FOR MADHUBAND COAL WASHERY, BCCL - Bharat Coking Coal ...

FOR MADHUBAND COAL WASHERY, BCCL - Bharat Coking Coal ...

FOR MADHUBAND COAL WASHERY, BCCL - Bharat Coking Coal ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

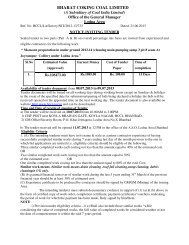

International Competitive BiddingREQUEST <strong>FOR</strong> QUALIFICATION (RFQ)<strong>FOR</strong><strong>MADHUBAND</strong> <strong>COAL</strong> <strong>WASHERY</strong>, <strong>BCCL</strong><strong>FOR</strong> NLW <strong>COAL</strong>(5.0 Mtpa)ON“BUILD-OPERATE-MAINTAIN” BASIS(ON <strong>BCCL</strong> FUNDING)JANUARY - 2009

International Competitive BiddingREQUEST <strong>FOR</strong> QUALIFICATION (RFQ)<strong>FOR</strong><strong>MADHUBAND</strong> <strong>COAL</strong> <strong>WASHERY</strong>, <strong>BCCL</strong><strong>FOR</strong> NLW <strong>COAL</strong>(5.0 Mtpa)ON“BUILD-OPERATE-MAINTAIN” BASIS(ON <strong>BCCL</strong> FUNDING)JANUARY - 2009BHARAT COKING <strong>COAL</strong> LIMITED(A Subsidiary of <strong>Coal</strong> India Limited)Koyla Bhawan , Dhanbad – 826005Jharkhand (INDIA)

CONTENTSCMPDIRequest for QualificationSection Particulars PageNo.SYNOPSIS Synopsis - 1 to 5BID NOTICE BN – 1 to 3DISCLAIMERI to II1 LIST OF ABBREVIATIONS 1-1 to 1-22 DEFINITIONS 2-1 to 2-113 INTRODUCTION & BACKGROUND 3-1 to 3-83.1 Desired Profile & Capability of Bidders/3-1Associates3.2 Scope of Work & Responsibility of BOMO and 3-2Supports by <strong>BCCL</strong>3.3 Salient Features of <strong>Coal</strong> Washery 3-64 DESCRIPTION OF THE SELECTION4-1 to 4-7PROCESS4.1 Bidding Process & Evaluation of Bid 4-14.2 Pre-Bid Conference 4-64.3 Final Award & Notification 4-64.4 Signing of Contract 4-75 QUALIFYING REQUIREMENTS 5-1 to 5-45.1 Technical Qualification Requirements (TQR) 5-15.2 Financial Qualification Requirements (FQR) 5-35.3 Disqualification of the Bidder 5-45.4 Responsibility of Holding Company 5-46 INSTRUCTIONS TO BIDDERS 6-1 to 6-126.1 Availability, Price and Downloading of Bid6-1Document6.2 Submission of Offers against Bid Document 6-36.3 Opening of Bids 6-46.4 Instructions to Bidders 6-46.5 Deposits to be paid by the Bidder & Its6-7Associate(s)6.6 Time Table and Milestones 6-10310208112 (Madh NLW Jan ‘09) iSignature of Bidderwith Seal and Date

Section Particulars PageNo.6.7 Validity of Terms of the Bid 6-106.8 Time Schedule for Bid Evaluation 6-116.9 Clarifications 6-116.10 Organisation of Bid 6-127.0 INTEGRITY PACT 7-1 to 7- 87.1 Preamble 7-17.2 Commitments of the Owner 7-17.3 Commitments of the Bidder/ Contractor 7-27.4 Disqualification from Bid Process and7-3Exclusion from future Contracts7.5 Compensations for Damages 7-47.6 Previous Transgression 7-57.7 Equal treatment of all Bidders/ Contractors/7-5Sub-Contractors7.8 Criminal Charges against violating Bidders/7-5Contractors/ Sub- Contractors7.9 External Independent Monitor/ Monitors 7-67.10 Pact Duration 7-77.11 Other Provisions 7-7CMPDI310208112 (Madh NLW Jan ‘09) iiSignature of Bidderwith Seal and Date

CMPDILIST OF EXHIBITS/ ATTACHMENTS/ ANNEXURERequest for QualificationExhibits/ Attachments/AnnexureParticularsPageNo.Exhibit - 1 Format of the Covering Letter E-1 to E-3Exhibit - 2 Format of Power of Attorney E-4Exhibit - 3 Format of Memorandum of Understanding E-5 to E-8with Associate(s)Exhibit - 4 Format for Submission of Information of Bid E-9for Qualification for <strong>Coal</strong> Washery on BOMconceptAttachment - 1 Format for Submission of Technical E-10 to E-11InformationAttachment - 2 Format for submission of Financial Information E-12 to E-13Exhibit - 5 Format of Bank Guarantee for Bid Security E-14 to E-15Exhibit - 6 Format of Letter of Credit for Bid Security E-16 to E-17Exhibit - 7 Format of Sight Draft E-18Exhibit - 8 Format of Notification by <strong>BCCL</strong> to the Bidder E-19for forfeiture of Bid Security submitted in theform of irrevocable Letter of CreditAnnexure - 1 List of Banks whose Bank Guarantees wouldbe acceptable for Bid Security, DevelopmentE-20 to E-22Guarantee & Contract PerformanceGuarantee etc.310208112 (Madh NLW Jan ‘09) iiiSignature of Bidderwith Seal and Date

SETTING UP OF A 5.0 MTPA <strong>COAL</strong>CMPDI<strong>WASHERY</strong> <strong>FOR</strong> NLW <strong>COAL</strong> AT <strong>MADHUBAND</strong> ON BOM CONCEPT <strong>BCCL</strong> FUNDING Sl.ParticularsDescriptionNo.1 Name of the Document Bid Document setting up of a 5.0 Mtpa <strong>Coal</strong>Washery for NLW <strong>Coal</strong> at Madhuband on ‘BUILD-OPERATE-MAINTAIN’ (BOM) basis (on Funding)2 Validity of Bid/ Offer 18 (eighteen) months (including Environmentalclearances) from the date of opening of the Bid againstRequest for Qualification (RFQ) document.3 Annual throughput Capacity 5.0 Million tonnes of raw coal4 Profile of Bidders Proprietary firm/ Registered Partnership Firm/ A BodyCorporate/ Joint Stock Company or equivalent in case ofForeign Bidder(s).5 Different routes of Bidding Sole Bidder/ Associate (Consortium)6 Scope of Work of BOMOperatorInstallation of a <strong>Coal</strong> Washery Plant for NLW coal ofthroughput capacity of 5.0 Million tonnes per annum(Mtpa) in the vicinity of existing Madhuband Washery of<strong>BCCL</strong> on BOM concept. The work includes Planning,Design & Engineering, Selection of necessaryequipment & machinery, Procurement, Delivery,Erection/ Installation, Testing, SuccessfulCommissioning of <strong>Coal</strong> Washing Plant including PGTwith two years’ critical spares and all allied activities aswell as its subsequent Operation & Maintenance forsupply of washed coal and middlings of requisite qualityat the designated delivery places and disposal ofwashery rejects on BOM concept.7 Technology of Washing Freedom of selection of efficient & cost effective stateof-the-arttechnology lies with the BOM Operator.Washing scheme has to be preferably based on Jig/Heavy Media Separation (Bath/ Drum/ Cyclone orcombination thereof)/ Froth Flotation/ SpiralConcentrator, etc and a combination of above butBidders are free to offer any other improved / proventechnology being used elsewhere in the world.8a)Contract Period:Construction Period(including PGT)Eighteen (18) months from the date of contract cominginto force i.e. signing of Contract.b)Commercial OperationTen (10) Years with a provision of reviewing by theOwner for renewal of the contract for each term of five(05) years thereafter, on the basis of same terms &conditions.310208112 (Madh NLW Jan ‘09) Synopsis - 1Signature of Bidderwith Seal & Date

CMPDI9 <strong>BCCL</strong>’s Obligations A. For Constructioni) Financing for setting up of the washery (including DGset as stand-by power arrangement for criticalequipment/ system) under BOM conceptii) Land free of any obstruction such as abandonedstructures, overhead electrical lines, debris/ dumpmaterials, hillocks etc. with clear approach road forsetting up of washeryiii)Soil investigation report and contour map of theProject site (indicative for bidding purpose only)iv)Supply of water (within 100m) & power at a singlepoint of the proposed washery site on chargeable basisupto successful PGT.B. For Operation & Maintenancei) Land/ mine voids required for disposal of washeryrejects at a distance of about 8.0 km.from the washerysite.ii) Assured raw coal supply of requisite quality andquantity of (–) 200 mm sizeiii) Assured receipt of washed coal & middlings into theloading hopper(s) at the existing railway siding ofMadhuband Washery, <strong>BCCL</strong>.iv) Despatch of washed coal & middlings throughRailways including arranging/ indenting of Railwaywagons as well as loading of washed coal & middlingsinto the railway wagons.v) Loading hopper(s) at the existing railway siding ofMadhuband Washery, <strong>BCCL</strong> for transportation ofwashed coal and middlings.vi) Providing power at 33 kV at Dugda sub-stationsituated at about 10 km from the washery site, on thebasis of agreed demand.vii) Reimbursement of additional operating expenses forDG set on actual.viii) Assured source of water at Jamunia River which isabout 7 km from the washery site.C. For Construction & Operation both<strong>BCCL</strong> will obtain all statutory & regulatory clearancesincluding Environmental Clearances on the basis oftechnology of the Lowest Bidder. This process ofobtaining various clearances may require one year timefrom the date of identification of Lowest Bidder. Afterobtaining such clearances, issue of Letter ofAcceptance/ Award (LoA) & signing of Contract will bedone and thereafter construction period of 18 monthswill commence. Moreover, Lowest Bidder will have to310208112 (Madh NLW Jan ‘09) Synopsis - 2Signature of Bidderwith Seal & Date

