Hardware Design of Vertical Axis Highway Windmill - IRD India

Hardware Design of Vertical Axis Highway Windmill - IRD India

Hardware Design of Vertical Axis Highway Windmill - IRD India

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

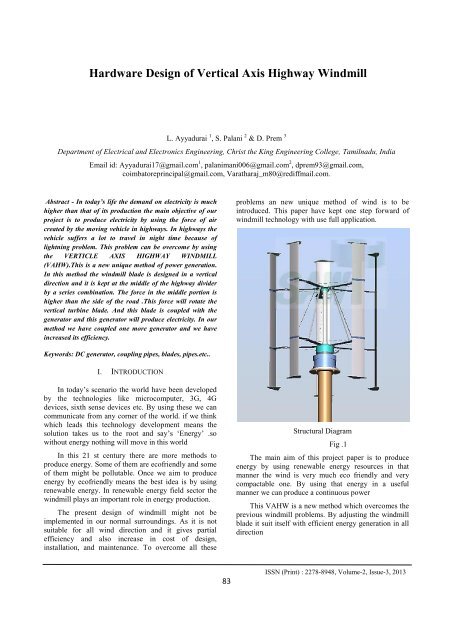

<strong>Hardware</strong> <strong>Design</strong> <strong>of</strong> <strong>Vertical</strong> <strong>Axis</strong> <strong>Highway</strong> <strong>Windmill</strong>L. Ayyadurai 1 , S. Palani 2 & D. Prem 3Department <strong>of</strong> Electrical and Electronics Engineering, Christ the King Engineering College, Tamilnadu, <strong>India</strong>Email id: Ayyadurai17@gmail.com 1 , palanimani006@gmail.com 2 , dprem93@gmail.com,coimbatoreprincipal@gmail.com, Varatharaj_m80@rediffmail.com.Abstract - In today’s life the demand on electricity is muchhigher than that <strong>of</strong> its production the main objective <strong>of</strong> ourproject is to produce electricity by using the force <strong>of</strong> aircreated by the moving vehicle in highways. In highways thevehicle suffers a lot to travel in night time because <strong>of</strong>lightning problem. This problem can be overcome by usingthe VERTICLE AXIS HIGHWAY WINDMILL(VAHW).This is a new unique method <strong>of</strong> power generation.In this method the windmill blade is designed in a verticaldirection and it is kept at the middle <strong>of</strong> the highway dividerby a series combination. The force in the middle portion ishigher than the side <strong>of</strong> the road .This force will rotate thevertical turbine blade. And this blade is coupled with thegenerator and this generator will produce electricity. In ourmethod we have coupled one more generator and we haveincreased its efficiency.problems an new unique method <strong>of</strong> wind is to beintroduced. This paper have kept one step forward <strong>of</strong>windmill technology with use full application.Keywords: DC generator, coupling pipes, blades, pipes.etc..I. INTRODUCTIONIn today‟s scenario the world have been developedby the technologies like microcomputer, 3G, 4Gdevices, sixth sense devices etc. By using these we cancommunicate from any corner <strong>of</strong> the world. if we thinkwhich leads this technology development means thesolution takes us to the root and say‟s „Energy‟ .sowithout energy nothing will move in this worldIn this 21 st century there are more methods toproduce energy. Some <strong>of</strong> them are ec<strong>of</strong>riendly and some<strong>of</strong> them might be pollutable. Once we aim to produceenergy by ec<strong>of</strong>riendly means the best idea is by usingrenewable energy. In renewable energy field sector thewindmill plays an important role in energy production.The present design <strong>of</strong> windmill might not beimplemented in our normal surroundings. As it is notsuitable for all wind direction and it gives partialefficiency and also increase in cost <strong>of</strong> design,installation, and maintenance. To overcome all theseStructural DiagramFig .1The main aim <strong>of</strong> this project paper is to produceenergy by using renewable energy resources in thatmanner the wind is very much eco friendly and verycompactable one. By using that energy in a usefulmanner we can produce a continuous powerThis VAHW is a new method which overcomes theprevious windmill problems. By adjusting the windmillblade it suit itself with efficient energy generation in alldirection83ISSN (Print) : 2278-8948, Volume-2, Issue-3, 2013

