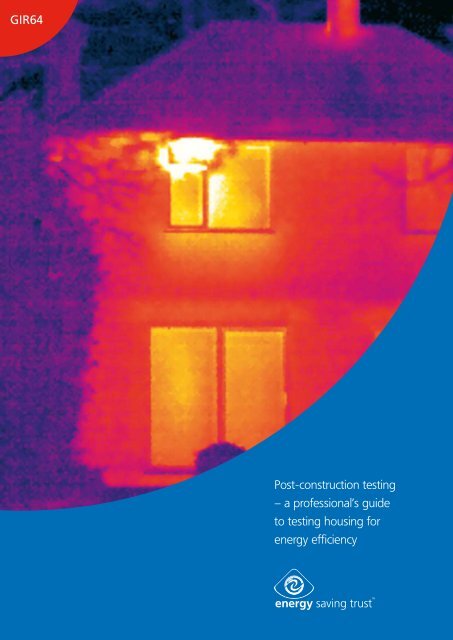

Post-construction testing - Energy Saving Trust

Post-construction testing - Energy Saving Trust

Post-construction testing - Energy Saving Trust

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Glazing system identificationSurveyors may be required to either confirm that thecorrect glazing units have been installed or specifyreplacement units for damaged ones. In potentiallyhazardous conditions they need to identify andconfirm the correct use of laminated glass, instead oftoughened glass.The wider use of double-glazed units with larger airgaps and glazing units with low-emissivity (low-e)coatings make it difficult for surveyors to identify thetype of glazing units without removing the unit.Commercially available laser gauges are a simple wayof identifying the type of glazing installed within awindow. The gauges measure the glass thickness,width of air gap and identify the presence of a low-ecoating or laminate.The gauges confirm that the unit has been installed thecorrect way round – essential for the full performanceto be achieved. However, they cannot detect thepresence of an argon or similar gas filling within adouble-glazed unit, or the type of coating applied tothe glass.Gauges offer a simple alternative to trying tomeasure the overall thickness of a multiple glazingunit with callipers. You can buy a gauge for under£200.Survey methodThe gauge is placed against the glazing unit andpowered up. Laser light passes through the unit,reflecting off each surface to give an instantaneousreading on a calibrated measurement scale. Thethicknesses of the glass and air gap are highlightedas a pair of lines of similar brightness on the scale.The presence of a low-e coating causes more lightto be reflected, showing up as a brighter line onthe scale. The location of the coating is indicatedby which line is brightest – either the second orthird. For a correctly installed unit, measured fromthe internal surface, the second line should appearbrightest.Manufacturers claim readings to an accuracy of0.1mm, and on units up to a total thickness of65mm. Direct sunlight does not affect the readings.Figure 10: Laser gauges provide a simple way of identifying the type of glazing installed within a window<strong>Post</strong>-<strong>construction</strong> <strong>testing</strong> – a professional’s guide to <strong>testing</strong> housing for energy efficiency (2005 edition)

Remote visual inspectionRemote visual inspection of building <strong>construction</strong>using a rigid borescope (or fibrescope) allows positiveidentification of hidden defects with minimal damageto the building structure.Applications for remote visual inspection within thebuilding industry include the inspection of services,particularly drains and sewers, and the investigationof voids within walls, floors and roofs. Investigation ofthese voids confirms <strong>construction</strong> details, the presenceof damp-proof courses, and identifies hidden defectssuch as failed wall ties.As a follow-up to a thermographic survey, the exactcause of a thermal pattern can be determined,e.g. missing or poorly installed insulation.Survey methodTypical systems comprise a portable, high-intensitylight source, a fibre optic light guide and an opticalviewing system. In the case of a follow-up inspectionto a thermographic survey, an inspection hole(approximately 13mm in diameter) is drilled usingthe thermal image as a guide to location, and theinstrument inserted. Viewing systems normally permitrotation through 360 degrees. Within the image, anindicator shows the scope’s orientation.The level of illumination available from high-intensitylight sources allows defects within 1.5-2m to be readilyidentified. Results can be recorded by either attaching aconventional photographic camera or a video camera tothe system.Inspections may be carried out, using a rigid borescopeor a flexible fibrescope, depending on access andlocation. Developments in digital technology haveallowed improved image recording facilities andmeasurement capabilities – high-definition portabledevices are now available.Figure 11: Bridged wall tie Figure 12: Borescope examination of wall cavity10 <strong>Post</strong>-<strong>construction</strong> <strong>testing</strong> – a professional’s guide to <strong>testing</strong> housing for energy efficiency (2005 edition)