assist <strong>BCCL</strong> in all these activitiesCMPDINote: However, arrangement for drawal of water andpower from the sources indicated above at Cl.No.3.2.2.2, to the washery during operation will be withinthe scope of BOM Operator.10 Core Competence of Bidders Sole Bidder Route: Core Competence in the field ofsetting up of <strong>Coal</strong> Washery/ Ore Beneficiation Plant andoperating experience of <strong>Coal</strong> Washery/ OreBeneficiation Plant.Associate/ Consortium Route: In case of Consortium/Associate Route of participation, the maximum no. ofconsortium partners may go up-to 04 (Four) and LeadMember (i.e. Bidder) must have 51% stake. Collectively,consortium partners must meet both the TechnicalQualification Requirements (TQR) i.e. towards ‘set up’as well as ‘operation of coal washery/ ore beneficiationplant’.11 Qualifying Requirements of Bidders (For Sole Bidder/ collectively for Associate/a.Consortium)Technical QualificationRequirementSetting up of <strong>Coal</strong> Washery/ Ore Beneficiation Plant ofat least 2.5 Mtpa capacityOperation of <strong>Coal</strong> Washery/ Ore Beneficiation Plant ofat least 2.5 Mtpa capacityb. Financial QualificationRequirement- Average annual sales turn over of at least INR 37.5Crores- Evidence of possessing adequate working capital of atleast INR 25.0 Crores & solvency certificate from Bank12 Stage of Bidding Single stage. However, bid scrutiny will be carried out ina phased manner13 Bid Document a) RFQ (Request for Qualification) Documentb) RFP (Request for Proposal) Document includingTechnical, Commercial & Price Bid along with SampleContract Form14 Bidding Currency INR and/ or any single convertible Foreign Currency15 Bid Price # 1) Cost of setting up of washery including critical sparesfor 2 (two) years operation and2) Washing charges for the first year of commercialoperation & maintenance.# In respect of washing charges on per tonne basis, bidders are requested to initiallyquote their firm price for first year of commercial operation. Thereafter, such charges willbe determined taking into account among other parameters, the average percentagevariation in WPI of RBI bulletin for Supplies, WPI in respect of Fuel/ Power, Oil &Lubricants; AICPI-IW & Indian Minimum Wages Act for services in respect of indigenouscomponents and similar such authenticated indices published by Central Bank orGovernment Institution or any other appropriate authority available in public domain asindicated by the Bidder in their offer subject to its acceptance by <strong>BCCL</strong>, as applicable incase of imported components.310208112 (Madh NLW Jan ‘09) Synopsis - 3Signature of Bidderwith Seal & Date

CMPDI16 Components of Bid Price Bid price (both for cost of Setting up of Washeryincluding critical spares for two years and washingcharges for first year of commercial operation &maintenance) should include all the components ofStatutory Levies like Custom duty, Excise duty, SalesTax, Work Contract Tax, Service tax, Education Cess,Ocean Freight & Insurance likely to be levied andgoverned under Indian Law apart from other suchcomponents as applicable in the foreign country of originincluding all incidental expenditure like packing, clearing& port handling charges, wharfage, inland insurance,inland freight, inland transportation etc. for execution ofthe subject work.17 Direct taxes- On Bidder’s accountTax liabilities such as Corporate Tax, Income Tax etc.applicable in India and/ or abroad- On <strong>BCCL</strong>’s account Liability on account of R&D Cess18 Bid Security/ Earnest Money This will be for an amount of five (5.00) Million (INR) inthe form of Banker’s/ Cashier Cheque or irrevocable L/Cor BG19 Release of Bid Security/ Shall be returned to the Bidders in the following eventsEarnest Moneywithin 30 days of occurrence :i) Bidders disqualified after evaluation of their Bid forQualification20 Financial Security :a) Development Guarantee(towards setting up of thewashery)b) Contract PerformanceGuarantee (towards operation& maintenance of the plant)ii) Other Bidders except the Lowest Bidder (afterfinalization of the Lowest Bidder)10% of value towards set up cost of 5.0 Mtpa plant inthe form of BG in INR. This DG is to be shared inproportion to their respective stakes of the Bidder (LeadMember) & its Associates or Consortium Partners.The aforesaid Development Guarantee (DG) will bereturned after obtaining Contract PerformanceGuarantee (CPG) of value equivalent to 10% of theannual washing charges in the form of BG. This CPGshall also be shared in the way similar to that of DGamong the Bidder (Lead Member) and its Associates orConsortium partners (likely to continue for the balancecontract period of operation & maintenance). Such BGwill be operational for the balance period of commercialoperation of the Contract Period. This CPG will besubstituted annually on the basis of the revised washingcharges. This BG for CPG has to be in INR.21 Release of ContractPerformance GuaranteeAt the end of the contract period related to operation &maintenance of the plant.22 LD for Delay @ 0.25% of the Contract price for setting up of thewashery per week of delay upto 10 weeks and @ 0.5%thereafter. However, total LD for delay shall not exceed10% of contract price for setting up of the washery.310208112 (Madh NLW Jan ‘09) Synopsis - 4Signature of Bidderwith Seal & Date

CMPDI23 Mobilization Advance The document envisages a provision for payment ofinterest bearing mobilization advance equivalent tocertain percentage of equipment & erection cost and itwill be recovered @ 20% from 2 nd running-on-accountbills. It should be backed by equivalent Bank Guaranteeas acceptable to the designated banker of <strong>BCCL</strong>.24 Raw <strong>Coal</strong> [size (-) 200 mm]Quality on ‘as received basis’25 Desired Ash% for Washed<strong>Coal</strong> on ‘as produced basis’i) Likely Monthly Average Ash % : 42.0ii) Range of Monthly Average Ash % : 42.0+ 4iii) Day to day basis Ash % : 42.0+ 4iv)Likely Total moisture content : 2.0.% (on day to daybasis)i) Targeted Monthly average Ash % : 18.0ii) Maximum Ash (cut-off limit) : 18.5% (on monthly basis)iii)Minimum Ash (cut-off limit) : 17.5 % (on monthly basis)26 Desired Ash% for Middlings onas produced basis’i) Targeted Monthly average Ash % : Less than 40.0%ii) Maximum Ash (cut-off limit) : 40.0% (on monthly basis)27 Desired Moisture% for Washed<strong>Coal</strong> and Middlings28 Guaranteed Yield% of Washed<strong>Coal</strong> at the targeted washedcoal ash of A%29 Guaranteed Yield% ofMiddlings at the targetedmiddlings ash of B%30 Indian Agent’s Commissionetc.Maximum total moisture in both the products i.e.washed/ clean coal and middlings shall not exceed 9.5%& 9.0% respectively on as produced basis.To be quoted by the Bidder for different monthly averageash% of raw coal (duly correcting the ash% parameteron dry basis)To be quoted by the Bidder for different monthly averageash% of raw coal (duly correcting the ash% parameteron dry basis)Under no circumstances, <strong>BCCL</strong> shall make any directpayments of whatsoever nature to the Bidder’s IndianAgent31 Financial Evaluation On the basis of lowest cost towards cost of set up ofwashery and washing charges including otherassociated cost, if any, including impact of Highestmonetary return value for Guaranteed Yield of washedcoal & middlings.310208112 (Madh NLW Jan ‘09) Synopsis - 5Signature of Bidderwith Seal & Date

310208112 (Madh NLW Jan ‘09) BN - 1 Signature of BidderWith Seal & DateCMPDI

310208112 (Madh NLW Jan ‘09) BN - 2 Signature of BidderWith Seal & DateCMPDI

310208112 (Madh NLW Jan ‘09) BN - 3 Signature of BidderWith Seal & DateCMPDI

CMPDIDISCLAIMERThe purpose of this Bid Document is to provide interested parties withinformation to facilitate formulation of their Offer/ Bid and to seek their Offer/ Bid for“Setting up of <strong>Coal</strong> Washery (on <strong>BCCL</strong> funding) as well as its operation &maintenance” (execution of the subject work) on BUILD-OPERATE-MAINTAIN(BOM) concept in the vicinity of existing Madhuband Washery of <strong>BCCL</strong>.The Bid Document includes statements, which reflect various assumptions,which may or may not be correct. This Bid Document does not purport to contain allthe information each Bidder may require. The Bid Document may not be appropriatefor all persons and it is not possible for <strong>BCCL</strong> to consider the investment objectives,financial situation and particular needs of each Bidder who reads or uses the BidDocument. Certain Bidders may have a better knowledge than the others forexecution of the subject work. Each Bidder should conduct its own investigations andanalysis and should check the accuracy, reliability and completeness of theinformation in the Bid Document and obtain independent advice from appropriatesources.Neither <strong>BCCL</strong> nor its employees or its consultants will have any liability toany Bidder or any other person under the law of contract, tort, the principles ofrestitution or unjust enrichment or otherwise for any loss, expense or damage whichmay arise from or be incurred or suffered in connection with anything contained inthe Bid Document, any matter deemed to form part of the Bid Document, the awardfor setting up, operating & maintaining of <strong>Coal</strong> Washery and any other informationsupplied by or on behalf of <strong>BCCL</strong> or its employees, any of its consultants orotherwise arising in any way from the selection process for execution of the subjectwork of the <strong>Coal</strong> Washery on BOM concept. The Bidder shall bear all costsassociated with preparation and submission of his/ their bid and <strong>BCCL</strong> will in no casebe responsible or liable for these costs, regardless of the conduct or outcome of thebidding process.310208112 (Madh NLW Jan ‘09) ISignature of Bidderwith Seal and Date