International Journal <strong>of</strong> Advanced Electrical and Electronics Engineering, (IJAEEE)The main advantage <strong>of</strong> VAHW is it can generatepower in all direction <strong>of</strong> wind flow. And the otheradvantages are the maintenance are less and the height<strong>of</strong> the tower is less.II. PRINCIPLES OF WIND ENERGY CONVERTION.The primary component <strong>of</strong> a wind turbine is theenergy converter which transforms the kinetic energycontained in the moving air, into mechanical for theinitial discussion <strong>of</strong> principle, the exact nature <strong>of</strong> theenergy concur is irrelevant the extraction <strong>of</strong> mechanical.Energy from a stream <strong>of</strong> moving air with the help <strong>of</strong> adisk shaped rotating wind energy converter follows itsown basic rules. The credit for having recognized thisprinciple is owed to Albertbetz. Between 1922and 1925.Betz published writings in which he was able to showthat by applying elementary. Physical laws themechanical energy extractable from air stream passingthrough a gives cross section area is restricted to acertain fixed proportion <strong>of</strong> the energy or powercontained in the air stream .moreover ,he found thatoptimal power extraction could only be realized at acertain ratio between the flow velocity <strong>of</strong> air in front <strong>of</strong>energy converter and the flow velocity behind theconverter all through BETZ .momentum theory whichassumes the energy converter working without losses ina fraction less air flow contain simplification if resultsair quite usable for performing rough calculation inpractical engineering .but it is true signification iffounded in the fact that if provides common physicalbasis for the understanding and operation <strong>of</strong> windenergy converters <strong>of</strong> various designIII. ELEMENTARY MOMENTUM THEORYThe kinetic energy <strong>of</strong> an air mass m moving at avelocity v can be expressed asConsidering a certain cross-sectional area althoughwhich the air passes at velocity V, the volume v‟ flowthrough during a certain time unit, the so called volumeflow isSCHEMATIC DIAGRAM OF VAHWFig.2IV. DESIGNING METHODOLOGYThis design methodology is to increase theefficiency <strong>of</strong> the windmill at first the designing stepsstarts with the design <strong>of</strong> windmill blades. Because thisblades will mainly affects the overall efficiency <strong>of</strong> thewindmill. For a particular application the wind millblade should be in required size. Before this gettingknowledge about the aerodynamic style <strong>of</strong> windmillblade in order to get the full efficiency is very muchimportant.The various considerations are.A. Wind speed:The speed <strong>of</strong> the wind is very much important forthe production <strong>of</strong> electricity in the windmill. Because inwindmill we are using the wind as a raw material for thepower production .this bakes the axis rotate and this axisis coupled with a dc generator and makes its also rotateand produce electricity.B. Tower height and design:The height <strong>of</strong> the tower is very much important fora windmill. In VAHW the tower is kept little sort toobtain whole air density passing from the vehicleWe also should concentrate in the design <strong>of</strong> thetower because it should able to withstand for its ownweight and also in the speed <strong>of</strong> the windC. Shape <strong>of</strong> the blade:As discussed earlier the shape <strong>of</strong> the wind millblades is the important one if one could place an84ISSN (Print) : 2278-8948, Volume-2, Issue-3, 2013