Heating should be maintained for the duration of themeasurement to provide a good contrast betweenindoor and outdoor temperatures. The measurementshould continue for a long enough period for thethermal mass of the structure to have a minimaleffect. If feasible, continuous heating is preferable tointermittent heating and a high heating setpoint ispreferable to a low heating setpoint.Table 3 shows some data which was collected duringa U-value measurement of a wall in a first floor flat.The U-values given are calculated from the heat fluxvalues and temperatures. The U-value entries near thetop of the table are of low accuracy because they arebased on relatively few readings. The U-value entriesnear the bottom of the table are much more accuratebecause they are derived from a larger dataset.Approximately 14 days should be allowed for amasonry wall structure, although a shorter period isusually possible for a lightweight wall or roof structure.For solid ground floors and basements, a much longerperiod of measurement is necessary, perhaps spanningtwo to three years.For the duration of the measurement, the heat flux(q – in W/m 2 ), the internal temperature (Ti) and the externaltemperature (Te) should all be recorded at frequentintervals. The measurement can be based on either surfacetemperatures (where the temperature probe is firmlyattached to the surface) or air temperatures (where theprobe is usually placed around 10mm from the surface).Where the measurement is based on air temperature, careshould be taken in interpreting the data as sunlight coulddistort the measurement of the temperature.At the end of the measurement period the heat fluxreadings and temperature readings may be used toderive a U-value. The resulting U-value is calculatedfrom the mean (time averaged) heat flux (in W/m 2 )divided by the mean difference between the inside andoutside temperature (in degrees Celsius).The U-value should be determined using data fromdifferent periods within the overall dataset in orderto establish whether, and by how much, the U-valuedrifts during the period of measurement. The degreeof drift provides an indication of the extent of randomerrors and those arising from storage of heat withinthe structure.The reported results should clearly show whethersurface or air temperatures were recorded during themeasurement; also an indication of whether sunlightcould have interfered with temperature or heat fluxmeasurements. It could also be useful to presentrainfall and wind data, as these could potentiallyaffect the U-value.Where heat storage could be a significant factor (e.g.where a very heavy <strong>construction</strong> is investigated orthe period of measurement is relatively short) it ispossible to make some corrections for heat storage.ISO 9869 Thermal insulation – building elements– in-situ measurement of thermal resistance andthermal transmittance shows how corrections can beapplied.Wall – Internal finishHeat flux meter – inactive areaHeat flux meter – active areaWall<strong>construction</strong>Substrate to take upundulations in surface profileElectrical wires to relay lowvoltage signal to loggerFigure 13: Illustration of a heat flux meter fixed against a wall withsubstrate to accommodate any undulations in the profiles of the surfacesFigure 14: Two heat flux meters pressurefixedagainst internal plasterboard12 <strong>Post</strong>-<strong>construction</strong> <strong>testing</strong> – a professional’s guide to <strong>testing</strong> housing for energy efficiency (2005 edition)