CMPDI<strong>BCCL</strong> reserves the right to reject any or all the bids or cancel/ withdraw theBidding process for execution of the subject work ofthe <strong>Coal</strong> Washery on BOMconcept without assigning any reason whatsoever and in such case, no bidder/intending bidder shall have any claim arising out of such action.Though, adequate care has been taken while issuing the Bid Documents, theBidder should satisfy himself that the documents are complete in all respects.Intimation of any discrepancy shall be given to this office (as mentioned below)immediately. If no intimation is received by this office upto 30 days before last date ofsubmission of the Bid, then this office shall consider that the Bid Document receivedby the Bidder is complete in all respects and that the Bidder is satisfied that the BidDocument is complete in all respects.Office :Chief General Manager (WC & CP),Washeries Construction Division,Koyla Bhawan (Level-VI),P.O <strong>BCCL</strong> TOWNSHIP,DHANBAD- 826005The Bid Document and the information contained therein are confidential andare for the use of only the person(s) to whom it is issued. It may not be copied ordistributed by the recipient to third parties (other than in confidence to the recipient’sprofessional advisors).<strong>BCCL</strong> confirms that all information submitted with the proposal of the biddershall be treated by <strong>BCCL</strong> as strictly confidential and such information shall be sharedby <strong>BCCL</strong> only with its consultants appointed for the purpose of Bid evaluation.310208112 (Madh NLW Jan ‘09) IISignature of Bidderwith Seal and Date

CMPDI1. LIST OF ABBREVIATIONSadbAICPI - IWAIEEapbarbASMEASQBARC<strong>BCCL</strong>BGBOMBOMO/BOMOperatorBSCGICILCMPDICPGDAEDCFDGEICEMPFCFQRFSFSAGCVICBINRIWSSJDULDLIBORLMAir Dried BasisAll India Consumer Price Index for Industrial WorkersAmerican Institute of Electrical EngineersAs Produced BasisAs Received BasisAmerican Society of Mechanical EngineersAgreed Scheduled QuantityBhaba Atomic Research Centre<strong>Bharat</strong> <strong>Coking</strong> <strong>Coal</strong> LimitedBank GuaranteeBuild-Operate-MaintainBuild-Operate-Maintain OperatorBid SecurityCorrugated Galvanised Iron<strong>Coal</strong> India LimitedCentral Mine Planning & Design Institute LimitedContract Performance GuaranteeDepartment of Atomic EnergyDiscounted Cash FlowDevelopment GuaranteeEngineer-in-ChargeEnvironmental Management PlanForeign CurrencyFinancial Qualification RequirementFinancial SecurityFuel Supply AgreementGross Calorific ValueInternational Competitive BiddingIndian National RupeeIntegrated Water Supply SchemeJoint Deed of UndertakingLiquidated DamagesLondon Inter Bank Operating RateLead Member310208112 (Madh NLW Jan ‘09) 1 -1Signature of Bidderwith Seal and Date

LoALRMCMESQmmMoU/ MOUMSQMtpaNITNLWPERTPGTRBIRFPRFQRLQRtphTQRTSQUHVUSDVMWPIYRFYTMLetter of Acceptance/ Letter of AwardLong Range Marginal CostMonthly Expected Scheduled QuantityMillimetreMemorandum of UnderstandingMonthly Scheduled QuantityMillion tonne per annumNotice Inviting TenderNon Linked WasheryProgramme Evaluation & Review TechniquePerformance Guarantee TestReserve Bank of IndiaRequest for Proposal DocumentRequest for Qualification DocumentReduced LevelQualifying Requirementstonnes per hourTechnical Qualification RequirementTentative Scheduled QuantityUseful Heat ValueUS DollarVolatile MatterWholesale Price IndexYield Reduction FactorYield to MaturityCMPDI310208112 (Madh NLW Jan ‘09) 1 -2Signature of Bidderwith Seal and Date

CMPDIDEFINITION310208112(Madh NLW Jan ’09)Signature of Bidderwith Seal & Date

CMPDI2. DEFINITIONSNote : The singular of any defined term includes the plural and vice versa, and anyword or expression defined in the singular has the corresponding meaning used inthe plural and vice versa.‘Accepting authority’ shall mean the management of <strong>BCCL</strong> (Owner) or theirauthorized representative.'Acceptable Quality' of washed coal and middlings shall mean specifications forwashed coal and middlings having ash content of 18.0 % & less than 40.0 %respectively on monthly average (on ‘as produced basis’) and maximum totalmoisture in both the products i.e. washed/ clean coal and middlings not exceeding9.5% and 9.0% respectively on as produced basis.The 'Agreement' shall mean the Contract entered into between the Owner & thePreferred Bidder (BOMO) for setting up of washery as well as operation &maintenance of the washery. The Agreement/ Contract will consist of two parts. Thefirst part of the Contract will contain terms & conditions governing the setting up ofthe washery and the second part will be for operation of the washery & maintenancethereof.'Approved' shall mean approved in writing including subsequent written confirmationof previous verbal approval.‘As Produced Basis’ shall mean condition of products as loaded into the railwaywagons or other means for despatch to customers.‘Associate’ shall mean a proprietary firm/ a registered partnership firm/ a bodycorporate/ Joint Stock Company or equivalent in case of Foreign Bidders who formsconsortium in such a way that the consortium collectively possess both the technicalqualifications (of set up as well as operation of <strong>Coal</strong> Washery/ Ore BeneficiationPlant) & Financial Qualification Requirement (FQR). Associate individually may ormay not possess any of the Qualifying Requirements (QR).310208112 (Madh NLW Jan ‘09) 2 - 1Signature of Bidderwith Seal & Date

CMPDI‘Authorised Signatory’ shall refer to the person/ persons and organization whohave been so authorised by the Bidder/ Owner to represent them in respect of theBid submitted.'Average Yield of Middlings' for monthly billing period shall mean the ratio of thequantity of middlings (on dry basis) actually measured & delivered to <strong>BCCL</strong> atdesignated point (loading hopper(s) at the existing railway siding of MadhubandWashery, <strong>BCCL</strong>) produced at desired ash% during the month to the correspondingraw coal quantity (on dry basis) utilised to process and produce the said quantity ofmiddlings in the same period. However, this dry basis of middlings & raw coal will bearrived by converting middlings (as produced basis) and raw coal (as received basis).'Average Yield of Washed <strong>Coal</strong>' for monthly billing period shall mean the ratio of thequantity of washed coal (on dry basis) actually measured & delivered to <strong>BCCL</strong> atdesignated point (loading hopper at the existing railway siding of MadhubandWashery, <strong>BCCL</strong>) produced at desired ash% during the month to the correspondingraw coal quantity (on dry basis) utilised to process and produce the said quantity ofwashed coal in the same period. However, this dry basis of washed coal & raw coalwill be arrived by converting washed coal (as produced basis) and raw coal (asreceived basis).‘Bank Guarantee’ shall mean the Bank Guarantee to be provided by the Bank onbehalf of BOM Operator to the Company/ Owner.'Base Date' shall mean the actual date on which plant commences its commercialoperation and the same will be considered as a reference date for determining theperiod to be considered for payment of washing charges.'<strong>BCCL</strong>' shall mean <strong>Bharat</strong> <strong>Coking</strong> <strong>Coal</strong> Limited (a subsidiary of <strong>Coal</strong> India Limited), acompany registered under the Indian Companies Act, 1956 having its registeredoffice at Koyla Bhawan-826005, Dhanbad, in the state of Jharkhand, hereinafterreferred to as Company/ Owner.‘Beneficiation/ Washing’ shall mean improvement created by scientific treatment(through wet processes) on coal without destruction of its physical identity for thedesired end use.310208112 (Madh NLW Jan ‘09) 2 - 2Signature of Bidderwith Seal & Date

CMPDI‘Beneficiation plant/ Washing plant/ <strong>Coal</strong> washery/ Washery/ Plant’ shall meanthe plant where improvement is created by scientific treatment (through wetprocesses) on coal without destruction of physical identity for the desired end use.‘Bidder’ shall mean a proprietary firm/ a registered partnership firm/ a bodycorporate/ Joint Stock Company or equivalent in case of Foreign Bidders who haspurchased the Bid Document and submitted the Bid. Bidding may be done either as aSole Bidder or with Associate (consortium partner) as a Lead Member (having atleast 51% stake) for setting up and operation & maintenance of <strong>Coal</strong> Washery onBOM concept. In case of Associate/ Consortium Route, Lead Member of Consortiumwill be termed as ‘Bidder’.‘Bid Document’ shall mean the documents such as RFQ & RFP (includingTechnical, Commercial & Price Bid along with Sample Contract Form) being issued tothe Bidders.‘Bid/ Offer/ Proposal’ shall mean the proposal of the Bidder submitted in responseto the Bid Document issued by <strong>BCCL</strong> (i.e. RFQ & RFP).‘Bid price’ shall mean price quoted by the Bidder(s) towards the costs of setting upof the washery including cost of critical spares for two years operation (i.e. ProjectCapital Cost) and washing charges (including operation & maintenance) for first yearof commercial operation.‘Bid for Qualification’ shall mean the proposal submitted by the Bidder in responseto the RFQ part of Bid document.‘Bid for Proposal’ shall mean the proposal submitted by the Bidder in response tothe RFP part of Bid document.‘Build-Operate-Maintain (BOM)’ refers to the concept in which the ownership ofplant, raw coal & its products will remain with <strong>BCCL</strong> and finance for setting up ofPlant will be made available by <strong>BCCL</strong> to the Selected Bidder who shall beresponsible for setting up as well as operation & maintenance of plant during theentire contract period on payment of the agreed washing/ processing charges.310208112 (Madh NLW Jan ‘09) 2 - 3Signature of Bidderwith Seal & Date

