Chemwatch Australian MSDS 4613-35 - Dentsply

Chemwatch Australian MSDS 4613-35 - Dentsply

Chemwatch Australian MSDS 4613-35 - Dentsply

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

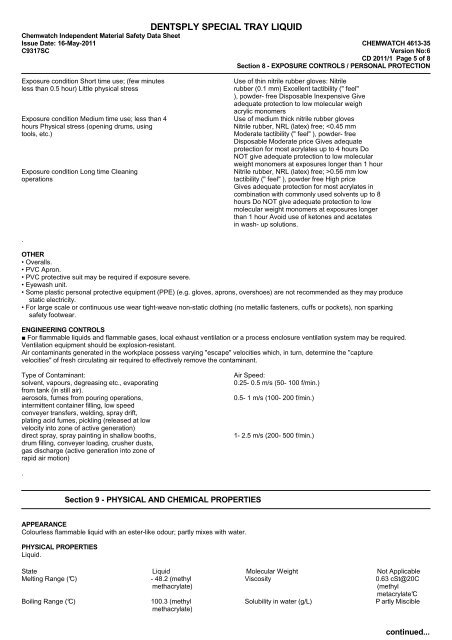

DENTSPLY SPECIAL TRAY LIQUID<strong>Chemwatch</strong> Independent Material Safety Data SheetIssue Date: 16-May-2011 CHEMWATCH <strong>4613</strong>-<strong>35</strong>C9317SCVersion No:6CD 2011/1 Page 5 of 8Section 8 - EXPOSURE CONTROLS / PERSONAL PROTECTIONExposure condition Short time use; (few minutesless than 0.5 hour) Little physical stressExposure condition Medium time use; less than 4hours Physical stress (opening drums, usingtools, etc.)Exposure condition Long time CleaningoperationsUse of thin nitrile rubber gloves: Nitrilerubber (0.1 mm) Excellent tactibility (" feel"), powder- free Disposable Inexpensive Giveadequate protection to low molecular weighacrylic monomersUse of medium thick nitrile rubber glovesNitrile rubber, NRL (latex) free; 0.56 mm lowtactibility (" feel" ), powder free High priceGives adequate protection for most acrylates incombination with commonly used solvents up to 8hours Do NOT give adequate protection to lowmolecular weight monomers at exposures longerthan 1 hour Avoid use of ketones and acetatesin wash- up solutions..OTHER• Overalls.• PVC Apron.• PVC protective suit may be required if exposure severe.• Eyewash unit.• Some plastic personal protective equipment (PPE) (e.g. gloves, aprons, overshoes) are not recommended as they may producestatic electricity.• For large scale or continuous use wear tight-weave non-static clothing (no metallic fasteners, cuffs or pockets), non sparkingsafety footwear.ENGINEERING CONTROLS■ For flammable liquids and flammable gases, local exhaust ventilation or a process enclosure ventilation system may be required.Ventilation equipment should be explosion-resistant.Air contaminants generated in the workplace possess varying "escape" velocities which, in turn, determine the "capturevelocities" of fresh circulating air required to effectively remove the contaminant.Type of Contaminant:solvent, vapours, degreasing etc., evaporatingfrom tank (in still air).aerosols, fumes from pouring operations,intermittent container filling, low speedconveyer transfers, welding, spray drift,plating acid fumes, pickling (released at lowvelocity into zone of active generation)direct spray, spray painting in shallow booths,drum filling, conveyer loading, crusher dusts,gas discharge (active generation into zone ofrapid air motion)Air Speed:0.25- 0.5 m/s (50- 100 f/min.)0.5- 1 m/s (100- 200 f/min.)1- 2.5 m/s (200- 500 f/min.).Section 9 - PHYSICAL AND CHEMICAL PROPERTIESAPPEARANCEColourless flammable liquid with an ester-like odour; partly mixes with water.PHYSICAL PROPERTIESLiquid.State Liquid Molecular Weight Not ApplicableMelting Range (°C) - 48.2 (methyl Viscosity 0.63 cSt@20Cmethacrylate)(methylmetacrylate°CBoiling Range (°C) 100.3 (methyl Solubility in water (g/L) P artly Misciblemethacrylate)continued...