66.8)2.25 0.43 (11.0) SS-16<strong>GU</strong>SW16T S-16<strong>GU</strong>SW16T 3.00 (76.2) 0.88 (22.4) 5.24 (133) 3.25 (82.6)1/4 in.S-4<strong>GU</strong>SW4P0.50 (12.7) 3.20 (81.2)0.45 0.20 (5.0)1.75 (44.5)3/8 in. S-4<strong>GU</strong>SW6P 0.63 (16.0) 3.33 (84.6)1/2 in.3/4 in.1 in.6 mm2.25 (57.2)0.45 0.20 (5.0) S-4<strong>GU</strong>SW8P 1.75 (44.5)3.45 (87.6) 2.50 (63.5)0.75 (19.1)1.20 0.31 (8.0) S-8<strong>GU</strong>SW8P 2.00 (51.0) 3.98 (101) 2.63 (66.8)—1.20 0.31 (8.0) S-8<strong>GU</strong>SW12P 2.00 (51.0)4.13 (105) 3.25 (82.6)0.88 (22.4)2.25 0.43 (11.0) S-16<strong>GU</strong>SW12P 3.00 (76.2) 5.24 (133) 3.50 (88.9)1.20 0.31 (8.0) S-8<strong>GU</strong>SW16P 2.00 (51.0)4.25 (108)1.00 (25.4)2.25 0.43 (11.0) S-16<strong>GU</strong>SW16P 3.00 (76.2) 5.35 (136)SS-4<strong>GU</strong>SW6MMT8 mm 0.45 0.20 (5.0) SS-4<strong>GU</strong>SW8MMT10 mm SS-4<strong>GU</strong>SW10MMT12 mm14 mm16 mm1.75 (44.5) 0.50 (12.7) 3.20 (81.2)3.50 (88.9)2.38 (60.5)2.00 (51.0)0.45 0.20 (5.0) SS-4<strong>GU</strong>SW12MMT 1.75 (44.5) 0.50 (12.7) 3.20 (81.2) 2.25 (57.2)1.20 0.31 (8.0) SS-8<strong>GU</strong>SW12MMT 2.00 (51.0) 0.63 (16.0) 3.87 (98.2) 2.63 (66.8)1.20 0.31 (8.0) SS-8<strong>GU</strong>SW14MMT —2.00 (51.0) 0.63 (16.0) 3.87 (98.2) 2.63 (66.8)2.25 0.43 (11.0) SS-16<strong>GU</strong>SW14MMT 3.00 (76.2) 0.88 (22.4) 5.24 (133) 3.75 (95.3)1.20 0.31 (8.0) SS-8<strong>GU</strong>SW16MMT 2.00 (51.0) 0.63 (16.0) 3.87 (98.2) 2.63 (66.8)2.25 0.43 (11.0) SS-16<strong>GU</strong>SW16MMT 3.00 (76.2) 0.88 (22.4) 5.24 (133) 3.50 (88.9)18 mmSS-16<strong>GU</strong>SW18MMT2.25 0.43 (11.0)25 mm SS-16<strong>GU</strong>SW25MMT3.00 (76.2) 0.88 (22.4) 5.24 (133) 3.25 (82.6)

OptionsTo order valves with multiple options, add the appropriatedesignator in alphabetical order.High-Temperature Stem Packing, Bonnet SealGraphite stem packing and bonnet seal material is availablefor temperatures up to 650°F (343°C).To order valves with graphite material, add ‐G to the valveordering number:Example: SS-4<strong>GU</strong>F4-GAntitamper HandleThe antitamper handle reduces therisk of human error and deliberatetampering. The valve can be operatedwith the antitamper key, sold separately.To order valves with antitamper handles,add -AT to the valve ordering number.Example: SS-4<strong>GU</strong>F4-ATAccessoriesAntitamper Key■ Fits all vent valveswithin the system■ Order separatelyValve <strong>Series</strong>4<strong>GU</strong>8<strong>GU</strong>16<strong>GU</strong>Ordering NumberS004468S007240Handle KitsStandard stainless steel bar handle kits contain a handle,washer, lock nut, and instructions.Optional round lockable nylon or stainless steel handle kitscontains a handle, lock shield, retaining ring, label, washer,lock nut, and instructions.Round Lockable HandlesThe lockable handles can lock the valvein any position. These round handlesac<strong>com</strong>modate shackle diameterssmaller than 0.22 in. (5.7 mm) for 4<strong>GU</strong>and 8<strong>GU</strong> series valves and 0.28 in.(7.0 mm) for 16<strong>GU</strong> series valves.NylonA nylon lockable handle is available for ambient temperaturesup to 250°F (121°C) and process temperatures up to 450°F(232°C).HandleStyleStainlesssteelbarRoundlockablenylonRoundlockablestainless steelValve<strong>Series</strong>4<strong>GU</strong>8<strong>GU</strong>16<strong>GU</strong>4<strong>GU</strong>8<strong>GU</strong>16<strong>GU</strong>4<strong>GU</strong>8<strong>GU</strong>16<strong>GU</strong>Kit OrderingNumberSS-5K-4<strong>GU</strong>SS-5K-8<strong>GU</strong>SS-5K-16<strong>GU</strong>SS-5K-4<strong>GU</strong>-NLHSS-5K-8<strong>GU</strong>-NLHSS-5K-16<strong>GU</strong>-NLHSS-5K-4<strong>GU</strong>-SLHSS-5K-8<strong>GU</strong>-SLHSS-5K-16<strong>GU</strong>-SLHTo order, add -NLH to the valve ordering number.Example: SS-4<strong>GU</strong>F8-NLHStainless SteelA stainless steel lockable handle is available for marine service.To order, add -SLH to the valve ordering number.Example: SS-4<strong>GU</strong>F8-SLH Packing adjustment may be required during theservice life of the valve to prevent leakage. <strong>Valves</strong> that have not been cycled for a period of timemay have a higher initial actuation torque.Safe Product SelectionWhen selecting a product, the total system design mustbe considered to ensure safe, trouble-free performance.Function, material <strong>com</strong>patibility, adequate ratings,proper installation, operation, and maintenance are theresponsibilities of the system designer and user.Caution: Do not mix or interchange parts with those ofother manufacturers.Warranty InformationSwagelok products are backed by The Swagelok LimitedLifetime Warranty. For a copy, visit swagelok.<strong>com</strong> or contactyour authorized Swagelok representative.Swagelok—TM Swagelok Company© 2005, 2007, 2009 Swagelok CompanyPrinted in U.S.A., GLIFebruary 2009, R4<strong>MS</strong>-02-312