CMPDI‘BOM Operator’ or ‘BOMO’ or ‘Contractor’ wherever occurs means the SelectedBidder and shall include legal representative of such individual or persons composinga firm or a company or the successors-in-interest and permitted assignees of suchindividual, firm or company, as the case may be.‘CIL or its subsidiary’ means <strong>Coal</strong> India Limited and/ or its Subsidiary Companiesand its successors-in-interest and assigns.‘Codes’ shall mean the following, including the latest amendments, and/ orreplacements, if any :(a)Standards/ Publications of Bureau of Indian Standards (BIS) relevant to theworks under the contract and their specifications.(b)Other Internationally approved Standards and/ or rules and regulations touchingthe subject matter of the contract, such as:(i)(ii)(iii)(iv)(v)(vi)(vii)(viii)ASME Test codes.AIEE Test codes.American Society of Materials Testing Codes.Indian Electricity Act and Rules and Regulations made there under.Indian Explosive Act and Rules and Regulations made thereunder.Indian Petroleum Act and Rules and Regulations made thereunder.Indian Mines Act and Rules and Regulations made thereunder.Other Rules & Regulations related to the washery environment etc.(c) Any other laws, rules, regulations and Acts applicable in the country withrespect to factory, labour, safety, compensation, insurance etc.‘Commercial Operation’ shall mean the operation & maintenance of plant in whichthe complete equipment covered under the contract is officially declared by theOwner to be available for continuous operation after successful PGT. Such310208112 (Madh NLW Jan ‘09) 2 - 4Signature of Bidderwith Seal & Date

CMPDIdeclaration by the Owner however, shall not relieve or prejudice any of the BOMOperator’s obligations under this contract.'Commissioning of the Washery' shall mean completion in all respect ofconstruction of the washery and successful Performance Guarantee Test andrendering the washery ready for commercial operation.‘Company’ or ‘Owner’ wherever occurs, means the <strong>BCCL</strong>, and/ or its assigns.‘Consulting Engineer’/’Consultant’ shall mean any firm or person duly appointedas such from time to time by the Owner.‘Contract’ shall mean the formal agreement executed between the Owner and theSelected Bidder for setting up of the washery, operation & maintenance thereof withthe terms & conditions mentioned therein including Bid Notice, the Bid as acceptedby the Owner, specifications, designs & drawings and those to be submitted duringprogress of work, scope of work, billing schedule/ schedule of quantities with ratesand amounts etc.‘Contract coming into force’/ ‘Effective Date of Contract’ shall mean the date onwhich contract is signed between the Owner and the Bidder for the subject work.‘Contract period’ shall mean a period of eighteen (18) months from the effectivedate of contract and extension thereof, if any, for setting up of the washery upto itssuccessful commissioning and thereafter a period of ten (10) years for operation &maintenance of the plant by BOM Operator.‘Contractor's Works’ or ‘BOM Operator’s Works’ shall mean the place of workused by the Contractor, their collaborators or sub-contractors for the performance ofthe works.Datum Line shall mean the last day of the scheduled month of expiry of completionperiod (i.e. 18 months) of the plant from the date of contract coming into force.A ‘Day’ shall mean a period of 24 hours from midnight to midnight.‘Drawings’/’Plans’ shall mean all:310208112 (Madh NLW Jan ‘09) 2 - 5Signature of Bidderwith Seal & Date

a) drawings furnished by the Owner/ Consultant as a basis for proposals,CMPDIb) supplementary drawings furnished by the Owner/ Consultant to clarify and todefine in greater detail the intent of the contract.c) drawings submitted by the BOM Operator with his proposal/bid provided suchdrawings are acceptable to the Owner/ Consultant.d) drawings furnished by the Owner/ Consultant to the BOM Operator during theprogress of the work, ande) engineering data and drawings submitted by the BOM Operator during theprogress of the work provided such drawings are acceptable to EIC.‘Engineer’ wherever occurs, means the authorised representative or any otherofficer specially deputed by the Company for the purpose of contract and to assist theEngineer-in-Charge.‘Engineer-in-Charge (EIC)/ Designated Officer-in-charge’ shall mean a person ofappropriate seniority who will be responsible for supervising and administering thecontract, certifying payment due to the BOMO, valuing variations to the contract,awarding extension of time and valuing compensation events. Engineer-in-Charge(EIC)/ Designated Officer-in-Charge may further appoint his representatives i.e.another person/ Project Manager or any other competent person and notify to theContractor who is directly responsible for supervising the work being executed at thesite, on his behalf under the Delegation of Powers of the company. However, overallresponsibility, as far as the contract is concerned during the period of set up as wellas operation & maintenance will be that of the Engineer-in-Charge (EIC)/ DesignatedOfficer-in-Charge.‘Final Acceptance’ shall mean the Owner's written acceptance of the works forsetting up of the washery performed under the contract, after successful completionof Performance Guarantee Tests. After completion of successful PGT, the plant willbe deemed to be handed over to the BOM Operator for its commercial operation.‘Government Approvals’ shall mean all permits, licenses, authorizations, consents,clearances, decrees, waivers, privileges, approvals from and filing with government310208112 (Madh NLW Jan ‘09) 2 - 6Signature of Bidderwith Seal & Date

CMPDIinstrumentalities necessary for the development, construction and operation of theplant/project.‘Guarantee Period’ of the <strong>Coal</strong> washery, in general, is to be looked by the Bidder &shall mean guarantee of the entire <strong>Coal</strong> Washery for at least one year from thecommencement of commercial operation after successful commissioning of the plant.However, in case the Bidder is having experience of ‘operation’ and its Associate(s)has/ have the experience of ‘set-up’, the Associate(s) is/ are required to render thesame guarantee.‘Initial operation’ shall mean the first integral operation of the complete equipmentcovered under the contract with sub-systems and supporting equipment in service.‘Inspector’ shall mean the Owner or any person nominated by the Owner from timeto time to inspect the equipment, stores or works under the contract and/or the dulyauthorised representative of the Owner.‘Lead Member’ (LM) shall mean the Bidder who has at least 51% stake and continueto perform the obligations towards the subject work for the entire contract period incase of Consortium/ Associate Route having maximum no. of consortium partnersup-to 4 (four). The Lead Member has to fulfil the Financial Qualification Requirementof the Bid. In case of Associate/ Consortium Route, Lead Member of Consortium willbe termed as ‘Bidder’. The Lead Member may or may not have any TechnicalQualification Requirement (TQR) though the Lead Member has to fulfil the FinancialQualification Requirement (FQR) of the Bid. Lead Member of Consortium/ Associatemust be identified through MoU and subsequently through JDU.‘Letter of Acceptance’/ ‘Letter of Award’ (LoA) of the Bid shall mean the officialcommunication issued by the Owner notifying the Preferred Bidder about acceptanceof its Bid & inviting for signing of Contract.‘Middlings’ shall mean the product (other than washed coal & rejects, having ash %more than washed coal but less than rejects) of Washery which satisfies the qualityparameters laid down in the Bid Document/ Contract Document.‘Month’ shall mean a calendar month according to the Gregorian calendar.310208112 (Madh NLW Jan ‘09) 2 - 7Signature of Bidderwith Seal & Date

CMPDI‘Performance Guarantee Tests (PGT)’ shall mean all operational checks and testswhich are required to determine and demonstrate capacity, efficiency and operatingcharacteristics (such as consumption of electricity & water etc.) as specified in the BidDocument.‘Preferred Bidder’ shall mean the eligible Bidder invited by <strong>BCCL</strong> for entering intocontract for execution of the subject work on BOM concept.‘Price Bid’ shall mean the proposal submitted by the Bidder giving details of the pricepart as per the formats given in the RFP part of the Bid document.The price part of the Bidder on BOM concept shall have two parts i.e. INR and/or anyconvertible Foreign Currency towards:i) the cost for setting up of coal washery andii)the charges for washing of coal to get desired quality (including maintenanceof the plant) for one year of commercial operation and subsequent delivery ofwashed coal and middlings to <strong>BCCL</strong> at the designated places.‘Project capital cost’/ ‘Set-up Cost’ shall mean the capital cost indicated by thebidder in their offer for setting up of the washery including cost of critical spares fortwo years operation.‘Project’ shall mean any and all infrastructure facilities proposed to be put up forsetting up of <strong>Coal</strong> Washery on BOM concept for which finance is provided by <strong>BCCL</strong>.‘Qualified Bidders’ shall mean the Bidders short-listed based on the Bid forQualification for further techno-commercial evaluation as per RFP part of the Bid.'Rejects' shall mean the waste coal product produced during operation of thewashery having ash% (as produced basis) as quoted by the BOM Operator.‘Request for Proposal or RFP’ shall mean one of the documents issued by <strong>BCCL</strong>as a part of Bid Document for submitting the Techno-commercial as well as Price Bid.It will also contain Sample Contract Form.310208112 (Madh NLW Jan ‘09) 2 - 8Signature of Bidderwith Seal & Date