Measuring specific heat lossIt is possible to investigate the overall thermalperformance of the building envelope by assessingthe specific heat loss. This can be particularly usefulfor assessments of the comparative performance ofdifferent forms of <strong>construction</strong>. This method also takesfull account of the heat loss attributable to thermalbridging, including thermal bridging at junctions andaround openings. In making the assessment, you shouldconsider a range of issues. Errors to the measurementscan be introduced as a result of incidental heat gainsand solar gains. Making comparative measurements onpairs of dwellings experiencing the same environmentalconditions will limit the impact of some of the issues.The basic approach is to measure the internaland external temperatures, together with the fuelconsumption, over a period of time. The heat input tothe dwelling is given by:Heat input = fuel used (kWh) x (multiplication) heatingefficiency (per cent)For electrically-heated dwellings the heating efficiencywill normally be 100 per cent (unless heat pumpsare used). For gas-heated and oil-heated dwellings,the SEDBUK efficiency rating of the boiler gives theappropriate efficiency. Lights and appliances shouldideally be switched off during the assessment; but ifany are switched on during this period, an allowanceshould be made for their contributions to the overallheat input to the dwelling. The effect of sunlightentering through windows and doors should also beallowed for.Due to uncertainties in the efficiencies of gas or oilheating systems, you should consider heating thetest dwellings continuously throughout the test, usingportable electric heaters. Monitoring of the totalelectricity consumption for the duration of the test, withno other loads connected, will permit the space heatingfuel use to be calculated. Monitoring of the electricityconsumption should be arranged, and the methodchosen will depend upon the type of electricity meter.To correct for weather conditions, the temperaturesboth inside and outside the dwellings should berecorded at frequent intervals to obtain average internaland external readings. Measurement of the internaltemperature should be in enough locations to allow themean internal temperature to be described. In practice,a minimum of four locations should be chosen, withtwo on the ground floor and two on the first floor.Measurement of external temperatures should becarried out at a location where sunlight does not undulyaffect the instrumentation.All temperature data should be recorded at regularintervals, typically 15 minutes, on data-loggers.Measurements should be continued for a sufficientperiod to overcome the impact of thermal inertia.Wind will also affect the results and recording thespeed and direction of wind at the site will allow betterassessment of the accuracy of the results. The recordedtemperatures and power consumption should bereduced to daily averages. The specific heat loss of thebuilding is calculated by dividing the space heating fueluse by the average temperature difference.Table 3: Explanation of how U-value is calculated from heat flow, and internaland external temperatureDateAverageheat flux(W/m 2 ),midnight tomidnightAverageinternaltemperature(°C),midnight tomidnightAverageexternaltemperature(°C),midnight tomidnightMeasuredU-value(W/m 2 K)16/02/1999 5.5 15.6 4.4 0.4917/02/1999 7.0 15.0 2.9 0.5418/02/1999 8.2 16.1 7.9 0.6619/02/1999 5.1 16.0 7.7 0.6520/02/1999 2.7 14.6 5.2 0.5821/02/1999 6.6 14.7 4.2 0.5922/02/1999 8.1 15.6 4.3 0.6123/02/1999 6.3 15.2 3.8 0.6024/02/1999 8.6 16.1 4.9 0.6225/02/1999 5.8 15.9 8.6 0.63Measured U-value(W/m 2 K)0.80.70.60.50.40.3Measured U-value17.2.99 19.2.99 21.2.99 23.2.99 25.2.99 27.2.99 1.3.99DateStabilisedU-value is0.62 W/m 2 KTable 3 and the figure below it show how U-value is calculated from the heatflow, the internal temperature and the external temperature. Each U-value isdetermined from the mean of the heat flux and temperature values, recordedfrom the start of the measurement up to the date corresponding to the givenU-value. By the end of the 10-day period, the U-value for this lightweight<strong>construction</strong> is stabilising at around 0.62W/m 2 K.<strong>Post</strong>-<strong>construction</strong> <strong>testing</strong> – a professional’s guide to <strong>testing</strong> housing for energy efficiency (2005 edition) 13

