The Mechanical Equivalent of Heat

The Mechanical Equivalent of Heat

The Mechanical Equivalent of Heat

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

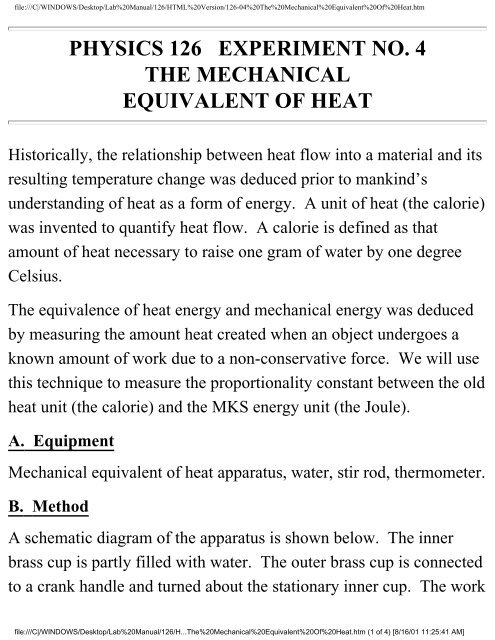

file:///C|/WINDOWS/Desktop/Lab%20Manual/126/HTML%20Version/126-04%20<strong>The</strong>%20<strong>Mechanical</strong>%20<strong>Equivalent</strong>%20Of%20<strong>Heat</strong>.htmPHYSICS 126 EXPERIMENT NO. 4THE MECHANICALEQUIVALENT OF HEATHistorically, the relationship between heat flow into a material and itsresulting temperature change was deduced prior to mankind’sunderstanding <strong>of</strong> heat as a form <strong>of</strong> energy. A unit <strong>of</strong> heat (the calorie)was invented to quantify heat flow. A calorie is defined as thatamount <strong>of</strong> heat necessary to raise one gram <strong>of</strong> water by one degreeCelsius.<strong>The</strong> equivalence <strong>of</strong> heat energy and mechanical energy was deducedby measuring the amount heat created when an object undergoes aknown amount <strong>of</strong> work due to a non-conservative force. We will usethis technique to measure the proportionality constant between the oldheat unit (the calorie) and the MKS energy unit (the Joule).A. Equipment<strong>Mechanical</strong> equivalent <strong>of</strong> heat apparatus, water, stir rod, thermometer.B. MethodA schematic diagram <strong>of</strong> the apparatus is shown below. <strong>The</strong> innerbrass cup is partly filled with water. <strong>The</strong> outer brass cup is connectedto a crank handle and turned about the stationary inner cup. <strong>The</strong> workfile:///C|/WINDOWS/Desktop/Lab%20Manual/126/H...<strong>The</strong>%20<strong>Mechanical</strong>%20<strong>Equivalent</strong>%20Of%20<strong>Heat</strong>.htm (1 <strong>of</strong> 4) [8/16/01 11:25:41 AM]

file:///C|/WINDOWS/Desktop/Lab%20Manual/126/HTML%20Version/126-04%20<strong>The</strong>%20<strong>Mechanical</strong>%20<strong>Equivalent</strong>%20Of%20<strong>Heat</strong>.htmdone by the frictional force is converted into heat.Since the inner cup is in equilibrium, the torque due to friction isbalanced by the torque due to the external force applied to the edge <strong>of</strong>the aluminum disk. Since work is equal to torque × angle, we find:W = τ × θ = FR 2πN = 2πR FN (1)where R is the radius <strong>of</strong> the disk, F is the force applied to keep theinner cup stationary, and N is the number <strong>of</strong> turns <strong>of</strong> the outer cup.We can analyze the amount <strong>of</strong> heat input to the system by measuringthe change in temperature. In general, Q = mc∆T for a single materialwhich does not undergo a phase change. In our case, several pieces <strong>of</strong>the apparatus are heated at the same time. <strong>The</strong> total heat input is:Q = m w c w ∆T + m b c b ∆T + m s c s ∆T + m th c th ∆T (2)where w represents the water, b the brass pieces, s the stir rod, and thfile:///C|/WINDOWS/Desktop/Lab%20Manual/126/H...<strong>The</strong>%20<strong>Mechanical</strong>%20<strong>Equivalent</strong>%20Of%20<strong>Heat</strong>.htm (2 <strong>of</strong> 4) [8/16/01 11:25:41 AM]

file:///C|/WINDOWS/Desktop/Lab%20Manual/126/HTML%20Version/126-04%20<strong>The</strong>%20<strong>Mechanical</strong>%20<strong>Equivalent</strong>%20Of%20<strong>Heat</strong>.htmthe thermometer. Using the known specific heats <strong>of</strong> each substance(in CALORIES/kg K), we can determine the heat flow in calories andcompare this result to the work done (in Joules).C. Procedure1. Disassemble the apparatus and measure the mass <strong>of</strong> eachrelevant part. <strong>The</strong> mass <strong>of</strong> the water can be deduced by weighing theinner cup with and without the water.2. Reassemble the device with the inner cup 3/4 filled with coldwater (roughly 6-8• C below room temperature). Stir the water andmeasure the starting temperature. Place a scrap <strong>of</strong> paper between theinner and outer cup during reassembly so that the crank will turnsmoothly.3. <strong>The</strong> crank handle is attached to a counter so that the number <strong>of</strong>turns can be measured. Record the starting value <strong>of</strong> the counter andbegin to crank.4. <strong>The</strong> force necessary to keep the inner cup stationary is readfrom a spring balance. Record its value. Try to keep the force steadyby turning the crank very smoothly and continuously.5. While one partner cranks, the other should record thetemperature <strong>of</strong> the water. DO NOT Stop cranking the device duringthese “spot-check” temperature measurements. If fatigue should setin, the lab partners should switch jobs.6. Continue to crank the apparatus until the final temperature isroughly as far above room temp as the initial T was below it. Aftercranking is finished, record the new reading on the counter.7. Take several temperature measurements even after the crankingfile:///C|/WINDOWS/Desktop/Lab%20Manual/126/H...<strong>The</strong>%20<strong>Mechanical</strong>%20<strong>Equivalent</strong>%20Of%20<strong>Heat</strong>.htm (3 <strong>of</strong> 4) [8/16/01 11:25:41 AM]

file:///C|/WINDOWS/Desktop/Lab%20Manual/126/HTML%20Version/126-04%20<strong>The</strong>%20<strong>Mechanical</strong>%20<strong>Equivalent</strong>%20Of%20<strong>Heat</strong>.htmis finished since the T value will continue to rise for a short time.8. Calculate the the work in Joules from equation (1) and the heatin calories from equation (2). Determine the ratio, W/Q and compareit to the accepted value.Q1. Why is it best to start the experiment below room temp andend above?Q2. Why is it necessary to stir the water before each temperaturemeasurement?Q3. Why is there a residual upward drift in temperature after thecranking is stopped?Q4. It takes about 100,000 Joules to toast break. Compare thisamount to the mechanical work you did during the experiment.file:///C|/WINDOWS/Desktop/Lab%20Manual/126/H...<strong>The</strong>%20<strong>Mechanical</strong>%20<strong>Equivalent</strong>%20Of%20<strong>Heat</strong>.htm (4 <strong>of</strong> 4) [8/16/01 11:25:41 AM]