CMPDI‘Request for Qualification or RFQ’ shall mean one of the documents issued by<strong>BCCL</strong> as a part of Bid Document for submitting the Bid for Qualification.‘Selected Bidder’ shall mean the Preferred Bidder that finally enters into contractwith <strong>BCCL</strong> for execution of the subject work of <strong>Coal</strong> Washery on BOM concept.‘Set up’ shall mean execution of <strong>Coal</strong> washery from concept to commissioning whichinter-alia includes planning, design & engineering, selection of necessary equipment& machineries, procurement, delivery, erection/ installation, testing, successfulcommissioning of coal washery plant including PGT and all allied activities with twoyears’ critical spares.Words importing ‘singular’ only shall also include the plural and vice-versa wherethe context so requires. Similarly the words with ‘masculine’ meaning shall also refer‘feminine’ meaning as per the requirement/ suitability of the text.‘Set up period’ is a period of 18 months and any extension thereof required for setup of the washery up to successful commissioning including Performance GuaranteeTests (PGT) after signing of the Contract.‘Site’ shall mean the place of the contract work including land and any building anderections thereon and any other land allotted by the company for Contractor's use inthe execution/ performance of the contract.‘Sub-contractor’, as employed in the Bid Document, includes those having a directcontract with Contractor either on piece rate, item rate, time rate or on any otherbasis and it includes one who furnishes work to a special design according to theplans or specifications of this work but does not include one who merely suppliedmaterials.‘Specification’ shall mean the technical specifications forming a part of the contractand such other schedules and drawings as may be mutually agreed upon.‘Start-up’ shall mean the time period, which is required to bring the equipmentcovered under the Contract from an inactive condition, when construction isessentially complete to the state ready for trial operation. The start-up period shallinclude preliminary inspection and check out of equipment and supporting sub-310208112 (Madh NLW Jan ‘09) 2 - 9Signature of Bidderwith Seal & Date

CMPDIsystems initial operation of the complete equipment covered under the Contract toobtain necessary pre-trial operation data, perform calibration and corrective action;shut down inspection and adjustment prior to the trial operation period.‘Subject Work’ shall mean entire scope related to ‘setting up of washery’ as well asits ‘operation & maintenance’.‘Techno-commercial Bid’ shall mean the proposal submitted by the Bidder inresponse to the RFP part of the document, except the Price Bid.'Temporary Works' shall mean all temporary works of every kind required in or forthe execution, completion or maintenance of the works.‘Washed / Clean <strong>Coal</strong>’ shall mean the final product of Washery which satisfies thequality parameters laid down in the Bid Document/ Contract Document.‘Works’ shall mean and include the furnishing of equipment, labour and the servicesin accordance with the contract or parts thereof as the case may be and shall alsoinclude all extra or additional, altered or substituted works or any work of emergentnature, which in the opinion of the Engineer-in-Charge (EIC), become necessaryduring the progress of the works to obviate any risk or accident or failure or becomenecessary for security.‘Written notice & serving thereof’ shall mean a notice or communication in writingand shall be deemed to have been duly served if delivered in person to the individualor to a member of the firm or to an office of the Corporation/ Company for whom it isintended, or if delivered at or sent by registered mail/ e-mail to the last businessaddress known to him who gives the notice.Notei) When the words "Approved", "Subject to Approval", "Satisfactory", "Equal to","Proper", "Requested", "As directed", "Where directed", "When directed","Determined by", "Accepted", "Permitted", or words and phrases of like import areused, the approval, judgment, direction etc. is understood to be a function of theOwner/ Engineer/ Engineer-in-Charge (EIC).310208112 (Madh NLW Jan ‘09) 2 - 10Signature of Bidderwith Seal & Date

CMPDIii) Terms and expressions not defined herein shall have the same meaning as areassigned to them in the “Indian Sale of Goods Act”, failing that in the “Indian ContractAct”, and failing that in the “General Clauses Act”.310208112 (Madh NLW Jan ‘09) 2 - 11Signature of Bidderwith Seal & Date

CMPDIINTRODUCTION & BACKGROUND310208112(Madh NLW Jan ’09)Signature of Bidderwith Seal & Date

CMPDI3. INTRODUCTION & BACKGROUND<strong>BCCL</strong> proposes to execute the subject work of a <strong>Coal</strong> Washery on BOMconcept in the vicinity of existing Madhuband Washery of <strong>BCCL</strong> for production ofwashed coal and middlings to be used by Steel Plants & Thermal Power Plantsrespectively, or as they deem fit. For this purpose, <strong>BCCL</strong> is inviting Bid through“International Competitive Bidding Route” from prospective bidders for execution ofthe subject work of <strong>Coal</strong> Washery on BOM basis. The objective is to select a Bidder,who has the technical, financial and organisational capability to Build, Operate &Maintain the <strong>Coal</strong> Washery and ensure reliable, uninterrupted supply of washed coaland middlings of requisite quality & quantity for the clients of <strong>BCCL</strong>.3.1 DESIRED PROFILE & CAPABILITY OF BIDDERS/ASSOCIATES3.1.1 PROFILEThe Bidder/ Associates shall be proprietary firm/ registered partnership firm/body corporate / joint stock Company or equivalent in case of foreign bidder(s).3.1.2 TECHNICAL CAPABILITYThe Bidder(s) should have access (either of their own in case of sole bidderroute or through their associates in case of associates/ consortium route) to the stateof-the-arttechnology and previous experience from concept to commissioning whichinter-alia includes planning, design & engineering, selection of necessary equipment& machinery, procurement, delivery, erection/ installation, testing, successfulcommissioning of <strong>Coal</strong> Washing Plant/ Ore Beneficiation Plant and all allied activitiesincluding PGT as well as operation & maintenance of <strong>Coal</strong> Washery/ OreBeneficiation Plant, so as to execute the subject work of <strong>Coal</strong> Washery and ensurereliable, uninterrupted supply of desired quantity & quality of washed coal andmiddlings for the client(s) of <strong>BCCL</strong>. Details are given at Cl.no.5.1 of this document.310208112 (Madh NLW Jan ’09)3 - 1Signature of Bidderwith Seal & Date

CMPDI3.1.3 FINANCIAL CAPABILITYThe Bidder in case of Sole Bidder Route & Lead Member in case ofAssociate/ Consortium Route should have adequate financial capability in terms ofaverage annual sales turn-over and working capital to meet the financialcommitments commensurate with the scope of work. Details are given at Cl. No. 5.2of this document. This financial capability of bidders shall be evaluated for thosebidders who will continue to perform the obligations towards the execution of thesubject work for the entire contract period, such as Lead Member in case ofConsortium/ Associate Route.3.2 SCOPE OF WORK & RESPONSIBILITY OF BOMO ANDSUPPORTS BY <strong>BCCL</strong>3.2.1 SCOPE OF WORK & RESPONSIBILITY OF BOMO3.2.1.1 SETTING UP OF <strong>COAL</strong> <strong>WASHERY</strong>The scope of work of the Bidder broadly covers Installation of a <strong>Coal</strong> WasheryPlant for NLW coal of throughput capacity of 5.0 Million tonnes per annum (Mtpa) in thevicinity of existing Madhuband Washery of <strong>BCCL</strong> on BOM concept. The work includesplanning, design & engineering, selection of necessary equipment & machinery,procurement, delivery, erection/ installation, testing, successful commissioningincluding PGT of coal washing plant and all allied activities for setting up of <strong>Coal</strong>Washery on BOM concept and ensure reliable, uninterrupted supply of desired quantity& quality of washed coal and middlings for the client(s) of <strong>BCCL</strong>. For safety & securityof the washery and its properties including raw coal & its products, the entire washerycomplex shall be provided with boundary wall of adequate height. <strong>BCCL</strong> will providerequired capital funding for setting up of the washery.Washery complex in general shall include the provision of raw coal receivingarrangement; main coal washing plant; delivery arrangement of washed coal andmiddlings; emergency stockpile of raw coal, washed coal & middlings and all alliedfacilities such as thickeners, slurry pond, different service buildings etc.310208112 (Madh NLW Jan ’09)3 - 2Signature of Bidderwith Seal & Date

CMPDI3.2.1.2 OPERATION & MAINTENANCE OF <strong>COAL</strong> <strong>WASHERY</strong>Though the Washery will wash the coal provided by <strong>BCCL</strong>, the ownership ofraw coal, washed coal, middlings and rejects including slurry (if any) shall remain with<strong>BCCL</strong>.The scope of work of the Bidder also covers operation and maintenance ofthe plant for a period of ten (10) years (after successful commissioning of thewashery). Performance of the contract shall be reviewed during the period of 10 thyear by the Owner and based on the performance of the BOMO, the contract may berenewed for a further period of five (05) years initially, from the date of expiry of 10 thyear with the option of renewal of the contract for further five (05) years after the endof such extended period of five (05) years, on the basis of the same terms &conditions and this scope include the following:i) Receipt of raw coal of specified quality & quantity at washery end provided by<strong>BCCL</strong>.ii) Washing of raw coal to meet requisite quality & quantity of washed coal andmiddlings.iii) Delivery of washed coal and middlings to <strong>BCCL</strong> at designated delivery placesi.e. loading hopper(s) at the existing railway siding of Madhuband Washery, <strong>BCCL</strong>which is about 1.6 km away from the proposed washery site.iv)Maintenance of the plant.3.2.1.3 DISPOSAL OF <strong>WASHERY</strong> REJECTSTransportation and disposal of washery rejects to the identified site from theproposed washery site shall be the responsibility of the BOMO. If the average grosscalorific value of the reject is more than 1500 kcal/ kg, it will be used in the FBCbased Power Plant to be set up by <strong>BCCL</strong> for the power generation in the manner tobe decided by <strong>BCCL</strong>. However, the rejects may be dumped by BOMO in the externaldump site which is at a distance of about 8.0 km from the washery site. In case theaverage Gross Calorific Value of the rejects is found to be less than 1500 kcal/kg (Or310208112 (Madh NLW Jan ’09)3 - 3Signature of Bidderwith Seal & Date