Other performance measurements of the buildingenvelopeMoisture measurementExcess moisture in masonry or timber usually results invisible staining to decorations and the onset of wet ordry rot in wood. Electrical moisture meters provide auseful indication of the presence of moisture. However,concentrations of salts at the surface may give amisleading reading.A variety of meters are available, measuring resistance,conductance or the reflection of radio frequencyemissions. Where an indication of moisture is recordedin timber, some reliance can be placed on the actualvalue measured. With masonry materials, the readingmay indicate the presence of hygroscopic salts(usually chlorides and nitrates), particularly in a humidatmosphere.The pattern of readings taken at several locations onthe surface can give a clue to any problems. Highreadings at low- to mid-wall height with no readingabove that level may well indicate rising damp.Readings only in the middle of a wall may haveuncovered localised rain penetration.A quantitative method of moisture sampling is todrill a small amount of powder from the masonry,weigh it as found, then dry it in an oven andreweigh it. From these values, the percentagemoisture content can be calculated. Alternatively,a carbide meter can be used to give an on-sitereading. A laboratory test should be undertaken totest for hygroscopicity. Full details of these methodsare given in BRE Digest 245.Ultrasonic scanningThis is a widely used technique with many medicaland industrial applications. It uses high-frequencysound waves, usually above 20,000Hz, to provide across-section through the material being examined.The equipment used does not produce an image, andcalls for a reasonable degree of skill and experience tointerpret the results.The technique can be used across very fragile surfaceswithout causing damage, and has been frequentlyused on historic buildings. It is a comparative techniquewhich can only detect areas of weakness in anotherwise sound material or when compared to areference sample.The principal application is the investigation of timbersto determine the presence and extent of decay. Usefulinformation can be gathered from the examination ofstonework for fault planes and zones of weakness. Thetechnique will not provide useful information where thestructure has a high number of discontinuities within it,such as a rubble wall, because the signal will scatter offthe various interfaces.Radar examinationDeveloped from military and geo-technical applicationsover the last 10 years, radar has found widerapplications in the examination of both structures androadways. It involves an echo-sounding technique usinglow-power radio pulses to determine structural makeupand condition. Continuous data collection gives across-section through the structure. The technique issuitable for covering large areas rapidly to determinethe extent of a problem, or for investigating a localisedproblem. It is effective in most <strong>construction</strong> materials.An antenna connected to a transmitter and receiverpasses over the surface of the structure at a controlledspeed. The receiver collects the reflected energywhich is subsequently processed. Real-time viewingof the data on-site can give an indication of areasfor subsequent investigations, but full analysis wouldgenerally be carried out off-site. Data processing hasbenefited from advances in computer technology, withmore rapid data capture possible and improved analysiswith the removal of signal noise.Expert assessment of the strength and scatter of thesignal can give an indication of the presence of cracking,corrosion and changes in moisture content andcompaction. The technique is successful in locating andmeasuring voids, and the identification of discontinuitieswithin walls and floors. It is particularly effective formapping the layers within a <strong>construction</strong> with differentsystem configurations used to vary resolution and depth(shorter wavelengths for shallower features and longerwavelengths for deeper features).Radar offers the advantage of only requiring accessto one surface for the scanning. The systems usuallyneed to be calibrated on-site and cannot penetratehighly conductive materials such as metals. You shouldengage only specialist companies with the necessaryexpertise in results analysis for this procedure.14 <strong>Post</strong>-<strong>construction</strong> <strong>testing</strong> – a professional’s guide to <strong>testing</strong> housing for energy efficiency (2005 edition)