International Journal <strong>of</strong> Advanced Electrical and Electronics Engineering, (IJAEEE)efficient design <strong>of</strong> a blade then the efficiency <strong>of</strong> thewindmill will be increased.The various windmill shapes are as follows;a) Flat, unmodified blade surface.b) wing shape with one leading edgec) Both edges tapered to a thin line.d) Both edges leading bladeA drawing <strong>of</strong> tested shape blades are provided below;fig.3D. Tipspeedratio:Thistipspeedratiodefinesthespeed <strong>of</strong>thewindthathit the tips <strong>of</strong> the blades and makes a rotation. In thisspeed the blade will give you a good performance.When the tip speed ratio increases the productivity <strong>of</strong>the windmill also increases.V. AERODYNAMICS CONCEPT:This aerodynamic concept shows the forces andvelocities cutting in a turbine The resultant velocityvector, W‟ is given byWhere,W’=U’+(-w’*r’)U‟-undistributed upstream air velocity(-w‟*r‟)-velocity vector <strong>of</strong> advancing blade.Thus the oncoming velocity varies, maximum is foundfor θ=0 0 and the minimum is found for,θ=180 0 whereθ is the azimuthal or orbital blade position. The angle <strong>of</strong>attack α is the angle between the oncoming air speed.HereW, and the blade cords, the resultant airspeed flow andthe angle <strong>of</strong> attack are calculated as follows:W=UThe blade turbine must place according to aerodynamicconcept. All the variables related to this model definitelyvaries according to the environment in which it is goingto be installedVI. DESIGN OF BLADES:For the design <strong>of</strong> blades the selection material isvery much important .because the material that we areselecting should be more weight less and it should ableto withstand at high air pressure. For that a special grade<strong>of</strong> aluminum metal can be used it has light weight and itcan able to withstand at high air pressure .the nextimportant thing is to choose a blade shape.The c-type blade is suitable for vertical axishighway windmill(VAHW).Because it shape can ableto collect maximum air pressure and it can able to givemaximum energy transformation from forced windenergy to rotational mechanical energy. The shape <strong>of</strong> theblade used is shown belowVIEWS OF BLADEfig.4)85ISSN (Print) : 2278-8948, Volume-2, Issue-3, 2013

International Journal <strong>of</strong> Advanced Electrical and Electronics Engineering, (IJAEEE)In vertical axis highway wind mill normally havefour c-type blades that are placed in vertical direction.These four blades have normally separated by 90-degreeangle with each other. So that in highways when vehiclepasses the VAHW will rotate in clockwise direction..The wind turbine blade design has been decided andnow the blades must be fixed to built the turbine thearrangement <strong>of</strong> blades and its rotating directions areshown in below diagramFig.5VII. DC GENERATOR IN VAHW:The alternators or generators are the heart <strong>of</strong> thewindmill and it must be properly sized to match yourswept area and to produce right type <strong>of</strong> power to matchyour application. The unit needs to make higher voltagesat lower rpms,otherwise it is not suited for wind poweruse, even motors can also be used a generators. In thisvertical axis highway windmill we are using two dcgenerators coupled with the wind blade turbine.NORMAL GENERATORFig.6Wind generators come in various voltages such as12volts, 24volts and 48volts DC and in a range <strong>of</strong>currents up to 80amps at 12volts. The wind generator isa square torque machine and the output increasesexponentially with increasing wind speed. Most qualitywind generators come with a blade stall facility that“stalls” the blades at high wind speed. Available also isan electrical blade lock that locks the generator on thethrow <strong>of</strong> a switch. This prevents the generator turningwhen servicing is in progress. Wind generatortechnology is very mature technology and has been usedby yachtsmen for at least the last 20 years. Thetechnology is reliable and reasonable priced.Maintenance <strong>of</strong> a wind generator is simple, just greasethe front and rear bearings and check all bolts andconnections on a basis Wind generators are capable <strong>of</strong>producing large amounts <strong>of</strong> current, up to 80amps at12volts and should always be fitted with a chargecontroller containing a power dump system. WindGenerators are a cost efficient way <strong>of</strong> producing powerusing a sustainable energy force the wind. They indicateeasily into an Hybrid Power System and work well withsolar arrays. The solar array controller can also be usedby the wind generator to control and dump any excesspower produced by the hybrid system. If the sun doesnot shine hopefully the wind will be blowing yearlya) start up speed:This wind speed at which the rotors starts turning. Itshould spin smoothly and easily when you turn it byhand, and keep spinning for few seconds. <strong>Design</strong>s that„cog‟ from magnetic force or that use gears or pulley toincrease shaft speed will be poor at start up. A gooddesign can start spinning in 5 mph winds cut in at 7mph.b) Inefficiency :Every generator has a certain speed at which it runsmost efficiently. But since the wind is not constant, wemust try to design to happy medium. As the wind speedrises, the raw power coming into the generator from thewind becomes more than the generator can effectivelyUse, and it gets more and more inefficient. This poweris wasted as heat in the stator coils.VIII. OPERATION EXPLANATION:This verticle axis highway windmill is placed in thehighway dividers. When the air is forced by passing thevehicle from both sides the speed <strong>of</strong> a wind at thecenter place is higher than the pedestrain walking lane.This wind make the VAHW to rotate at high speed andit is coupled to generator to produce electicity and thepower can be stored in the battery and it is utilised iatthe night time86ISSN (Print) : 2278-8948, Volume-2, Issue-3, 2013