CMPDIthe heat value to be decided by <strong>BCCL</strong> during actual operation of the washery) andnot suitable for use in FBC based Power Plant, then also the rejects will have to bedumped separately at the same external dump site by earmarking a different place.The methodology of determination of GCV & mechanism of segregation of rejects oflower & higher heat value will be jointly decided by BOMO & <strong>BCCL</strong>. The details anddistances of these identified sites from the washery site are indicated in the ‘Site Planshowing land use’ (Refer Drg. No. HQ/CMP/310208112(Madh NLW)/04/001) in theBid Document. The disposal of rejects will be with due arrangement of compactionand consolidation as per norms of Environment Management Plan (EMP) dulyapproved by State/ Central and other concerned agencies.3.2.1. 4 STATUTORY & REGULATORY CLEARANCESThough, the responsibility of obtaining statutory and regulatory clearanceslies with the Owner (<strong>BCCL</strong>) but while operating, the BOMO must comply with allstatutory and regulatory requirements.3.2.1.5 SCHEDULESThe indicative schedules for the Bid process are as follows:Name & Description of WorkSetting up of a 5 Mtpa <strong>Coal</strong>Washery for NLW coal atMadhuband on BOM concept :Planning, Design & Engineering,Selection of necessaryequipment & machinery,Procurement, Delivery, Erection/Installation, Testing, SuccessfulCommissioning of <strong>Coal</strong>Washing Plant including PGTwith two years’ critical sparesand all allied activities as well asits subsequent Operation &Maintenance for supply ofwashed coal & middlings ofrequisite quality at thedesignated delivery places anddisposal of washery rejects onBOM concept.Provision of Fundand infrastructure<strong>BCCL</strong> will providethe capital fundingfor set up ofwashery and otherinfra-structuralfacilities like land,water, power etc.ThroughputCapacity5.0milliontonnesperannum(Mtpa) ofraw coalLocationIn thevicinity ofexistingMadhubandWashery of<strong>BCCL</strong>SchedulesConstruction Operation &Maintenance18 Months Ten (10) years(including with a provision ofPGT) from reviewing by thethe date of Owner for renewalsigning of of the contract forContract each term of five(5) yearsthereafter, on thebasis of sameterms &conditionsThe other details and information of general nature are indicated in thisdocument under the caption of “Salient features of the <strong>Coal</strong> Washery” at para 3.3 ofthis Section of RFQ document.310208112 (Madh NLW Jan ’09)3 - 4Signature of Bidderwith Seal & Date

CMPDI3.2.1.6 ENVIRONMENTAL AND OTHER STATUTORY & REGULATORYCLEARANCESThe Selected Bidder shall be responsible for execution of coal washery fromconcept to commissioning which inter-alia includes planning, design & engineering,selection of necessary procurement, delivery, erection / installation, testing,successful commissioning as well as operating & maintaining the coal washing plantand all allied activities in compatible manner as per the norms laid down by Central/State Pollution Control Boards or any other agency as applicable. However, <strong>BCCL</strong>shall be responsible for obtaining all such environmental and other clearances fromCentral/ State Pollution Control Boards or any other agency as applicable. However,the Bidder shall provide all necessary assistance/ support in this regard asnecessary.3.2.2 SUPPORTS BY <strong>BCCL</strong>hereafter.<strong>BCCL</strong> shall provide the supports to the BOMO for the subject work as given3.2.2.1 <strong>FOR</strong> CONSTRUCTIONii)iii)iv)i) Financing for setting up of the washery (including DG set as stand-bypower arrangement for critical equipment/ system) under BOM conceptLand free of any obstruction such as abandoned structures, overheadelectrical lines, debris/ dump materials, hillocks etc. with approach roadfor setting up of washerySoil investigation report and contour map of the Project site (indicativefor bidding purpose only).Supply of water (within 100m) & power at a single point of the proposedwashery site on chargeable basis upto successful PGT.3.2.2.2 <strong>FOR</strong> OPERATION & MAINTENANCEi) Land/ mine voids required for disposal of washery rejects at a distanceof about 8.0 km from the washery site.310208112 (Madh NLW Jan ’09)3 - 5Signature of Bidderwith Seal & Date

CMPDIii) Assured raw coal supply of requisite quality and quantity of (–) 200mm size.iii) Assured receipt of washed coal & middlings into the loading hopper(s)at the existing railway siding of Madhuband Washery, <strong>BCCL</strong>.iv) Despatch of washed coal & middlings through Railways includingarranging/ indenting of Railway wagons as well as loading of washedcoal & middlings into the railway wagons.v) Loading hopper(s) at the existing railway siding of MadhubandWashery, <strong>BCCL</strong> for transportation of washed coal and middlings.vi) Providing power at 33 kV at Dugda sub-station situated at about 10 kmfrom the washery site, on the basis of agreed demand.vii) Reimbursement of additional operating expenses for DG set on actuals.viii) Assured source of water at Jamunia River which is about 7 km from thewashery site.3.2.2.3 <strong>FOR</strong> CONSTRUCTION & OPERATION BOTH<strong>BCCL</strong> will obtain all statutory & regulatory clearances includingEnvironmental Clearances on the basis of technology of the Lowest Bidder. Thisprocess of obtaining various clearances may require one year time from the date ofidentification of Lowest Bidder. After obtaining such clearances, issue of Letter ofAcceptance/ Award (LoA) & signing of Contract will be done and thereafterconstruction period of 18 months will commence. Moreover, Lowest Bidder will haveto assist <strong>BCCL</strong> in all these activities.Note:However, arrangement for drawal of water and power from the sourcesindicated above at Cl. No.3.2.2.2, to the washery during operation will be within thescope of BOM Operator.3.3 SALIENT FEATURES OF <strong>COAL</strong> <strong>WASHERY</strong>The salient feature of the provision, which is covered in detail in the RFPDocument, is given hereafter.310208112 (Madh NLW Jan ’09)3 - 6Signature of Bidderwith Seal & Date

1. Washery Capacity : 5.0 Mtpa of raw coal inputCMPDI2. Selection of Technology: Freedom of selection of efficient & costeffective state-of-the-art technology lies withthe BOM Operator. Washing scheme has tobe preferably based on Jig/ Heavy MediaSeparation (Bath/ Drum/ Cyclone orcombination thereof)/ Froth Flotation/ SpiralConcentrator, etc and a combination of abovebut Bidders are free to offer any otherimproved / proven technology being usedelsewhere in the world.3. Construction/ Set-up : 18 months including PGT (from the date ofPeriodsigning of the Contract).4. Life of the Washery : 18 years after successful commissioning of theplant.5. Washing Charges : Washing charges will be paid to the SelectedBidder in Indian Rupees (INR) and/ or singleconvertible Foreign Currency, in which thebidder has quoted, on the basis of rate for pertonne of raw coal washed. However, for arrivingat such quantity of raw coal washed, thefollowing mechanism will be followed:i) Normally the quantity of raw coal deliveredto BOMO in a particular month by <strong>BCCL</strong> will beconsidered.ii) In case, the quantity of raw coal processedin the washery by BOMO in the particular monthis more or less than the quantity of raw coalsupplied by <strong>BCCL</strong>, then the BOMO will givedeclaration (to the satisfaction of the owner)regarding the actual quantity of raw coalwashed. The washing charge will be arrived on310208112 (Madh NLW Jan ’09)3 - 7Signature of Bidderwith Seal & Date

CMPDIthe basis of declared quantity of raw coal in thatparticular month under consideration. However,such quantity of raw coal processed during theyear shall match with the raw coal quantitydelivered to BOMO by <strong>BCCL</strong> in that year.6. LD for delay : In the event of failure to successfulcommissioning of the plant within the stipulatedperiod, the Selected Bidder will be liable to payLiquidated Damages (LD) for delay. LD fordelay will be @ 0.25% of the Contract price forsetting up of the washery per week of delayupto 10 weeks and @ 0.5% thereafter.However, total LD for delay shall not exceed10% of Contract Price for setting up of thewashery.7. Validity of Bid/ Offer : 18 (eighteen) months (including Environmentalclearances and signing of Contract) from thedate of opening of the Bid against Request forQualification (RFQ) document.310208112 (Madh NLW Jan ’09)3 - 8Signature of Bidderwith Seal & Date

CMPDIDESCRIPTION OF THE SELECTIONPROCESS310208112(Madh NLW Jan ’09)Signature of Bidderwith Seal & Date