Further readingEuropean StandardsInternational Organisation for Standardisation. BS EN13187:1999. ‘Thermal insulation – qualitative detectionof thermal irregularities in building envelopes – infraredmethod’ (IOS, 1999)International Organisation for Standardisation. BS EN13829:2001. ‘Thermal insulation – determination ofbuilding airtightness – fan pressurisation method’ (IOS,2001)International Organisation for Standardisation. ISO9869:1994. ‘Thermal insulation – building elements– in-situ measurement of thermal resistance andthermal transmittance’ (IOS, 1994)Building Research Establishment (BRE)information papers and digestsBRE Report BR176 ‘A practical guide to infraredthermography for building surveys’(BRE, Garston, 1991)Digest 245 ‘Rising damp in walls: diagnosis andtreatment’ (BRE, Garston, 1981)BRE Report BR262 Thermal insulation, avoiding risks(BRE, Garston, Second Edition, 1994)BRE Report BR359 ‘Airtightness in UK dwellings: BRE’stest results and their significance’ (BRE, Garston, 1998)IP7/90 ‘An introduction to infrared thermography forbuilding surveys’ (BRE, Garston, 1990)Swedish Council for Building ResearchPetterson, Bertil and Axen, Bengt. ‘Thermography– <strong>testing</strong> of the thermal insulation and airtightness ofbuildings’Chartered Institution of Building ServicesEngineers (CIBSE)CIBSE Guide A Environmental design(CIBSE, London, 1999)CIBSE TM23 Testing buildings for air leakage 2000National Regulations & Support DocumentsThe Building Regulations 2000, Approved Document L1,Conservation of Fuel and Power, The Stationery Office,London, 2001.The Building Standards (Scotland) Regulations 1990, 6thamendment: Technical Standards to Part J, Conservationof Fuel and Power.The Building regulations (Northern Ireland) 1994,Technical Booklet part F, Conservation of Fuel andPower (1998).Limiting thermal bridging and air leakage: robust<strong>construction</strong> details for dwellings and similar<strong>construction</strong>s. (The Stationery Office. 2001)(Please note that this document is used in conjunctionwith Approved Document Part L1 in England and Walesonly. Scottish Building regulations stipulate that BREReport BR262 can be used to demonstrate that thermalbridging and infiltration is reduced to a minimum).<strong>Post</strong>-<strong>construction</strong> <strong>testing</strong> – a professional’s guide to <strong>testing</strong> housing for energy efficiency (2005 edition) 15

GIR64Further informationThe <strong>Energy</strong> <strong>Saving</strong> <strong>Trust</strong> sets energy efficiency standards that go beyond building regulations for use inthe design, <strong>construction</strong> and refurbishment of homes. These standards provide an integrated package ofmeasures covering fabric, ventilation, heating, lighting and hot water systems for all aspects of new buildand renovation. Free resources including best practice guides, training seminars, technical advice and onlinetools, are available to help meet these standards.The following publications may also be of interest:• <strong>Energy</strong> Efficiency in New Housing: summary of specifications for England, Wales and Scotland (CE12)• <strong>Energy</strong> Efficiency in New Housing: summary of specifications for Northern Ireland (CE24)• Improving air tightness in dwellings (CE124/GPG224)To obtain these publications or for more information, call 0845 120 7799, email bestpractice@est.org.ukor visit www.est.org.uk/housingbuildings<strong>Energy</strong> <strong>Saving</strong> <strong>Trust</strong>, 21 Dartmouth Street, London SW1H 9BP Tel 0845 120 7799 Fax 0845 120 7789bestpractice@est.org.uk www.est.org.uk/housingbuildingsCE128 © <strong>Energy</strong> <strong>Saving</strong> <strong>Trust</strong> March 2005. Reprinted February 2006. E&OEThis publication (including any drawings forming part of it) is intended for general guidance only and not as a substitute for the application of professional expertise. Anyone using thispublication (including any drawings forming part of it) must make their own assessment of the suitability of its content (whether for their own purposes or those of any client or customer),and the <strong>Energy</strong> <strong>Saving</strong> <strong>Trust</strong> cannot accept responsibility for any loss, damage or other liability resulting from such use. So far as the <strong>Energy</strong> <strong>Saving</strong> <strong>Trust</strong> is aware, the information presented inthis publication was correct and current at time of last revision. To ensure you have the most up-to-date version, please visit our website: www.est.org.uk/housingbuildings/publications. Thecontents of this publication may be superseded by statutory requirements or technical advances which arise after the date of publication. It is your responsibility to check latest developments.All technical information was produced by BRE on behalf of the <strong>Energy</strong> <strong>Saving</strong> <strong>Trust</strong>.Printed on Revive Silk which contains 75% de-inked post consumer waste and a maximum of 25% mill broke.