International Journal <strong>of</strong> Advanced Electrical and Electronics Engineering, (IJAEEE)BLOCK BIAGRAM OF VAHW:This energy convertion process is explained by severalfollowing steps:Step-1:In the first step the forced wind and middle part <strong>of</strong> thehighway will hit wind turbine blades and make arotation in it The wind turbine blade will rotate atclockwise direction even when the vehicle move in any<strong>of</strong> the side <strong>of</strong> the highway.because thw arrangement <strong>of</strong>the wind turbine blades are in that manner.Step-2:The verticle axis highway windmill the wind bladeturbine is couled with the two generatos .one is in thetop and the other one is at the bottom <strong>of</strong> the windturbine blades.when the turbine blade rotate the coupledgenerators will produce electricity in both direction.Step-3:Thus the mechanical energy is converted into electricalenergy by using dc generator and this produced power isstored in the battery and is utilised by application wise.IX. PROTOTYPE MODELwe made shaft by using 1.5” pipe and we fix silverplates as a blade.we have used ony DC motor instead <strong>of</strong>DC generator .the two motors coupled athe top andbottom <strong>of</strong> the wind turbine.we use a gear pulse toincrease the rpm <strong>of</strong> the motor shaft and increse its RPMand makes it to generate and the output <strong>of</strong> the motor isconnected to the power LED with the range <strong>of</strong> 6v to 9v.the prototype model is shown in the above fig.X. CONCLUSIONThis verticle axis highway windmill gives an ideaabout the new way <strong>of</strong> power generation and also aboutthe new windmill technology. The power generationusing VAHW is an ec<strong>of</strong>riendly methodand powerproduced here is almost an continuous one .By usingthis technology all the highways can be lightenedwithout use <strong>of</strong> non- renewable energy resourses. And ifthis method is implimented in all national highways wecan able to produce large amount <strong>of</strong> power.and it canalso provide job for many educated fellowship.XI. FUTURESCOPE DEVELOPMENTBy fixing solar pannel in this vahw will increase theeffeciency.Fixin more in series or in parellel manner will givemore efficiency.XII. ACKNOWLEDGMENTWe express our sincere thanks to Dr.S.V.Saravanan,principal and Mr.M.Varatharaj Asst.pr<strong>of</strong> & HOD andmy Department staff members ,Department <strong>of</strong> Electricaland Electronics Engineering,Christ The KingEngineering College ,Coimbatore.XIII. REFERENCES[1] j.g leishman chailenges in modelling the unsteadyaerodynamics <strong>of</strong> wind turbine.[2] wind power plant and project developmentjoshuaearnest[3] www.scribd .com[4] images taken from http://www.alternativeenergy-news.info/vertical-axis-windmill/[5] IEEE research paper <strong>of</strong> highway windmillFig.7We have done a prototype model <strong>of</strong> this project . inthat prototype model we have used only pvc pipes andsilver plates.the wind turbine is made by 5” pvc pipe and87ISSN (Print) : 2278-8948, Volume-2, Issue-3, 2013