CMPDI4. DESCRIPTION OF THE SELECTION PROCESS<strong>BCCL</strong> is conducting the Bidding Process (on single stage bidding) for settingup of <strong>Coal</strong> Washery in the vicinity of existing Madhuband Washery of <strong>BCCL</strong> on BOMbasis based on the fulfilment of necessary qualification criteria by the Bidder, toensure reliable & uninterrupted supply of desired quantity & quality of washed coal andmiddlings to <strong>BCCL</strong> for its linked clients.4.1 BIDDING PROCESS & EVALUATION OF BID4.1.1 A) BIDDING PROCESSBidding will be single stage.The Single Stage Bidding shall comprise of issuing the following twodocuments altogether:i) Request for Qualification (RFQ)ii) Request for Proposal (RFP) & Sample Contract FormThe Bidder is required to submit their offers in a sealed envelope containingthree sealed envelopes 1, 2 & 3 comprising of the following:Envelope 1 :Bid for Qualification against RFQ in three parts duly sealedseparatelyPart-1 : Bidders who have purchased the Bid Documentshall have to furnish Bid Security only at the time ofsubmission of bid but the bidders who have downloaded thebid Documents shall have to furnish Bid Security, cost of BidDocument (If not submitted before Pre- Bid meeting) &undertaking of non-tampering of Bid Document. Both (a) & (b)shall be sealed separately.a) Bid Securityb) Cost of Bid Document & undertaking(in case of downloaded Bid Document)Part-2 : Bid for Qualification against RFQ Document.Part-3 : Integrity Pact.310208112 (Madh NLW Jan ‘09) 4 - 1Signature of Bidderwith Seal & Date

Envelope 2 :Envelope 3 :CMPDIBid for Proposal against RFP and Sample Contract Form inthree parts duly sealed separatelyPart 1 : Technical BidPart 2 : Commercial BidPart 3 : Acceptance of provision of `Sample ContractForm’Price Bid (duly sealed separately) against RFP.4.1.1 B) EVALUATION OF BIDPart-1 of Envelope 1, i.e. a) Bid Security and b) cost of Bid Document &undertaking (in case of downloaded Bid Document) shall be opened first and if thesame is found compliant to the requirements of the Clause 6.5.1 & 6.1.3 of Section 6of this RFQ Document, then only the Part-2 & Part-3 of Envelope 1, i.e. Bid forQualification & Integrity Pact respectively shall be opened.The offers against RFQ part of Bid (i.e. Envelope 1) will be opened &scrutinised for meeting the stipulated qualifications based on which bidders will beshort-listed, who will be referred to as ‘Qualified Bidders’ thereafter.After short-listing, the offers against RFP part of Bid (i.e. Envelope-2)containing Part 1, 2 & 3 will be opened for the Qualified Bidders only. ‘Price Bid’(Envelope-3) will be opened after evaluation of Bid contained in Envelope 2. Amongstshort listed bidders, after complete evaluation of offers against RFP part of Bid(Envelope 2 & 3) ‘Lowest Bidder’ will be identified. On the basis of technology of the‘Lowest Bidder’, <strong>BCCL</strong> shall obtain Environmental & other clearances and issue LoAto the ‘Lowest Bidder’ and shall be referred to as ‘Preferred Bidder’ who will beeligible for entering into Contract. After entering into contract, the ‘Preferred Bidder’will be referred to as the `Selected Bidder’ for all practical purposes.4.1.2 FINANCIAL EVALUATION<strong>BCCL</strong> or its consultant will evaluate and compare the Price Bids, afterevaluation of Technical & Commercial Bids and acceptance of provision of ‘SampleContract Form’ against RFP part of Bid Document as per Clause No. 4.1.1 of RFQ.310208112 (Madh NLW Jan ‘09) 4 - 2Signature of Bidderwith Seal & Date

CMPDIThe financial evaluation of bid shall be made on Long Range Marginal Cost(LRMC) basis using Discounted Cash Flow (DCF) technique. In order to calculateLRMC, the time stream of the cash outflow for eleven & half (1.5+10) years onaccount of all payments (both quoted & notional) to be made (both FC and INR) tothe Selected Bidder by <strong>BCCL</strong> towards setting up of the washery and washingcharges payable during the contract period of commercial operation for 10 years shallbe considered. Details are as given hereafter:a) The quoted offer price on account of set-up will be treated as firm price andwill be considered for the purpose of this Financial Evaluation. While, the quoted offerprice on account of washing charges per tonne of raw coal for the first year will beconsidered as the cash outflow in its absolute value for the first year of commercialoperation and will be treated as the base prices for projection of washing charges forthe next year.b) For the purpose of this evaluation, yearwise notional cash outflow onaccount of washing charges will be determined. Washing charges for the 2 nd year ofcommercial operation will be determined using average variation for the last fiveyears immediately preceding the 1 st year under consideration (for which the Biddershave quoted their firm washing charges) in the respective indices such as WPI of RBIfor the applicable items in respect of supplies; WPI in respect of Fuel/ Power, Oil &Lubricants; AICPI – IW; Indian Minimum Wages Act as applicable in case ofindigenous labour component and similar such authenticated indices published byCentral Bank or Government Institution or any other appropriate authority & availablein public domain as indicated by the Bidder in their offer, as applicable in case ofimported components for operation & maintenance of the plant. The same averagevariation in the indices will be utilised to arrive at the washing charges for each yearof the balance period of 08 (eight) years of commercial operation. Using theseyearwise washing charges, notional cash outflow on account of washing charges foreach year of 10 years period of commercial operation will be determined.310208112 (Madh NLW Jan ‘09) 4 - 3Signature of Bidderwith Seal & Date

CMPDIIn case, there is more than one Bidder for the subject work quoting theirprice in the same currency but indices quoted differ from bidder to bidder, then insuch case the evaluation will be done utilizing the respective indices quoted bydifferent bidders. However, bidders have to quote the indices applicable in thecountry of the currency (ies) in which they have quoted their price offer.c) Apart from the above said quoted price, this evaluation will also considerthe following:- any additional cost proposed to be incurred by <strong>BCCL</strong> towards anysupplies to be arranged and/ or services to be rendered at the specific request of theBidder.- annual power and water cost to be incurred by <strong>BCCL</strong> on the basis of theguaranteed specific power and water consumption per tonne of raw coal processed.The prevailing rate of power and water tariff will be considered for determination ofsuch cost. Though, the supply of power & water for operation & maintenance of theplant for the agreed demand will be provided without any charge, the cost incidenceof these components will be escalated considering 75% as fixed wherever required.-Prospective Bidders will have to quote Minimum Guaranteed Yield (MGY)for different monthly average ash% of raw coal at the targeted ash% (monthlyaverage) of washed coal and middlings (As per Appendix-2B of RFP part of BidDocument). The bidder, who will quote values of MGY both for washed coal &middlings at their respective targeted ash% in such a way that the combinedmonetary return expected to be fetched by multiplying the quantity of washed coal &middings with their respective prevailing / indicative sale prices is highest, will betermed as ‘Reference Bidder’ and no impact due to lower yield will be imposed onthat ‘Reference Bidder’ whereas on other bidders who have quoted different yields ofwashed coal & middlings and fetch lesser monetary return, impact due to differentyields will be imposed. Different quantities of washed coal and middlings for ten years(because of different yields) of commercial operation corresponding to the annualthroughput capacity will be worked out for each bidder and these quantities ofwashed coal & middlings will be multiplied by the respective prevailing/ indicative sale310208112 (Madh NLW Jan ‘09) 4 - 4Signature of Bidderwith Seal & Date

CMPDIprice of washed coal and middlings (on the date of opening of Price Bid) to ascertainthe quantum of impact to be considered on each bidder for the purpose of financialevaluation.d) To facilitate evaluation & comparison, the discounting rate for calculation ofpresent value of the above outflow shall be as follows:i) In case of cash outflows in Foreign Currency, the rate of discount will be 10(ten) years SWAP rates against three months’ LIBOR of the respective ForeignCurrency plus 150 basis points for such purpose. The present value of ForeignCurrency during the time stream thus calculated is to be converted into equivalentINR amount at bill selling rate of State Bank of India as on the date of opening ofprice bid.ii) In case of INR component of the cash outflow, the discounting rate willbe the Yield to maturity (YTM) rate of ten years Government of India bonds prevailingon the date of opening of the price bid plus 150 basis points.iii) Impact of different yields will simply be considered without anydiscounting (as this is to be arrived on the present realisable value of washed coal &middlings at the prevailing/ current sales price of washed coal & middlings at theirrespective targeted ash%).e) The bidder with the lowest cost in terms of present value of overall cost willbe identified as ‘Lowest Bidder’ and will be intimated. However, <strong>BCCL</strong> reserves theright to reject even the lowest bid in the event the project becomes unviable.f) For understanding of the prospective bidders, a ‘Format for DCF Analysisfor Financial Evaluation of the Price Bid’ is given at Enclosure – 1 of Section – 10 ofRFP Document.310208112 (Madh NLW Jan ‘09) 4 - 5Signature of Bidderwith Seal & Date

4.2 PRE-BID CONFERENCECMPDIThe Bidders, seeking any clarification, are required to submit the same inwriting to <strong>BCCL</strong> up to 30 days before the last date of submission of the Bid. <strong>BCCL</strong>may organise a Pre-Bid Conference with all the parties who purchased the BidDocument, wherein such clarifications shall be discussed and necessary clarificationswill be provided. For the purpose of participation in any pre-bid meeting, all biddersare directed to ensure that they have procured the Bid Document on payment ofrequisite fee or downloaded the Bid Document and have paid for it before attendingthis Pre-Bid Conference ( Also refer Cl. No. 6.1.4 of RFQ document).4.3 FINAL AWARD & NOTIFICATION4.3.1 LETTER OF AWARD/ LETTER OF ACCEPTANCE (LOA)Award shall be made by <strong>BCCL</strong> to a Preferred Bidder subsequent tocomprehensive evaluation of Qualification Requirement, Techno-commercial andPrice Bids received for the scope of work defined in the Bid Document, as elaboratedabove and after obtaining Environmental & other clearances by <strong>BCCL</strong>.Thereafter, <strong>BCCL</strong> shall enter into Contract with the Preferred Bidder within 30days after issue of LoA. In case the Preferred Bidder fails to enter into a Contract with<strong>BCCL</strong> due to any reasons whatsoever, within the stipulated time to be indicated by<strong>BCCL</strong>, then <strong>BCCL</strong> shall go for retendering.The Bidder, who finally enters into a Contract with <strong>BCCL</strong> for the subject workin the vicinity of existing Madhuband Washery of <strong>BCCL</strong> shall be designated as the‘Selected Bidder’.4.3.2 NOTIFICATION OF AWARD4.3.2.1 <strong>BCCL</strong> will notify the Preferred Bidder in writing by registered letter or by cableor fax to be confirmed in writing by registered letter, that its bid has been accepted.4.3.2.2 Upon issuance of written notification of award in terms of sub clause 4.4.2. ofthis Section, bid process shall be deemed to have concluded & Contract come intoforce between the Selected Bidder and <strong>BCCL</strong>.310208112 (Madh NLW Jan ‘09) 4 - 6Signature of Bidderwith Seal & Date

CMPDI4.4 SIGNING OF CONTRACT4.4.1 In case <strong>BCCL</strong> notifies the Preferred Bidder that its bid has been accepted,<strong>BCCL</strong> will send the Bidder the Contract Form, sample of which is provided in theBidding Documents, incorporating all terms and conditions for execution.4.4.2 Within 30 days of despatch by air-courier of the Contract Form the PreferredBidder shall sign & date the Contract and return it to <strong>BCCL</strong>. <strong>BCCL</strong> wouldcommunicate the Bidder about despatch of Contract Form by Fax.310208112 (Madh NLW Jan ‘09) 4 - 7Signature of Bidderwith Seal & Date

CMPDIQUALIFYING REQUIREMENTS310208112(Madh NLW Jan ’09)Signature of Bidderwith Seal & Date

CMPDI5. QUALIFYING REQUIREMENTSThe Bidders for <strong>Coal</strong> Washery under “Build- Operate-Maintain” (BOM)Concept should meet the Qualifying Requirements stipulated hereunder:5.1 TECHNICAL QUALIFICATION REQUIREMENTS (TQR)5.1.1 ‘SET UP’ QUALIFICATION REQUIREMENTShould have set up (during the last seven years ending 31.12.2008) <strong>Coal</strong>Washery/ Ore Beneficiation Plant at least of capacity 2.5 Mtpa.5.1.2 ‘OPERATING’ QUALIFICATION REQUIREMENTShould have minimum two (2) years experience of operating <strong>Coal</strong>Washery/ Ore Beneficiation Plant (during the last seven years ending 31.12.2008)at least of capacity 2.5 Mtpa.5.1.3 SOLE BIDDER ROUTEIn case, the Bidder meets both the requirements i.e. 5.1.1 & 5.1.2 above, hemay participate as a “Sole Bidder”.5.1.4 ASSOCIATE/ CONSORTIUM ROUTEIn case of Consortium/ Associate Route of participation, the maximum no. ofconsortium partners may go upto 04 (four) and the Lead Member (Bidder) must have51% stake. Collectively consortium partners must meet both the TQR i.e. towards‘set up’ as well as ‘operation’ of coal washery/ ore beneficiation plant. In this route,individual associate may or may not possess any of the TQR as well as FQR. Insuch a case, the Bidder:a) shall furnish a MoU with his Associate(s) / Consortium partner(s) (as performat given in the RFQ bid document) along with the RFQ Bid, andb) shall furnish a JDU (Joint Deed of Undertaking) prior to signing ofContract (provided the bidder has got LoA on the basis of bid evaluation) as per310208112 (Madh NLW Jan ’09) 5 - 1Signature of Bidderwith Seal & Date

CMPDIformat given in the RFP bid document wherein the Bidder and his associate(s), shallbe jointly and severally responsible for setting up of <strong>Coal</strong> Washery as well asperformance of the contract with regard to operation & maintenance as per the periodspecified hereafter.i) In case the Bidder (Lead Member) himself meets the TQR as stipulated at5.1.2 (towards operation) then at least one of its associates must meet the other TQRas stipulated at 5.1.1 (towards set up). In such case, any of the associate(s) otherthan the Lead Member (LM) may have the liberty to dissociate any time but after aminimum period of one year from the date of expiry of Guarantee Period of the <strong>Coal</strong>Washery. However, the Bidder (LM) having TQR of 5.1.2 shall have to continue forthe entire contract period.ii) In case the Bidder (Lead Member) himself meets the TQR stipulated at5.1.1 (toward set up) then at least one of its associate(s) must meet the other TQR asstipulated at 5.1.2 (towards operation). In such case, any of the associate(s) exceptone associate having TQR of 5.1.2 may have the liberty to dissociate any time butafter a minimum period of one year from the date of expiry of Guarantee Period of the<strong>Coal</strong> Washery. One associate having TQR of 5.1.2 shall have to continue for entireterm of the contract period alongwith the bidder.iii) In case, the Bidder (Lead Member) himself meets only the FQR stipulatedat 5.2, then the other associate(s) must collectively meet both the TQR (5.1.1 i.e.towards set up & 5.1.2 i.e. towards operation). In such case, any of the otherassociate(s) except one associate having TQR of 5.1.2 (towards operation) may havethe liberty to dissociate any time but after a minimum period of one year from thedate of expiry of Guarantee Period of coal washery. However, the Bidder (LM) havingFQR of 5.2 alongwith one of the associate(s) having experience of 5.1.2 (towardsoperation) shall have to continue for the entire contract period.5.1.5 SUBMISSION OF MOU & JDUBidders shall be required to submit Memorandum of Understanding (MoU)entered with the Associate(s) alongwith their Bid against RFQ (i.e. Envelope 1). The310208112 (Madh NLW Jan ’09) 5 - 2Signature of Bidderwith Seal & Date

CMPDIJoint Deed of Undertaking (JDU) shall be submitted on the date specified by <strong>BCCL</strong>prior to signing of the Contract.5.1.6 LEAD MEMBERLead Member (LM) shall mean the Bidder who has at least 51% stake andcontinue to perform the obligations towards the subject work for the entire contractperiod in case of Consortium/ Associate Route having maximum no. of consortiumpartners upto 4 (four). The Lead Member has to fulfil the Financial Requirement ofthe Bid. In case of Associate/ Consortium Route, Lead Member of Consortium will betermed as ‘Bidder’. The Lead Member may or may not have any TechnicalQualification Requirement (TQR) though the Lead Member has to fulfil the FinancialQualification Requirement (FQR) of the Bid. Lead member of Consortium/ Associatemust be identified through MoU and subsequently through JDU.5.2 FINANCIAL QUALIFICATION REQUIREMENTSFinancial Qualification Requirements (FQR) will be applicable for thoseBidders who will continue to perform the obligations towards the execution of thesubject work for the entire contract period such as Sole Bidder. However, in case ofConsortium/ Associate Route, Lead Member only will have to meet the FQR of theBid.5.2.1 TURNOVER & WORKING CAPITALa) TurnoverAverage annual sales turnover during last 3 (three) years, ending31.03.2008 should be at least INR 37.5 Crores (INR Thirty Seven Crores Fifty Lakhs)supported by furnishing audited Annual Reports & Accounts.b) Working CapitalEvidence of possessing adequate working capital for execution of thecontract should be of at least INR 25.0 (Twenty Five) Crores inclusive of access tolines of credit and availability of other financial resources to meet the requirement. Asolvency certificate from Bank shall also be submitted.310208112 (Madh NLW Jan ’09) 5 - 3Signature of Bidderwith Seal & Date

CMPDINote: 1. Bidders are required to submit ‘Financial Qualification RequirementsInformation’ for execution of the subject work as per the format at Attachment-2.2. Average Annual Sales Turnover shall be given a weightage of 5% per year(average annual rate of inflation to bring them at current price level) for INR. In caseof Foreign Exchange component such weightage shall be determined in terms of ratioof current Foreign Exchange rate of the convertible Foreign Currency (quoted by theBidder) to corresponding Foreign Exchange rate of the year for which financial datahas been furnished.3. Sub-contractor’s experience and resources will not be taken into accountin determining the Bidders’ compliance with qualifying criteria.5.3 DISQUALIFICATION OF THE BIDDEREven though the bidders meet the above Qualifying Criteria, they are subjectto be disqualified, if they have:a) Made misleading or false representations in the forms, statements andattachments submitted in the proof of the qualification requirements; and/orb) Record of poor performance such as abandoning the works, not properlycompleting the contract, inordinate delays in completion, litigation history, or financialfailures etc.5.4 RESPONSIBILITY OF HOLDING COMPANYIn case the Bidder being a Subsidiary company, submitting its Bid documenton the financial strength and/ or technical competence of its holding company, it hasto obtain and produce a Letter of Undertaking to the effect that in case of anyuntoward happenings towards the successful execution of the contract and/ or eventoccurring that are distinct and different from the stipulated terms & conditions of theBid Document and attributable to Bidder’s account, its holding company shall belegally bound both jointly and severally to this contract for discharging all thecontractual obligations on behalf of bidder (refer Cl. No. 6.1 (d) of Section – 6 of RFPDocument).310208112 (Madh NLW Jan ’09) 5 - 4Signature of Bidderwith Seal & Date

CMPDIINSTRUCTIONS TO BIDDERS310208112(Madh NLW Jan ’09)Signature of Bidderwith Seal & Date